Tin Box Plant

We specialize in offering a wide range of Tin Boxes. These are extensively acclaimed for their finest quality and reliability. Following the demands of clients, we provide these in various shapes including square, rectangular, round and many others as per the specific requirements of clients. These are extensively used in various industries for the proper storage of gift ware, food, confectionery, cosmetics/toiletries, pharmaceutical, healthcare, personal care and general line products. Features: Robust Durable Rust resistanc

...more

Soya Chunks Drying Oven

Structure: The structure for the full length of the oven will be fabricated by 75 * 40 mm channels and 50 * 50 mm angles and reinforced with cross frame jigs and gusset plates. The structures shall be erected at every 5 ft. distance and connected with 50 * 50 mm running angles. Conveyor Band: The three tier conveyor will be of S.S.-304 tray type with 6" pitch roller chain. The dyno drive will be provided to vary the speed of conveyor. Insulating Panels: All the top, side and bottom insulating panels shall be fabricated from CRCA prime quality sheets. The 4" gap in the panels will be filled with mineral wool to conserve heat and increase efficiency. The extreme bottom portion on both sides of the oven shall be covered with CRCA sheets. Jointing covers with minerals wool be used for jointing the individual panels to avoid leakages and heat loss. Firing Chambers: There shall be 1 no. stainless steel shell in shell type heat exchanger with firing chamber having exhaust fan mounted on the top of the chamber. The Bentone Automatic Oil burner with complete control system and the main circulating blowers shall be mounted on the either sides of the chamber. Complete chamber with suction box shall be insulated with glass/mineral wool panels and coverings to avoid heat loss, increasing the thermal efficiency. Air Ducts: Both sides air circulation ducts with perforated holes are fabricated by 18 swg CRCA sheets. The main connecting & supply ducts are made of Stainless Steel. The adjustable dampers are provided at appropriate intervals to have uniform circulation of hot air throughout the length. Electricals: The electric motors such as 10 HP 2 nos. for main circulating fan, 0.3 HP 1 no. for burner, 5 HP 1 no. for driving, 1 HP 1 no. for exhaust and 3 HP 1 no. for extract are included in this quotation. D.O.L. starters for lower H.P. and Star Delta for 10 HP, with indicators and control instruments shall be fitted in the control panel. The wiring from control panel to motors and incoming to the control panel are excluded from this quotation. The guarantee for electrical instruments and accessories shall not be covered by us.

...more

Sheet Unloader

This is specially constructed for heavy duty services & operations and efficiently handles tinplate or aluminum.Features:- Durable Precision functioning Low Maintenance Operation:-As the oven wickets move around the end sprockets of the oven and reach a horizontal position, the sheets are withdrawn by the belts of the extraction conveyor. These are then forwarded along the belts and on to the four-belt centre conveyor, a drop wheel and two bowing discs bowing them slightly as these move along the belts to assist

...more

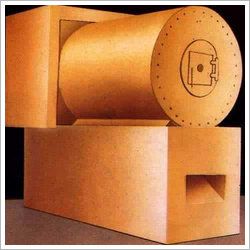

Rotary Rack Oven

Avail from us recently launched Quadri rotary rack ovens and Rotary Rack Ovens, which have carved a niche for themselves in the national and international markets. Manufactured in sync with international quality standard, these ovens are preferred for their large baking capacity and high fuel efficiency compared to other ovens. Item Code: 01 we have new model rotary rack oven in rupees 4,25,000.00OFFER VALID 20 SEP, 2013 Some of the Specifications of Rotary rack Oven are as follows:- Easy to operate Low maintenance Minimum wastage Most economical

...more

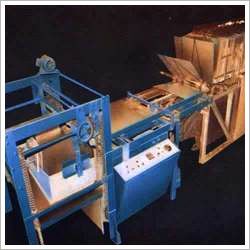

Pan Masala or Supari Drying Oven

Direct / Indirect Oil fired Oven having specially designed tray conveyor, suitable for Baking / Drying Pan Masala, Tobacco, Pulses and Soya Bean etc.

...more

Metal Decorating Oven

This is specially designed for drying coated or printed Tin and Aluminum Sheets. The temperature of the oven is maintained consistently by automatic temperature controller operating the burner. Burner enables the temperature profile uniform.

...more

Indirect Type Rusk Oven

This is multi region Indirect fired bread Oven appropriate for bread / Rusk baking. This Oven is separated into numerous self-regulating heating zones along with the chamber. Each zone consists of necessary hot wind circulation system consisting of a combustion zone comprising of burner, circulating fan, turbulence fan, and the associated duct work leads the banks of radiator tubes. The oven identified by technology council has reached to the international level. It can fulfill the technological necessities for production of diverse types of Bread and Rusk.

...more

Indirect Type Bun Oven

The Indirect Fired Oven machine is required to bake different types of biscuits as per requirement in a continuously traveling operation through convection and radiation heating.

...more

Indirect Type Bread Oven

Specially designed traveling type Direct or Indirect oil fired ovens along with 6" Pitch slat type conveyor, suitable for baking Bread, Buns, Rusk, Fruit Bread and Bakery Biscuits etc.

...more

indirect fired biscuit oven

This is a multi zone Indirect fired biscuit oven suitable for general purpose biscuit baking. This oven is divided into a number of independent zones each comprising a combustion chamber with burner, circulating fan, turbulence fan, and the associated duct work leading the banks of radiator tubes. Radiant Heating System: The products of combustion are recalculated through 102 mm. diameter tubes above and below the band. The gases in the radiator tubes are negative pressure to ensure that the products of combustion cannot contaminate the goods in the event of leakage. This system gives maximum economy and temperature stability as only a proportion of gases is exhausted to atmosphere, the remainder to the combustion for re-heating. Turbulence System and Steam Extraction: Turbulence is normally fitted to all but the initial (feed end) zone or zones of the oven and is completely independent of the heating system. It is re-circulatory to give the maximum heat loss from the baking chamber. The system comprises an extraction duct with openings into the baking chamber, a turbulence fan in a steel case having impellers with air-cooled bearings driven by an electric motor, mild steel delivery ducts with turbulence control dampers, leading to the top and bottom turbulence tubes in the baking chamber. The turbulence tubes are fitted to improve the heat transfer to the product, the velocities not being high enough to disturb flour or sugar dust on the product. The ratio of the top and bottom turbulence can also be controlled by dampers on the burner side of the oven. The ductwork includes a spill over outlet with linage connections for a steam tube with control damper. Should the turbulence system not be specified , then each zone is provided with its own extraction fan mounted over the heater bay and extracting from the chamber. The extraction rate is varied by means of a damper. Additionally, a small steerage extraction fan is fitted at the delivery end to extraction velocity slot built in the end to prevent under spillage of baking chamber air into the bakery.

...more

Dough Mixer

We are offering Dough Mixer. Our experts manufacture the offered mixers by making use of excellent quality raw material, sourced from the most authentic vendors of the industry. Further, to ensure the complete and effective mixing, our professionals base the offered mixers on the principle of the rotation of the planetary blades on their own axis while they travel around the center of the mixing bowl which ensures complete and effective mixing. Planetary Mixer is also knows as a Dough Mixer, Dough Mixture, Dough Kneader, Spiral Mixer, Cake Mixer, Bakery Mixer

...more

Direct Gas Fired Oven

Salient Features:- Structure: The structure for the full length of the oven will be fabricated by 75 x 40 mm channels and 50 x 50 mm angles and reinforced with cross frame jigs and gusset plates. These structures shall he erected at every 5 ft. distance and connected with 50 x 50 mm running angles. Insulating Panels: The 4" thick, side & top panels shall be fabricated by prime quality 16 gauge CRCA sheets with perforated sheet metal channels & are filled with mineral wool as insulation to avoid any heat loss to the atmosphere. Bottom portion of the oven shall be covered with 18 gauge CRCA sheets, which also protect the wickets & avoid heat loss. Conveyor: The full length of the oven will be consisting of alloy steel wickets having riveted construction fabricated out of rolled alloy steel wires of 8x3 and 7 x 2.5 mm dimensions. The extended pin type specially designed British standard chains will be used on which the wickets will be fitted with easy replacement system. The tensioning arrangement for the conveyor will be provided with sprockets etc. Mechanical varispeed system with HP motor shall be fitted to vari the speed of the conveyor. Oil Firing Chambers: There shall be nos stainless steel shell in shell type heat exchanger with firing chamber having exhaust fan mounted on top of the chamber. The oil burner with complete control system and the main circulating blowers shall be mounted on the either sides of the chamber. Complete chamber with suction box shall be insulated with glass/mineral wool panels & coverings to avoid heat loss, increasing the thermal efficiency. Gas Firing Chambers: There shall be 3 nos. stainless steel shell in shell type heat exchanger cum firing chamber. The automatic gas burner with complete control system and the main circulating blowers shall be mounted on the either sides of the chamber. Complete chamber with suction box shall be insulated with glass/mineral wool panels and covering to avoid heat loss, increasing the thermal efficiency. Air Ducts : The hot air will be from the top of the oven through nozzle type ducting fitted at both sides of the oven. The Diversion of supply air will be from bottom of both sides of the oven. Electricals : The electric motors, such as HP nos for main circular inline fan HP nos for burner, HP one no for driving 1 HP no for exhaust, 1 HP nos. for cooling, and 3 HP no. for solvent extractor fan are included in this quotation. Star Delta starters, for 10HP & above shall be used in the control panel. The wiring from control panel to motors and incoming to the are excluded from this quotation. The guarantee for electrical instruments and accessories shall not be covered by us. We supply the following accessories for Electrical & Control Instruments: Automatic temperature controller Flame Failure device: This is safety for the firing chamber, which operates in case of flame failure closing the solenoid valve automatically, thus stopping the oil flow. Interlock system is also provided not to operate burner unless the main circulating fan is on We shall supply automatic oil fired "Bentone" or equivalent burner

...more

decorating oven

We are manufacturers and suppliers of oven machinery like Decorating Oven. The temperature profile is maintained uniformly by mechanical temperature controller that operates the automatic oil & gas furled burner.

...more

Cap Drying Oven

hese Converised Ovens are smaller in size, suitable for precious drying of PVC lined Crown and Lug Caps etc.Our oven is widely preferred in FMCG, baking and packaging industries. In addition, we also offer tin printing oven, tin printing drying oven, tin printing traveling oven and automatic barrel drying traveling oven .Features: Excellent performance Durable Low fuel consumption Low maintenance .

...more

Bread Slicer

Gravity feed slicers are best suited to the small wholesale and large retail bakeries where a greater number of Sliced breads are produced. slicers are designed for maximum safety. This Multipurpose cutting Machine with gravity feed closes the gap in requirements between the manual bread cutting machine and the actual industrial machines..

...more

Bread Baking Oven

Biscuit Baking Oven

Biscuit Baking Gas Oven

Also known as traveling ovens, these biscuit baking gas ovens consist of a steel steam tight tunnel having equally divided zones of the radiators. For preventing oven section expansion, the ovens are provided with SS expansion joints. Our commercial biscuit baking ovens are known for their excellent baking process that is continuously monitored through the inspection doors. Moreover, the oven chamber is insulated with miner wool to conserve heat and increase efficiency. These ovens can be effectively operated with oil, gas and electricity.

...more

barrel drying oven

These Converised Ovens are suitable for Barrel and Lids paint baking as well as lacquer Drying. PVC / Rubber lined Barrel Lids can also be dried in specifically designed cleat type Conveyor Oven. The Barrel and Lids can be dried after washing operation. This oven is mainly meant for Canning and Printing Industries. It used to dry the painted or coated cans or barrels. Although, these can be used for lacquer drying processes. The barrel and lids are dried out at the closing stage of washing operation. A specially designed cleat type Conveyor Oven can be used to dry Rubber or PVC lined barrel lids. This oven comprises of a chained conveyor which provides increased performance as compared to conveyor belts. The main heat exchanger along with entire chamber is insulated, to avoid heat loss and bid increased fuel effectiveness.

...more

bakery baking oven

Rotary Rack Ovens

bun baking oven

Bakery Oven

rusk baking oven

Be first to Rate

Rate ThisOpening Hours