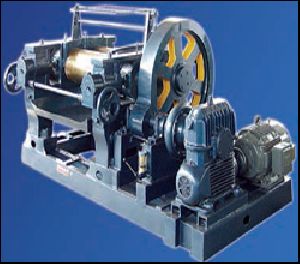

Unidrive Rubber Mixing Mill

Get Price Quote

As a customer-centric company, Ravi Machine Works is affianced in providing Unidrive rubber mixing mill to precious clients. The products are outstanding for use in a variety of manufacturing sectors. The expert team of professionals designs the products by using top-quality grade raw stuff. The product makes sure for the best quality by undertaking varied quality checks carried under the management of trained experts. As a renowned unidrive rubber mixing mill manufacturer in Delhi, we are serving the needs of the customer base. If you are interested in our products, you can contact our team for more information.

Rubber Mixing Mill

900,000 Per Piece

Are you looking for a rubber mixing mill? Slach Rubbermac Private Limited is the best choice for you. We supply our clients with quality machines that are hard to be found elsewhere. Our mills ate suitable for sheeting pictures that are temperature-sensitive. The fully integrated capabilities of this machine bring a lot of benefits to the clients and customers. The mills can help you achieve high cooling performance and also their larger roller surfaces are amazing. This is the best feature of this machine.It is also the reason why they are ideally suited for processing compounds that are temperature sensitive. Thus, these machines are beingused in the technical rubber goods industry also. Our customers appreciate the machines that we sell and they have voted us as the best rubber mixing mill machine supplier. Our mills stand out because they are compact and have a robust construction and are made with all relevant EU standards and also havethe universal potential for the process of automation. Our products are wear and tear protected and we manufacture them with extra care. We became the best rubber mixing mill manufacturers. To know more about our company and the features of our products visit our website. Choosing us will be the best idea as we are the best rubber mixing mill exporter in India.

Best Deals from Mixing Mills

Laboratory Mixing Mill

Get Price Quote

1 Piece (MOQ)

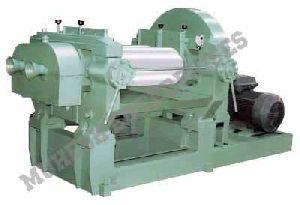

Rubber Mixing Mill

Get Price Quote

We have established ourselves as a renowned Manufacturer, Exporter and Supplier of Rubber Mixing Mill from Delhi, India. Manufactured from high quality components, the offered Mixing Mill is extremely efficient and has a long functional life. We stock the Mill in our large warehouse to cater to bulk requirement of the buyers. Customers across the globe can avail from us Rubber Mixing Mill at highly economical rates.

Used Rubber Mixing Mill

3 Per Set

We are offering used rubber mixing mill & rubber kneader machine rubber hydraulic press machine all size.

Rubber Mixing Mill

Get Price Quote

Uni-Drive Rubber Mixing Mill

Get Price Quote

Extensively applied for providing homogeneous composition of rubber with a number of ingredients backed by a single drive, Uni-Drive Rubber Mixing Mill is offered by us with anti friction roller bearings. These bearings make sure it is simple to install and stays geared up to work. It superior performance comes with lower maintenance and operating cost. At affordable rates, we provide it in safe packaging. Applications Rubber Industry Plastic Industries Bakelite Industries Features Superior Mixing Performance as no Friction Loss. Low Operating Cost with High Productivity. Latest Technology Update, Meets Current International Standards. No continuous Lubrication hence heavy saving on lubrication cost. Equipped with Anti Friction Bearings so No wear & tear as in Bush Bearing type Machines. Maintenance Free. Easy to Install & Ready to Run. No Deep Foundation Required. Compact Construction, maximum Floor Utilization. Designing Specifications Rolls : Alloy Chilled Cast Iron rolls with surface hardness 510 ~ 550 BHN. The Rolls are mirror finished & polished, duly grinded and are hollowed for cooling or heating. Roll Cooling : Through universal funnel type drop tray System (Standard Type) / Universal Rotary joints with inner Spray pipes system for water circulation and roll cooling. Roll Clearance Adjusting Unit : Manual using separate screws and Nut arrangement / Worm Gear drive system with Hand Wheels / Motorized Nip Adjustment system. Roll Bearings : Anti Friction Roller Bearings fitted in sealed bearing housings which Saves power bills 20% ~ 25% compared to Bronze Bush Bearing machines and very Silent Operation. Stand Frame & Caps : Heavy Duty Graded Cast Iron Stand Frames and M.S. Steel Casting Caps. Gearbox: Helical reduction gearbox of Premium (Greaves) / Shanty make with suitable safety factor. Electric Control Panel : Star Delta Electric operating panel with Auto Reversing, Voltmeter, Ampere, Overload protection relay, 3 Phase Indicator and Emergency Stop Switch. Safety Devices : Emergency Stop through Overhead Cradle Bar System operated by limit switch. Emergency Stop through Hydraulic Thruster Drum brake mounted on motor drive shaft for emergency halt of the machine rotation operated by push Button.

two roll rubber mixing mill

190,000 Per piece

1 Piece (MOQ)

Rubber Mixing Mill

25 - 78 Per piece

1 piece (MOQ)

Rubber Mixing Mill

2,200,000 Per Piece

Lab Rubber Mixing Mill

Get Price Quote

Laboratory Mixing Mill

Get Price Quote

1 Piece (MOQ)

Santec's Two Roll Mixing Mills are widely used for mixing and kneading raw rubber, synthetic rubber, thermoplastics or EVA with chemicals into even materials. The even materials can be fed to calender, hot presses or other processing machinery for manufacturing rubber or plastic products. These mills are available in various capacities with bushings or self-aligning roller bearings, and manual or motorized nip adjustments. Mills are specially fabricated to mix newer and tougher compounds in a silent and trouble-free manner. Two Roll Mixing machine can also be customized to meet the specific application requirements of the clients.

two roll rubber mixing mill

Get Price Quote

We are offering two roll rubber mixing mill. Two roll rubber mixing mill main uses are following in rubber product factory: natural rubber refining, raw rubber and compound mixing. Rubber beating mixing and rubber tab letting. This machine is double roller opening to be used for rubber mixing. It consists of seat, frame, rubber, driving device, lubricator and cooler, range adjusting device of roller. Safety brake. Motor and reducer, etc. The roller is made from safety cooled and hard cast steel, smooth surface is polished in term of different case. Saturated steam and cooling water can be inputted in the empty roller to adjust speed of roller. Colloidal particles are drawn into the gap of the two rollers which make relative rotation in different velocity to mix rubber.

Rubber Mixing Mills

Get Price Quote

We are offering rubber mixing mills. Universal nip roll adjustment. Roller revolution on anti-ffriction roller bearings. Drive - uni-ddrive system through specially designed coupling. no foundation required - machine mounted on anti vibro mounts. power saving. emergency knee operated mechanism for operator's safety. Thrystal braking with auto reversing (operator & machine safety measures). operator friendly. dust stop roller guides. minimum maintenance. steel casted stands & caps.

Mixing Mill

Get Price Quote

The basic desining and construction of the Zenith Mixing Mill has been subjected to continuous improvements. which have permitted them to keep pace with the day-to day needs of the industry. Available in sizes varying form 6” x 16” to 26” x 84” for compounding, warming, sheeting of various grades and types of rubber and other material. Silent Features No. Of Rolls Two Material of Rolls Chilled Cast Iron hollow ground finished, bored through for even heating & cooling, having surface Hardness of 500 - 550 BHN No. Of Guides Four (Two fixed and two movable) Roller Bearing Spherical Roller Bearing Type of Housing Sealed Housing Housing is made from Graded Cast Iron of High quality casting free from holes & casting defects Column Frame Two Nos. Made of Graded Cast Iron as per housing material Nip Adjustment Nip adjustment at two roller ends is done manually using two separate screw attached to the housing through shear plates/fuses (0-10 mm) Friction Gears High precision-machined sets made of forged steel Lubrication System Radial Grease Lubrication Pump Base Frame Uni - Bed design with heavy-duty base frame made up of Carbon Steel sections suitable for anti - vibration mounting or fitment with anchor bolts in concrete floorings Transmissions Through a suitable Helical Gearbox Standard Accessories Panel Board consists of Voltmeter, Ammeter, Phase Indicators, On & Off Switches, Emergency Stop with Auto reversal arrangement I Electromagnetic brake for emergency stop actuated by overhead cradle bar operated by limit switches I Gear covers I Safety Trip Rod\ I Material Collection Tray I Shear Discs/ Fuses I Return Water Funnels I Glass see through tubes I Radial Grease Lubrication Pump.

Rubber Mixing Mill

Get Price Quote

The esteemed clients spread across the nation can avail high quality Rubber Mixing Mill from us. The Rubber Mixing Mill, we offer, is precision-made using high-grade raw material. The Rubber Mixing Mill is greatly demanded for the excellent performance and long service life. Loaded with advanced features, the Rubber Mixing Mill we manufacture efficiently serves the purpose of Rubber industry. The clients can avail the Rubber Mixing Mill from us at affordable price. Construction Of Our Rubber Mixing Mill Pinion & friction gears of steel Both side gear covers Tray and safety trip rod M.S. fabricated common base plate with reduction gear box Our Rubber Mixing Mill Is Provided With Chilled cast iron rolls Leaded bronze bushes lined in Cast Iron housings Bull gear of Cast Iron/ Steel

Direct Drive Mixing Mill

Get Price Quote

We are the foremost organization in the market for making available Direct Drive Mixing Mill to valued clients. These products match to the diverse requirements of valued clients and present the user with optimum functionality. The product is developed by employing quality grade raw material in agreement with set quality standards. Offered product diversity is quality checked by experienced professionals on a variety of constraints. Features : Longer functionality Best designs Sturdy make

Two Roll Mixing Mill

Get Price Quote

Two Roll Mixing Mill Developed for your unique mixing applications, high productivity through advanced design. Emkay Two Roll Mixing Mill is a highly developed range of equipments for Rubber, Plastic and other Polymers with high productivity and consistently good mixing with minimum energy consumption. Engineered for easy maintenance. Featuring self contained and floor mounted. Eliminating the need for foundation or grounting. It is very easy to install Emkay Two Roll Mixing Mill. Salient Features Low, initial cost Clean, safe environment. Less operational cost with high productivity. Superior mixing performance. We manufacture complete range of Two Roll Mixing Mills from lab size 6" x 15" upto a production Mill of 26" x 84". Refiners, Crackers, Grinders (flutted/grooved rolls) for reclaim rubber industries and crumbing/refining of wastage from footwear industry. We can manufacture special mills as per the requirement and specifications of the customers. Each mill is designed to absorb heaviest specified mixing load with minimum deflection. The standard friction ratio of the mills are 1: 1.25 app. Which can be varied upon customer's requirement. Rolls speeds are based on the rheological characteristics & compound to be processed to assure the best possible quality & productivity. Emkay Mixing Mills are designed to run lower or higher RPM than standard as per specifications given by customers (it is optionally). Variable speed is also supplied (DC drive/ hydraulic drive. Optionally).

V-Belt Drive Rubber Mixing Mill

Get Price Quote

Major Constructional Details: Rolls: Made of Chilled Cast Iron. The rolls are cooled by water or heated by steam inside. Stands & Apron: Steel Fabricated. Bed: Common bed construction, steel fabricated. Bush Bearing: Phosphorous Bronze bushes switch line in graded cast iron. Lubrication: Force-feed lubrication motorized pump for recirculation of oil in brass bushes. Roll Clearance Adjusting Unit: NIP adjustment at two roller ends is done manually using two separate screws attached to the brass housing body. Reduction Gear Box: V belt drive self-made reduction gear box having all EN series forged steel gears helical hob cut gears.

Lab Mixing Mill

Get Price Quote

1 Piece(s) (MOQ)

We offer our lab mixing mill engineered to score over the conventional mills used for mixing of polymers between 2 rotating rolls in terms of higher efficiency and improved machine life. The transmission by 3-stage helical reduction gear box connecting drive motor to the rear roll coupled with anti friction roller bearings instead of bush bearings result in a substantial reduction in power consumption. Another futuristic feature on our mills is the optional addition of hydraulic sensing circuits incorporated for roll loading records of different batches compounds.