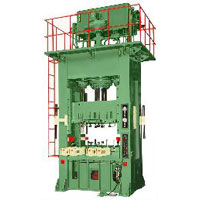

Hydraulic Deep Drawing Press

600,000 Per Piece

We are the leading manufacturers, exporters and supplier of this products.

Hydraulic Deep Drawing Press Double Action

800,000 Per Piece

We are the leading manufacturer and exporter of Double Action Hydraulic Deep Draw Press. We offer Double Action Hydraulic Press (Blank Holder). We, at Flowmech, also manufacture double action hydraulic press with highly compact, rigid and space saving design. Double action hydraulic presses are equipped with PLC, L.V.D.T depth control automatic photo sensor. Double action hydraulic presses are used for manufacturing stainless steel sinks, geysers, A.C., L.P.G. Cylinders and other automobile draw components. With this highly efficient double action hydraulic press, we are successfully satisfying the needs of our esteemed customers through specialized designs and latest trends. Instructions: Model No. Cap. Ton Main cyl. cap. (mm) Blank holder cap (mm) bolster size (mm) day-light gap blank holder stroke main cyl. stroke motor h.p. Ejector cyl. cap. (tons) FDaP 150 150 75 75 700 X 700 600 300 550 7.5 X 1 10 FDAP 250 250 150 150 900 X 900 600 300 550 10 X 1 15 FDAP 400 400 200 200 1200 X 1200 750 400 700 20 X 1 20 FDAP 500 500 250 250 1200 X 1500 800 450 750 20 X 1 20 *FDAP 500 500 250 250 1200 X 1800 800 450 750 25 X 1 20 FDAP 600 600 300 300 1500 X 1800 900 450 850 20 X 2 25 FDAP 800 800 400 400 1800 X 1800 1000 500 900 30 X 2 25 FDAP 1000 1000 500 500 2000 X 2000 1200 600 1100 40 X 2 25 Note: The Press Is Available Up To 2000 Ton Capacity As Per The Customer Requirement The Press Can Be Designed Pillar Gate Frame Type High Capacity Press Will Be Designed Column Type Preferably The Press Can Be Provided With Speed As Per Your Requirement The Motor H.P Can Be Changed As Per The Speed Provided Specially Designed For S.S. Kitchen Sink Manufacturing

Best Deals from Hydraulic Deep Drawing Press

Joint Forming Press

Get Price Quote

Pressing of cased-in books and simultaneous burning-in of the JOINTS for forming perfect hinge and permanent shape with the help of temperature-controlled pressure blades (Joint Forming Bars) for Flat or Rounded Spine of Book-Blocks. These blades are spring loaded for adjusting to different depth of joints automatically and hydraulic pressure can be set from 100-300/400kgs to achieve the desired results. The bars (Joint Formers) are supplied for Flat and Rounded Spine Book-backs respectively.Temperature of the Joint Formers is set through Digital Temperature Controller (PID) to suit properties of Glue (Adhesive), Binding material and operating speed. The PLC (Programmable Logic Controller) enables choice of single or multiple stroke/s for accurate control of burning-in the Joints and consistent results. Counter on PLC indicates number of books processed at the end of each cycle. The system automatically releases the book on completion of the set timing cycle. Back-gauge (setting handle mounted on the front panel) is provided for faster make-ready / production; Light Guide indicates the Joint Forming position and also reduces the make-ready time. Specially designed operator Safety Device in addition to Emergency Switch incorporated.Provision for Joint Forming of foam padded cases available.PLC based control panel for optimum reliability and simplified diagnostics. Press equipped with Castors for maximum space saving / utilisation.

hydraulic cold forging press

1,150,000 Per Piece

Joint Forming Press

Get Price Quote

Pressing of cased-in books and simultaneous burning-in of the JOINTS for forming perfect hinge and permanent shape with the help of temperature-controlled pressure blades (Joint Forming Bars) for Flat or Rounded Spine of Book-Blocks. These blades are spring loaded for adjusting to different depth of joints automatically and hydraulic pressure can be set from 100-300400kgs to achieve the desired results. The bars (Joint Formers) are supplied for Flat and Rounded Spine Book-backs respectively. Temperature of the Joint Formers is set through Digital Temperature Controller (PID) to suit properties of Glue (Adhesive), Binding material and operating speed. The PLC (Programmable Logic Controller) enables choice of single or multiple strokes for accurate control of burning-in the Joints and consistent results. Counter on PLC indicates number of books processed at the end of each cycle. The system automatically releases the book on completion of the set timing cycle. Back-gauge (setting handle mounted on the front panel) is provided for faster make-ready production; Light Guide indicates the Joint Forming position and also reduces the make-ready time. Specially designed operator Safety Device in addition to Emergency Switch incorporated. Provision for Joint Forming of foam padded cases available. PLC based control panel for optimum reliability and simplified diagnostics. Press equipped with Castors for maximum space saving utilisation.

Hydraulic Forging Press

Get Price Quote

Hydraulic forging is the process in which the metal is stretched beyond the yield point to form the desired shape. The forced used in forging must be strong enough to change the dimensions of the material without breaking it. When material is forms new shape, it is called the yield point and the point at which it breaks is called the fracture point.Santec specializes in designing and developing Hydraulic Forging Presses based on the specific requirements of the customers. Major Components of a 'H' type Press Consist of the bed, side Housings (uprights), crown & slide. The bed often has a removable bolster.

Joint Forming Press

Get Price Quote

Joint Forming Press is a Special Purpose Systems for Book Binding for finishing of Hard-Cover/Perfect-Bound Books, Diaries, Dictionaries & Directories etc. Pressing of cased- in books and simultaneous burning-in of the JOINTS for forming perfect hinge and permanent shape with the help of temperature-controlled pressure blades (Joint Forming Bars) for Flat or Rounded Book·back. These blades are spring loaded for adjusting to different depth of joints automatically and hydraulic pressure can be set from 100-300 / 400kgs to achieve the desired results. The bars are supplied for Flat and Rounded Spine Book-backs respectively. Temperature of the blades is set through Digital Temperature Controller (PID) to suit properties of Glue (Adhesive), Binding material and Operating speed. The PLC enables choice of single or multiple stroke/s for accurate control of buming-in the Joints and consistent results. Counter on PLC indicates number of books processed at he end of each cycle. The system automatically releases the book on completion of the set timing cycle. Back-gauge (Setting handle mounted on the front panel) is provided for faster make-ready production ; Light guide indicates the Joint Forming position and also reduces the make-ready time. Adequate operator safety device in addition to emergency switch incorporated. PLC based control panel for optimum reliability and simplified diagnostics. Heating for platens (optional) with thermostatic control (PID) to expedite the settings of cased-in Books.

Hydraulic Deep Drawing Press

Get Price Quote

Hydraulic Forming Press

Get Price Quote

We are offering antec's brand new line of heavy duty hydraulic presses are widely used manufacture various parts for automobiles and cars. These parts include roof linings head liners, hood & dash insulator woodstocks carpets, etc. The machine features heavy duty steel weldments and a superior guidance system that provides accuracy and reliability. Straight side with high rigid structure is coordinated with eight-side guide rail against eccentric load to achieve high precision. The press utilizes hydraulic logic circuits to offer complete control over the process with the best mechanical functions. Santec also offers customization of the machines in order to meet the specific application requirements of the clients.

Deep Drawing Hydraulic Presses

Get Price Quote

Being a reputed manufacturer, exporter and supplier, our enterprise is betrothed in providing best in quality Deep Drawing Hydraulic Presses. These presses are commonly used to manufacture steel sinks, cylinders, geysers and sheet metal components by performing drawing, stamping and bending operations.

Hydraulic Straightening Press

Get Price Quote

Hydraulic Straightening Press, C Type Hydraulic Press

hydraulic deep drawing presses

Get Price Quote

hydraulic deep drawing presses, hydraulic compression moulding presses

Deep Drawing Press

Get Price Quote

Deep Drawing Press, Injection Moulding Machines