Water Softening Plant

We are engaged in manufacturing, exporting and supplying effective Water Softening Plant designed on advanced Ion-Exchange technologies. Apart from standard models of the Water Softening Systems, we also provide customized units that are suitable for particular operations. Our Water Softening Plant is demanded BY Petrochemical Industry, Pharmaceutical Industry, Sugar Industry, Nuclear Plants, Food & Beverage Industry, Chemical Industry as well as Power Plants. Models Available From : 1KLpH-150KLpH Salient Features : Sturdy construction Advanced functions Hassle free maintenance Long functional life Cost effective

...more

Water Softening System

Water Filtration System

Water Filtration Plant

We are one of the most reliable Manufacturers, Suppliers and Exporters of a huge assortment of Water Filtration Plants in India. High on demand, the Water Filtration Plant is developed using latest technologies and is in tandem with the international standards. Apart from this, customers can be eased with the availability of water filtration system at the economical prices. Widely used for : Process water Potable water Waste water Households Range : Rapid sand filter Dual media filters Multi grade filters Activated carbon filters Micron filters Iron removal filters

...more

Water Desalination Plant

We are engaged as a Water Desalination Plant Manufacturer, Exporter and Supplier. The process includes separation of saline water into two streams, where one contains fresh water having low concentration of salts and the other one having the higher concentration. The separation can be affected by using different technologies and this can be driven either mechanically or thermally. Water Desalination Plant works on the basis of osmosis where the flow of solvents takes place through semi permeable membranes and the impurities are trapped to be separated from the water. With the modern technology of our Water Desalination Plant, you can purify municipal water for medicinal usage or even make seawater fit for drinking. The various processes used include:Nano Filtration : This process aids the removal of water particles and organic substances, aside from reducing the ionic solution strength in a selective manner. Ultra Filtration : Various macro molecules as well as colloids are removed from water using this process. High pore size here removes various contaminants but leaves dissolved salts.

...more

Water Demineralization Plant

We have established ourselves as a prominent Manufacturer, Supplier and Exporter of a wide assortment of Water Demineralization Plant in India. Water Demineralization Plant is used for removal of minerals as well as ions from water. Depending on the variable quality of water, different plans of Water Demineralization Plant are used (basically two, three, four bedded systems are used). Attributes : Rugged construction Longer service life Trouble free operation Higher functionality Optimum performance Zero maintenance Widely used for : Industrial applications Municipal use

...more

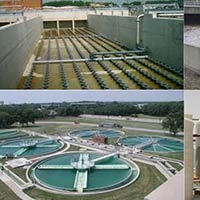

Wastewater Recycling Plant

Wastewater Recycling Plant is designed by expert engineers as per the challenging requirements of various industries. Our organization is counted amidst the prominent Wastewater Recycling Plant Manufacturers, Suppliers and Exporters. Our Wastewater Recycling Plant is suitable for various biological and chemical processes of water treatment. Wastewater Recycling Plant is suitable to treat municipal and industrial wastewater. Our valued clients can avail Wastewater Recycling Plant at economical price.

...more

waste water recycling plant

Sewage Water Treatment Plant

Sewage treatment is the process that removes the majority of contaminants from wastewater or sewage and produces both a liquid effluent suitable for disposal to the natural environment and sludge. To be effective, sewage must be conveyed to a treatment plant by appropriate pipes and infrastructure and the process itself must be subject to regulation and controls. Some wastewaters require different and sometimes specialized treatment methods. At the simplest level, treatment of sewage and most wastewaters is carried out through separation of solids from liquids, usually by sedimentation. By progressively converting dissolved material into solids, usually a biological floc, which is then settled out, an effluent stream of increasing purity, is produced. Ionberg Sewage Water Treatment Plant ensures that only clean water is discharged into rivers. In addition, through a combination of innovative treatment processes, we facilitate the reutilisation of wastewater for industrial and municipal purposes and thus help in the conservation of resources. Ionberg provides a range of optimized solutions extending from water softening to almost total nutrient removal. The key technologies employed include one- and two-stage activated sludge processes, membrane bioreactor technology, biofiltration and moving bed biology, Submerged aerated fixed films. Our vast experience is continually being supplemented through intensive research work. Therefore, apart from standard technical processes, we are also able to offer highly efficient new developments. Our proven and advanced processes include amongst others : Activated Sludge Process – Biological Wastewater Treatment Hybrid Process – The two-stage activated sludge process for nitrogen removal Hollow fiber modules – Membrane bioreactor (MBR) Biofiltration for wastewater treatment Moving Bed Bio Reactor for waste water treatment Submerge Aerated Fixed films biological treatment SBR – Sequencing Batch Reactor Combined chemical-oxidative and biological effluent treatment

...more

Moving Bed Biological Reactor

We offer highly efficient Moving Bed Biological Reactor or submerged aerobic fixed film reactor. We are engaged in providing clients Moving Bed Biological Reactor that primarily removes wastewater in three stages that are primary settlement, aeration and final settlement. This robust treatment plant is simple in design and suitable for broad range of applications. This system can be supplied and installed with air blowers. Apart from this, minimum civil work is required. Work Process : Primary Settlement : initial settlement of wastewater and separation of gross solids occurs in the primary settlement tank. The gross solids in the wastewater form sludge at the bottom of the tank and lighter social debris forms a crust on the surface. The settled liquor that is contained between the sludge and crust passes forward through an outlet filter for treatment in the aeration chamber. Aeration : the moving bed biological reactor (MBBR) employs a submerged media onto which micro-organisms attach. This biomass requires oxygen to flourish. This is supplied by aerating the liquid in the chamber. The biomass retained on the media provides effective treatment for effluent. The media are kept in motion by the course bubble aeration. The air introduced into the tank ensures thorough mixing and turnover of the media within the reactor. Final Settlement : the effluent passes forward for the final stage of treatment and enters the final settlement tank through a stilling well. This slows the velocity of the effluent and allows any remaining fine solids to settle. The base of the tank is coned allowing final settlement of the effluent to take place with minimal disturbance to any settled particles. The return sludge pump is located at the base of the tank and any remaining fine solids are returned via a sludge return line to the primary settlement tank. The treated effluent emerges from the system through the outlet for disposal. Benefits Of MBBR : High treated effluent quality Small footprint Robust treatment plant (concrete tanks) Below ground installation simplicity of design, installation & operation Suitable for a broad range of applications The MBBR treatment process can be provided for a new sewage treatment works or for retrofitting or upgrading existing wastewater treatment plants where a higher treated effluent. Features included as standard in the MBBR treatment plant : Pre-cast concrete tanks Air blowers supplied and installed Minimum civil work required

...more

Mineral Water

We are an established Mineral Water Plant Manufacturer, Exporter and Supplier from Delhi, India. Mineral Water Plant is developed using innovative techniques to ensure effective purification of water, by removing salts, asbestos, silica, iron, turbidity and other contaminants. Mineral Water Plant offered by us is highly demanded for food processing and production of mineral water by industries in India, Asia and Africa.

...more

Membrane Bio Reactor

The company offers high quality Membrane Bio Reactor that is basically used for wastewater treatment. This Membrane Bio Reactor has a high pollutants removal rate & renders steady operation. We are even a single supplier in India that provides high quality membrane bio-reactor at low cost. Membrane Bio Reactor (MBR) technique is a new method for wastewater treatment that integrates membrane separation and biotechnology, rejects activated sludge and macromolecular organic matter in aerobic tank or MBR tank with membrane separation plant, thus saving the use of secondary sedimentation tank. Consequently, the concentration of activated sludge rises greatly, the HRT and the SRT could be controlled separately, and difficult degraded matters are constantly degraded and reacting in reactor. Therefore, compared to traditional biological treatment methods, MBR technique greatly strengthens the function of the bioreactor with the using of membrane separation, it has advantages as follows: high biochemical efficiency, strong load impact resistance, stable effluent quality, smaller foot print, long period of sludge discharging, easily automatic control, etc. MBR is a high effective combination with membrane separation and biological treatment instead of secondary sedimentation tank of activated sludge process to separate.Features : High pollutants removal rate, strong capacity of sludge bulking resistant, steady treated effluent quality, suspend solid (ss) in effluent near to zero. Accomplish complete separation between hydraulic retention time (hrt) and sludge retention time (srt). Operation is simple and flexible. Stop loss of activate organism by membrane mechanical interception. Keep high concentration of activated sludge in bioreactor so that enhance volume load largely and reduce sludge load. Membrane reactor integrates traditional aeration tank and secondary sedimentation tank into one system and displaces all equipment after secondary sedimentation tank which in conventional process. Largely reduce foot print, and save investment of civil works. Due to the function of membrane interception, srt is prolonged, this process create good growing environment for microorganism (example: nitrobacteria) which grow slowly. It can enhance system nitrification ability. It will enhance efficiency of big molecular organism degradation. Lead them to degrade completely. Due to very long srt, membrane bioreactor can be role of sludge nitrification tank so that it’s remarkable to reduce sludge production, decrease disposal cost of sludge. Activated sludge in bioreactor will not be lost during treated water production. Concentration of sludge will be along with organism concentration change to change, and reach a dynamic balance. So, the treated water quality is steady and the system has strong impact load tolerant capability. The reactor special structure causes wastewater mix uniformly, so activated sludge has good dispersibility, largely increase sludge specific surface area. This is another reason of our system has good efficiency. This is also the characteristic which conventional biological methods cannot compare with it because conventional biological methods will easily cause larger bacteria & colloid bulk in the wastewater. Material polypropylene (PP) We have two types of MBR system to suit different client’s requirement. First, is a small capacity compact steel tank MBR system for private parties, such as hotel, villa, car wash workshop, house to treat shower & bath grey water, domestic wastewater, car wash wastewater, etc. The treated effluent can be used to garden, landscape, car wash, toilet flush, irrigation, other recycling utilization. This system can be designed to fit international container size, ship easily. We also accept to supply our full design to guide you build RCC STEEL FRP tank in your place. Below photo is system RCC MBR for hotel wastewater treatment. Another is big capacity MBR system for government tenders; RCC tank is in client’s scope as per our drawing. For equipment in system, clients also can follow specification we submit to purchase locally, we will supply complete technical support, if necessary we can send engineer to give training at your place. hydrophilic before using the membrane, it should be treated by the hydrophilic process, the method is as follows first keep it in 95% industrial alcohol for about 2 minutes (attention: avoid the water collecting tubes of both sides be immersed in the alcohol), then use clean water to immerse and flush it for 13 minutes. If the membrane is not used immediately after the process, it should be packed hermetically, to keep the membrane fiber wet. Fouling prevents and membrane cleaning micropore air diffuser is recommended. The bubbles and stream produced from aeration can shake membrane fiber and scour it. Meanwhile using intermittent operation process, self-suction pump works for 13 minutes and stops for 2 minutes, to prevent membrane clogging and guarantee the long stable running. Before running the membrane, we should make sure that microorganisms in the biochemical tank grow activated and low stickiness. During operating, keep flow constant, strictly prohibit product water flow is non-stable. The suction negative pressure could be read out through electrical-touched pressure gauge, the operating negative pressure of membrane is -0.01 ~ -0.03mpa; if condition permitted, draw off water using a siphon type, and keep water level difference between biochemical tank and treated water tank is 3.0~4.0m, thus membrane slice could not be polluted easily and the using period could be longer. When the operating negative pressure is over 0.05mpa, membrane slice should be cleaned. Take off the membrane slice from the frame, wash its surface with clean water, clean away the activated sludge stuck on the surface; and then immerse the membrane slice in 3-5% naoh for over 2 hours (overnight is better), clean away organic matters and colloids on the surface, again wash the membrane slice with clean water, then the flux will be recovered. If wastewater contains high content of calcium, magnesium ion and metal hydroxid, after naoh solution cleaning, should immerse membrane in 2-3% hcl solution for 1-2 hours (better shake membrane in order to make Hcl and pollutants mix and react fully). And then wash it with clean water. In order to prevent corrosion, demount all metallic connection fitting before acid cleaning. If effect of above two ways is not ideal, could immerse membrane in 0.5% naclo for 0.5-1 hour, eliminate all organism on the surface, then washed by clean water. But, do not immerse membrane for so long time to avoid damage from oxidation, and it will reduce strength. During cleaning process, handlers are required to be careful to avoid fiber damage. Meanwhile, keep surface of membrane wet, prevent freezing and dry which will affect flux even no effluent. Note : Keep membrane wet at any time, because if dry, it will cause irreversible damage. Whatever naoh solid or solution and naclo, HCL solution all have high corrosiveness. Handlers should put on prevention things, avoid touching them directly. Naclo solution has strong oxidation, it will affect membrane life, only use it if acid and alkaline methods are not ideal Others make sure hydrophilic membrane and equipment be kept in 5-40 during the process of transporting and storing to avoid damaging the membrane. Prevent the equipment from long-time sunshine to avoid plastic damage by ultraviolet ray. If the site temperature is below 0, we suggest conducting hydrophilization process on site, if not use it immediately, should keep the membrane wet by sealing up and keeping warm; prevent freezing during hydrophilization and cleaning process.

...more

Tube Settler System

Be it lamella plate or titled plate, we offer varied types of Tube Settler Systems. The Tube Settler System increases the settling capacity of circular clarifier and/or rectangular sedimentation basins by reducing the vertical distance a floc particle. This floc particle must settle before agglomerating to form larger particles. Several Wastewater and Drinking Water Plant Manufacturers use our Tube Settler Systems. Construction & Working : The Tube Settler Systems use multiple tubular channels sloped at an angle of 60° and adjacent to each other, which combine to form an increased effective settling area. This, in turn, provides for a particle settling depth that is significantly less than the settling depth of a conventional clarifier, reducing settling times. Tube settlers capture the fine floc that can be settled, but if overlooked escapes the clarification zone beneath the tube settlers and allows the larger floc to travel to the tank bottom in a more settled form. The settler's channel collects solids into a compact mass which promotes the solids to slide down the tube channel.

...more

Lamella Plate Settler

Inclined plate settler or Lamella Plate Settler for clarifying and thickening Ionberg lamella principle uses several parallel inclined plates to maximize the available area for any available floor area. In this way, the size and cost of the gravity settler can be minimized by matching the thickening and clarifying requirements more closely. The two basic criteria for gravity settling equipment are good clarity of the overflow liquid and maximum density of the underflow solids discharge. The area needed to clarify a suspension is often greater than that needed for thickening. This means that in a cylindrical thickening tank, the lower section with rakes and drive mechanism can be oversized. Last years there has been an increased interest for using the Ionberg IPS in the textile and steel industry. The Inclined plate settlers or Lamella Plate Settler, IPS(LPS) are suitable for : Sand & Gravel Potash Zinc Concentrate Soil Treatment Iron Ore Contaminated Soil Coal Slurry, Chemical Process Industry FGD Oil Sand/Water separation Limestone Salt Crystal separation Main Advantages of IPS (LPS) are : Delivered as one-piece unit or in prefabricated sections together with smaller foundations and less floor space needed gives lower installation costs Square outline for easier planning and construction Can be installed in any system and is easy to relocate to adapt to process changes gives flexibility for plant extensions Small internal volume and surface area Easily insulated against heat loss or toxic fume emissions Evaporative losses are minimized. Simple construction of sheet steel and standard profiles Special materials and coatings can easily be incorporated Easy to maintain Main features of IPS are : Heavy duty construction of tank, sludge hopper and lamella plate packs, as well as the rake system. Rake lifting mechanism as option Positioning of specifically designed feed ports for optimum ratio between clarification and thickening area Wide spacing of lamella plates to handle high density feed pulps and coarse solid particles No short circuiting or surface turbulence Integrated flocculator with variable speed stirrer Shorter pipework runs High level installation for gravity feed to downstream processes Easier supervision Some Additional Advantages of IPS are : Capable of cutting coagulant dosage up to its half maintaining lower influent turbidity Requires less filter backwashing for both water and electricity Compact design for increased flow capability By adding plate settlers, flow of existing water treatment plants can be increased By expanding settling capacity, flow capacity of plant settler can be increased By increasing solid removal rate in settling tanks, flow capacity of plant settler is increased

...more

Fire Fighting System

The outbreak of fire can not only be perilous for property but life too; owing to such reasons, we bring forth some of the best Fire Fighting Systems in the market. The latest technology is adopted while designing the Fire Fighting System. The adherence to such high standards of fire preventive technology has led in manufacturing of such Fire Fighting Systems, which are responsible for extinguishing fire of any type in no time.Range : Fire Detection and Alarm Systems Conventional as well as microprocessor based automatic fire detection and alarm systems Analogue Fire Detection System Addressable & intelligent Fire Detection Alarm Systems Ultraviolet & Infrared Sensor Based Fire Detection Systems Laser Based Early Smoke Detection Systems Water Based Fire Fighting Systems Fire Suppression Systems Automatic Fire Hydrant Wet Riser Systems Sprinkler Systems High Velocity Water Spray Systems Water Mist Systems Water Curtain Systems Gas Based Automatic Fire Suppression Systems Co2 Local Application & Total Flooding Systems BOC FS125 Fire Suppression System HFC-227EA Total Flooding System Gas Detection Systems (fixed installations & portables for toxic, inflammables & explosive gases)

...more

Effluent Water Treatment Plant

Also known as Industrial Wastewater Plant, this Effluent Water Treatment Plant is known for the adoption of cutting-edge purification technologies. Sources of industrial wastewater include manufacturing, commercial businesses, mining, agricultural production and processing, and wastewater from cleanup of petroleum and chemical contaminated sites. Industrial wastewater discharged under CPCB and NPDES permits may be subject to federal Effluent Limitations Guidelines (ELG). In addition, all industrial wastewater discharges must provide reasonable assurance of meeting water quality standards for surface water or ground water in order to receive a discharge permit. We are synonymous with long-term experience in the Effluent Water Treatment Plant. The resulting expertise is advantageously employed for the technical and economic optimization of every subsequent facility. The treatment process adopted by the Effluent Water Treatment Plant contains mechanical, biological and chemical physical process steps. Following Processes Are Used : Aerobic biological processes Anaerobic biological processes Physical-chemical process Electro-coagulation Aerobic biological processes of the Effluent Water Treatment Plant are designed to meet differing purification demands, which relate specifically to the effluent to be treated. As a rule, the concentrations of organic and inorganic substances in industrial wastewater are considerably higher than those found in the municipal sector. In the biological wastewater treatment segment, we can supply both aerobic (with oxygen) and anaerobic (without oxygen) processes and thus furnish optimum solutions for individual requirements. It is often the case that both processes are combined in order to achieve the highest possible purity levels in the treated wastewater. Also, we have technologies, which allow the cleaning of wastewater containing compounds that are difficult to degrade. Among others, the following processes are employed by our Effluent Water Treatment Plant : Activated sludge process Submerged aerated fixed films Moving bed bioreactor Sequencing batch reactor

...more

biological treatment plant

Air Pollution Control Equipment

We deal in a range of Air Pollution Control Equipment. Air Pollution Control Equipment is demanded to control atmospheric emissions and greenhouse gases for complying with various environmental guidelines set for industries. Our Air Pollution Control Equipment is manufactured with the aid of latest technologies to control air quality by using different devices. Air Pollution Control Equipment sucks the pollutants and passes them through proper media like bag houses or scrubbers. While the bag houses filter the air by dry means through stacked material, the scrubbers use water for dissolving the hazardous gases and flushing them. The water thus produced can be cleaned for drainage later. Functioning on the same principle, our Air Pollution Control Equipment provides efficient pollution removal and are appreciated for their performance.

...more

Green House Framing

We are engaged in establishing plant tissue culture laboratories, complete solution projects on turn key basis as well as built to operate basis. Highly chemical resistant finishes, many built-in safety features, excellent aerodynamics, noiseless operation, imported materials makes it compete with any international brand with standards that pass the stringent performance standards.

...more

Cooling Water Program

The Ionberg chemicals offer you comprehensive range of cooling water chemicals comprising of: • Scale and Corrosion Inhibitors • Dispersant • Biocides • Bio-dispersants • Alkalinity Reducers

...more

Green Chemicals

The term green chemistry is defined as the invention, design and application of chemical products and processes that reduce or eliminate the use and generation of hazardous substances

...more

Sugar Chemicals

One Kilogram (MOQ)

• Sugar Mill Sanitation Biocides SH-401 is a caramate based microbiocide specially formulated to inhibit growth of bacteria and fungi in cane sugar mills. • • These chemicals are highly effective against acid producing bacterial and fungi found in sugar mills. It also improves sugar recovery from stored sugar by reducing bacterial sugar inversion. SH-401 also inhibits enzyme action for the time between crushing of cane and lime neutralisation. Evaporator Anti-Scalants • OMNICORP-4000 is a multi-component liquid chemical specially formulated to inhibit scale formation in sugar cane juice evaporators and vacuum pans. • Improved Heat Transfer Powerful active agent in OMNICORP-4000 keeps heat transfer surfaces clean and free from excessive deposition. OMNICORP-4000 contains a sequestering agent which keeps calcium and magnesium salts as water soluble complexes preventing them from scaling. Depending upon the nature of scale forming compound, dosage of OMNICORP-4000 can be adjusted to improve the capacity of evaporation.

...more

Gear Motors

One piece (MOQ)

We offer Gear Motors. Pump & Motors Hydro-Pneumatic System Gear Motors Air BlowerGas Blower Surface Aerator Ozone System Membrane Diffuser Disc Diffuser FRP- Pressure-Vessel Membrane Housing RO & Nano Membranes, UF Module & MBR hallow Fiber Module Chemicals Dosing System Bulk Acid Handling System Coal Gasifier Cooling Systems Sand Filter Media: Activated Carbon Bone Charcoal Media for Fluoride Removal Manganese Greensand media for Iron Removal Submerge Aerated Fixed Film(SAFF) Moving Bed Bio Reactor Tube Settler Media Tube Dec Mix Bed Resin Resin for Demineralisation without silica removal Resin for Demineralisation with silica removal Softening Resin Ion Exchange Resins for Fluoride Removal from Smelter Wash Water Speciality Resins for Groundwater Remediation and Purification Decanter Centrifuge Belt Press Filter Filter Press ManualMechanical Bar Screen

...more

Submerged Aerated Fixed Film Reactor

We offer Submerged Aerated Fixed Film Reactor. Submerged Aerated Fixed Film ReactorSubmerged Aerated Fixed Films (SAFF) technology is a process used to reduce the organic loading of residential and commercial sewage waste water, and in doing so will reduce the Biological Oxygen Demand (BOD) and a significant quantity of Suspended Solids (SS) which if otherwise untreated would contaminate river and sea outfalls, in other words it is used to substantially improve effluent discharge quality.

...more

Green House Farming

lant tissue culture laboratories we are engaged in establishing plant tissue culture laboratories, complete solution projects on turn key basis as well as built to operate basis. Highly chemical resistant finishes, many built-in safety features, excellent aerodynamics, noiseless operation, imported materials makes it compete with any international brand with standards that pass the stringent performance standards.

...more

Outsourcing Services

Operation and Maintenance Contracts (O&M) It is a comprehensive service contract where OMNICORP undertakes complete responsibility of supply of treated water in required quantity and of desired quality at any client’s place. Right from Manpower to services to consumables are provided by OMNICORP and the client is free of worries. Annual Maintenance Contacts (AMC) A professional service packages which covers the Water & waste water equipments with the most trusted people from the Industry. The preventive maintenance concept is followed to deliver value to customer. Regular features of this package include scheduled inspection visits and scheduled maintenance and services. Customers can also customize this package by opting for our value added services like monitoring, Lab and Instrument support. ENVIRO CARE Industries today are rewriting their resource based profitability profile. Agents of Change are environmental pollution by industrial effluents, stricter statutory compliance to environmental laws and the need for better cost management. It is now necessary for industries to install the most modern and efficient water and effluent treatment plants. While companies focus on their core business, they need the assurance that the maintenance and smooth running of their water and effluent treatment plants are secure in the hands of professionals. Envirocare Services helps to prevent potential problems before they become costly or hazardous. From Installation of the most appropriate equipment to routine inspections and maintenance, the company offers solutions for everything. Envirocare’s aim is always the same – to provide service support for the effortless, long term management of waste water. Water Audits A Comprehensive study of Total water Circuit with an objective to enhance the efficiency ( Quality as well as Quantity) of the entire circuit is performed by industry experts with high qualifications and enormous experience. A detailed report along with detailed recommendations is submitted at the end of the study to allow you to take a wise decision on Water Management. On Call Services This is the mantra which we follow for this service package, be it a troubleshooting call or seasonal service requirement, we provide services on demand. We offer a wide array of services here with experienced technicians with commitment, we assure you your problem, however complex, will be well attended to.More Inspection Services We offer Consultation from our experts on your water problems. Our consultants are derived from a knowledge pool that has wide experience in technology, both current and emerging, they can optimize your existing technology or provide you with the best solution which we can also execute. After inspection a report is submitted to customers in order to make judicious decisions for water related issues. Automation Automation of Existing water treatment systems to reduce breakdown and costs by experts. In today’s world reliability on machines is very high in production and manufacturing processes. This drives the need for automating the processes which in turn calls for automation of all individual equipment. OMNICORP provides comprehensive support to their clients in automating their conventional water Treatment equipment to achieve consistent operation of equipment with less human interference and very low maintenance cost. The conventional which are frequently automated are softeners and DM plants. Up-gradation With expansion in production, Water requirements will also increase. To provide the best possible solution for this, we upgrade the existing water treatment scheme for enhanced requirements through retrofitting. All of this is planned and supervised by professionals with high qualifications and years of experience and executed by technicians with enormous experience and a through commitment to the customer.

...more

Activated Sludge Treatment

Biological processes used for wastewater treatment. The influent wastewater (e.g. Municipal wastewater) goes through several stages in which different compound are removed out of the wastewater.

...moreBe first to Rate

Rate This