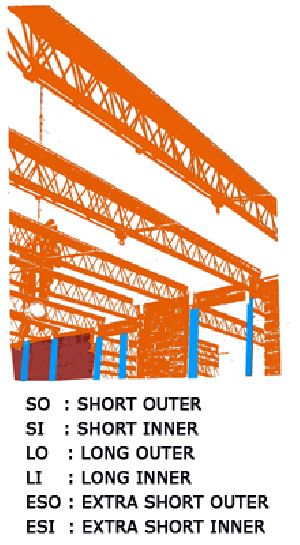

Waffle Slab Systems

Quick strip system can be used very conveniently for supporting In situ or pre-cast waffle moulds of size 900mm x 900 mm.Salient features are: Light weight interchangeable primary and secondary beams carried by Drop Heads form accurate grids. Robust construction to with stand site abuse with long life and less maintenances. Wide Beam flanges for supporting moulds. Early striking facility incorporated using well proven Drop Head System. Beams can be used with cuplok scaffolding system or standard props. Early striking facility allows Beams and Moulds to be reused while the concrete remains supported during curing, thereby reducing the overall amount of equipment required.

...more

Telescopic Spans

Telescopic Spans are result of many years experience in building construction and civil engineering. They incorporate all the feature which are demanded by industry for today's method of construction.Advantages of Telescopic Spans Saving on time and cost by relating the use of the same section on the same job. Quick and easy erection and stripping. Single simple adjustment for length of span. Intermediate supports eliminated. No loose parts to be lost. Compact for storage and transport. Stand rough site handling and reduce maintenance cost. Eliminates cost of cutting and wastage of timbe

...more

Telescopic Props

Hi - Reach props provide ideal and most economical method of support for all kind of formwork to slab, beams, walls and column. They are invaluable for a wide variety of other applications in general building construction. Props eliminate cost of skilled labour and timber wastages. Props are adjustable to various height requirements. Quickly and easily erected by unskilled labour. Props are easy to handle and can be used time and time again. No loose parts to be lost or mislaid. U - Head/ Base plate can accommodate standard formwork accessories. No more lost pins and broken chains. Props are made out of inner and outer pipe of 40 NB and 50 NB class tubes confirming to IS - 1161/1239 ID = 48.3mm OD = 60.3mm Nut = malleable casting Wire rope = flexible G.I. steel wire Top = fork Head/Base Plate optional Base = Plate 150 X 150 X 6mm

...more

Swivel Coupler

SWIVEL COUPLER (DROP FORGED)A one-piece load bearing coupler for connecting two scaffold tubes at any angle.

...more

Sleeve Coupler

SLEEVE COUPLERAn external connection for joining two scaffold tubes end-t-end. It has a central, circular division place so that equal lengths of each tube can be inserted and separately secured. Suitable for joints where tension will be developed in the tubes.

...more

Road Forms

Strong all - welded construction in 5 mm plate throughout. Designed for maximum strength and extra long life. Easily handled and fixed in position. Simple, accurate and rigid alignment. Wedges easily replaced without special equipment. Supplied complete with heavy duty stakes.STANDARD TYPEFor all types of edge formwork necessary for the construction of ground slabs. Roadways, foundation and footings, etc. three welded stake housing are incorporated together with a locking tongue for accurate alignment of adjacent forms.

...more

Putlog Coupler

PUTLOG COUPLER (PRESSED STEEL)A one-piece load bearing coupler for connecting two scaffold tubes at any angle.

...more

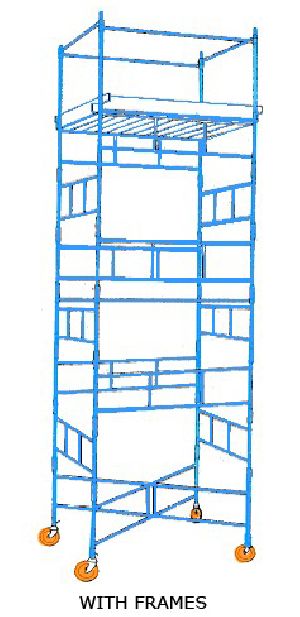

mobile towers

Mobile Towers are the most economical method of providing access where only a small working platform is required and the work front is spread over a large area. SAFETY POINTS Maximum Height : The height of free standing tower should not exceed 3 times the smallest base dimension for external use. Towers of greater height must be tied in or adequately secured. Movement of Towers : Towers should only be moved form the base. No personnel should be on the working platform during this operation. All castors should be firmly secured to the frames. Wheel loads should be re - applied after re - positioning.

...more

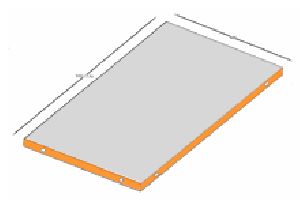

floor forms

Floor forms are made out 14 G / 12G press bent sheet and are light in weight as compared to the conventional angle shuttering plate. Adjustable floor forms fill up odd shapes and unstandard slab forms, thus eliminating cutting and wastage of timber all together. Standard slab forms are made in 600 mm width and 1150 / 900 mm length. Adjuster plates are made in 250 mm width and 1150 / 900 mm lengths. Perfect solution to slab shuttering problem. Cuts labour cost. Gives excellent concrete finish. Light weight combined with rigidity. STANDARD SIZES1150 x 6001150 x 300900 x 600900 x 300Adj. Panel 1150 x 250Adj. Panel 900 x 250

...more

FIXED FINIAL

FIXED FINIALConnects a scaffold tube at right angles directly to the end of another tube with no projection. ideal for guardrails, crowd control barriers etc.

...more

Double Coupler

DOUBLE COUPLER (DROP FORGED)A one-piece load bearing coupler used for connecting two scaffold tubes at right angles.

...more

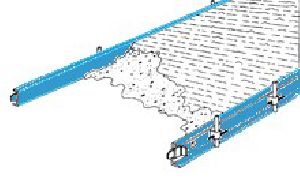

Conventional Slab

Floor forms are manufactured in standard sizes of 1150 x 600 and 900 x 600. Depending upon the length of floor form, spacing of the quick strip beams has to be maintained. Series of quick strip beams are joined in lengths depending upon the space available. Quick Strip beams are normally available in lengths of 1.2m, 1.5m, 1.8m and 2.0m. Top width of the Beams is 100 mm.These Beams are fixed into Drop Heads which have inserts to receive Q.S. Beams. Floor Forms are firmly secured into the L shape seats provided on either side of Q.S. Beam

...more

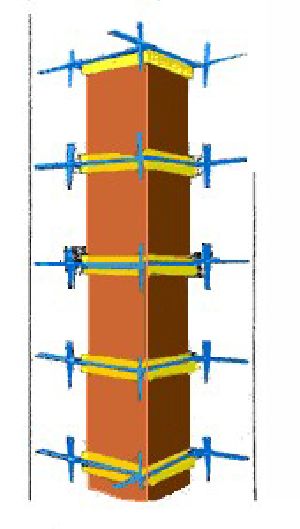

Column Clamps

For greater speed & economy Column clamps are quickly adjusted and secured to ensure absolute rigidity of steel and timber formwork for concrete columns, beams, hanging soffits and casings to steel stanchions. They save time, labour and materials by completely eliminating the cutting to waste of timber and the eventual deterioration and scrapping of materials. The arms of all three sizes are interchangeable and suitable for square and rectangular sections. The slot arrangement allows for simple, speedy and accurate adjustment to any dimension within the size range. There are no loose parts to be lost or mislaid and the clamps can be used an unlimited number of times. Wedges are secured to the arms by a flexible galvanized steel wire instead of the usual chain and ring.The greater strength and flexibility of this wire provides the solution to the perpetual and costly problem of broken chins and lost wedges

...more

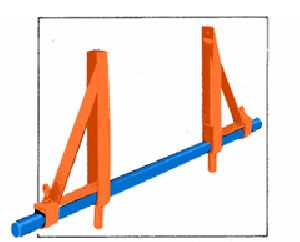

Beam Clamps

FOR FAST, ACCURATE AND RIGID CLAMPING OF BEAM FORMWORK AND CASINGS! The fastest method of clamping beam formwork and casings. Simple to adjust and lock. Interchangeable arms ensure maximum versatility Longer base tubes of ordinary scaffold tube can be used forextra wide beams. Can be used with both steel and timber shuttering. Robust, lightweight construction. Spigots provided for positive location in prop heads. Nail holes in arms. No loose parts. Easily dismantled for compact storage and transport.

...more

Base Plate

BASE PLATEA 150mm x 150mm steel plate providing a 0.023m2 flat bearing surface for load distribution from standards. It has a 50mm high intefral spigot and two fixing hole for use with sole plates.

...more

adjustable base

ADJUSTABLE BASEAdjustable base or Head Plate gives adjustment between 45 mm to 225 mm.

...more

wall formwork

Wall formwork is a multi purpose formwork and is suitable for most types of in situ concrete construction such as walls, foundations, columns, rectangular or circular tanks, dams, Sea defense works etc. These are made from high finish steel sheets duly stiffened by steel angles and held together by a rigid clamping and waling system to ensure a good quality finish time after time. This system of formwork gives complete versatility and at the same time being durable, accurate and fast, allowing simple erection with long life and low maintenance. It may be assembled to give a strip and re-erect sequence or may be formed into large crane handled units. Whether positioning by hand or moving large areas of formwork by crane, steel panels will give a consistently good finish with only a single joint mark between panels.

...moreBe first to Rate

Rate ThisOpening Hours