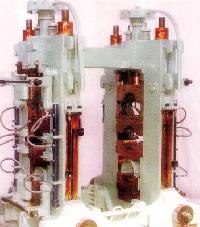

Mixing Mill Fully Unit Drive

Get Price Quote

Mixing Mill fully unit drive manufacturers are among the chief Rubber blending apparatus producer. Their organization has made so far because of the items that they supply such as mixing mill fully unit drive offer to the customers. The elastic blending factories and machines are utilized for blending elastic and it is generally utilized in the elastic business, recovery industry, and even footwear industry. They have machines that have against erosion rollers bearing and are utilized broadly for pushing homogenous organization of elastic with an incredible assortment of fixings alongside the help of the single drive. The mixing Mill fully unit drive suppliers are easy to introduce and are outfitted to run. We as the best among the other elastic blending apparatus provider and ensure that we produce low upkeep items so you acquire the most extreme benefit and set aside cash or support costs. Our machines have an incredible ability to work with and no working expense. Applications • Plastic industry • Rubber industry • Bakelite industry Features • Low working expense and high efficiency • The blending execution is incredible as there is no rubbing misfortune • Latest innovation and fulfills the guidelines universally • Easy to introduce • Ready to utilize • without maintenance • Compact plan • No profound establishment is Required

ROLLER MILL DISC PLATE

50 - 100 Per piece

500 Piece (MOQ)

Best Deals from Milling Machine Accessories

ball mill head trunnion head assembly

83,514 Per piece

10 Sets (MOQ)

Steel Rolling Mills Equipments

Get Price Quote

With complete help and support of our team members, we deliver high grade and excellent range that commensurate to globally accepted standards. We have a strong security system that helps us to make online transactions possible without getting worried about the security. You need to share your details with us and we make sure that the details are kept confidential.

Pcd Milling Inserts

Get Price Quote

Rotary Table

Get Price Quote

Vertical & Horizontal Quick-clamping device High grade cast iron construction Excellent for boring & spot facing Circular cutting & angle setting gear ratio 90:1. Table surface accurately ground in to base of the body to ensure smooth rotation.

HAMMER MILL BEATERS / BLADE

Get Price Quote

Hammer Mill Hammers - Beaters: EN8 METERIAL

Milling Tools

Get Price Quote

With WIDIA milling cutters & inserts which are engineered for challenging applications we can provide solution for all your milling applications & provide you the timely supply os SPARES for milling cutters whenever needed. Face Mills 90-Degree Shoulder Mills Helical Mills Slotting Mills Copy Mills Chamfer Mills Classic Mills Additional Inserts All above is available from the basket of WIDIA.

Zcc Ct Milling Insert

Get Price Quote

Stainless Steel Roller Guide Box

Get Price Quote

We are offering Stainless Steel Roller Guide Box.

Rotary Table

4,000 - 5,500 Per

Roller Guide Boxes

Get Price Quote

Our company has worked hard to establish an efficient distribution network. Therefore, buyers can order the product in mass and expect on time delivery. Courtesy a state-of-the-art warehousing unit and an ultramodern inventory control system, we take care of product storage related work with ease. Our warehouse and system empowers us to maintain year round products' availability. Roller Guide Boxes have a protective polish on the surface for heat, chemical and rust resistance.

Stub Milling Arbors

Get Price Quote

We are offering stub milling arbors.

Milling Machine Boring Head

Get Price Quote

With the assistance of our secure payment procedures including both Online and Offline Payment Processing, we are able to ensure safety of the payments with us. We follow strict quality procedures that are as per the guidelines, help us in presenting dependable and cost-effective product range.

Milling Reduction Sockets

2,000 - 5,000 Per piece

1 Piece (MOQ)

Hollow Rotary Table

200 - 500 Per Piece

1 Piece(s) (MOQ)

Twin Channel

Get Price Quote

We are offering twin channel. The twin channel offers solution to bar handling at cooling bed at high speeds. Twin channels are available for bar sizes up to 40mm in India and stock speeds as high as 30meters per second.

TMT Quenching Box

Get Price Quote

The twin channel is used to collect the TMT bars leaving the Quenching boxes after being sheared by the Flying Shear in two strands. These channel comprises of CI central box, water cooled to prevent warping during rolling, and C-type CI channe ls which are suspended from a longitudinal structural.The closed C-type channels ensure highest level safety during the operation. This is an excellent system as the bar is carried in the close channel , minimizing the risk of accident. It is the most desirable feature in a high speed rolling system.High Speed Bar Collection System: In case of higher capacity mills,where he finishing speed of the bar is high, the twin channel is replaced with a high speed bar collection system;a drop wall system or a rotating twin channel which can receive more thanone finished bar simultaneously.

Rolling Mill Stand

Get Price Quote

milling tool

Get Price Quote

We are offering milling tool. The new helido square s845 sxmu 1606 adtr-mm insert has 8 helical right-hand cutting edges, providing a very economical solution. It is very thick and strong and has a wiper which leaves an excellent surface finish. The insert is clamped by a strong m5 screw into an inclined dovetail pocket which provides a very rigid clamping. Due to the most advanced production technology, excellent grade combinations, unique chip deflector and positive cutting angles, the new face milling tools family features high durability, low cutting forces and excellent tool life.

cnc milling tools

Get Price Quote

Horizontal Rolling Mill Stand

Get Price Quote

450mm Horizontal 3Hi Mill Stand

Universal Dividing Head

Get Price Quote

Universal Dividing Head, which is apt for easy indexing of divisions. This machine is designed for all types of gear cutting operations. The worm and spindle in the machine are hardened and ground and has features of spiral machining capability. The Universal Dividing Head allows the customer to divide in any angle by the direct, indirect or differential methods with unique dividing head.

Universal Dividing Head

Get Price Quote

The Universal Dividing Head, Type BJUDH-135 is a very useful acessory for all machine shops especially for tool room work. It can be used on Milling, Drilling and Grinding Machines for a variety of operations. It has a wide range of application in tool manufacture, jigs and fixtures, gears, splines, polygonal components, milling cutters etc. The Universal Dividing Head is rigid in construction. It consists of close grained heavy duty cast iron housing and body. The main spindle is hardened and ground. The worm and wheel run in oil bath to reduce the wear minimum.

Belt Driven Milling Spindle

Get Price Quote

Grinding Milling Lathe Spindles

Get Price Quote

We Have Been Counted Amongst The Most Trusted Names In This Domain, Engaged In Providing Standard Quality Range Of Grinding Milling Lathe Spindles. These Grinding Milling Lathe Spindles Are Available In Different Specifications And Dimensions According To The Requirements Of Clients. Our Product Range Is Checked For Quality Under Various Set Norms Of Industry. These Are Highly Appreciated Amongst Customers For Their Superior Finish.

Twin Channel

Get Price Quote

This is an excellent system as it carries the bar in a closed channel, minimizing the accident hazards. Specifically while carrying out high speed rolling the system is an absolute necessity.Its design features makes it possible to work in conjunction with braking pinch rolls, minimizing the length of run-in. The operations of twin channel are automated and are guided by the discharge of the rods from dividing shear. An innovative idea for cast iron center boxes has drastically brought down maintenance time.

Rotary Table 6

Get Price Quote

We are offering rotary table 6. 6" horizontal and vertical

High Speed Milling Spindle

Get Price Quote

5-axis milling with a redefined swivel rotary table

Get Price Quote

For the first time, the highly dynamic DMU 65 monoBLOCK® combines all of the stability benefits of the monoBLOCK® construction with the advantages of a fast swivel rotary table, and is the most compact machine in its class with a 7.5 m2 footprint. Equipped with an optimal and accessible large working area of 735 × 650 × 560 mm (X Y Z), this machine dominates all milling technology disciplines at an exceptionally high level with flexible expansion stages, 3- to 5-axis machines and roughing and finishing operations – A machine for all industries at an attractive price.