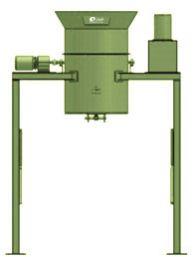

Turning Crushers

Turnings are bulky, sharp-edged and difficult to handle. They are generally tangled up in & occupy lots of storage space & become uneconomical to transport. With Jain Hydraulics turning crushers, you can easily and economically process your turning into tiny chips that are easy to handle and is much cheaper to transport. Turning crushers from Jain Hydraulics are ideal for processing long, curled, bushy and voluminous turnings of steel, aluminium, brass and other metals. They combine advantages such as increased output, high insensibility to coarse pieces and the highest possible economy. Jain Hydraulics turning crushers operate with highly wear-resistant freely suspended crushing tools instead of rigid blades that become blunt over time. These tools are virtually immune to solid parts such as screws, nuts and bolts that are consistently found in turnings. The turnings are crushed under high rotor speed and discharged through the grid openings at the bottom of the unit. The centrifugal mass of the rotor disk ensures high torque that is required for better performance of the machine. Salient Features: Special grade steel is used for hammers and mesh for longer maintenance free life Specially designed heavy duty rotor with hammers crushes the ferrous & non-ferrous turnings into small chips free from dust & rust Easy & continuous charging of scrap via input conveyer or a grabber Metal sorting equipments can be attached in line with the output mesh Rigid & Sturdy in construction with heavy ribs & stiffeners to bear the overall impact of crushing Benefits The Jain Hydraulics “Turning Crushers” has numerous advantages. They enable large, bulky & sharp edged turnings to be processed into easy to handle tiny chips. These turning chips are cheaper to transport and consume lesser storage space. Our turning crushers are equipped with high end hydraulics that consumes effectively less power. The Jain Hydraulics turning crushers also enable better charging possibilities and reduced melting losses in the furnace. The turning chips can be briquetted to increase the density and further en-cash on the above stated benefits.

...more

triple action baling press

A Triple Action baler presses the scrap from three sides i.e. from the Top, Length wise & Side ways. Such balers are best suited to meet the high production requirements and produce significant cost savings during the scrap transportation. These also enable the maximum feeding of scrap in the EAF during the heat. These balers are available in various sizes and with various capacities. The large portfolio of Jain Hydraulics can fulfil the needs of all. Balers that can bale 5 tons of scrap in a shift are available besides those which can bale 25 tons every hour. Thus, the needs of small scrap traders are served as are also of the big ones.

...more

sterilizing machine

The system is totally Micro-processor controlled and highly automated. No Human effort is required except putting waste bags inside the vessel. The waste loading door closes automatically, preshredding is done inside vessel resulting in Homogeneous nature of the waste inside the equipment thus allowing for maximum penetration of steam to each and every part of the waste. The unloading of the waste is by the tumbler arm and tumbler tilt, both operate fully synchronized and automated without any human effort, Final discharge on to the shredder and then to the storage bins (optional).

...more

steel turning scrap

Hydraulics turning crushers operate with highly wear-resistant freely suspended crushing tools instead of rigid blades that become blunt over time. These tools are virtually immune to solid parts such as screws, nuts and bolts that are consistently found in turnings. The turnings are crushed under high rotor speed and discharged through the grid openings at the bottom of the unit. The centrifugal mass of the rotor disk ensures high torque that is required for better performance of the machine. Special grade steel is used for hammers and mesh for longer maintenance free life Specially designed heavy duty rotor with hammers crushes the ferrous & non-ferrous turnings into small chips free from dust & rust

...more

steel recycling machine

“Metal is a part of the Indian mystique as each Metal has its own alchemic and healing powers”; documented in the ancient Indian Scriptures written over 5000 years ago. As the metal industry faces a huge challenge with its limited resource, it is imperative to recycle the existing metal scrap

...more

Single Action Baling Press

Single Action baler was the first compactor manufactured at Jain Hydraulics. Such a baler is basic in design and call for minimal trouble shooting. Small and compact in size, this is best suited for lesser processing applications. Single Action baler is easy to operate and produce considerate cost savings for small traders. Salient Features: 1. Easy to operate by a single, manually operated Direction Control Valve 2. Single compact unit mounted over channel 3. Limit valves & Check valves are provided to avoid any accident 4. No Civil Foundation is required 5. Efficient after sale service Optional Features: 1. Replaceable wear-resistance plates can be provided for the long life of the feeding chamber 2. The machine can be customised as per requirement under the sole discretion of Jain Hydraulics

...more

Shredders

Today, every business recognizes the importance of reducing the waste and treating it more responsibly, thereby reducing the carbon foot print and lowering its environmental impact. Sustainable business strategy is on everyone’s list as our world is scarce with resources and hence, we ought to bring business models that create minimum waste. Jain Hydraulics understands this consensus & thus manufactures Shredders for various applications. The Jain Hydraulics brand Industrial Shredders are unmatched and with the introduction of the two shaft series, the portfolio is unbeatable. Industrial Shredders for every application, ranging from Plastics, Tyres, Bio-Medical Waste, MSW to E-Waste, wood etc virtually allows all types of scrap / waste to be shredded. The MSW shredders allow better utilization of landfills & recovery of reusable materials. Similarly, E-waste shredders allow recovery of expensive metals such as copper etc. thus exhibiting its advantages. Shredding complex, unpredictable flows of bulky, resilient, and abrasive materials is a major challenge. It requires exceptionally robust shredding equipment that processing operations can rely on for uninterrupted flows, maximum efficiency, and a minimum of downtime. Thus, Jain Hydraulics manufactures shear qualitative equipments that are exactly required by its customers.

...more

Shearing Machines

our 40 years of rich experience in the recycling domain and our commitment of meeting the needs of customers with the desired standards have made jain hydraulics a leader in the shears sector. Our outstanding technology and manufacturing quality has set high standards within the industry. We have been completely covering every requirement profile with our various models of shearing machines. The required shear for your production process depends on the average amount & type of scrap to be processed. Thus, we provide you the best for your requirement.

...more

scrap processing machine

We are a leading manufacturer of Scrap Baling Presses(Balers), Shredders and Crushers, Shearers, Bio-medical waste sterilizers & shredders, Box balers & shearers, Continuous feed high production & heavy duty paper balers, Paper shredders, Slag crushers & finer, Briquette making machines, Aluminium casting crackers and other scrap processing machines in India.

...more

Scrap Baling Presses

scrap baling presses enjoy excellent reputation in scrap yards, ferrous processing plants and non-ferrous metal remelting plants. They compact virtually all the metal scrap such as sheet metals and wire scrap into square bales. The journey began way back in 1970s when Jain Hydraulics manufactured its first single action hydraulic scrap baling press to the now known fully automatic, continuous hydraulic scrap baling press. This new generation of metal presses metal compactors sets high standards for efficient scrap processing & thus, we offer the best solutions for them. The continuous scrap baling presses are powerful and efficient in operation. These metal balers produce high-density bales.

...more

Scrap Bailing Press

This new generation of metal presses metal compactors sets high standards for efficient scrap processing & thus, we offer the best solutions for them. The continuous scrap baling presses are powerful and efficient in operation. These metal balers produce high-density bales.

...more

Scrap Aluminum Cans

Shall consist of clean old alloy aluminum sheet of two or more alloys, free of foil, venetian blinds, castings, hair wire, screen wire, food or beverage containers, radiator shells, airplane sheet, bottle caps, plastic, dirt, and other non-metallic items. Oil and grease not to total more than 1%. Up to 10% Tale permitted.

...more

Pre Shredder

Jain Hydraulics pre-shredders are capable of processing 5-100 tons of ferrous scrap per hour including: Complete cars with or without engines or flattened condition White Goods such as household appliances, washing machines, refrigerators, etc Any Iron and steel scrap up to 8 mm thick Hard packed bales These pre-shredders allow smaller shredders to process heavier materials in lesser time. This enables a stress free operation of the shredder machine due to reduction of explosions and lesser downtime. The throughput increases due to the homogenisation of the in-feed material. The hammers used in the Jain Hydraulics pre-shredder machines are manufactured out of costly, special alloy steel cold rolled castings containing 11-14% Mn, 1.0-1.3% C, Si, P & S in the required proportions. The wear parts used in the machine are manufactured from such work hardened steel alloys in the local foundries under strict quality control measures. All such parts are of highest quality of steel alloys in order to resist the wear & tear. These pre-shredders enable the best densification & liberation inside the main shredder plant thereby allowing a perfect separation downstream. Salient Features: Special grade steel is used for hammers and mesh for longer maintenance free life Specially designed heavy duty rotors with hammers pre-shreds the in feed scrap into smaller portions that are free from dust & rust Easy & continuous charging of scrap via input conveyer or a grabber Metal sorting equipments can be attached in line with the output mesh Rigid & Sturdy in construction with heavy ribs & stiffeners to bear the overall impact of pre-shredding

...more

Msw Shredder

Shredders are unmatched and with the introduction of the two shaft series, the portfolio is unbeatable. Industrial Shredders for every application, ranging from Plastics, Tyres, Bio-Medical Waste, MSW to E-Waste, wood etc virtually allows all types of scrap waste to be shredded. The MSW shredders allow better utilization of landfills & recovery of reusable materials. Similarly, E-waste shredders allow recovery of expensive metals such as copper etc. thus exhibiting its advantages.

...more

metal shredder

A Shredder is a machine that tears large scrap into smaller portions of higher density that are free from rust, dust & colour contents. The scrap is fragmented into small pieces by specially designed Hammers that strike the in feed scrap with very high torque. These hammers beat, shred and shear the scrap feed inside the machine until it is converted into the sheave size which is provided at the bottom structure of the machine. The hammers are made of special alloy steel for longer life and impact resistance.

...more

metal recycling equipment

Today we can hardly imagine life without Steel. Steel, which is an Iron alloy containing carbon, is by far the most used ferrous alloy in our daily appliances. We touch or use ferrous alloys every day and can imagine the enormous application of Iron. From domestic usage (refrigerators, washing machines, microwaves, stoves, burners, furniture, cars etc.) to industrial use (equipments, tools, burners, heavy trucks, computers, nut bolts etc.), today we are totally dependent on these ferrous metals. We understand the minimum resources that we have and hence, “Recycling is Imperative”.

...more

Medical Waste Shredder

he waste is heated indirectly by providing steam in the jacked instead of main chamber. The moisture in the waste is used to generate the necessary steam pressure for most optimum sterilization at minimum (Least) cost. Uses Principle of Hydrolysis to treat the waste.The waste loading door closes automatically, preshredding is done inside vessel resulting in Homogeneous nature of the waste inside the equipment thus allowing for maximum penetration of steam to each and every part of the waste.

...more

medical sterilizers

The system is totally Micro-processor controlled and highly automated. No Human effort is required except putting waste bags inside the vessel. The waste loading door closes automatically, preshredding is done inside vessel resulting in Homogeneous nature of the waste inside the equipment thus allowing for maximum penetration of steam to each and every part of the waste. The unloading of the waste is by the tumbler arm and tumbler tilt, both operate fully synchronized and automated without any human effort, Final discharge on to the shredder and then to the storage bins (optional).

...more

Manure Weighing Equipments

It is used to weight the manure. These machines are knownfor their accurate measurement and quality. This weighing machinehelps to control the addition of cement and other products in the specifiedquantity. We offer manure weighting machine that are speciallydesigned to weight manure. Hi tech and modern, these machines usage is easy andmeet the requirements of the clients. These are available at both economicaland market rates as the techno used.

...more

hydraulic nibbler

We have been completely covering every requirement profile with our various models of nibbling machines. The required nibbler for your production process depends on the average amount & type of scrap to be processed. Thus, we provide you the best for your requirement.

...more

Hydraulic Baling Machine

Highly Automated but very simple in operation through one no. Manually operated Direction Control Value.The above data are indicative and not binding. Replaceable wear-resistance plates can be provided for long life of the feeding chamber.

...more

Heavy Duty Metal Shredder

A Shredder is a machine that tears large scrap into smaller portions of higher density that are free from rust, dust & colour contents. The scrap is fragmented into small pieces by specially designed Hammers that strike the in feed scrap with very high torque. These hammers beat, shred and shear the scrap feed inside the machine until it is converted into the sheave size which is provided at the bottom structure of the machine. The hammers are made of special alloy steel for longer life and impact resistance. Today, every business recognizes the importance of reducing the waste and treating it more responsibly, thereby reducing the carbon foot print and lowering its environmental impact. Sustainable business strategy is on everyone’s list as our world is scarce with resources and hence, we ought to bring business models that create minimum waste. Jain Hydraulics understands this consensus & thus manufactures Shredders for various applications. A metal shredder with a magnetic conveyor belt can shred & segregate the ferrous and non ferrous scrap; a bio-medical waste shredder can shred the sterilized medical waste & reduce its size and a car shredder can transform the complete car into small pieces within minutes. Therefore, a few key aspects are worth considering before finalising what type of shredder best suits your requirement. They are: How intense is your recycling program What is your scrap profile What is the required output What is the expected return per ton of shredded scrap Does your scrap require pre-shredding How big is your recycling plant What all information you want from the equipment What is the expected life of the equipment & its parts What is the machine downtime The shredded scrap is of great importance for the EAF as the amount of recovery and the associated costs that they incur depend greatly on the quality of the shredded scrap. Shredding is a capital intensive process & one should aim to achieve the highest recovery rate possible that ensures maximum revenue gain. Thus, after considering all such parameters, Jain Hydraulics manufactures shredders that produce the best results at the minimum possible costs. The Shredded steel scrap has many advantages over other types of scrap particularly when used in an electric furnace. They are: There is a high yield of hot metal as a ratio of input shredded scrap The chemistry of the hot metal is more uniform heat after heat The good density means there are less back charges in order to reach furnace capacity There is less electrode breakage There is longer furnace lining life There is less sulfur in the hot metal There is less phosphorus in the hot metal There is less electric consumption per ton of hot metal There is less air pollution There are less hot spots in the furnace When shredded scrap is mixed with other feed stock the shredded scrap fills the voids providing a more dense mix Shredded scrap lends itself to better material handling techniques

...more

hydraulic lifting equipment

Grabbers help you in easy handling and sorting of heavy scraps. At Jain Hydraulics we have engineered the art of making Hydraulic Grabbers depending on the application. Our Grabbers are designed combining light weight with rugged strength. Grease fittings are provided at all points of friction. Highly efficient, low maintenance and with superior quality.

Country of Origin : India

Certification : ISO 9001:2008 Certified

...more

EOT Cranes

E.O.T. Cranes At Jain Hydraulics we manufacture Single and Double Girder EOT cranes. All cranes are manufactured using high grade material. Single Girder is ideal for material handling in small and low production units and warehouses. For small space we recommend a Single Girder EOT crane. Double girder EOT cranes are ideal for lifting and conveying loads of more than 1OT and for span of over 25m. Our cranes are highly acknowledged for excellent lifting capacity of heavy loads and wide spans. These double girder travelling cranes have two torsion free box girders.

...moreBe first to Rate

Rate ThisOpening Hours