Soft Drink Filling Process

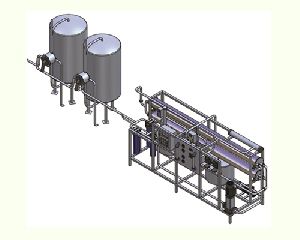

The Warmer & Cooler is widely used for normalizing the temperature of Filled Bottle.The Warmer can be used for Soft Drink Filling Process & the Cooler is suitable for Hot Juices Filling Process. Salient Features Completely built in S.S-304. Two zone warming process/ four zone cooling process. Water heated or chilled through PHE. Temperature Interlocking of all zones. Cooling or warming zone can be customized as per customer requirement. Different principle of cooling & warming can be used depending upon product.

Country of Origin : India

Phase : Single Phase

...more

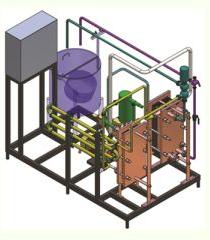

ultra filtration

JP Engineers have recently added a new feature The Ultra Filteration & Reverse Osmosis Equipments in their RO manufacturing. We are manufacturing the water treatment plants With Ozonation & UV System for any capacity using 1000 liters to 20,000 liters as required by Customer. The Product is exclusive Design & Engineered For Mineral Water Plant Juice Plant Soda/ Soft drink plant Natural Water Plant ETC

...more

TRIO BLOCK AUTOMATIC FILLING

The term Trio block is used for a combination of Rinser, Filler & Capper equipment. It incorporates Rinsing, any type of Filling & Capping system. Various combinations are possible depending upon the type of product, container, capper, & capacity required. Neck superstar is an innovative technology of Rinsing, Filling, Capping & bottle handling of international standard. It allows handling without equipment change over, for bottles with different sizes & diameters.

...more

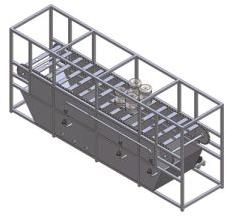

Pasteurization Machine

Hot fruit juices, Milk and other Beverages can be Pasteurized. The Pasteurization is done through Plate/ Tubular/ Spiral Flow/ Scrapped Surface Type Heat Exchangers. The processed juice can be hot filled in pet bottles or in glass bottles. The Machine is Equipped With PHE, Balance Tanks, Spiral Tubes.

Country of Origin : India

...more

Mixing Tanks

We facilitated with the state of art infrastructure for manufacturing of storage Tanks, Mixing Tanks Agitator & Radial jet mixing in different Capacity & Application. The material should be tested before any process; we use the TIG welding for better finishing & applications.

...more

MANUAL JAR WASHING MACHINE

JAR SCRUBBER

soft drink making machinery

INTERMIX units are designed for the production of soft drinks containing Carbon Dioxide. In this process, water is de-aerated under a high vacuum and then carbonated with CO2 and doses in any desired proportion with syrup. The finished product is then carefully fed by adjustable CO2 overpressure to the bottle filler.The main advantage of the process lies in the mixing of syrup with water already containing Carbon Dioxide. By this means the carbonation vessel remains free of syrup, washing out can be done particularly quickly and effectively. The wide range of models for hourly outputs from 1,000 to 6,000 liters of finished product ensures that there is an INTERMIX to meet practically all requirements. The CO2 is mixed in proper proportion through an electro-pneumatically controlled system based on temperature of product & flow of CO2. Thus maintaining the gas volume in the final product. After production is finished the system is cleaned/ sterilized through the product pipes.

...more

honey processing plant

The processing of honey is divided under three steps including filtration for removing wax, foreign particles after heating honey to 45 degree C, heating honey to 60-65 degree C for destroying presence of yeast and other bacteria and cooling honey to atmospheric temperature and storage in closed vessel for defined time period and then packing the honey in different weight bottles

...more

Homogenizer

Homogenizer is a piece of laboratory or industrial equipment used for the homogenization of various types of material. Homogenization requires the ingredients to be processed until of a uniform globule or particle size.

...more

Filter Press

The horizontal plate Filter Press is used by several industries for a variety of applications. The main application of the Filter Press is to filter solid Particles from liquids. The press is available in varying combination of number of plates 12, 18, 22, & 40″ dia. This model is offered with suitable pressure pump & other accessories to suit related application. This is also available in reverse flow design.

...more

Edible oil Packaging Plant

Mustard oil has had contradictory reputations in different parts of the world over the years. It is a very popular oil on the Indian Subcontinent, specifically in the Eastern parts of India and in Bangladesh. There, it is used as an edible oil and is considered very healthy, whereas in the rest of the world, it is often considered toxic, irritable and not suitable for edible purposes.

...more

CARBONATORS

carbonated drink plant

Soft drinks are enormously popular beverages consisting primarily of carbonated water, sugar, and flavorings. Nearly 200 nations enjoy the sweet, sparkling soda with an annual consumption of more than 34 billion gallons. Soft drinks rank as America’s favorite beverage segment, representing 25% of the total beverage market. In the early 1990s per capita consumption of soft drinks in the U.S. was 49 gallons, 15 gallons more than the next most popular beverage, water.

...more

C. I .P SYSTEM

The full form of CIP System is cleaning in Place System. C.I.P system is used to clean product handling equipments, interconnecting pipes & fittings to maintain hygiene & sanitary standards in place. Depending upon the number of cleaning stages, it can be classified as Tank CIP System Salient Features: Semi Automatic Wall System Display for Main Machine Interface Skid mounted modules available Heating through STEAM Different temperature maintained using steam control valve on line

...more

bottle packaging machines

Bopp Labeling Machine

Automatic Jar Washing Machine

bottle packaging machinery

Be first to Rate

Rate ThisOpening Hours