Vibro Sifter

The Vibro sifter unit consist of Specially designed vibratory motor to run on 400/440V, suitable HP, 3 phase, 50 cycles electric supply .

...more

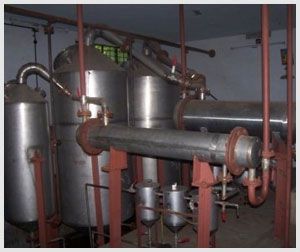

Used Oil Recycling Plant

Lube oils or lubricating oil are just one of many fractions, or components, that can be derived from raw petroleum, which emerges from an oil well as a yellow-to-black, flammable, liquid mixture of thousands of hydrocarbons (organic compounds containing only carbon and hydrogen atoms, which occur in all fossil fuels) There are several jobs that the lube oil is designed to perform. Lubrication of moving parts, cooling, cleaning, corrosion control, and etc. Therefore, the establishments of the contaminant free used lube oil re-refining plants are required which will have following benefits: Reduce environment pollution. Save our aquatic life. Protect the underground water recourses. Produce much needed local fractions for local use and export. Create employment and more room for some academic and environmental research. Gives a second life to waste. REFINING PROCESS: Vacuum distillation process is involved in order to recover good quality light and heavy base oils. Whole process constitutes of three section i.e., Dehydration section. Distillation section. Bleaching section. The process goes like this : Lube oil is first dehydrated in the dehydrated section where water content is totally removed and kerosene so obtained are stored in receiver. The dehydrated oil is pumped into distillation vessel where the oil is heated up & we obtain three fractions, Diesel, mixed oil and lube oil. Due to rigorous heating, lube oil obtains darker color so in order to minimize the color and to derive the original color of the lube oil, we mix the lube oil with activated carbon and fuller’s earth (bleaching agent) in bleaching vessel.

...more

Ss Storage Tanks

Specification: Material: Stainless Steel Storage Capacity: Cap. 100 – 50KL Tank Orientation: Horizontal

...more

Sparkler Filter zero hold Pressure

Design, Manufacturing and Supply of ZERO HOLD SPARKLER FILTER.Features: Complete filtration process without any hold up· The opposite direction of flow saves large time and cost.· Single pass filtration with no solid bypass.· Full batch recovery, no need of separate scavenging system.· Proper sealing which allows filtration of toxic, hazardous and explosive liquids.· Available with different diameters and numbers of plates.Application Areas: Pharmaceutical Industries, Chemical Industries, Food Processing Industries, Oil Industries, Distillation Plants, Beverages like Liquid Filter ans many more.

...more

solvent recovery plants

Solvent plays crucial role in modern society. However, complete world’s production of solvent ends up by being destroyed or dispersed in biosphere. Solvents are the source of about 35% of the Volatile Organic Compounds (VOC). Industrial Processes emit solvent vapours in large quantities. These emissions are harmful to environment as well as public health and shall be subject to stringent statutory norms in near future. So, emitted solvent vapour need to be recovered to reduce the harm it is causing to the environment, also it has attractive market value.Our Solvent Recovery systems employ modern distillation technology to separate and recover valuable chemical products from waste mixtures. Using our systems, you can recover and reuse solvents from a wide range of processes – even from complex mixtures with high variability from batch to batch.Generally there are FOUR methods for solvent recovery and they are as follows: Distillation Liquid-liquid extraction Steam stripping Absorption Out of these four processes we only focus on distillation process. Distillation systems are used to separate and recover high purity solvents suitable for reuse. OUR distillation system can provide both batch and continuous process. We are also involved in trading of solvent. We are the preferred choice by customers in the chemical, pharmaceutical, and other specialty industries around the world for recovery, recycle and reuse of solvents. PROCESS DISCRIPTION:Waste solvent which is to be recovered is heated in the kettle/reactor. Heated (contaminated) solvent is then sent to the distillation column where the separation takes place on the basis of difference in boiling point of the two liquids. Vapors so formed are condensed in primary condenser and the remaining uncondensed vapors are condensed in secondary condenser. Condensate (solvent) is collected in receiver tank which packed, sold and reused . Impurities present in the waste solvent settled down because of sedimentation and drained off from the bottom of the reactor.MPL provides atmospheric, vacuum and azeotropic multi-component distillation systems to separate and purify solvent mixtures. The ranges of solvent includes that are distilled are as follows : Low boilers: Acetone Toluene IPA(isopropyl alcohol) MDC Methanol Ethyl acetate High boilers: Sulfolane Phenol

...more

Screw Conveyor

Design, Manufacturing and Supply of Screw Conveyor , MOC Stainless Steel (304,316) Screw including following control device. Screw Feeder Rotary Airlock Volumetric Feeder Gravimetric Feeder

...more

Ribbon Blender

Ribbon Blenders consist of a U-shaped horizontal trough and a specially fabricated ribbon agitator. A ribbon agitator consists of a set of inner and outer helical agitators. The outer ribbon moves materials in one direction and the inner ribbon moves the materials in the opposite direction. The ribbons rotate at approx. 300 fpm moves materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 100% of the rated capacity of the blender. An alternate agitator is our paddle design. The paddles are positioned to move materials in opposing lateral directions and radially. The paddle design is normally applied where friable materials are being blended and when batches as small as 15% of the total capacity are going to be mixed in one blender.

...more

Reaction Vessels

Our engineered adroit are explored to manufacture reaction vessels using the spiral technology. Raw material used to manufacture the equipment is stainless steel, carbon steel. These are extensively used in pharmaceutical and chemical industry.These reaction vessels are designed to handle corrosive reactions at elevated temperatures & pressures with flat, dished end, conical top & bottoms for applications such as chlorination, acid oil formation and pulp bleaching. The material of construction is selected considering the chemical & temperature conditions. Some of its note worthy features are as follows: Low maintenance cost Cost effective Corrosion resistant

...more

PULVERIZER

Design, Manufacturing and Supply of Steel Impact Pulverizer along with dust collector for grinding hard, medium or soft material. With its excellent crushing efficiency, this product is demanded in various markets. Meshes depending to a considerable extent on the particular materials being handled. This one is a versatile grinding unit of heavy and rugged construction and built for continuous operation day after day. These are made available to our customers at industry leading rates.Features:· Fine size reduction· Advanced technology is implemented· Accurate operationApplications:· Granulating the materials· Mills· Grinding

...more

Pressure Vessel

Our Pressure Vessels are used in different industrial applications. The pressure vessels we are offering to our clients are closed containers, which are designed to hold gases or liquids at a certain pressure that is different from ambient pressure. Our range of pressure vessels, available in different capacities conform to the ASME code quality processes. Features: Durability Dried With Pneumatic Air Built-In Temperature Sensors & Control System Good tensile properties Chemically stable High impact resistance Corrosion resistant Applications:These pressure vessels finds its application in different industries and functions as: Industrial compressed air receivers Domestic hot water storage tanks Diving cylinder Re compression chamber Distillation Towers Autoclaves Vessels in mining or oil refineries and petrochemical plants Pneumatic reservoir Hydraulic reservoir under pressure Storage vessels for liquefied gases such as ammonia, chlorine, propane, butane and LPG

...more

Pneumatic Conveying System

Design, Manufacturing and Supply of Two most distinct categories of pneumatic conveying System. Low pressure (dilute phase) and High pressure (dense phase) systems. Dependent on the material properties.

...more

octagon blender

The blender features an octagon shaped body with rectangular central portion and top & bottom polygonal frustum. These are provided with baffles for fast and efficient mixing, charging port and outlet with butterfly valve. In the octagonal blender, granules come in a uniform way from all the sides due to its octagonal shape; hence requirement of RPM is less. The Octagonal Blenders are ideally suited for Crystalline & Granular type of materials.

Feature : The entire unit is mounted on a sturdy stand, complete with electric motor and gear box,The machine is provided with control panel board and safety railing Etc.

...more

Nutsche Filter

The Nutsche Filter is the industrial version which is designed to operate under either on vacuum or pressure. Present day Nutsche Filters are constructed to perform a multitude of tasks including reaction, filtration, cake washing and thermal drying on a single unit. As such these are very sophisticated machines with tight process control on parameters such as pressure, temperature and pH. Nutsche Filters are well suited for handling flammable, toxic, corrosive and odor-noxious materials since they are autoclaved and designed for use in hazardous and ex-proof environments when extremely safe operation is required. Nutsche Filters are available in almost any size with the larger machines for a slurry filling. The Nutsche in its full configuration consists of four major components The vessel The filter floor and cloth, woven mesh screen or sintered metal plate medium The re-slurry arms for cake washing and smoothing The cake discharge mechanism.

...more

Ms Storage Tanks

Specification: Material: Mild Steel Pressure: 0.1-10Mpa Storage Capacity: Cap. 100 – 50KL

...more

Mixer Powder And Liquid System

Design, Manufacturing and Supply of POWDER AND LIQUID MIXING SYSTEM with a solid material dosing feeder and mixing tank. Depending on the application and the requirement of the Customer.The Powder(Solid) material can be fed Via a bulk bag un-loader, a funnel sack-emptying boxes or directly from the bag via a suction lane.

...more

Microbrewery Equipment

We, microbrewery equipment Malik Polychem Limited are a leading manufacturer of MicroBrewery Equipment, Brewery Machinery, Micro Brewery

...more

Mass Mixer/ Paddle Mixer

Mass Mixer is a pharmaceutical machine, specially designed for thorough mixing of wet as well as dry or lump material. It is suitable for tablet granulation process. The equipment has paddle like blades for efficient granulation and mixing. It also consists of a leak proof seal tilting arrangement for convenient unloading of products. Engineered to precision, the machine provides with transparent polycarbonate dust cover with inter locking system to view the raw material being mixed. Easy to operate, the range of our Mass Mixers is ideal for homogeneous mixing of particles in diverse industries including Food, Mineral, Pharmaceutical, Paint & Chemical Industries.

...more

Limpet Reactor

Backed by our industrial experience of more than 1 decade, we are able to manufacture Limpet Reactors as per the industry standard. In addition, the array can also be designed as per the client specifications and requirements. These are made from M.S, SS 304 and SS 316, Hastelloy, Titanium and Nickel. The reactor is durable and performs efficiently for longer period. Available in wide capacity ranging from 0.1 KL to 30 KL, our collection is widely used in pharmaceutical and chemical industries.

...more

Heat Exchanger

We supply precision engineered Heat Exchangers that is used in transferring heat from one fluid to other and also in supplying essential heat from one place to other in various industrial applications. We use qualitative raw material in the manufacturing process which includes carbon steel, stainless steel, titanium, cupro nickel or inconel depending upon the application and the nature of fluid. Our heat exchangers are tailor made as per the specifications and drawings given by our clients. Our heat exchangers can perform at different pressure condition and improves the quality of the product.Features: Durable Simple in use Maintenance free

...more

Essential Oil Extraction

Over years of experience and expertise we decide the technology of process for extraction of essential oils from various planting material like wood, herbs , flower, root, bark, spices, gums resins and its nature of volatile and percentage of oil yield. We are specialized in providing Plant & Technology on turnkey basis for all kinds of Essential oils from various planting material like wood, herbs , flower, root, bark, spices, gums resins and its nature of volatile and percentage of oil yield. Type of plants· Ordinary steam Distillation Plant both in MS & SS· High pressure steam Distillation Plants· Low Temperature vacuum Distillation Plant,· Hydro Distillation Plant· Hydro Distillation Plant with Cohabitation system· Steam Distillation Plant· Sandle Wood Oil Distillation Plant· Multipurpose Distillation Plant with a provision of Hydro distillation, Steam Distillation (with & without pressure) and Cohabitation System.· Pilot & lab scale plant.Our Distillation Plants are for :Aromatic Species for essential oil DistillationRose, Geranium, Rosemary, Lavender, Lemon Balm, Chamomile, Vetiver, Lemon grass, Ajowan, Cypruss, Eucalyptus, Thyme, Organoe (sweet Marjoram), Clary sage, Palmarosa, Citronella, Davana, Patchouli, Sandal wood, Agar wood, Champa, Kewda, Marry Gold.Distillation For Spice Oils :Cinnamon bark & Leaf, Nut mug, Ginger, Garlic, Frankincense, Cardamom, Pepper, Mace, Clove.Why Distillation Plant from MALIK POLYCHEM LT· For Higher yield & best Quality of oil,· For low operational cost,· For best Appropriate Technology· For best price of plant· For best after Sales service

...more

Essential Oil Distillation Plants

Over years of experience and expertise we decide the technology of process for extraction of essential oils from various planting material like wood, herbs , flower, root, bark, spices, gums resins and its nature of volatile and percentage of oil yield. We are specialized in providing Plant & Technology on turnkey basis for all kinds of Essential oils from various planting material like wood, herbs , flower, root, bark, spices, gums resins and its nature of volatile and percentage of oil yield.

...more

Distillation Columns

We provide our clients with the premium durable Distillation Columns that are used in various foods, pharmaceutical and chemical processing industries. These distillation columns are specifically designed for the separation of liquid or vapor mixture of two or more substances into its component. This column carries out its process effectively and accurately to separate and give fractions of desired purity, by the application and removal of heat. We offer distillation column in different configurations to meet the varied requirements of clients.

...more

Dairy Plants

Approx Price: Rs 2.5 Lakh / PlantThe Dairy Processing Plants manufactured by us are suitable for processing various types of dairy products such as milk, ice cream, flavored milk, curd and other allied products. We provide customized, highly energy efficient turn-key projects, including training in operation and management to our clients.

...more

Coleus Extract

Your search for exceptional quality and reliable Coleus Extract; we are a leading Supplier in this domain. Over the years, we have catered to the voluminous and urgent requirements of our clients from Delhi(India).

...moreBe first to Rate

Rate ThisOpening Hours