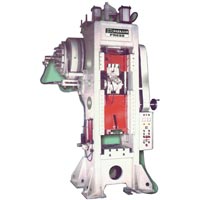

Knuckle Joint Press Schuler

Get Price Quote

1 Piece (MOQ)

We have for sale, from stock in Delhi Used 400 Ton KnuckleJoint Press Schuler PKNR 400 The design of the knuckle-joint press is over 200years old. The advantages of the simple but very effective principle are stillused today for many applications. With a knuckle-joint press like Schuler400 Ton Knuckle Joint Press the force is guided through a knee-likejoint. The knee-lever effect, which it is named after, causes the pressingprocess to become very fast at first, but during the working process itreceives a proportional increase in force with decreasing speed.

Knuckle Joint Press

40,000 Per Piece

Best Deals from Knuckle Joint Press

knuckle joint presses

Get Price Quote

From India, we are offering Knuckle Joint Presses that are manufactured with perfection and widely reckoned for their excellence. The offered Presses are widely used for manufacturing products and can also be equipped with automatic devices to facilitate material handling and speedy production. One can also get them in tailored specifications, from us. Approach us for price quotes and placing orders. Knuckle Joint Leverage Details : Forming techniques is greatly modernized, many products which were produced by conventional methods can now be produced on knuckle Joint Presses more economically to close tolerances thus eliminating subsequent machining. These presses are designed for work requiring slow, powerful presses close to bottom stroke, suiting to work involving coining, embossing, extruding, beading, sizing and swaging operations. Knuckle Joint Presses have virtually eliminated use of expensive machines for subsequent operations by producing components to close tolerances and these machines can be equipped with automatic feeding devices to facilitate material handling and speedy production. Regarding press cycle, from production point of view idle stroke is driven at high speed until mould touches material and forming takes place at slow speed exerting full rated machine capacity. The sketch will show the differences of moving curved lines of knuckle Joint press and an eccentric press, where stroke length is same, the dwell increases efficiency and accuracy of formed components. The Knuckle type drive of presses thus develops considerable power and tremendous mechanical advantage near bottom stroke. Slide adjustment is easily accomplished by taper wedge placed on upper portion of Knuckle mechanism either manually or with motive power at extra cost. Frame : Consist of two or several members assembled by tie bars made of special steel and shrunk in position.Crankshaft : Forged from solid billet is machined and ground all over and runs in two bronze bearing which is well lubricant from centralized system.Clutch & Brake : Low inertia multidisc clutch and brake is used for transmitting power to the machine. Wear adjustment is compensated by little additional movement of inbuilt air cylinder.Counter Balance : Slides are counter balanced by pneumatic cylinders to eliminate any possibility of its running ahead of specified speed and also to counteract possibility of rebound due to bottom ejector.Safety : All presses are equipped with pneumatically operated safety controls with provision of single and continuous stroking, inching and two hand operation.Standards with Machine : Lubrication Knock out device in slide Knock out at press bed Plain bolster plate.

Knuckle Joint Press Machine

Get Price Quote

Knuckle Joint Press Machine, Single Action Press Machine

knuckle joint presses

Get Price Quote

knuckle joint presses, precision power presses, single crank power press

knuckle joint power press

Get Price Quote

knuckle joint power press