Silicone Rubber Extruder Machine

Get Price Quote

The silicone rubber extruder machine manufacturers are occupied with offering astounding quality items and extraordinary scope of silicone Rubber Extruder machines on the lookout. These machines are unmistakably appropriate for various sorts of sealants and rubbers. They offer machines in plain barrel tubes, dot covering, profiles, slugs, spaces, fuel tubes, cover beds, and another excellent scope of specialized expulsions. They are a notable rubber extruder machine maker and are broadly well known for the nature of the machines that we sell. Our scope of items is supplanting the machines sold by different organizations since we utilize great quality parts while producing. We have prepared and talented designers who are consistently at your administration. They additionally alter and develop machines according to the necessities and prerequisites of the customers and clients. This is one of the best products for industrial usage and gives Benefits in producing silicone. Subsequently, on the off chance that you are searching for a silicone rubber extruder machine supplier, pick the best Private limited company. You won’t be frustrated with the items that they sell and supply to the clients. They just sell verified machines that will make your work simpler and are low support and practical machines which set aside your cash and time.

Recycling Extruder Machine

Get Price Quote

Best Deals from Rubber Extruder Machine

Extruder Machine

Get Price Quote

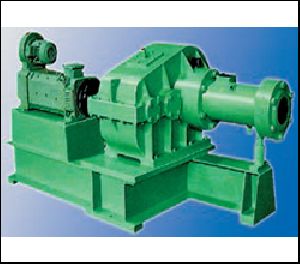

Hot feed screw type extruders are heavy-duty machines built to suit individual needs. They are made in many different type and sizes to meet the production requirements for straining extruding, tubing, slab production or contoured shapes. The extruder’s size depends upon the hourly output required and method of feeding with a complete line of equipment is available to meet with all customers need. The Cold feed Extruders have been developed for processing cold rubber compound. Since these machines in addition to extruding profiles also plasticize rubber; they differ from hot feed extruders, they have longer screws; heavier gears boxes and higher drive power. According to present stage of development cold feed extruders can be used for extruding almost all rubber compounds, which are process able on hot feed extruders. Feeding is normally in the form of strips or pellets. Machines with longer screw diameters are often fed directly with wig-wag stored slabs. Silent Features BED The basic bed is heavily steel fabricated, machined to a single frame on which whole machine with gearbox and motor is fitted. WORM / SLEEVE The worm is mill cut and polished. Sleeve is fine machined and polished and ground hardened by Nitrating process along with cooling arrangement with close clearing to achieve longer life of worm and sleeve and efficient traveling of material (i.e. Rubber). BEARINGS Extruder is jacketed with heavy-duty single double taper roller bearings as per Extruder Loads. DRIVE Worm is driven with belt and reduction gearbox arrangement. HEATING / COOLING Cast iron / Steel fabricated body is jacketed for water-cooling or heating of worm and sleeve. NOTE : Technological improvements may result in change in specifications.

Extruder Machine

Get Price Quote

extruder machines, High Speed Mixer, Plastic Molding Machines

screw food extruder machine

Get Price Quote

screw food extruder machine, Snack Food Extruder Machine

Extruder Machine

Get Price Quote

Extruder Machine, heavy duty grinder machine, low sound grinder machine

Extruder Machine

Get Price Quote

Extruder Machine, granulators, Agglomerator, High Speed Mixers

Extruder Machine

Get Price Quote

Extruder Machine, Injection Moulding Machines, plastic processing machine

Rubber Extruder Machine

Get Price Quote

Rubber Extruder Machine, pvc extrusion machine

Extruder Machine

Get Price Quote

Extruder Machine, Plastic Extruder, Rotomolding Machine