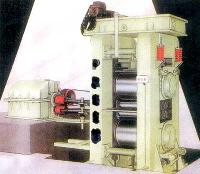

Hot Steel Rolling Mill

300,000 Per Sets

1 Set (MOQ)

we are pleased to introduce piyali engineering corporation, located in delhi, india. we are leading manufacturer and supplier specializing in the production of sponge plant dri (direct reduced iron) equipment and vital components for steel plants, alongside catering to a diverse range of industries including sugar mills, cement plants, fertilizer plants, chemical plants, coal washeries, activated carbon plants, and ball mills. with a strong focus on quality and innovation, piyali engineering corporation stands as a trusted provider of cutting-edge solutions across various industrial sectors. with a wide range of offerings and a strong customer base, we have been serving the industry for several years. our product range includes various capacities of dri kilns and coolers, ranging from 50tpd to 600tpd & 900tpd, along with components such as support rollers, pinions, shafts, shells, combined bearing housing complete assemblies, spring plates, ball mill pinion shaft, mill head end cover for ball mill manufacturer, girth gears, and more. these offerings are designed to meet the needs of cement plants, power plants, steel plants, sponge iron plants, chemical plants, fertilizer plants, and various other industries. explore top-notch lime kiln paper mill equipment at piyali engineering corporation for customized, cost-effective solutions. our commitment to excellence ensures reliable expertise and high-quality equipment, guaranteeing seamless paper mill operations. specializing in rotary pulp dryers, we provide comprehensive solutions for your paper manufacturing needs. choose piyali engineering corporation, your trusted manufacturer and supplier of rolling mill equipment including, mill roll stands, roll chocks, roll bearings, rolling mill gear universal couplings, gearbox parts, chain sprockets & plummer blocks and more. our excellence ensures seamless rolling mill operations.our commitment to excellence guarantees seamless operations for industries with reliable equipment and top-notch services. at piyali engineering corporation, we prioritize quality and strive to deliver products that meet and exceed customer expectations. our adept and seasoned team is deeply committed to providing unparalleled service and ensuring utmost customer satisfaction.

Rolling Mill

50,000 Per

Best Deals from Rolling Mills

jewelry rolling mill

103,000 - 105,000 Per Piece

cold rolling mills

Get Price Quote

ROLLER MILL Manufacturers and Exporters

100,000 - 500,000 Per Piece(s)

1 Piece(s) (MOQ)

Rolling Mill

5,200,000 - 5,500,000 Per Full setup of rolling mil

80000 Kilogram (MOQ)

SM-07 Work Roll Drive 4 Hi cold rolling Mill

Get Price Quote

We are Offering Work Roll Drive 4 Hi C.R. Mill

Italian Type Hand Powered Rolling Mill

Get Price Quote

Italian Type Hand Powered Rolling Mill is available with us. It is known for its sturdy construction, smooth functioning and longer functional life. We are enlisted among the reputed Suppliers of Rolling Mill. We have a vast distribution network that enables us to deliver retail as well as bulk orders for Rolling Mill within the promised time frame. It can be obtained from us at the best market price.

Rolling Mill

Get Price Quote

We are offering rolling mill. We are wir drow mil with motar saiz 5". 6" 8".

wire rod rolling mill

Get Price Quote

Main rolling line equipment supply (including: mechanical, lubrication and hydraulic equipment) and management of design works. Sinosteel Mecc undertaken supply of mechanical equipment and management of design works.Design annual capacity of this project is 350,000 tons.plain rod: f5.5-16mm plain rod coil and f6-16mm rebar coil. The whole rolling line consists of 28 stands mill. Stand 1-14# are 2-highs closed type rolling mill, H-V arrangement , stand15-18# are cantilever mill, H-V arrangement , 19-28# is 10 stand ‘V’ type no-twist heavy duty block mills. Whole rolling line is continuous and no-twist. The guarantee rolling speed is 80msAll equipment of this project were made of China, the finishing block is the first “V” type high speed wire rod mill developed in China. We supplied all equipment and managed of design works. During erection period, we correspond relationship of owner, design institute, manufacture and erection part, solved various problems in time, insured the wire rod mill put into production as soon as possible.

TMT Rolling Mill

30,000,000 Per Unit

1 Set (MOQ)

Cold Rolling Mill

Get Price Quote

Roller Pot Mill

Get Price Quote

Roller pot mills are manufactured and supplied from Delhi, India. Each model produced is of standard quality and is provided with variable speed controls. It comes fitted with electrically interlocked roller guards which prevent access to the rollers while the mill is being operated, providing good safety while it is being used. It comes in three different models each of which requires a voltage supply of 230V. They are available with 13” long roller or with 22” long roller consisting of either two or three rollers.

Two Roll Mill (Fixed Roller Speed)

Get Price Quote

Housingless Mills

Get Price Quote

High rigidity, reliability and quick roll change capabilities are the key features of the state of the art mill stands, which are designed for producing bars, wire rod, angles, channels, and universal beams. The connection and disconnection of the spindles and all the fluid utilities are fully automatic and therefore the stands can be interchanged very quickly. Different versions including horizontal, vertical, convertible and drop-in-joker (which converts a horizontal to a vertical) are in operation, allowing rapid adaptation to the variety of the rolled products needed to fulfill stringent market demands. Line flexibility allows rolling with low temperature, high alloy, wide forming passes, etc. Features: High competent rigidity Reduced stress path Fully automatic operation Axial roll adjustment Automatic screw- down system Possibility for adjustment under load A roll balance system, which eliminates backlash Minimum wear and positive engagement due to self-balancing spindle support Long bearing Life Automatic utility connections Sliding Stands Modern 2-high sliding stands are reversible and fully automatic. They represent an innovation solution for roughing and intermediate mills and constitute the latest stage of 3-high stand evolution.

Tmt Mill

Get Price Quote

"No Twist Block Technology" has been used in this mill to maintain best surface finish and other desired features in the TMT bars.made TMT bars of sizes 8 mm to 32 mm.Using "No Twist Block Technology" to make the product stable, uniform and free from any type of scale.

hot rolling mills

Get Price Quote

We are leading supplier of Hot Rolling Mills.

ROLLER MILL

Get Price Quote

Roller Mill Plant We are offering wide range of Roller Mill Plant that are manufactured from quality material. Our Roller Mill Plant are offered as per the requirement of the client at leading price.

Steel Rolling Mills

Get Price Quote

Applications include: Wearing Pads Sleeper Pads Brake Gear Fulcrum Bearings Anchor Sheaves Sheave Bearings Conveyor Rollers Bearings

Roller Grinding Mill

500,000 Per Piece

Cold Rolling Mill Steel Plant

Get Price Quote

IIPL design manufactures and supplying 2-HI / 4-HI / 6-HI CR plant complete with all auxiliaries and electrical with erection & commissioning at client’s location. We are engaged in research and development of precision Cold Rolling Technology and specialized in designing and engineering of cold rolling production line for strip material of carbon steel, high alloy steel, stainless steel and copper etc. Pickling Line Preparing line Cold Rolling Mill (Reversing, double stand reversing, with auto gauge control system) Bell Type annealing furnace Leveling line/ Skin Pass Mill Slitting Line Coating Line & Varnishing Line Cut to Length Line Packing Line

Flat Rolled

Get Price Quote

We have a state-of-the-art aluminium rolling mill with automatic flatness and shape control equipment which is equipped to produce superior quality of aluminium flat rolled products at our manufacturing facility at damtal (himachal pradesh, india). Manufacturing practices and quality standards are being maintained as per requirements of technologically advanced industrial segments globally. The facility has downstream equipment like tension leveller, colour coating line slitting and blanking line to supply quality products catering to various end use segments.

Flat Rolled

Get Price Quote

We have a state-of-the-art Aluminium rolling mill with automatic flatness and shape control equipment which is equipped to produce superior quality of Aluminium Flat Rolled Products at our manufacturing facility at Damtal (Himachal Pradesh, India). Manufacturing practices and quality standards are being maintained as per requirements of technologically advanced industrial segments globally. The facility has downstream equipment like Tension Leveller, Colour coating line slitting and blanking line to supply quality products catering to various end use segments. Combining expertise with prompt service, the Metenere Ltd. represents a mark of quality and strength. There is a strong commitment to invest in long-term business relations to help in developing new products and technologies.

hot rolling mill

Get Price Quote

hot rolling mill, Cold Rolling Mill, Gear Boxes, Steel Rolling Mill

Cold Rolling Mill

Get Price Quote

Cold Rolling Mill, Work rolls and back-up rolls

Housingless Mills

Get Price Quote

High rigidity, reliability and quick roll change capabilities are the key features of the state of the art mill stands, which are designed for producing bars, wire rod, angles, channels, and universal beams.

cold rolling mills

Get Price Quote

cold rolling mills, Stainless Steel, Tension Leveler

Roller Flour Mill

Get Price Quote

Roller Flour Mill, Rice Cleaning Machine, grain cleaning machine

aluminum rolling mill

Get Price Quote

aluminum rolling mill, Copper Sheet, Rolling Mills, Straightening Machine

Roller Pot Mill - Triple

Get Price Quote

Roller Pot Mill - Triple, Small Jaw Crusher, Bulk Density Apparatus