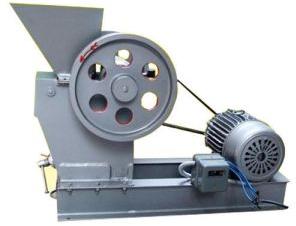

Laboratory Jaw Crusher

475,000 Per Piece

1 Piece (MOQ)

Aggregate Jaw Crusher

Get Price Quote

Best Deals from Jaw Crusher

Laboratory Jaw Crusher

Get Price Quote

Capitalizing on the proficiency of our engineers and technicians, we have been able to put forward for our clients highly durable and reliable range of Laboratory Jaw Crushers. Compact in size and rugged in construction, the range designed for fast crushing of aggregates, ores, minerals, coal, coke, chemicals and other similar materials.Ideal for general laboratory or small pilot plant operations, the range comes with following specifications:Size: 8”X12”Feed Size: 100mmDischarge Size: 6 – 20mmCapacity: 500Kg/Hr.Operation On: 10 H.P. 3 Ph. 1440 R.P.M. 440 Volts 50 Hz Main AC supply with starterOperations:Designed with two movable manganese steel jaws which produces two blows for every revolution, thus reducing over sizing to a minimum A combination of forward and downward strokes with a rocking action exerts pressure on the coarser material, yet permits the finished material to pass through pre Jaws For feeding material a hopper is provided at the top The smooth Jaws ensure a uniform product Warring: Please insert 40 no. mobile oil before using the jaw crusher. One cup cover is added with the Jaw crusher.

Single Toggle Jaw Crusher

Get Price Quote

Laboratory Jaw Crusher

Get Price Quote

Lab Jaw Crusher

Get Price Quote

We offer jaw crusher suitable for crush coal, coke, minerals etc.in lab jaw size- 100 x 150 mm feed size 50 mm discharge size 6 mm production 80 kg/hr.

Jaw crusher

Get Price Quote

We have state-of-the-art warehouse that is well-maintained by the storage experts. They ensure that our wide array of products is kept safe before making the final dispatch. In order to deliver an exceptional lot of products, we make use of the finest grade material for producing them. As a result, the finished products comply with high quality standards. Jaw Crusher Details : Designed to speed up crushing of Aggregates, Ores, Mineral, Coal and Similar Materials Compact and rugged for laboratory and small production units Manganese steel jaws adjustable up to 6mm opening 250kg materials can be crushed in approx eight hours Supported with strong steel frame Suitable for operation with 440 V, Three Phase A.C. Supply

Laboratory Jaw Crusher

55,000 Per Piece

Jaw crusher

Get Price Quote

By analyzing customers requirements and absorbing the world-class advanced technology, CMMAC developed the HJ series jaw crusher. This machine has larger capacity but the energy consumption is quite low. It is to be the ideal substitute products for old ones.

Aggregate Jaw Crusher

Get Price Quote

The laboratory Aggregate Jaw Crusher is designed for fast crushing of aggregates, ores, minerals, coal, coke, chemicals and other similar materials. Its compact and of rugged construction is advantageous for general laboratory or small pilot plant operations. Two jaws of manganese steel are provided in this laboratory jaw crusher. The moveable jaw produces two blows for every revolution, thus reducing over sizing to a minimum. A combination of forward and downward strokes with a rocking action exerts pressure on the coarser material, yet permits the finished material to pass through the jaws. TECHNICAL SPECIFICATION

Jaw crusher

Get Price Quote

Numerous RolIcon Crushers have been installed all over the world across applications. It has been proved that this series of crushers not only effectively increase productivity and final product quality, but also greatly reduce the investment cost and operating costs. Unmatched excellent performance is shown in the secondary crushing, tertiary crushing and material recovery. New generation crusher, jaw crusher is born with innovative significance. It is newly designed keeping in mind the cast in-depth crusher manufacturing and designing experience. The unique design concept make this series crusher achieve perfect combination between crushing efficiency and operating cost. Means while, it has wide range of application, particularly suitable for crushing herd rock, such as basalt, reviser pebbles.

Jaw Crusher Series Mobile Crusher

Get Price Quote

Details The jaw crusher series mobile crushing machine is a new type rock crushing equipment which can greatly expand the concept of mobile crushing processing areas. Advantage High Quality Jaw Crusher The vehicle-mounted jaw crusher of EMCC is an efficient and versatile device which concentrated research and development according to the operating environment of mobile crushing plant and experience of stone processing in site. Quality Thick Steel frame Structure High quality thick steel frame structure makes mobile crushing plant run smoothly extending equipment’s service life. High Quality Vibrating Feeder Professional designed new type feeder which can uniformly convey bulk materials for primary and secondary crusher. Scalable Regulation Stand The stent body can be easily retractable according to the different ground level to ensure stable operation of the vehicle when running thus prolonging equipment life. Working principle The jaw crusher series mobile crushing machine is a new type rock crushing equipment, which can greatly expand the concept of mobile crushing processing areas. Its purpose of design idea stands in customers’ position, putting eliminating obstacles about the limitation of crushing space and environmental pollution as the primary solution. Truly provide customers with simple, efficient and cost-effective operation hardware facilities of projects. With large crushing ratio, the strong crushing pioneer-Jaw crusher type mobile crushing station is well fit for construction waste crushing and other mining region. Product introduction Production capacity : 16-400T / H Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone granite marble basalt iron ore river stone shale bluestone coal cobblestone construction waste etc. Range of Application : Mining smelting building material highway railway water conservancy chemical industry and other industries The jaw crusher series mobile crushing machine is a new type rock crushing equipment, which can greatly expand the concept of mobile crushing processing areas. Its purpose of design idea stands in customers’ position, putting eliminating obstacles about the limitation of crushing space and environmental pollution as the primary solution. Truly provide customers with simple, efficient and cost-effective operation hardware facilities of projects. With large crushing ratio, the strong crushing pioneer-Jaw crusher type mobile crushing station is well fit for construction waste crushing and other mining region.

Laboratory Jaw Crusher Machine

Get Price Quote

Jaw crusher

47,500 Per Piece

1 Piece(s) (MOQ)

Jaw Crusher Series Mobile Crusher

Get Price Quote

The jaw crusher series mobile crushing machine is a new type rock crushing equipment which can greatly expand the concept of mobile crushing processing areas. Advantage High Quality Jaw Crusher The vehicle-mounted jaw crusher of EMCC is an efficient and versatile device which concentrated research and development according to the operating environment of mobile crushing plant and experience of stone processing in site. Quality Thick Steel frame Structure High quality thick steel frame structure makes mobile crushing plant run smoothly extending equipment’s service life. High Quality Vibrating Feeder Professional designed new type feeder which can uniformly convey bulk materials for primary and secondary crusher. Scalable Regulation Stand The stent body can be easily retractable according to the different ground level to ensure stable operation of the vehicle when running thus prolonging equipment life. Working principle The jaw crusher series mobile crushing machine is a new type rock crushing equipment, which can greatly expand the concept of mobile crushing processing areas. Its purpose of design idea stands in customers’ position, putting eliminating obstacles about the limitation of crushing space and environmental pollution as the primary solution. Truly provide customers with simple, efficient and cost-effective operation hardware facilities of projects. With large crushing ratio, the strong crushing pioneer-Jaw crusher type mobile crushing station is well fit for construction waste crushing and other mining region. Product introduction Production capacity : 16-400T / H Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone granite marble basalt iron ore river stone shale bluestone coal cobblestone construction waste etc. Range of Application : Mining smelting building material highway railway water conservancy chemical industry and other industries The jaw crusher series mobile crushing machine is a new type rock crushing equipment, which can greatly expand the concept of mobile crushing processing areas. Its purpose of design idea stands in customers’ position, putting eliminating obstacles about the limitation of crushing space and environmental pollution as the primary solution. Truly provide customers with simple, efficient and cost-effective operation hardware facilities of projects. With large crushing ratio, the strong crushing pioneer-Jaw crusher type mobile crushing station is well fit for construction waste crushing and other mining region.

Jaw crusher

45,000 Per Piece

Jaw crusher

Get Price Quote

Jaw crusher is a type of effective and energy conservation crushing machinery. Medium and large scale jaw crusher is main product of EMCC, and we have reached international level on designing and producing large scale crusher. Advantage Compact Structure and Unique Design Unique jaw head structure and perfect seal lengthen bearing’s service life.Unique flywheel design reduces the shock of machine to guarantee stable operation. Adjustment Device of Discharge Port Spacer type discharge port adjustment device is very reliable wide range of adjusting flexibility of the machine is increased. Energy-Efficient & Long Service Life Deep crushing cavity no dead corner. Input size range and capacity are increased; big crushing radio even final product new oil-way design can match up with oil pump easier and effective operation. Mono-Block Cast & High Safety Factor Adopting mono-block cast and and new assembly technology could make it match up with rack perfectly radial strength is increased. Working principle Motor drives eccentric shaft rotating by belt pulley moving jaw is forced to move to or leave from fixed jaw material will be squeezed twisted and been grinding material will be crushed to smaller size and final product will fall down and discharged from discharge port. Product introduction Production capacity : 1-500T/H Notice: this capacity is mean value and the specific production capacity is subject to clients’actual equipment configuration. Processable Material : granite marble basalt iron ore cobble shale bluestone coal cobblestone construction material. Range of Application : mining metallurgy constrction material highway railway water conservancy chemical engineering industry. Jaw crusher is a type of effective and energy conservation crushing machinery. Medium and large scale jaw crusher is main product of EMCC, and we have reached international level on designing and producing large scale crusher. Jaw crusher is main applied in all kinds of ore and big block material medium size crushing, material’s hardness should be less than 320Mpa, coarse crushing and fine crushing are available. This series has a complete range of specifications, feeding size could be 125mm~750mm, it’s the first choice of primary crushing. Jaw crusher could be widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industries.

Jaw crusher

15,000 Per Piece

Duromech Double Toggle Oil Type Jaw Crusher

Get Price Quote

Salient Features :- 1. Longer life of jaw plates as compared to other crushers. 2. Easy Replacement and Long life of spare parts. 3. Safe and Easy CSS adjustment. 4. Overload protection through Safety Arm. 5. Operating mechanism is totally enclosed for maximum life and minimum maintenance. 6. Cast steel swing jaw is balanced to avoid power losses through lifting on crushing stroke.

Jaw crusher

Get Price Quote

1. Designed to speed up crushing of Aggregates, Ores, Mineral, Coal and Similar Materials2. Compact and rugged for laboratory and small production units3. Manganese steel jaws adjustable up to 6mm opening4. 250kg materials can be crushed in approx eight hours5. Supported with strong steel frame6. Suitable for operation with 440 V, Three Phase A.C. Supply