zoloto valves

We offer superior quality Ball Valves, which is appreciated for their quality and performance among the clients. Ball Valves cater to varied industries such as chemicals, construction, petroleum, etc.

Feature : PTFE body rings & gland packing, Chrome plated finish etc.

...more

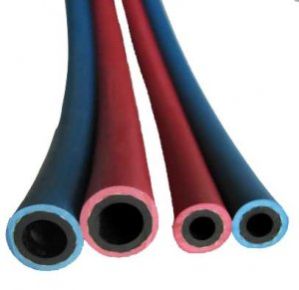

Welding Hose

Welding hose is used to connect regulators with torches. It must be light, strong, nonporous and flexible enough to allow for easy movements. It must be strong enough to bear pressure of up to 100 psig and must be made of the rubber specially treated to remove sulphur that could prompt spontaneous combustion. Single and double line welding hose lengths are available in the markets. The appropriate size of the hose depends on the type of work to be done. Light work typically requires hose with 3/16’’ or ¼’’ inside diameter and one or two piles of fabric. Heavy duty welding and cutting applications may require 5/16’’ inside diameter and three to five piles of fabric. Single hose is available in the above standard sizes and also in ½’’, 3/4'’ and 1’’ sizes. Use with large cutting machines and other heavy duty applications may require larger sizes. Length:The length of the hose used affects the delivery pressure of the torch. A longer hose results in a lower pressure, therefore, longer hoses should have larger inside diameter to allow for adequate gas flow into the torch. Color:Hoses used for oxygen and fuel gas have different colors but have same construction. Color coding is a precautionary measure to minimize the chances of confusion and dangerous errors. Red hose is used for the fuel gas Green hose is used for Oxygen. The hose is supplied as per IS: 447-1988 specificationsApplications: Recommended for use in gas cutting and welding work in workshops, construction sites, manufacturing units and ship yards. Construction Tube:It is manufactured with natural and synthetic rubber and comes with uniform thickness.Reinforcement:High tensile synthetic yarnCover:Blend of natural and synthetic rubberFinish – Four types of finishes are offered – Smooth, Plain, Fluted and Wrap Finish. Color:Red for fuel gases Blue for Oxygen and non-fuel gases

...more

Water Meter

1,550 Per Piece

Size : 15-50mm

Material : Brass

Water Hose

General Purpose Water Rubber Hose Conforming to IS 444/87 Type 1, 2 and 3A Application:This hose is used for delivery purposes and is widely used in a variety of industries, construction sites, railways, dams, mines, horticulture and also in calamities like floods for dewatering, firefighting and several other uses.

...more

Viton Rubber Sheets

Viton is a brand of synthetic rubber and fluoropolymer elastomer which is widely used in O-rings and other extruded and molded goods. The brand name is a registered trademark of DuPont Performance Elastomers L.L.C. Viton fluoroelastomers are categorized under the ASTM D1418 and ISO 1629 designation of FKM. This class of elastomers is a family comprising ofcopolymers of hexafluoropropylene (HFP) vinylidene fluoride (VDF or VF2), teropolymers of tetrafluoroethylene (TFE), hexafluoropropylene (HFP), vinylidene fluoride (VDF) and perfluoromethylvinylether (PMVE) containing specialties. The fluorine content of the frequently used Viton grades may vary from 66% to 70%.Viton Fluoroelastomer Rubber sheet shows resistant to a wide range of solvents and oils, and exhibits good tear and abrasion resistance. Application: Viton Rubber Sheet is resistant to a wide range of solvents and oils.

...more

thunder hose

We manufacture superior grade Thunder Hose with smooth inner and outer walls. These hoses are resistant to acids, pressure, chemicals, bases, vacuum and oils. Moreover, they are highly flexible also and non-toxic in nature. These hoses can also be used to substantiate other hoses in different states of media. They are also used for the transportation of food stuff, agriculture machinery, drainages and also in pumps. PVC Thunder Spring Hose is manufactured with transparent PVC having immovable spring steel wire. Its smooth inner and outer hose walls provide additional benefits for the users. Since it maintains its properties over a large range of temperature variations, from -200 ºC to 700 ºC., these hoses are in high demand in the markets. As the hoses are being marketed at highly competitive rates, they have become a hit among the customers. Dues to its easy availability with a variety of dimensions, it has created a niche for itself in the psyche of the customers. Features: Good chemical resistance Good resistance to pressure Highly flexible Good resistance to oils Non-toxic Smooth inside and outside walls Used in construction industry Used in sewer cleaning Used as a Suction Hose Used in Agricultural Machinery Used in Vacuum Pumps Used in ground water drainage Used in the transportation of food stuffs Also used in a variety of other industry applications Life span of durable DWC Pipes – 50 YearsExtensive studies have been conducted about the durability and life span of DWC Pipes all over the world. Plastic Pipe organization is a Europe based premier research institute whose findings have proved the fact the DWC pipes could last for 50 years provided that are manufactured with standard procedures and are properly used and installed. Structural Design – StrengthBeing flexible, HDPE corrugated pipe are best suited both for high cover and low cover applications. Since the pipe can effectively distribute and support dead as well as live loads, it could be used for almost each type of installation condition. JointsHDPE corrugated pipe could be used both for water tight and slit tight joints. The pipe ensures that what is outside of the pipe remains outside, and what is inside remains inside of the pipe. Durability and Chemical InertnessThese pipes are made with high density polyethylene which is chemically very inert and hence HDPE corrugated pipes are extremely corrosion and chemicals resistant. Abrasion ResistantDue to the use of inert polyethylene, HDPE pipe is very abrasion resistant. This property of the pipe makes it usable for more applications than metal and concrete pipes. Cost savings in installationsSince HDPE pipe is light but robust and is supplied in long lengths, you can save significantly on its installation in the structures. Important Note:Research and tests by reputed institutes have proved that HDPE DWC pipes being ductile reduce the damage to cables significantly. Thus you will save substantially on your maintenance costs and hence the pipes add to the cost savings for the purchasers. DWC Pipes – Specifications: BSEN 50086 IS 14930 Part- II IEC- 61386 part- 2-4 BSNL- GR/DWC-34/01 Due to their better properties and cost effectiveness, DWC pipes are being increasingly used in structures as a viable alternative for conventional ducts like RCC, GI, Stone Wear, Solid Wall, PVC or HDPE pipes. Product Highlights:The pipe provides high degree of protection against the ingress of water and duct for the joints having BIS-IP 67 level. Our portfolio – Following are some of the valued and satisfied clients of Namokar Enterprises:Indian Railways: We have offered our services to 08 zones of Indian Railways viz. Northern Railways, Southern Railways, Eastern Railways, Western Railways, Central Railways, North Western Railways, South Central Railways and South Eastern Railways. Rail Tel Corporation and Delhi Metro Rail Corporation (DMRC) Bharat Sanchar Nigam Limited (BSNL) Tata Rail Vikas Nigam Limited (RVNL) HIAL, DIAL and MIAL Bharati Airtel Delhi Development Authority (DDA) Larson & Toubro Limited (L&T) Delhi Transport and Tourism Development Authority (DTTDC) Maharashtra State Road Development Corporation (MSRDC) Others: CPWD, State PWDs, HUDA, PUDA, MCD, various Industrial Development Authorities and Electricity Boards.

...more

thermoplastic elastomeric water stop seal

Use of Thermoplastic Elastomeric (TPE) water stops made of Poly Vinyl Chloride blended with Nitrile Butadiene Rubber is commonly recommended by engineers and architects for a variety of water applications and chemical environments. These water stops function as a watertight and fluid tight diaphragm in concrete structures. TPE water stops when installed in concrete structures develop excellent mechanical bonding with the structure and work as an effective barrier against the flow of water and other fluids through the joints. Maruti TPE water stops have great resistance to a variety of fluids, oils, minerals, solvents, acids, glycols, alkalis, fuels, chlorinated sea water and other aggressive chemicals. Maruti TPE water stop also has high resistance to ozone and oxidation processes. The water stops have excellent staining resistance and ageing properties, and display good reliance and compression set resistance properties at very low temperatures of up to -32º C.

...more

Synthetic Ruber Sheet

We manufacture rubber sheets based on different synthetic polymers as per their use and applications. Synthetic rubber is a polymer and an artificial elastomer. An elastomer is a material that has mechanical and material properties to tolerate far more elastic deformation under stress than most of the materials and still regains its original size without permanent deformation. Synthetic rubber serves as a substitute for natural rubber in several cases, especially when improved properties of the materials are required. Synthetic rubber can be manufactured from the polymerization of monomers including chloroprene (2-chloro-1, 3-butadiene), isoprene (2-methyl-1, 3-butadiene), isobutylene (methylopropene) and 1, 3-butadiene with a small percentage of isoprene for cross linking. All such monomers can be mixed in a variety of proportions for copolymerization purposes to obtain a wide range of chemical, physical and mechanical properties. The monomers can be produced in pure form or added with impurities or additives to obtain optimal properties and design. Polymerization of pure monomers can be effectively controlled to get a desired proportion of cis and trans double bonds.

...more

Steel Wire Reinforced Corrugated Hose

APPLICATION Steel Wire Reinforced Corrugated Hose comprises of clear PVC reinforced with blue tensile steel wire spiral. It is apt for usage in functions such as discharge and suction of chemicals, slurry, water, granules, sewage and assorted waste products. Discharge or suction of foodstuffs is also an important application of this product. Its other application areas include: Electrical Wirings Gas & Fumes removal Railway Coaches, Aircrafts, Ships & Bus Wirings Radiator connections Airconditioning and Vacuum Cleaners For dust collection in textile, Saw and Paper Mills For Hospital, Office and Hi-Tech Equipments. For Agricultural Machines For vantillations of Mines, Multistoried Buildings, Industries, etc. For transporting Powder & Liquids To help install and connect conduit pipes, special purpose connectors and fittings are available as per illustrations A, B, C and D.

...more

Steam Hose

Application: For transfer of steam at high temperatures. Meets or exceeds IS 10655 Type 2 standard. Steam Hose (Double Wire) Application: For hydraulic applications requiring medium pressure. Meets or exceeds SAE 100 R1 standard.

...more

ss bellow

Pipe Expansion Joints are necessary in systems that absorb movements and vibrations, or convey high temperature commodities such as exhaust gases or steams. Bellows is a typical expansion joint for pipe systems that can be manufactured from metals like stainless steel, fabric such as glass fiber, elastomer such as rubber or plastic such as PTFE. A bellow is made with a series of one or more convulsions whose shape is designed to withstand the internal pressures of the pipe but at the same time it is made flexible enough to bear the axial, angular and lateral deflections. Other criteria like noise absorption, earthquake movement, anti-vibration and building settlements are also considered during the designing of expansion joints. Metal expansion joints need to be designed as per the guidelines of EJMA while the Fabric Expansion Joints need to be manufactured as per the guidelines laid out by the Quality Association for Fabric Expansion Joints. Metal Bellows are elastic vessels that compress when pressure is applied to the outside of the vessel or extended under the vacuum. When the pressure or vacuum is removed, the bellows will regain their original shape provided the metal is not stressed beyond its yield strength. A lot of improvements have been done in the past one century in the development of technology for the metal bellows. Current day high technology metal bellows have little resemblance to the traditional leather bellows that were earlier used in forges and fireplaces.Metal BellowsMetal Bellows are usually supplied in two types – welded and formed. Formed bellows, also known as Sylphons or Convoluted Bellows are manufactured by employing a series of processes like electroforming, cold forming (rolling) and hydroforming. On the other hand, Welded Bellows, also known as Diaphragm Bellow or Edge-Welded Bellows are produced by welding many individually formed diaphragms with one another. However, the above two types of bellows vary in their performance and cost. Hydroformed bellows usually have high tooling cost but have lower piece price when mass produced. However, they have relatively low performance characteristics as they have thick walls and are stiff also. On the contrary, welded metal bellows have lower initial tooling cost but have relatively higher performance characteristics. However, a major drawback of the welded bellows is that they have reduced metal strength at weld joints, which is caused by the high temperature of the welding. Electroformed bellows can be manufactured with modest tooling cost and with thin walls of 25 micrometers or less, that provides them high precision and sensitivity which is required in many exacting applications. These two types of the bellows also make use of different metals in their construction. Hydroformed and rolled bellows are usually made with metals having high plastic elongation characteristics while the welded bellows may be fabricated from a much wider range of exotic and standard alloys such as titanium, stainless steel as well as corrosion resistant and high strength materials. Electroformed bellows are usually made of Copper, Nickel and its high strength alloys.Welded Bellows can be fabricated by making use of some exotic metals and alloys. However, Formed Bellows are made with alloys having good elongation, like brass. Welded bellows are typically not fabricated from brass as it has poor weldability. Ability to be compressed to solid height with no damage, compactness (higher performance in a small package), noticeably greater flexibility and resistance to dents and nicks are some of the worthwhile advantages of welded bellows. Welding of metal bellows is a microscopic welding process which is typically done under laboratory conditions with high magnifications. Hydroformed Bellows are manufactured by forcing a metal tube to expand under hydraulic pressure inside a bellows shaped mold that provides convoluted shape to the mold. Electroformed Bellows are manufactured by plating metal onto a bellows-shaped model called Mandrel, which is subsequently removed by physical or chemical means. Applications:Bellows, both welded and convoluted (or formed) are used in numerous industrial applications; some of the important ones are discussed below:Load Cells: A load cells deforms when a strain or pressure of certain level is applied on it. A strain gauge detects this deformation through which a direct current of low voltage flows. This voltage changes is detected and made visible to the humans on a control panel. Bellows is typically mounted over the gauge to protect it from external influences. Mechanical Seals: These seals are usually used to close the inside of a pump for the outside world to prevent any leakage. A mechanical seal is mounted on the shaft for the purpose. As the pump shaft rotates, a rotating sealing element having a rotating and stationary ring is needed. One of the two rings is fitted with a spring to enforce the appropriate pressure. The spring could have the form of a diaphragm or welded bellow.Vacuum Interrupters: Sparks should not be used to switch the very high voltages in the transformer stations. To prevent any explosion or other danger in the surrounding atmosphere, oxygen needs to be removed from the area of the occurrence of spark. This can be done by sealing the area completely where spark occurs. Bellows are used to seal such confined volumes or areas whose inside is filled with an inert gas or simply evacuated.Sensors: In these applications, convoluted or diaphragm bellows are completely sealed and filled with a particular gas. Two electrical poles penetrate inside of the bellows. The temperature inside the bellows can be regulated by varying the current of these two poles. The contraction or expansion of the bellows is used as an actuator to control the movements. Pressure Gauges: If the pressure of gases or aggressive fluids needs to be measured, the gauge has to be isolated from the flow. For critical applications, a diaphragm sealing is used in the gauge instead of a bourdon tube. This provides better security and prevents the leakage of aggressive media. The diaphragm is a self contained sensor that efficiently transmits the displacement to the measuring device. Couplings for Stepper Motorsand Servomotors: The flexible part which is capable to compensate for the misalignment is made by bellows. It ensures that no angular positioning difference exists between the two coupling halves. This is essential if positioning accuracy of extreme precision is required. Valve Sealing: A bellows is used between the rising stem and the housing to seal the inside completely from the outside world. This arrangement is of particular importance in European countries because of the regulations like TA Luft that prohibit any leakage. Piping Expansion Joint: In this application, bellows are formed in series to absorb the vibrations and thermal movement in piping system that transport high temperature media like the steam or exhaust gases. Exhaust Bellows: Running engines cause self vibration. To compensate these temperature differences that may result in thermal expansion, and also the movements, bellows are installed to connect the exhaust gas pipe with the funnel. Metal Bellows are also used in medical applications like implantable drug pumps, aerospace applications like altitude sensors, in industrial actuators and also in fluid management devices like volume compensators, accumulators, fluid storages and surge arresters. Metal bellows have also found usage in space applications, and are also used to provide potable water to the reservoirs, and also to accumulators to collect waste water. Stainless Steel Bellows provide the best price to performance ratio for any material. Stainless steel bellows maintain their custom design and high strength capabilities even with varying thickness. Bellows Tech makes use of superior welding practices to ensure that our bellows perform to the customer’s specifications. Stainless steel bellows with AM350, 316L, 347, 321 and 304L SS ratings are available. AM350 is a high strength alloy that produces highly accurate and repeatable results with the operating temperature range of - 420° up to 800°F. 316L material also offers better resistance to corrosion for applications requiring the use of acids. 321, 347 and 304L stainless steels are available for the use of customers which are typically used for drop in replacement applications, and legacy. Bellows Tech produces bellows by stamping metal diaphragms, welding inside diameters to form convolutions and finally welding the outside diameters. The arrangement creates a flexible but very strong mechanical conduit which is compatible with gases and liquids. Diaphragms with varying thicknesses as well as two ply constructions for higher pressures are also available.Bellows Tech can build its assemblies using stainless steel, from ultra high vacuum (UHV) to positive pressures. Whether you require volume compensator, flexible seal, actuator or expansion joint, Bellows Tech can design and manufacture the same as per the specifications of the clients. With custom capabilities of connections, shape and size, the flexibility of stainless steel bellows of Bellows Tech is practically unlimited. Bellows Tech can also offer designs configured from the standard sizes. There are over 80 standard diaphragm sizes that make it easy to select the one that fits best your requirements in a cost and time effective manner. You can also add any type of mechanical flange or end piece connection to the bellows assembly to make the installation easy.

...more

Sluice Valve

5,100 Per Piece

Seat Ring : 1.0Mpa

Sluice Valve

Item Code: Sluice We source and supply the best quality Sluice Valve that ensures uninterrupted flow of water. Available in different sizes, Sluice Valve caters to the different requirements of the clients. Sluice Valve can be availed at reasonable prices.Salient Features Design Standard IS 14846 PN 1.0/ PN1.6 Flanged ends, Bolted bonnet, Inside Screw, Non rising stem Hand Wheel Operated Suitable For Water

...moreSilicone Tubing

Silicones are inert and synthetic compounds that are found in a variety of forms and have numerous uses. These are rubber like, show resistance to heat and are extensively used in lubricants, sealants, medical applications like breast implants, adhesives, insulation and cookware. Silicones are polymers that constitute silicon with hydrogen, carbon, oxygen and some other chemicals at times. Some of the most important and useful properties of silicones are: Low thermal conductivity Low toxicity Low thermal conductivity Silicones have ability to repel water from watertight seals, though they are not hydrophobes Good thermal stability. Silicones maintain their properties over a wide range of temperature, ranging from -100 °C to 250 °C. Silicones do not support microbiological growth Silicones do not stick to several substrates but adhere very well with others like glass. Silicones have excellent resistance to ultraviolet (UV) light, oxygen and ozone. This property of silicones has resulted in their extensive use in automotive industry (external trim and external gasket) and construction industry (glazing seals, coatings, fire protection etc. ). Good electrical insulation: Silicones have good electrical insulation and can be easily formulated to be electrically conductive or non-conductive. These are extensively used in a range of electrical applications. High Gas Permeability: Silicones have high permeability at room temperature (25 °C). The permeability of silicone rubber for gases like oxygen is nearly 400 times* that of butyl rubber, making is very useful for medical applications where enhanced aeration is required. Silicone rubbers, however, cannot be used where gas tight seals are required. Silicone rubber is able to resist a large variation in temperature, ranging from - 150 F to 500 F (-101°C to 260°C). It displays a natural translucent color that allows for it easy visual flow. It has good resistance to the temperature variations, ozone gases, UV rays and moisture. It is also very resilient, resistant to compression set, stretchable, is tasteless, odorless and inert. Silicone remains extremely resistant to corona concentration and ozone for a longer period of time. It self-extinguishes itself within 3 to 8 seconds and has good electrical properties, which make silicone a preferred choice for computer applications and other appliances. It does not contain any sulphur or other acid producing chemicals, and therefore does not cause any staining, deterioration or corrosion to the materials that come in its contact. Lined hose clamps and standard barbed fittings are recommended for most of the applications. Namokar Enterprises offers a range of hose and tubing products made of this very versatile material Silicone, including silicone hose, platinum cured silicone tubing etc. to ensure the least possible extractable. Our very clean facility is equipped with state of the art tools and machinery to produce high quality products for pharmaceutical and medical applications. Our industrial grade products offer exceptional performance and are available at relatively lower prices. Silicone tubing is long been used for medical tubing as its meets the high standards of non-toxicity and hygiene of the medical industry. Since it is also resistant to extreme temperature variations, silicone tubing is also used for flexible tubing applications as plastic or rubber tubing cannot be used in such applications.Silicone tubing and hose is a rubber like thermoset material which is extremely elastic and pliable, and does not alter due to the effects of the weather. It shows inertness for ozone and UV radiation, making it a preferred choice for a variety of electrical applications. Capabilities and Ranges for Rubber Tubing and Silicone Tubing Single, Coextrusion, and Triextrusion capabilities Insert Extrusion Multi-Lumen Extrusion O-Ring Fabrication Multiple Durometer/Hardness Multiple Material/Color Extrusion 0.010 inch To 3 inch Plus Custom Formulation for Mechanical Properties, Chemical Resistance, Color Matching and Temperature Resistance Cutting from 0.010 inch Thick To Unlimited Bonding Special Put-Ups Special Packaging Thin Walled PSA Application Typical Applications for Rubber Tubing and Silicone TubingVanguard’s rubber tubing and silicone tubing are extensively used in a variety of industries around the world. Vanguard has expertise, capabilities and vast experience of designing and manufacturing of a range of tubing products like: Washers and Seals for Electronics, Electrical Equipment, and Food Processing Equipment Fiberoptic Sheathes Architectural and Window Seals Electrical Connector Seals and Sheathes Medical Equipment Seals Tubing HVAC Equipment Condensate Drains and Sensing Tube Automotive Electrical Enclosure Weather Seal Outdoor Cellular Telecommunications Enclosures Outdoor Electrical Enclosures Water Purification Tubing Small Appliance Heater Tubing Aerospace and Military Fluid Conveyance Dairy Fluid Handling Tubing Wastewater Sampling Tubing Peristaltic Tubing Humidifier Tubing High Voltage Insulation Optical Surgery Drains Composite Thermoforming Materials for Rubber Tubing and Silicone TubingVanguard makes use of a wide range of quality materials to manufacture silicone and rubber tubing that can be used in various industries, applications and specific environments. If you are not sure to find the best material for your specific applications, do not hesitate to contact our nearest application expert who will be very glad to assist you.

...moreSilicone Rubber Sheet

Silicone Rubber Sheet maintains its resistance to a wide range of temperature variations, from -101 C to 260 C or -150 F to 500 F. It also displays good resistance to UV, ozone gases, moisture and has a natural translucent color, so its flow could be easily observed visually. It is highly resilient, resistant to compression, odorless, stretchable and is inert and tasteless also. Silicone maintains its resistance to corona concentration and ozone over an extended period of time. It typically self-extinguishes itself within 3 to 8 seconds, which is one of its good electrical properties that make it a preferred choice for computer applications and other appliances. Since it does not contain sulphur or any acid producing chemicals, it does not cause corrosion, staining or any other deteriorating effects on the materials coming in its contact. Lined hose camps and standard barbed fittings should be used for most applications. Application: The Rubber Sheet is specially manufactured for use in the applications requiring High Temperatures. Silicone Rubber is an elastomer (rubber like substance) whose main component is silicone polymer and it also contains hydrogen, carbon and oxygen. Silicon rubber formulations may have one or two part polymers and may contain fillers to improve properties or reduce costs. It is widely used in the industry and is usually stable, non-reactive and resistant to a wide range of temperature, varying from -55 °C to +300 °C. Since it maintains its properties even in high temperatures and could be easily manufactured and given desired shape, silicone rubber is widely used in a variety of applications including automotives, food storage products, baking, apparels, cooking, sportswear, electronics, undergarments, footwear, home repair, medical devices & implants, and in hardware like silicone sealants. During its manufacturing, heat may be required to vulcanize (set or cure) it into its rubber like form. Vulcanization is done during manufacturing, which is a two stage process through which silicone rubber is given its desired shape and then a prolonged post cure process is done. The rubber can also be injection molded if required. Silicone rubber is resistant to a high range of temperature variations, ranging from 55 °C to +300 °C and maintains it properties within this wide temperature range. Under extreme temperature conditions, silicone rubber still displays far better tensile strength, tear strength, compression set and elongation than conventional rubber though it may be relatively low as compared to other materials. Organic rubber has a carbon to carbon backbone which makes it susceptible to UV rays, ozone radiation, heat and other aging factors, while the silicone rubber can withstand them to a good degree. All these properties of silicone rubber make it a favorite elastomer for extreme environments. However, silicone rubber has a very low tensile strength in comparison to organic rubber. Therefore, care should be taken to design products to withstand low imposed loads. Silicone rubber is sensitive to fatigue resulting from cyclic loading. It is a highly inert material and does not react with a large number of chemicals. Due to this property, it is used in medical implants and various other medical applications. Applications:Once being mixed and colored, silicone rubber can be easily extruded into tubes, solid cord and strips, or even custom profiled as per the size specifications of the manufacturer. The cords can be easily joined to make O-rings while the extruded profiles can be easily joined to make seals. Silicone rubber can also be moulded into desired shapes and given custom designs. Manufacturers need to set industry tolerance when extruding, joining or cutting silicone rubber profiles. In the UK, silicone rubber is produced as per BS3734 rating. For extrusions of silicone rubber, tightest level is E1 while the widest is E3. Silicone rubber is widely used by the consumers and could be seen in a variety of items that are found in a typical home. It is widely used in automotive applications, electronics, hardware, food storage products, baking, cooking, sportswear, undergarments, apparels and a host of other applications. Freeze tolerant solar water heating panels exploit the elasticity of silicone, allowing it to repeatedly accommodate for the expansion of water on freezing. Extreme temperature tolerance of silicone rubber makes it less tolerant to brittleness while it shows excellent tolerance to temperatures above 150 °C. It does not have a carbon backbone but a chemically robust silicone backbone. It’s a good hygienic property which reduces its potential as a food source for dangerous waterborne bacteria like Legionella. Non-dyed silicone rubber tape with an iron-oxide additive provides it a red orange color. This variant of silicone rubber has non-flammable nature and is widely used in aerospace and aviation related wiring applications as a wrapping or splice. Addition of iron-oxide enhances thermal conductivity of silicone rubber but does not affect its high electrical insulation properties. This type of tape self-fuses or amalgamates and does not require any adhesives for the purpose.

...more

Sap Wafer Check Valve

Pressure Rating : PN10 (Max.)

SAP GATE VALVE

Features: Sap cast steel gate valves have been designed to meet the requirements of API 600 / BS 1414 / API 603 / API 6D /ASME B 16.34 Face to Face and End to End dimensions conform to ASME B 16.10 /BS 2080 / DIN End flange dimensions conform to ASME B 16.5 / API 605 / BS 3293 / DIN Butt weld end dimensions conform to ASME B 16.25 The stem nut design allows for the removal of the hand-wheel while keeping the Stem and Gate in a fixed position. Anti-frictional Ball bearings are provided in higher sizes and classes. The strength of Stem to Gate connection is stronger than the strength of the Stem at the root of the operating thread Outside screw and yoke construction All the valves provided with back seat arrangement Bi-directional shut-off The gland is of self aligning two piece type Deep stuffing box Body ports are streamlined, permitting unobstructed flow, reduces turbulence, results in lower pressure drop & lower erosion The Seat-rings are cylindrical bottom seated type having ample cross section for strength are provided with welded in and threaded Seat-rings will be supplied on request. In case of SS valves the Seat-rings are integral to Body The Body to Bonnet joint is flat in ASME 150 valves, a male and female joint is used in 300 & 600 and ring joint is used in higher classes Valves meet the requirements of fugitive emission levels Shell category B as per MESC SPE 77/312

...more

SAP FORGED GATE VALVE

Sap forged steel valves have been designed to meet the requirements of API 602 / BS 5352 / ASME B 16.34 Socket weld ends dimensions conforms to ASME B 16.11 Screwed ends dimensions conforms to ASME B 1.20.1 Outside screw and yoke construction The gland is of two piece self aligning type Back seat arrangement for Gate and Globe Valves. Valves meet the requirements of fugitive emission level Shell Category B as per MESC SPE 77/312

...more

Sant Brass Ball Valve

210 Per Piece

10 Piece (MOQ)

Material : Brass

Size : 15 mm

Usage : Industrial

Brand Name : Sant

Valve Size : 15 mm

Country of Origin : Made in India

...more

Sand Gravel Suction and Discharge Hose

Rubber Hose for sand & gravel suction and discharge services should be of IS 13071/91 standard. Heavy duty abrasion resistant suction hose is widely used in vacuum trucks and also for handling of abrasives such as crushed rock, dry fertilizer, pea gravel, sand, cement powder, iron ore and grains. Note: This hose should not be used for bulk handling such as uploading of rail cars.

...more

Sand Blast

Rubber Hose for sand blasting should be as per IS 5894/90 specifications Application:High pressure flexible hose is used for conveying sand and other abrasive materials which are engineered for sand & shot blasting purposes in ordnance factories, heavy engineering industries, workshops manufacturing steel furniture etc.

...more

Rubber Mud Hose

Rubber Mud Hose is used wherever suction of mud and slurry is required. It has high suction capacity and is highly flexible as well.Type of Hose Suction & Discharge HoseLining – A blend of synthetic and natural rubber compound having high resistance to abrasion and water absorption. Cover – Modified rubber having high resistance to abrasion and weather. Reinforcement- Natural and synthetic fabrics, GI wire and SS pipe. End Correction- Each length of the hose has soft ends or built in flanges fitted at the ends.

...more

Rubber Chequered Mat

520 Per Piece

Color : Black

Material : Rubber

Pattern : Chequered

Thickness : 6-25mm

Type : Electrical Rubber Mats

...more

Rock Drill Hose

Type 1 and Type 2 hoses have multiple industrial applications and can be used with compressors and also as a pneumatic tool for engineering applications and other equipments. Type 3 hose is better suited for use in deep excavation operations in mines, dams, construction of hydro projects and in the applications where drilling is required in rocky terrains and hilly areas. Most often, Rock Drill Hose of the size 25 x 40 is used which is ID X OD of the hose.

...moreBe first to Rate

Rate ThisOpening Hours