Two Roll Rubber & Plastic Mill

Get Price Quote

two roll rubber mixing mill

190,000 Per piece

1 Piece (MOQ)

Best Deals from Roll Mill

Two Roll Mill

Get Price Quote

We hold expertise in manufacturing, exporting & supplying Two Roll Mill from Delhi, India. We are equipped with our in-house production unit for fabricating superior quality Two Roll Mill. We manage a huge stock of the Mill in our spacious warehouse to address the customer’s bulk demands. Customers can rely on us for handling small or bulk orders of Two Roll Mill and ensuring their delivery within postulated time. Details : Dispersion Kneaders offered by us are specially designed so as to meet requirements of Rubber, Plastic and Chemical industries. Ever since the introduction, kneaders have enjoyed reputable performance edge over conventional mixers that has been made possible due to its exclinet dispersion capability, distinctive tilting mechanism as well as compact common bed construction. This is also entirely attributed to peculiar jacket construction that develops remarkable cooling effect & low temperature mixing, which is a very important feature for rubber compounds.

Roll Mill

Get Price Quote

Gearboxes like Rolling Mill Gearbox and Crane Gearboxes are made up of Gears forged, tempered alloy steels, hardened & ground, enclosed in a sturdy fabricated steelcast iron housing.

two roll rubber mixing mill

Get Price Quote

The basic desining and construction of the Zenith Mixing Mill has been subjected to continuous improvements. which have permitted them to keep pace with the day-to day needs of the industry. Available in sizes varying form 6” x 16” to 26” x 84” for compounding, warming, sheeting of various grades and types of rubber and other material.

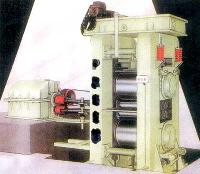

SM-07 Work Roll Drive 4 Hi cold rolling Mill

Get Price Quote

We are Offering Work Roll Drive 4 Hi C.R. Mill

two roll rubber mixing mill

Get Price Quote

Triple Roll Mill

Get Price Quote

We offer extremely efficient triple roll mill. We use only high quality steel and iron to manufacture our triple roll mill. The machine is manufactured by employing the most sophisticated technology. Moreover, our triple roll machine is very easy to operate. We offer our triple roll mill at affordable price.

Two Roll Mill (Fixed Roller Speed)

Get Price Quote

two roll rubber mixing mill

Get Price Quote

We are offering two roll rubber mixing mill. Two roll rubber mixing mill main uses are following in rubber product factory: natural rubber refining, raw rubber and compound mixing. Rubber beating mixing and rubber tab letting. This machine is double roller opening to be used for rubber mixing. It consists of seat, frame, rubber, driving device, lubricator and cooler, range adjusting device of roller. Safety brake. Motor and reducer, etc. The roller is made from safety cooled and hard cast steel, smooth surface is polished in term of different case. Saturated steam and cooling water can be inputted in the empty roller to adjust speed of roller. Colloidal particles are drawn into the gap of the two rollers which make relative rotation in different velocity to mix rubber.

Two Roll Mixing Mill

Get Price Quote

Two Roll Mixing Mill Developed for your unique mixing applications, high productivity through advanced design. Emkay Two Roll Mixing Mill is a highly developed range of equipments for Rubber, Plastic and other Polymers with high productivity and consistently good mixing with minimum energy consumption. Engineered for easy maintenance. Featuring self contained and floor mounted. Eliminating the need for foundation or grounting. It is very easy to install Emkay Two Roll Mixing Mill. Salient Features Low, initial cost Clean, safe environment. Less operational cost with high productivity. Superior mixing performance. We manufacture complete range of Two Roll Mixing Mills from lab size 6" x 15" upto a production Mill of 26" x 84". Refiners, Crackers, Grinders (flutted/grooved rolls) for reclaim rubber industries and crumbing/refining of wastage from footwear industry. We can manufacture special mills as per the requirement and specifications of the customers. Each mill is designed to absorb heaviest specified mixing load with minimum deflection. The standard friction ratio of the mills are 1: 1.25 app. Which can be varied upon customer's requirement. Rolls speeds are based on the rheological characteristics & compound to be processed to assure the best possible quality & productivity. Emkay Mixing Mills are designed to run lower or higher RPM than standard as per specifications given by customers (it is optionally). Variable speed is also supplied (DC drive/ hydraulic drive. Optionally).

Laboratory 2 Roll Mixing Mills

Get Price Quote

santec's two roll mixing mills are widely used for mixing and kneading raw rubber, synthetic rubber, thermoplastics or eva with chemicals into even materials. The even materials can be fed to calender, hot presses or other processing machinery for manufacturing rubber or plastic products. These mills are available in various capacities with bushings or self-aligning roller bearings, and manual or motorized nip adjustments. Mills are specially fabricated to mix newer and tougher compounds in a silent and trouble-free manner. Two roll mixing machine can also be customized to meet the specific application requirements of the clients.

roll grinding mill

Get Price Quote

If you need roll grinding wheel, polishing stone 6001200, scotch brite , end mill cutter , blades, drill, any typoe grinding wheel , tool bits , emery papers etc.

Laboratory 2 Roll Mixing Mill

Get Price Quote

We are offering laboratry 2 roll mixing mill. Santec's two roll mixing mills are widely used for mixing and kneading raw rubber, synthetic rubber, thermoplastics or eva with chemicals into even materials. The even materials can be fed to calender, hot presses or other processing machinery for manufacturing rubber or plastic products. These mills are available in various capacities with bushings or self-aligning roller bearings, and manual or motorized nip adjustments. Mills are specially fabricated to mix newer and tougher compounds in a silent and trouble-free manner. Two roll mixing machine can also be customized to meet the specific application requirements of the clients.

two roll rubber mixing mill

Get Price Quote

two roll rubber mixing mill, bale cutters, Rubber Extruder Machine

Two Roll Mill

Get Price Quote

Two Roll Mill, Horizontal Autoclave, Lab Equipment, Vertical Autoclave

two roll rubber mixing mill

Get Price Quote

two roll rubber mixing mill, rubber mill machines, Rubber Kneader

tube roll mills

Get Price Quote

tube roll mills, Tube Mill Machine, Hr / cr Slitting Machine

cold roll tube mill

Get Price Quote

cold roll tube mill, Tube Mill, Stainless Steel Tube Mill

Two Roll Mill

Get Price Quote

Two Roll Mill, Cadaverous Injector, Autopsy Table

Two Roll Mill

Get Price Quote

Two Roll Mill, Cadaverous Injector, Sequential Marking Machine