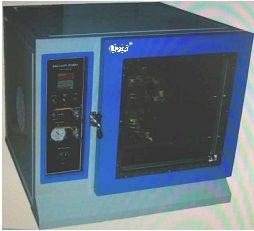

Hot Air Oven

90,000 Per Piece

The Hot Air Oven, which we deliver, is reckoned for its efficient performance and longer service life. We source the required raw material from the certified places after complete quality confirmation. As a result of which, the finished products comply with elevated industry standards. We have with us a well-maintained and capacious storage unit that is facilitated by advanced and automated warehousing system, which is operated and supervised by experts only.

Conveyor Pizza Oven

Get Price Quote

Best Deals from Industrial Ovens

Laboratory Rectangular Vacuum Oven

60,000 Per Piece

1 Piece (MOQ)

These are double walled units with outer made of M.S. sheet duly powder painted and inner made of heavy gauge S. Sheet. Gap between the two walls is duly filled with high grade glass wool to avoid thermal loss. Temperature range from ambient to 150°C is controlled by Digital Temperature Controller with an accuracy of ± 1°C. It is capable of with standing a high vacuum. Provided with vacuum gauge, see through transparent window of toughened glass and one shelf. To work on 220/230 Volts A.C. supply. (Without Vacuum Pump)

double walled vacuum oven

Get Price Quote

The Vacuum Oven Double Walled that we offer is designed and manufactured specially for withstanding high vacuum. The oven’s fineness is attributed to our expertise in designing and developing it flawlessly. Its quality is assured by us, leaving our clients with no doubts on the performance of oven. We are enlisted with the chief Manufacturers and Suppliers of Double Walled Vacuum Oven in Delhi. Details These are double walled units with outer made of M.S. Duly powder coated and inner chamber are Made of heavy gauge S.S. – 304 Grade sheet. Gap between the two walls is duly filled with high grade Glass wool to avoid thermal loss. Temperature range from 50° C, to 150° C, is controlled by Digital Temperature indicator-cum controller with an accuracy of + 1° C, It is capable of withstanding a high Vacuum. Provided with vacuum gauge, see through transparent window of toughened glass and one Shelf. To work on 220/230 volts. A.C. Supply. Size 250x300 mm 300x300 mm 300x500 mm

Gas-Wood Fired Pizza Oven In Mosaic Tiles

Get Price Quote

Wood-fired ovens that use wood fuel for traditional cooking & unique taste.Food is cooked in that same chamber while the fire is still going,or in the heated chamber after the fire and coals have been swept out.Such ovens became popular in the world wide use in bakeries and pizzerias,as well as some restaurants featuring pizzas and baked dishes.The most common method is the stoneware pizza stone, which storesheat while the oven is preheating and transmits it directly to the bottom of the pizza. Feature's: Mosaic Hand Crafted Natural wood Taste Great Quality Heat container up to 400 to 500 Celsius Available in Wood Fire

Drying Ovens

Get Price Quote

Bottle Drying Oven

Get Price Quote

We are offering bottle drying oven. electrically heated out side dimension 56” width x 24” depth x 50” height, with actual working dimension 33” width x 22” depth x 46” height, made of double walled mild steel/stainless steel body, heavily insulated with glass wool, total load 6 kw with dial type thermometer and thermostate for controlling temperature, with ½ h.p.motor and one fan for circulating air able to accomodate 240 bottles of 1 lb. Capacity in 8 mild steel fabricated crates of size. 19”x15”x9.5” deep with starter suitable for operation on ac/440v/3p/50c supply as per your requirements. available in two models: · routine model · gmp model m.s body of the machine cladded with stainless steel sheet

UVC LED Oven

Get Price Quote

Hot Air Oven

20,000 - 22,000 Per Piece

Vacuum Oven

Get Price Quote

The vacuum ovens from Weiber are heating equipments that are designed to operate across a wide temperature range under normal atmospheric pressure or vacuum conditions up to 30” Hg, for day to day heating and vacuum drying applications. Designed for high-precision temperature control and equipped with a flexible vacuum system, they provide fast and gentle drying solutions for heat-sensitive and air-sensitive materials such as cosmetics, books, food items, clocks, PCBs and other electronic components. These vacuum heating and drying ovens are designed for excellent temperature and Vacuum performance, facilitating their use for drying and desiccation of samples, powder drying, vacuum embedding and electronic component processing. These economical and highly efficient vacuum ovensare employed for a wide range of scientific and research applications and find widespread usage in research laboratories, defence installations, educational institutes and industrial units. The vacuum ovens from Weiber are available in various sizes and configurations and are completely customizable as per the specific requirements. They are designed in accordance with ASTM standards and bear CE certification for safety and reliability. The Vacuum ovens are essentially double walled equipments that feature high quality, heavy gauge SS 304 stainless steel internal surfaces and external surfaces made up of powder coated galvanized sheets with paint finish. The equipment features highly resistant and non-corrosive external and internal surfaces and the internal surfaces are argon welded for seamless welds and strong bracing. The gap between the outer and inner wall is filled with high-grade mineral glass wool for maximum thermal efficiency. The double plenum design of these vacuum ovens ensures a cooler outer surface for easy handling of the equipment. The equipment is also provided with a toughened glass door for increased visibility. Economical and versatile usage Energy Efficient units Long life Low Maintenance Scientifically designed for excellent vacuum and temperature control Smooth, highly resistant and non-corrosive external and internal surfaces Argon welded internal surfaces for seamless welds Highly reliable and safe operation Toughened glass door for increased visibility Double plenum design for safe handling Precise Vacuum Control: 28” (70.2 cm) Hg displayed on analog gauge Calibration And Protocol Documentation Designed in accordance with ASTM standards Bear CE certification

barrel drying oven

Get Price Quote

These Converised Ovens are suitable for Barrel and Lids paint baking as well as lacquer Drying. PVC / Rubber lined Barrel Lids can also be dried in specifically designed cleat type Conveyor Oven. The Barrel and Lids can be dried after washing operation. This oven is mainly meant for Canning and Printing Industries. It used to dry the painted or coated cans or barrels. Although, these can be used for lacquer drying processes. The barrel and lids are dried out at the closing stage of washing operation. A specially designed cleat type Conveyor Oven can be used to dry Rubber or PVC lined barrel lids. This oven comprises of a chained conveyor which provides increased performance as compared to conveyor belts. The main heat exchanger along with entire chamber is insulated, to avoid heat loss and bid increased fuel effectiveness.

Electrode Drying Oven

Get Price Quote

KTMC offering reliable Electrode Drying Ovens which works hour after hour, day after day the same faithfull consistency. Temperature Control Provided with thermostat control for precise setting of drying temperature required for various types of electrodes.

Microwave Oven

Get Price Quote

Wood Fired Oven

Get Price Quote

With evenness of the heat distribution, and imparting a rich smoky flavor to add an extra flavor dimension, our newest creation hold's the moisture within the food only to get released when you cut into it just before serving. Our Wood Fired Oven is the most easy to use and cook lip smaking recipes from the stable of one of the most reputed brands of India. Large oven entrance opening allows for maximum visibility and easy usage. Also Available in steel, brass other material finishing, this oven is ideal for domestic and commercial use as well.

Hot Air Oven

15,000 Per Piece

1 Piece (MOQ)

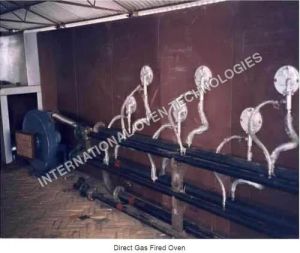

Direct Gas Fired Oven

Get Price Quote

Hot Air Oven

12,500 Per Piece

1 Piece (MOQ)

Hot Air Oven

Get Price Quote

Industrial Drying Oven

Get Price Quote

Industrial Drying Oven (Tray Drier) (PLT-129) APPLICATIONS OF INDUSTRIAL DRYING OVEN Triple Walled Industrial Drying Oven (Tray Drier) is Suitable for heat treatment, baking and drying applications in industries, or Institutes engaged in the production of vaccines. Tablets, Bottle Sterilizing Drying Chemicals, PCB Processing, Armature Windings, Soaking electronic components like Yoke, Coils, EHT Coils, Transformers etc. SALIENT FEATURES & CONSTRUCTION OF INDUSTRIAL DRYING OVEN Triple walled construction on heavy iron angle, inner chamber made of Mild steel painted with temp. resistant paint and outer finished with hammer tone paint Forced convection system by motor & blowers fitted ensures good mixing, strong dispersion and maintains higher temperature uniformity inside the chamber & no cross contamination. Air circulation is provided by heavy duty blower with ventilators are provided on the top of Oven. Thermal loss is prevented by filling mineral wool (Insulation) in space between the outer body & Inner chamber. Door Gasket fixed on the double walled door for proper sealing. Fitted with heavy hinges with a ball catcher, spring loaded door closing device. Door is duly insulated. Tubular Air heaters made of SS are placed at bottom and sides for uniform heat distribution. Temperature is controlled by electronic digital temperature indicator cum controller from 50°C to 250°C ± 5°C. fitted on the front panel for easy operations. Temperature is displayed by Digital LED with SV and PV display at front of the oven. Front Panel is provided with ON/OFF switch, temperature controller and indicators Supplied with other accessories but without trays & trolley Operating Voltage: 440 Volts three phase AC supply.

Vacuum Ovens

Get Price Quote

A prominent supplier of huge range of Vacuum Ovens.

Microwave Oven

4,200 Per Piece

Vacuum Oven

Get Price Quote

Pre Heating Vacuum Conveyor Oven

Get Price Quote

PLC Conveyor Design Heating & Vacuum Oven for Mass Production Hot Air Convection Heating Glass Travels Vertically Consists of Oven Body, Conveyor, Vacuum System, Heating System & Control System Stable Chain Conveyor Carries Glass Consistently Vertical Rods Attached to Conveyor Frequency Converter Infinitely Regulate Glass Travel Speed Well Assembled Laminated Glass with PVB Films Loaded on Conveyor Separated by Vertical Rods Hoses of Silicon Rubber Rings Connected to Vacuum Pipes Inside Oven Vacuuming Evacuates Air Trapped Between Two Pieces of Glass by Means of Silicon Rings Air Fan Creates Powerful Hot Air Convection to Uniformly Preheat Glass & PVB Films Glass Edges Well Sealed with Pre-Melting & Pre-Bonding between Glass & PVB Film Well Thermal Insulation Materials of Oven Body Minimizes Heat Loss Automatic Heating Control

Powder Coating Ovens

Get Price Quote

Powder coating ovens are equipmentâs that can improve the efficiency and productivity in the industrial plants. These are incorporated with the latest and the most developed technology. These ovens are considered as excellent alternative for manufacturers of metals, wood products, medium density fireboard and also plastic products.

Hot Air Oven

Get Price Quote

Industrial Drying Oven

Get Price Quote

Air circulating fan with heavy duty blower fitted on the Side of the oven with on/off switch. Ventilation is provided the top of the oven. Temperature range from 50-250°C thermostatically controlled. Inner chamber made of M. Steel silver stoving painted. Works on 220 / 240V, single phase AC supply. Optional Accessories:Digital Temperature Controller cum indicator

INDUSTRIAL OVENS AND DYERS

Get Price Quote

We are offering Spray Dryer R.N.S. Spray Dryers are relatively simple in operation which accept feed in fluid state and convert it into a dried particulate form by atomizing the fluid into a hot drying medium. Atomization is done using high pressure nozzle, high pressure air, two fluid nozzles or centrifugal disc atomizer. The heating of drying air can be through steam radiator or thermic fluid air heater according to the service conditions available. Direct or indirect fired hot air generator through oil or gas according to fuel availability with client. The unique Fines Re-circulation System produces highest quality of agglomerated powder. Apart from that it also offers spray nozzle, atomizer, diversion valve, blow through valve, ss pipes & fittings Applications: Milk Powder Whey Powder Ceramic Slurry Magnesium Chloride Molasses Poly Aluminum Chloride Enzymes Catalysts Calcium Chloride Instant Tea Instant Coffee Ice Cream Mix Powder Bakers Yeast UF Resin Fruit Juice Powder Protein Hydrolysate Egg Powder Polyvinyl Acetate Dyes Detergent Powder Herbal Products and Lots of other products

Curing Chambers

Get Price Quote

Curing Chambers, Mica Strip Heater, Finned Strip Heaters, Strip Heaters

Industrial Ovens

Get Price Quote

Industrial Ovens, Glass Products, Furnace, Refractories

Hot Air Oven

Get Price Quote

The unit is electrically heated drying chamber, suitable for drying granules, with double walled body, housing, insulated with heavy fibre glass wool, with special u type heaters, air circulation fan, thermostat, panel box etc.