Turbine Nozzles

Turbine nozzles are center key supportedin the casings, avoiding any misalignments,beingsafe and extremely user friendly. The design of Nozzles is a critical parameter in the overall working and the efficiency of a Steam Turbine. These Nozzles are specially fitted and welded into the diaphragms, with the utmost care taken to ensure complete sealing and to avoid steam leakage and eventual energy loss. These specially designed and fitted Diaphragms, together with a wide variety of Nozzle designs to suit the steam conditions and power requirements make Kessels Steam Turbines one of the most efficient in the World.

...more

Turbine Casing

Turbine casing are rugged and heavy across the entire range, designed with contoured walls and robust flanges to achieve rapid conduction of heat and prevent large temperature gradients. These measures are undertaken to ensure a safe and long operational life.From the process of casting to getting machined, these casings undergo continual quality checks such as Chemical analysis, Physical property tests, magnaflux examinations and dye penetrant checks on machined surfaces, and ultimately hydraulic testing at minimum 1.5 times the working pressure. In addition to the above, Kessels leading practice of controlled stress relieving after each critical stage of casting and rough machining ensures its casings are the safest, and of the highest standards possible in the World.

...more

Steam Turbine Blades

Steam turbine blades in Kessels Steam Turbines are designed with a high factor of safety and possess special aerodynamic profiles that provide for maximum heat drop across the stages, resulting in higher generated power.With over 300 different combinations incorporating different metallurgies such as chromium stainless steel alloy and titanium to suit different applications, Kessels is one of the few Steam Turbine manufacturers in the World to actively integrate and use long blades with tapered and twisted profiles for the last few stages, achieving optimal operating efficiency. Kessels blades are specially treated to prevent edge erosion, ensuring a long operating life, and tested and examined by the Zyglo method for crack detection before use.

...more

Steam Condenser

Steam Turbines complying to and exceeding API-611 standards for general-purpose steam turbines.steam turbines are driving various pumps, fans and compressors across Oil Refineries in the Middle east, India and South East Asia that meet the stringent design engineering practices laid out by Oil giants and end customers alike.

...more

Single Stage Steam Turbine

Kessels Single Stage Steam Turbines are economical and reliable mechanical drives for Pumps, Fans, Knives, Compressors and Generators. For last 2 decades our engineering staff has worked hard reviewing the customers Consultant requirements and their queries to meet the strict standards of API 611 and 612.Our Single Stage Steam Turbines are available in more than 15 frame sizes and design options to meet steam conditions and application requirements up to 4,000 HP in single stage configurations.

...more

Rotor Machine

Kessels gets its Rotors machined from a solid alloy forging of a specific metallurgy. These rotors are forged under a strict control on the grain size, the entire manufacturing process and with an adequate reduction ratio.The machining at different stages is done on Conventional and CNC machines to ensure high precision and utmost quality. The trademark of Kessels turbines across different power ranges is the application and use of rotors with a large journal diameter. Large diameter rotors increase the torque carrying capacity, and are significantly safer in operation under varying steam conditions. Kessels stresses upon stringent quality checks and tests throughout the process of forging,to the final machined rotor. Quality control checks include the test of Physical and Chemical properties, Hardenability test, an Ultrasonic examination and dye penetrant examination after finished machining. To ensure minimal vibration, the finished bladed and shrouded rotors are dynamically balanced at varying speeds.

...more

Labyrinths

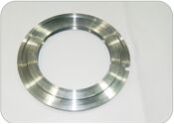

Through years of experience and continued R&D by Kessels, the most reliable, user friendly and maintenance free method of inter-stage and end steam sealing for Turbines have been found to be the use of Carbon Rings, Labyrinth Seals and Sealing Fins. Kessels offers all the three options in its varied range of Steam Turbines. Kessels Single Stage Turbines use special carbon ring packing for mechanical sealing of the steam for their ease of use and in-situ replacement. Thespecially designed Labyrinth seals are machined from special grade stainless steel, are of spring backed type and placed between the rotor and the casing to prevent and minimize steam leakage. Under normal operating circumstances, these labyrinth seals do not contact the rotorand do not warrant any maintenance for an extended period of time. The larger Multistage Turbines from Kessels use J-Type sealing fins for mechanical sealing and preventing steam leakage. J-Type sealing fins are significantly safer than regular seals, being easily replaceable and limiting the damage to the rotor by rubbing in the event of an accidental run-away.

...more

Industrial PRV Replacement Turbine

applications. Kessels Single Stage Steam Turbine lineup is especially suited for handling of Saturated Steam at low inlet pressures to allow for the pressure drop of the steam to generate power through the turbine via geared or gearless Turbo Generator set solutions. These Turbo Generator sets can comprise either of Induction Generators or Synchronous Generators depending on the requirement of the customer and their needs. Kessels Industrial PRV replacement solutions can recover wasted energy by reducing the pressure of the steam through its steam turbines, rather than through a PRV. This would not only generate useful power for industrial use, but also cater to the process steam requirement of the Industry. The end result is drastically reduced operational costs and reduced dependency on the Grid/Other more expensive power sources. Kessels Single Stage Steam Turbines are designed in such a way that enables the customer to enjoy the complete benefits of a PRV (reducing the steam pressure to what the process demands), while generating useful power, and without compromising on the stability or safety of the system or their setup. Kessels also offers the option of Multiple valve operated Steam Turbines, which ensure that the customers get the maximum power output, even at partial loads and steam flows. These valves are also available in Kessels Single Stage Steam Turbine range, and can be controlled automatically via the special PLC based governing system Kessels offers for its Turbines that are coupled to Induction Generators

...more

Extraction Condensing Turbines

The extraction condensing turbines are used when a constant pressure steam flow has to be extracted for process purposes. The constructional characteristics of these turbines are very similar to condensing turbines From the second admission valve chest it is possible to inject low pressure steam, available in the plant to supply the power required by the plant. These turbines are typically used for co-generation where the turbine meets both the power and steam demand of the process plant. In these type of turbines the power generated can be maintained more or less at a steady level despite variation in process steam demands. In some cases it may be necessary to have both bleed and controlled extraction steams from the condensing turbine. These turbines are of bleed cum extraction condensing type.

...more

Casings Diaphragms ,casings Nozzles

The Diaphragms, housing the Nozzles are center key supportedin the casings, avoiding any misalignments,beingsafe and extremely user friendly. The design of Nozzles is a critical parameter in the overall working and the efficiency of a Steam Turbine. These Nozzles are specially fitted and welded into the diaphragms, with the utmost care taken to ensure complete sealing and to avoid steam leakage and eventual energy loss. These specially designed and fitted Diaphragms, together with a wide variety of Nozzle designs to suit the steam conditions and power requirements make Kessels Steam Turbines one of the most efficient in the World

...more

Condensing Turbines

The condensing turbines take high pressure steam, expand it in turbine nozzles and blades, and exhaust it to a condenser at lower than atmospheric pressure. It is principally used when power must be generated with minimum steam consumption. The condensing turbine may also have bleed points (uncontrolled extractions) to satisfy steam demands at medium intermediate pressures. This provision is applicable when the bleed (medium pressure) steam volume demand is low and pressure variations can be tolerated. These turbines are of bleed cum condensing type. These type of turbines find application mainly for power generation where bleed steam is required for feed water heating (HP heater, LP heater and Deaerator requirement) and / or where bleed steam is utilized to meet small process demands.

...more

Condensing Steam Turbine

The condensing turbines take high pressure steam, expand it in turbine nozzles and blades, and exhaust it to a condenser at lower than atmospheric pressure. It is principally used when power must be generated with minimum steam consumption. The condensing turbine may also have bleed points (uncontrolled extractions) to satisfy steam demands at medium intermediate pressures.This provision is applicable when the bleed (medium pressure) steam volume demand is low and pressure variations can be tolerated. These turbines are of bleed cum condensing type.

...more

Condenser

Kessels sources its Condensers from some of the leading manufacturers in India. These Shell and Tube type surface condensers are designed as per best practices and according to the latest HEI and ASME specifications and standards.Rigorous quality practices and the use of adequately sized tubes ensure the condensers supplied with Kessels Turbines have just as long an operating life

...more

Casings

Kessels Casings are rugged and heavy across the entire range, designed with contoured walls and robust flanges to achieve rapid conduction of heat and prevent large temperature gradients. These measures are undertaken to ensure a safe and long operational life. These casings are cast at some of the best and leading foundries, and further machined in-house in one of the three Kessels workshops spread across India. From the process of casting to getting machined, these casings undergo continual quality checks such as Chemical analysis, Physical property tests, magnaflux examinations and dye penetrant checks on machined surfaces, and ultimately hydraulic testing at minimum 1.5 times the working pressure. In addition to the above, Kessels leading practice of controlled stress relieving after each critical stage of casting and rough machining ensures its casings are the safest, and of the highest standards possible in the World.

...more

Casing End Seal

Casing end seal are machined from special grade stainless steel, are of spring backed type and placed between the rotor and the casing to prevent and minimize steam leakage. Under normal operating circumstances, these labyrinth seals do not contact the rotorand do not warrant any maintenance for an extended period of time. The larger Multistage Turbines from Kessels use J-Type sealing fins for mechanical sealing and preventing steam leakage. J-Type sealing fins are significantly safer than regular seals, being easily replaceable and limiting the damage to the rotor by rubbing in the event of an accidental run-away.

...more

Steam Turbines Blades

The blades used in Kessels Steam Turbines are designed with a high factor of safety and possess special aerodynamic profiles that provide for maximum heat drop across the stages, resulting in higher generated power. With over 300 different combinations incorporating different metallurgies such as chromium stainless steel alloy and titanium to suit different applications, Kessels is one of the few Steam Turbine manufacturers in the World to actively integrate and use long blades with tapered and twisted profiles for the last few stages, achieving optimal operating efficiency. Kessels blades are specially treated to prevent edge erosion, ensuring a long operating life, and tested and examined by the Zyglo method for crack detection before use

...more

Back Pressure Turbines

Back pressure turbines are available in single stage or multi-stage options. Primarily, this kind of turbine is used as a reducing station between boiler unit and the process steam header. Back pressure turbines are commonly employed in industrial plants where a large quantity of steam is required. Their straight-back pressure nature makes them useful in applications where exhaust steam is fully utilized to meet process demands. The electrical power generated in the process is consumed as per the process steam demand. Two main applications of a Back Pressure turbine. For drive application- Popularly used in (Sugar mills, Sugar fibrizor, Shredder drive, Pump drives and so on) For power generation application- Used as to generate electricity by powering the generator. Bleed cum Back-Pressure Steam TurbinesBleed Points or uncontrolled extraction vents in steam turbines enable steam extraction within a medium pressure range. i.e Bleeding Steam is practically possible at low volume steam demands and when there is a high tolerance for pressure variations. Kessels turbines are built on both bleed and back pressure mechanism. Extraction cum Back-Pressure Steam TurbinesIf there is a need for steam extraction when the process steam demand volume is high and tolerance for pressure variations is minimal, steam turbines with one controlled extraction vent can be very effective. These work under intermediate pressure levels.

...more

API-611 Steam Turbines

Kessels has the distinction of being a premier supplier of Steam Turbines complying to and exceeding API-611 standards for general-purpose steam turbines. Today, Kessels steam turbines are driving various pumps, fans and compressors across Oil Refineries in the Middle east, India and South East Asia that meet the stringent design engineering practices laid out by Oil giants and end customers alike. Some of the distinguishing features of Kessels API-611 Single Stage Steam Turbines are: Meets & Exceeds API-611 standard. Provision for Direct Drive Oil relay constant speed governors conforming to NEMA class ‘A’ & NEMA class ‘D’. Over speed mechanical trip with safety shut off as standard. Gland sealing through carbon rings (upto six, removable), labyrinths or mechanical steam seals. Any combination of the above three options is also available. Provision for Single disc single row, and, Single disc two-row Curtis impulse-type wheels (forged steel). Built in steam strainer (removable) as standard. Provision for centerline and foot mounted support. Provision for solenoid trips for remote shutdowns as standard. Suitable for high inlet and high exhaust steam pressures. Horizontal and Vertical shaft orientation. The above features ensure that the customer has complete peace of mind while operating a Kessels API-611 compliant Steam Turbine for their mechanical driving needs.

...more

Single Stage Steam Turbines

Extraction Condensing Steam Turbine

Steam Turbine Governors

Be first to Rate

Rate ThisOpening Hours