Universal Shearing Machine

The frame adopt structure of welding by steel plate, the whole fram dealed with heating treat. • Drived by hydraulic system, stroke back by accumulator. the operation is easy and reliable • Adjustment of gap clearance is showed by indicator, it's easy to adjust. • Light linear equipment can adjust the stroke of upper blade with non-stepness. • It adopt safty protect equipment with fixed fence.

...more

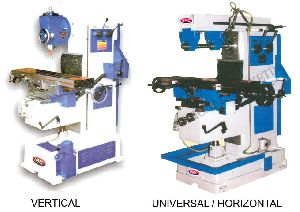

Universal/Horizontal/Vertical Milling Machine

Vertical attachment head, Slotting attacment, Rack cutting attacment, Dividing Head, Rotary table, Milling machine vice, Machine lamp. Specifications are not binding and are subject to modification and change without notice. The standard and optional accessories listed are provisional. Final list will be as per our offer.

...more

Turret Milling Machine

Milling Machines have been designed to give its user with accurate and precise results. It has 55 degree dovetail Y-Axis and Z-axis guide way, making the machine more stable and easy to adjust. The guide way on saddle is lined with TF wearable material. The worktable surface and 3 axis guides way are hardened and precisely ground.

...more

Surface Grinding Machine

Semi Automatic Bandsaw

• Roller Bearing / Carbide wear pad Blade guide system • Automatic work height control & fast approach • Power driven Chip removal Wire Brush • Hydraulic Blade tension • Split main vise for better gripping • Idler Wheel Motion Detector with Blade Stalling & Breakage shut off • ldler Wheel Motion Detector with Blade Stalling & Breakage Shut off • M-42 Bi Metal Bandsaw Blade Optional Accessories • Chip Conveyor • A.C. Drive for Infinitely variable speed control • Bundle cutting attachment • Job Roller Stand • Variable Vise pressure for thin walled job • Wire Brush • Bi-metal Bandsaw blade • Job Feeder Unit (Mechanical Type)

...more

roll turning lathes

Radial Drilling Machines

Extra Accessories • AR25/AR40: Belt Driben & Fine Feed • AR40A : Belt Driben & Auto Feed • AR40AG : All Geared & Auto Feed Salient Features • Closed Grain Cast iron Coloumn, arm, work head & gears. • Parts Finished on imported grinding machine all moving parts Finished to close tolerance. • Parts Properly balanced prior assemly. • Main Spindle & pinion mode on DM forged steel. • Alloy steel spindle rom. Standard Accessories • Motor pulley in all machines. • Complete Electrical Suitable for 415 Volts 50Hz 3 phase AC Supply (Electrical Panel Board & Switched) in Model R40BA & P40AA Extra Accessories • Electrical Motors • Drill Chuck & Arbor • Tapping Control panel board • Vee Belts • Work table • Coolant pump with coolant tank • Keyless drill chuck & arbor • Extra long Column

...more

40mm Radial Drilling Machine

290,000 - 310,000 Per Set

1 Set(s) (MOQ)

precision, accurate and heavy duty all geared 12 speed head with 3 feed head gear box with limit siwtches - pls see the catelogue attached for all features.

Application : Drilling, Industrial Use

Color : Light Blue

Voltage : 380V

Condition : New

Automatic Grade : Automatic

Driven Type : Electric

Feature : Accuracy, Easy To Operate, Fine Finished, Hard Structure, Long Life, Zero Tilling

Warranty : 1year

Certifications : ISO 9001:2008

Brand Name : ACCUDRILL

Material : STEEL

Certification : ISO

After-Sales Service Provided : YES

Drilling Speed : AS PER CATELOGUE

Power : 380V

...more

Radial Drill

Precision Surface Grinder

Vibration-free and Noiseless Working. Precised Engineering and Simple Easily Accessible Controls Mean time saving and accerate Operation. The Grinding accurancy on the machine guranteed and contols of the machine are withing the easy reach of the operator Electricals Diamond Dresser Tool kit, Grinding wheel, auto lubrication system

...more

Pitch Control Tapping Machine

• Closed grained cast iron ribbed machine parts, inimize vibration and distortion. • All moving parts are hardened and ground for long life. • Bore honed to give high accuracy and close tolerance. • Rack pinion also provided with feed friction clutch. These are designed to be idle on encounter of any obstacle or meeting any wrong point on tapping. • Hardened change gears controls the pitch, which gives precise and rapid production of high accuracy. This reduces the set lime and increase production. • Main spindle pulley mounted with manually adjustable safety clutch. • The change gears are used over and over again. This way conventional lead screw and nut are replaced; which have a poor repeatability and short Life span. • Threads are never fractured or over cut due to elimination of excessive thrust force of feeding spindle. • Tapping strokes are adjustable for high accuracy automatic reversing which is specially important for blind hole tapping applications. • Capacity varies according to pitch material, type of thread etc. • Optional pully available subject to material and thread. • Standard equipments — Electrical panel, Electrical motor, Pully, V-belt & Two set of Gears for any pitch required.

...more

Pillar Drilling Machine

• Main spindle and pinion made from EN steel by forging. • Column, arm, work-head & gears made from finest closed grain cast iron; while spindle Ram trim Alloy steel. • Main spindle run out is checked for accuracy as per IS 2199. • For the smooth sliding of sliding arm, special 'slide-reliever-slots' are given. • All moving parts are fine-finished with grinding to a close tolerance. • International technic of 'Taper wedge setting'. for complete slide-setting instead of normal one point setting. • Quality bearings with grease bath, so for permanent oiling. • Main gear and pulley are perfectly balanced. • Powder coated accessories for longer life and prevention of corrosion and pillage associated with usual chrome plating. • P = Pillar Drill m/c • 19/25/40 = Drilling capacity • S = Square Head Model • R = Round Head Model • L = Long Spindle Travel • A = Autofeed Model • X = Xtra Heavy Model

...more

pillar drill

mtr milling machine

Milling Machines have been designed to give its user with accurate and precise results. It has 55 degree dovetail Y-Axis and Z-axis guide way, making the machine more stable and easy to adjust. The guide way on saddle is lined with TF wearable material. The worktable surface and 3 axis guides way are hardened and precisely ground.

...more

Metal Cutting Bandsaw Machines

• Complete With Electricals ie., Saw drive Electric Motor, Coolant pump, On off Contacter with Push Buttons • V-belt Pulleys with V-belt • Job Stopper • Oil Field Gearbox & Hydraulic Cylinder • Friction Type Chip Removal Wire Brush

...more

Matchless Drilling Machines

For over five decades, MACHLESS has been in the fore front of manufacturing of Drilling and Tapping machines. MACHLESS always believes in quality. We strive to put the best components and materials so that you can get the best cutting power in your hand. We invite you to make it A CHOICE OF LIFETIME. These machines are available in bench, pillar and gang type. The machine covers wide range of operations like drilling, reaming, tapping, lapping and counter boring. These machines present a unique combination of metals rigidity and accuracy for both and it’s suitability for mass production and tools room jobs. HEAD The drilling head is of heavy duty. It is reinforced and ribbed with cast iron around bores to withstand any distortion while drilling or boring. The bearing surface is precision bored. Internal bores are honed to provide close tolerance for spindle movement. It has a mechanical locking device, which enables the head lobe raised, lowered or swung to any required position. SPINDLE The Spindle is made of alloy steel. Spindle drives in internally broached sleeve, fitted in deep grooved ball bearings and tapper bearings. Bearings are widely supported and belt tension is not transmitted to spindle. This type of drive ensures a more efficient operation as compared with conventional single key drive. TABLE The accurately machined table surface is provide with slots & can be adjusted vertically at the required height by means of rack and pinion set and it is also capable of revolving fully through 3600. Table can also be tilted to required angle up to maximum 45° both sides (Fig. 1 ).This can be measured with the help of a scale fitted on the rim of the arm. The table holding the arm is held at its place with the help of tapered bolts and cylindrical dowel pin locked in it’s place at its base. DRIVE The drive to splined is transmitted through a v-belt on stepped pulley. In gear type machine additional slow speeds are obtained by engaging back gear (Fig. 2).All geared model machines are provided with additional heavy duty ball bearing for long life and better load taking capacity in the front area of front machine pulley. These and many more unparallel features are responsible for the super performance and long serving life of MACHLESS products.

...more

Lathe Machines

Hardened & ground bed ways, four position tool post, Change gear set, Chuck plate Tool Post key, Centre adaptor, Motor pulley,Electric motor Dog chuck, true chuck Coolant pump, tank and nozzle Quuick change tool post/ rear tool post taper turning attachment Reverse- forward switch, vee belts Splash guard. Salient Features • Bed is made from 25 grade cast iron of 180 bhn hardened strictly • Boring of head stock is done on WMW boring machine fitted with induction hardended and ground spindle made from alloy steel. • Apron is totally enclosed oil bath system with lever type arrangment for automatic feeds. • Double screw norton gear box :- provided as time saver equipmentwith separate thread & feed shaft. thus, feed & thread gears could be • changed rapidly and decreases the wear and tear in half nut and lead screw. • Hexagonal shaped tail stock with hardened and ground tail stock spindle made from alloy steel having external and internal grinding • Oil dipped slid box • Oil dipped norton gear box with 8 speed spindle head • All pulley's are balanced on balancing machine • Double bearing in the front of head stock (total 3-bearrings in the head)

...more

Hydraulic Surface Grinder Machine

Handwheel, Flange, Retainer with Steel balls (two units), Synchronous bell, Demagnetizer, Digital readout system, Precision Vice, Tiltable permanent chuck, Dust collector, Electromagnetic chuck Tool box • Balancing stand and balancing arbor • Star type nut • Flange wrench • Screw driver • Balance screw • open-end wrench • Innerhexagon spanner • Wheel dresser • Setting plate

...more

Hydraulic Shearing Machine

• THE FRAME ADOPT STRUCTURE OF WELDING BY STEEL PLATE, THE WHOLE FRAM DEALED WITH HEATING TREAT. • DRIVED BY HYDRAULIC SYSTEM, STROKE BACK BY ACCUMULATOR. THE OPERATION IS EASY AND RELIABLE • ADJUSTMENT OF GAP CLEARANCE IS SHOWED BY INDICATOR, IT'S EASY TO ADJUST. • LIGHT LINEAR EQUIPMENT CAN ADJUST THE STROKE OF UPPER BLADE WITH NON-STEPNESS. • IT ADOPT SAFTY PROTECT EQUIPMENT WITH FIXED FENCE. COMPONENT • SEAL RING FROM CYLINDER: VALQUA SEAL RING IMPORTED FROM JAPAN, FIETZ BRAND IS FROM GERMANY. • INCLUDING NITROGEN CYLINDER AND PLATE-PRESS CYLINDER) CYLINDER: MADE BY PROFESSIONAL COMPANY, PISTON ROD'S SURFACE IS DEALED WITH CHROMEPLATE. • HYDRAULIC SYSTEM IS ADOPT IMPORTED BOSCH-REXROTH • ELECTRIC SYSTEM: THE MAIN COMPONENT FROM ELECTRIC BOX IS FROM IMPORTED SCHNEIDER, SIEMENS,OMRON ETC • OIL PUMP IS ADOPT THE GEAR PUMP WHICH MADE IN CHINA. • VARNISH: IMPORT FROM HOLLAND. ACCESSORY • ANCHOR SCREW 1SET • FOOT PEDEL 1SET • FRONT FEED FRAM 1SET • PIPE CONNECTOR SEALING 1SET • CUSHION 1SET • AIR FUFILL TOOL 1SET

...more

Hydraulic Hacksaw Machine

Hydraulic Control Hacksaw Machine has been designed to cut quickly & accurataly all material from nickel chroma steel to plastic, controls are simple & easy, An automatic cut out operates at the completion of the operation & the bow slide returns to the top position, the machines has attractive appearance, The bed is of rigid casting with a wide through for collection of coolant, swan & also houses the V-belts device, bed is single piece casting The saw frame is of rigid construction & runs in prismatic guide ensuring a square & parallel cut & this cut takes place on the backward pull stroke, the blade is hydraulically lifted out of contact with work place on the forward stroke to prevent wear of the blade.The drive is given to the machine through V-pullys with provision to adjust fully the tension of the V-Belts. The shafts are fitted with taper and ball bearing which eliminate friction. Two speeds has been provided in order to make it suitable for all metals. High speed for metals like mild steel, brass, copper etc. and low speed for cast iron. Feed saw is controlled hydraulically by two levers provided at the dash-pot. One controls the rate of feed, while the other enables the bow slide to be raised or lowered and the motor gets switched off on completion of the cut.

...more

geared drilling machine

“AMT” 40MM Capacity, All Geared Auto Feed Radial Drilling Machine is having hase Plate, provided with in-built coolant Tank. Steel ram and pinion with 2.82 module heavy teeth enables greater load capacity.

...more

Fully Automatic Bandsaw

The job is placed for initial cut (first cut). After pushing the 'CYCLE START' button job would be clamped by front vice and rear vice. Blade would come rapidly down (quick approach) up to the job height and then after it would slow down as per cutting feed valve setting (manual setting one time as per requiremet), and the cutting operation continues, after finishing the cutting operation blade would be moved upward up to the set height ( Quick approach sensor) then rear vice would push the job automatically as per its set lenght (lenght counter). Again blade would come down rapidly up to the job height and thten starts cutting and this cycle repeats as per our required number of pieces, set on pieces counter. Multiple indexing is also possible in this cycle for longer job length cutting for more then 350 mm. PLC operated panel would display the no of operation completed. Bundle cutting (more than 2 jobs) facility is available as optional in this type of machine. • PLC control for all electric & hydraulic functions • Shuttle Type Automatic Job Lenght Feeding • Floating Shuttle vise for handling of bent job • Automatic work height control & fast approach • Power driven Chip removal Wire Brush Assembly • Hydraulic Blade tension • Split main vise for better gripping • Idler Wheel Motion Detector with Blade Stalling & Breakage shut off • Roller Bearing / Carbide wear pad Blade guide system • Bi Metal Bandsaw Blade Optional Accessories :- • Chip Conveyor • A.C. Drive for Infinitely variable speed control • Bundle cutting attachment • Job Roller Stand • Variable Vise pressure for thin walled job • Wire Brush • Bi-metal Bandsaw blade

...more

Autofeed Drill Machine

AMT” 40MM Capacity, All Geared Auto Feed Radial Drilling Machine is having hase Plate, provided with in-built coolant Tank. Steel ram and pinion with 2.82 module heavy teeth enables greater load capacity. The all new design of gear box iii Model PMW-R4OAA, R400 and P4OAA is having 9 speed with all 9 gears of hardened NiCr steel up to HRC 50-55. Oil bath gear box and hardened gears give very long life to the machine. Rotation and easy sliding of gears in bearings gives very high reliability. Gears are internally six splined and shafts are externally All the gears in gearbox are machined on imported WMW Germany make gear shaper. All the splines in the gear box are machined on imported PFAUTER Germany make spline milling machine. • Electrical Motors • Vee” Belts. Keyless Drill Chuck • Tapping Control Panel Board • Drill Chuck & Arbor • Work Table • Extra long column • Coolant Pump with Coolant Tank.

...more

All Geared Lathe Machines

Features • GRADE – 25 HARDENED AND GROUND BED GUIDEWAYS. • HARDENED & GROUND ALLOY STEEL GEARS & SPINDLE IN HEAD STOCK • HARDENED & GROUND TAIL STOCK RAM • ALL CRITICAL COMPONENTS LIKE SHAFTS, GEARS, PINS, LEAD SCREW ARE MADE OUT OF EN-8/ EN-9 ALLOY STEEL • ACCURACY CONFORMS TO INDIAN STANDARD No. I.S. : 1878 (PART - l) – 1993. Salient Features: • IS.20/25 graded casting • Rigid and box section type 240 mm wide bed provides maximum torsional stiffness. • Rigid and accurate, alloy steel hardened and ground main spindle mounted on precision taper roller bearings & ball bearings. • Forced lubrication in universal feed gear box. Apron with oil bath. • Thread and feed mechanism interlocked (Only one can be engaged a time). • Camlock spindle nose (DI-4 type) • Overload Protection through suitable relays and contractors. • Switch shaft lever fix at carriage to rev. forward & stopped main spindle. Built-in Accuracy: • All major castings are artificially seasoned for retaining built-in accuracy. • Critical components precision machined on imported mother machines. • Induction hardened and alloy steel gears of head stock mounted on precision spined shaft and running in oil bath. • Flame hardened and ground bed for sustained accuracy. • Alloy steel lead screw threads produced on WMW thread milling machine. • Each machine is tested to IS-1878 (Part) 1993. Versatility: • Built-in gap bed. • Universal feed gear box for easy selection of wide range of feeds and threads through levers. No change gears required. • Instantaneous spindle reversal while threading. • Wide variety of optional accessories for higher productivity.

...moreBe first to Rate

Rate ThisOpening Hours