WATER, GAS AND AIR PIPELINES

We design and supply superior quality steel pipes for various water, air and gas transport applications. Made of high quality material, these are high in performance and have found various uses in different industrial applications. These pipelines are meant for the movement of water, oil & natural gas at a very high pressure. Buried high pressure oil and gas pipelines are tested for strength by pressurizing them to at least 125% of their maximum operating pressure (MAOP). Since many long distance transmission pipelines are designed to have a steel hoop stress of 80% of specified minimum yield (SMYS) at MAOP, this means that the steel is stressed to SMYS and above during the testing. Leak testing is performed by balancing changes in the measured pressure in the test section against the theoretical pressure changes calculated from changes in the measured temperature of the test section.

...more

W Beam Crash Barrier

Guardrail provides highly-visible protection in all weather conditions helping to increase driver confidence. The Guardrail system absorbs the impact of out-of-control vehicles while guiding the vehicle to safer stops. Proven results and consistent material quality make steel Guardrail systems the right barrier choice.

...more

Structural Steel Tubes

Our wide range of steel scaffolding pipes are of superior quality which meet the international standard and guidelines. The pipes are made from high quality Hot Rolled Coils, making it highly erosion resistance. They are available in various specifications. The scaffolding pipes are used in the construction or repair of buildings for supporting the structure.Thick steel scaffolding pipes are used to support heavy platforms, which hold heavy loads & withstand movements. Generally made of hot dipped galvanized steel, so as to offer long term corrosion resistance, even Black pipes are used depending upon the usage conditions. Other Application of Structural Steel Tubes : Casing Columns Fence Handrails Load Bearing Structure Piling Posts Poles Railings Scaffolding Sign poles Skywalks Towers

...more

steel tubular sections

The use of steel tubular sections provides for strong, light and profitable structures and as a result offer a host of possibilities in terms of application (expressive capacity). The use of these products also facilitates designs with a greater aesthetic appeal.

...more

Steel Hollow Sections

The use of steel tubular sections provides for strong, light and profitable structures and as a result offer a host of possibilities in terms of application (expressive capacity). The use of these products also facilitates designs with a greater aesthetic appeal.

...more

SQURE HOLLOW SECTIONS

The use of steel tubular sections provides for strong, light and profitable structures and as a result offer a host of possibilities in terms of application (expressive capacity). The use of these products also facilitates designs with a greater aesthetic appeal. Design Lighter and more diaphanous structures. Pieces of greater length with fewer joints. Large spans. More transparent trusses and purlins with the possibility of eliminating transversal bracing. More slender supports. Fewer sections, which can be reduced even more with the use of tubular sections filled with concrete. Economical solution. Easily executed direct joints, shorter construction times and easy maintenance, are the results of a correct design and the guarantee of a competitive delivery date and price. Expressive capacity. Circular, square, rectangular and elliptical sections, a range of wall thicknesses for every dimension of tubular section, absence of sharp edges,etc. These are the elements that provide innovating, wide ranging possibilities forarchitects and engineers. Strength Compression. For the same centred compression load and under the same conditions tubular sections allow for the use of longer elements than possible should open sections be used. If pillars are involved, a concrete fill permits to reduce further the amount of sections used. Torsion. Their stiffness is the highest of all commercial steel sections. For this reason, their behaviour is unbeatable in the case of lateral bulging or warpage. Bending. Due to the distribution of material on two axes, their behaviour in bending in two directions, is close to that of a beam and better than that of open sections. Tensile. The use of welded joints throughout their extension means that the resistant section in the joints is used completely, unlike bolted joints or those with gusset plates. Fatigue. The wide range of mechanical applications in which we can find steel tubular sections are eloquent proof of their perfect behaviour in these conditions. Fluid-dynamic. Their low opposition to the thrust of fluids allows lighter sections to be used and makes them the perfect element in outdoor or underwater structures, such as posts, masts, towers, cranes, etc. Safety Protecting steel tubular sections by means of surface coating is easier and more economical than open sections due to the absence of cavities and the lower surface area to be covered. Passive protection Structures made from Tubular Sections offer higher fire resistance than open sections due to a lower surface area exposed to fire in relation to mass(lower form factor/mass). Mixed structures based on tubular sections filled with concrete, show excellent behaviour in the presence of fire because of a delay due to the higher thermal inertia. Active protection Filled with water, or when water flows through them due to the thermalsiphon effect, irrigated structures provide almost unlimited fire resistance. Maintenance of water circulation, with the replacement of any losses that might occur due to vaporisation, ensures that the structure is cooled in such a way that gradually the temperature stabilizes at values not very much higher than the water status change temperature and very much lower, therefore, than the critical temperature of steel. In addition to:Introducing longer elements in structures. Reducing the number of joints. Eliminating struts. Stiffeners and plate brackets, to reduce weight. A concrete fill increases the surface area per floor. Their shape facilitates maintenance and represents an economic solution.

...more

rectangular hollow sections

The use of steel tubular sections provides for strong, light and profitable structures and as a result offer a host of possibilities in terms of application (expressive capacity). The use of these products also facilitates designs with a greater aesthetic appeal. Design Lighter and more diaphanous structures. Pieces of greater length with fewer joints. Large spans. More transparent trusses and purlins with the possibility of eliminating transversal bracing. More slender supports. Fewer sections, which can be reduced even more with the use of tubular sections filled with concrete. Economical solution. Easily executed direct joints, shorter construction times and easy maintenance, are the results of a correct design and the guarantee of a competitive delivery date and price. Expressive capacity. Circular, square, rectangular and elliptical sections, a range of wall thicknesses for every dimension of tubular section, absence of sharp edges,etc. These are the elements that provide innovating, wide ranging possibilities forarchitects and engineers. Strength Compression. For the same centred compression load and under the same conditions tubular sections allow for the use of longer elements than possible should open sections be used. If pillars are involved, a concrete fill permits to reduce further the amount of sections used. Torsion. Their stiffness is the highest of all commercial steel sections. For this reason, their behaviour is unbeatable in the case of lateral bulging or warpage. Bending. Due to the distribution of material on two axes, their behaviour in bending in two directions, is close to that of a beam and better than that of open sections. Tensile. The use of welded joints throughout their extension means that the resistant section in the joints is used completely, unlike bolted joints or those with gusset plates. Fatigue. The wide range of mechanical applications in which we can find steel tubular sections are eloquent proof of their perfect behaviour in these conditions. Fluid-dynamic. Their low opposition to the thrust of fluids allows lighter sections to be used and makes them the perfect element in outdoor or underwater structures, such as posts, masts, towers, cranes, etc. Safety Protecting steel tubular sections by means of surface coating is easier and more economical than open sections due to the absence of cavities and the lower surface area to be covered. Passive protection Structures made from Tubular Sections offer higher fire resistance than open sections due to a lower surface area exposed to fire in relation to mass(lower form factor/mass). Mixed structures based on tubular sections filled with concrete, show excellent behaviour in the presence of fire because of a delay due to the higher thermal inertia. Active protection Filled with water, or when water flows through them due to the thermalsiphon effect, irrigated structures provide almost unlimited fire resistance. Maintenance of water circulation, with the replacement of any losses that might occur due to vaporisation, ensures that the structure is cooled in such a way that gradually the temperature stabilizes at values not very much higher than the water status change temperature and very much lower, therefore, than the critical temperature of steel. In addition to: Introducing longer elements in structures. Reducing the number of joints. Eliminating struts. Stiffeners and plate brackets, to reduce weight. A concrete fill increases the surface area per floor. Their shape facilitates maintenance and represents an economic solution.

...more

Precision Tubes

Precision Tubes are extensively used in automobiles, power & industrial boilers, transformers, superheaters, economisers, heat exchangers, bicycles, automobiles, railway electrification, and furniture applications. A team of highly qualified engineers in the Research and Development wing keeps pace with improved techniques and latest developments in tube technology pertaining to this field. Furniture Industry Application • Chairs & Tubes • Beds & Sofas • Computer Table • Curtain Rod • Umbrella Rod Advantage Precision Tubes Precision ERW tubes offer many advantages such as close tolerances on diameter & thicknesses, exceptional concentricity and a smooth finish, both inside & outside of the tubes.These features enable designers to obtain uniformity of flow under controlled temperature, pressure conditions, while fabricators can exercise greater control over close bending and tube alignment in butt welding

...more

Grooved Fire Fighting Pipes

We also manufacture pipes with grooves directly rolled into the pipe ends. This is achieved using a new processing station which mainly consists of twoautomatic groove rolling systems which clamp the pipe, turn it and thereby produce the groove using hydraulically controlled sets of rollers. The economic advantage compared with weld-on grooved sockets results from the saving in costs incurred for preparing separately turned pipe ends and for welding them to the pipe. This type of pipe is especially suitable for the transport of water, air or solid matter under the rugged conditions prevailing on construction sites, which necessitate swift and easy connection of pipes using commercially available couplings without any special tools. The groove is compatible with all commercially available couplings, fittings and fasteners. These pipes are preferred for use in the construction of Sprinkler systems, in the construction of ducts for air as well as for cooling or service water, in mining and civil engineering, e.g. for dewatering systems, carbon and mud pipelines etc. as well as in agricultural applications for irrigation plants. Grooved systems not only Surpass performance expectations and deliver value, quality and dependability but also eliminates costly fire watch and hazardous flames and fumes during installation and maintenance with the no-flame joining method. We also manufacture pipes with grooves directly rolled into the pipe ends. This is achieved using a new processing station which mainly consists of twoautomatic groove rolling systems which clamp the pipe, turn it and thereby produce the groove using hydraulically controlled sets of rollers. The economic advantage compared with weld-on grooved sockets results from the saving in costs incurred for preparing separately turned pipe ends and for welding them to the pipe. This type of pipe is especially suitable for the transport of water, air or solid matter under the rugged conditions prevailing on construction sites, which necessitate swift and easy connection of pipes using commercially available couplings without any special tools. The groove is compatible with all commercially available couplings, fittings and fasteners. These pipes are preferred for use in the construction of Sprinkler systems, in the construction of ducts for air as well as for cooling or service water, in mining and civil engineering, e.g. for dewatering systems, carbon and mud pipelines etc. as well as in agricultural applications for irrigation plants. Grooved systems not only Surpass performance expectations and deliver value, quality and dependability but also eliminates costly fire watch and hazardous flames and fumes during installation and maintenance with the no-flame joining method. Major Application : • Fire Protection Systems • HVAC • Plumbing • Waste Water Treatment Plants • Plant Piping • Oil Fields

...more

Gas Pipeline

We design and supply superior quality steel pipes for various water, air and gas transport applications. Made of high quality material, these are high in performance and have found various uses in different industrial applications. These pipelines are meant for the movement of water, oil & natural gas at a very high pressure. Buried high pressure oil and gas pipelines are tested for strength by pressurizing them to at least 125% of their maximum operating pressure (MAOP).

...more

Galvanized Coils

Our range of galvanized coils are known for their superior performance and conformance to industry standards and guidelines. Made from highest quality material, our galvanized coils are available in various specifications and are mainly used in home appliances, construction and machineries. In these galvanized coils, the thickness of plating is controlled with low tolerance and high erosion resistance.

...more

Galvanized Coil

Our range of galvanized coils are known for their superior performance and conformance to industry standards and guidelines. Made from highest quality material, our galvanized coils are available in various specifications and are mainly used in home appliances, construction and machineries. In these galvanized coils, the thickness of plating is controlled with low tolerance and high erosion resistance.

...more

erw precision tubes

Precision Tubes are extensively used in automobiles, power & industrial boilers, transformers, superheaters, economisers, heat exchangers, bicycles, automobiles, railway electrification, and furniture applications. A team of highly qualified engineers in the Research and Development wing keeps pace with improved techniques and latest developments in tube technology pertaining to this field.

...more

crca strips

We offer superior quality cold rolled sheets and strips conforming to highest industry standards. These are available in various specifications to match growing demand and varying needs. Made from highest quality steel, these are superior in performance and the custom built thickness and width combination minimizes wastage at the customers' end. Highest order shape control and consistent flatness is a special feature of our CR sheets and strips.

...more

crca

We offer superior quality cold rolled sheets and strips conforming to highest industry standards. These are available in various specifications to match growing demand and varying needs. Made from highest quality steel, these are superior in performance and the custom built thickness and width combination minimizes wastage at the customers' end. Highest order shape control and consistent flatness is a special feature of our CR sheets and strips. Our Cold Rolling Complex comprises of Six 4-hi cold rolling mills that can handle thickness of 0.18mm to 2.0mm and a width up to 1000 mm. The total capacity of all these mills together is 100,000 MT/Year. All these mills are supported by HR side slitters, hi -speed continuous pickling line, skin pass mills and stretch leveling facility.

Coil Weight : 2-18 Kg / mm width

Surface Finishing : Bright / Matt / Mirror

...more

Cr Sheets

We offer superior quality cold rolled sheets and strips conforming to highest industry standards. These are available in various specifications to match growing demand and varying needs. Made from highest quality steel, these are superior in performance and the custom built thickness and width combination minimizes wastage at the customers' end. Highest order shape control and consistent flatness is a special feature of our CR sheets and strips.

...more

Cold Rolled Products

We offer superior quality cold rolled sheets and strips conforming to highest industry standards. These are available in various specifications to match growing demand and varying needs. Made from highest quality steel, these are superior in performance and the custom built thickness and width combination minimizes wastage at the customers' end. Highest order shape control and consistent flatness is a special feature of our CR sheets and strips. Our Cold Rolling Complex comprises of Six 4-hi cold rolling mills that can handle thickness of 0.18mm to 2.0mm and a width up to 1000 mm. The total capacity of all these mills together is 100,000 MT/Year. All these mills are supported by HR side slitters, hi -speed continuous pickling line, skin pass mills and stretch leveling facility.

Coil Weight : 2-18 Kg / mm width

Surface Finishing : Bright / Matt / Mirror

...more

cold rolled pipe

We offer superior quality cold rolled sheets and strips conforming to highest industry standards. These are available in various specifications to match growing demand and varying needs. Made from highest quality steel, these are superior in performance and the custom built thickness and width combination minimizes wastage at the customers' end. Highest order shape control and consistent flatness is a special feature of our CR sheets and strips.

...more

circular hollow sections

Our wide range of steel scaffolding pipes are of superior quality which meet the international standard and guidelines. The pipes are made from high quality Hot Rolled Coils, making it highly erosion resistance. They are available in various specifications. The scaffolding pipes are used in the construction or repair of buildings for supporting the structure.Thick steel scaffolding pipes are used to support heavy platforms, which hold heavy loads & withstand movements. Generally made of hot dipped galvanized steel, so as to offer long term corrosion resistance, even Black pipes are used depending upon the usage conditions. Other Application of Structural Steel Tubes : Casing Columns Fence Handrails Load Bearing Structure Piling Posts Poles Railings Scaffolding Sign poles Skywalks Towers

...more

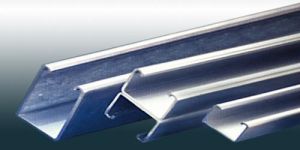

Nickel Alloys C Channel

In Today’s scenario of rising cost of steel, it is most essential to use such products that provide optimum utilization such as least possible weight without compromising on the strength and custom lengths and punches for faster application and installation. Cold Roll Formed sections are the perfect replacement for the heavy, unviable traditionally formed sections. Cold-formed sections hold a superior edge in comparison to other traditionally produced sections. The following advantages are offered by cold-formed sections : • Better strength to weight ratio. • High rigidity due to use of High Tensile Steel saves weight and hence, cost. • Flexibility in thickness and custom lengths can be offered. • Complex geometrical shapes can be produced. • Closer tolerances of the produced sections. • Better consistency and accuracy are achieved. • Smoother and Better surface finish. • Sections directly from Galvanized or Color Coated coils can be formed. • On-line cutting and custom punching increases production speed and cost. • Better and consistent chemical and mechanical properties achieved.

...more

Crca Coils

Our Cold Rolling Complex comprises of Six 4-hi cold rolling mills that can handle thickness of 0.18mm to 2.0mm and a width up to 1000 mm. The total capacity of all these mills together is 100,000 MTYear. All these mills are supported by HR side slitters, hi -speed continuous pickling line, skin pass mills and stretch leveling facility.

...moreBe first to Rate

Rate ThisOpening Hours