Soap And Detergent

We manufacture different types of soaps and detergent. These are the substances that, when dissolved in water, possess the ability to remove dirt from surfaces such as the human skin, textiles, and other solids. These are available in following categories:-Foaming and Non-foaming detergents. cleaning PowersAll SoapsDish washesHerbal DeodorantsDisinfectantsAir FreshenersCar ShampoosNew Generation Car PolishGlass CleanersPurifiers

...more

Nitrous Oxide Gas Plants

Perfect safeguards are incorporated in design against water and power failures, and also to keep the reaction temperature well under control.NITROUS OXIDE at room temperature and atmospheric pressure is a colorless gas with a barely perceptible sweet odor and taste. It is non-flammable but will support combustion. At higher temperature nitrous oxide decomposes into nitrogen and oxygen. Nitrous oxide is moderately soluble in water, alcohol and oils. N2O, also known as laughing gas finds its use as anesthetic agent. So far this has become a standard anaesthetic agent world over and medical operations are performed with the help of this gas. There are other uses of nitrous oxide which have been developed in food, cosmetics and electronic industry, for example it has become a good whipped cream propellant. This has become a propellant for high quality perfumes and cosmetics. It is used for Cryosurgery. Nitrous oxide as an oxide gas for atomic absorption in spectrophotometer and as fuel oxidant for racing vehicles.The slight oxidizing property of N2O is used for �etching� microchips. This application is now consuming upto 30% of all the nitrous oxide produced in Korea and Japan. With the increase in standard of living of third world countries nitrous oxide consumption is bound to increase.

...more

H2 Gas Plant

GASLAB designs and supplies complete hydrogen gas plants with cylinder filling facility.On small scale Hydrogen is produced from electrolysis of water in either Knowel�s type Mono Polar Cells or Filter press type Bi-polar cells known as electrolysers.Knowel's Type Electrolytic Cells1. Tanks and bells are welded by special quality electrodes to avoid Hydrogen and Caustic soda embrittlement. 2. Bells are manufactured out off C.R.C. Sheets which are specially recommended for Caustic soda handling. 3. The Asbestos diaphragm cloth is manufactured from 100% pure long fiber asbestos without cellulose core and closely woven to avoid pin holes. 4. Extra length of cloth is provided at the bottom to guard against bye-pass of gases. 5. Ebonite Insulators are tested against warping under high temperature and they are checked by Meger for infinity resistance. 6. Nickelling of Anodes is done under strict supervision for a minimum of .002 thick coarse deposit and each plate is tested chemically for pores. 7. The bells are fabricated by special fixtures and pneumatically tested to avoid leakage. 8. Side plates of bells are welded to avoid leakage. 9. Each Electrode plate is made straight by special Jigg and all the plates are perfectly parallel when assembled. 10. The 1" pipes are fixed on the bells with the help of a special Jigg to enable all the tubes to be equidistant and parallel for quick and easy fitting of the Electrode plate. 11. Each Electrode plate has two FULL-LENGTH copper rods. Feed of waterThe performance and long life electrolyser depends on the quality of feed water. As only Hydrogen and Oxygen together with some water vapour escape from the electrolyser. Each impurity introduced with the feed water will accumulate in electrolyte, i.e. Chloride, Sulphate and iron. The former two will have harmful effect on Nickel metal which leads to heavy corrosion and the later will cause impure Oxygen gas, The most suitable and economical method for production of pure feed water is by Ion Exchanger (DM water). The immediate detection of impurities in the feed water is its specific conductivity which should not exceed 2 x 10 ohm/CM Every cubic meter of Hydrogen produced, requirement 1 lt., of feed water, which is measured by rotameter provided with each plant. Purity of Gases: Hydrogen=99.8+ 2 by Vol.Oxygen =99.5+ 0.5 by Vol.Gas Pressure:Max. 250 mm of water Column which is sufficient for stroage in low pressure Gas Holders. When oxygen is not required to store in Gas holder it is vented through pressure balancing tank to atomsphere. Air Pollution: (in filter press type) : NIL(in Knowel type) :Minor leakage of gases connot be detected, which cause caustic atomsphere in the cell room.Fire Hazards:(in filter press type) : NIL(in Knowel type) :1. In case of loose electrical connection.2. In case of Blocking of the cells from bottom by desposition of soild Caustic and Carbonate3. Short circuit due to leakage of electrolytes.Design of Electrolyser1. The cell is in circular shape for uniform distance between Anode and Cathode. 2. The asbestos diaphragm is fixed on solid frames with bolting, which keeps the generated gases separate and maintain uniform purity.3. The frames, center electrodes, end electrodes, end frames are fully machined from selected steel and Nickel-plated to have uniform pressure on each frames and gasket. Thus the iron in electrolyte and leakage is fully controlled.4. The installation of Electrolyte separation tanks, Gas coolers and Gas washing tanks are arranged in such a manner that the cell can be attended without dismantling the complete plant. The cell can be easily installed in a room of 15 feet height.5. The +Ve(Anode) -Ve(Cathode) connection are provided on top of cell to have minimum length of Bus Bars and maximum safety.6. The filter provided will remove any fine fibers of Asbestos, dust, rust and carbonate which causes resistance to electricity and reduce efficiency.7. The Anode and Cathode electrodes are designed and fabricated from 1.6 mm thick CRCA steel to have minimum over voltage of gases and uniform distribution of electrolyte and electricity.8. The plants are supplied with base frame and insulators ready to install without foundation. 9. The VE: 1000 and 2000 filter press type can be easily installed in parallel and series with 2000 Amps. Knowel's cells. The combination will produced more gas using the rectifier already in use.The disconnected Knowel's cells can be kept as spare for replacement of damaged Knowel's cells. Thus cells can be replaced most economically.

...more

Gas Plant Instruments

Instruments

gas filling equipments

Electrical Panel

We are offering electrical panel.

Dry Ice Storage Boxes

We are offering dry ice storage boxes. Pu insulated with fibre glass body these storage boxes ensure minimal evaporation.quite sturdy for transportation.

...more

Dry Ice Maker

DIMENSIONS:Top: Dia 5.75 inchesBottom: Dia 5.5 inchesHeight: 9"Temperature at which cake is formed: -81%Time required in formation of a cake: 30 secondsCake Weight: 500 Gms.

...more

Dry Ice

The wonder refrigerant/cooling agent scores over any other on many accounts. It evaporates directly without leaving any traces, provides 70% more Kcal of refrigeration cooling than conventional water ice, and is an ideal cooling medium for reducing temperature to as low as -78°C. CO2 is obtained by direct fuel burning, or from by-product of boiler/furnace flues, brewery/distillery fermenters, fertilizer gases or any other sources. CO2 so obtained is purified. The purified CO2 gas is first made into liquid, which is then processed to make dry ice. Dry ice is formed by allowing pure liquid CO2 under pressure to expand to a reduced pressure. Because of Joule-Thomson effect cooling takes place and 'snow' is formed. The snow is compressed to form blocks or nuggets. MachinesFoundry Chemical makes different types of dry ice machines for various applications. We can supply machines with cylindrical blocks or with rectangular blocks. Generally block size is 5" dia x 12" length and weighs about 7-8 kg. The Dry Ice Plant sizes from 45 kg/hr to 300 kg/hr are readily available. Dry ice machines making small size blocks/nuggets of 1.0" - 1.5" are also available. For very small requirements we can offer a small inexpensive gadget which can make dry ice from a CO2 cylinder. You can make dry ice snow at the rate of 5-10 kg/hr but the "block" is not firm and efficiency is less as compared to dry ice obtained from regular CO2 plants. This equipment is ideal if requirement is small and occasional. We also supply machine to cut blocks, machines to put/spray dry ice on continuous conveyer belts of food/medicine for filling CO2/dry ice in food/medicine/chemical packages. Special freezer for temperature as low as -45°C can also be made available.StorageWe make FRP-Polyurethane insulated boxes and also canvas bags with polyurethane sheets for storage of dry ice. These have excellent insulation properties and keep the dry ice for longer time with minimum evaporation losses.

...more

Cooling Tower

FEATURES: Fibre glass reinforced Plastic (F.R.P.) casing. Metallic parts fully galvanized powder coated or epoxy coated. Corrosion and dry rot problems are never encountered as in the case of steel and wooden towers.AIR INTAKE: The bottle type design is highly resistant against strong wind and even takes in air from all directions, thus it can be installed quite independent of prevailing wind direction giving greater flexibility & freedom in selection of site for erection.FAN: Directly driven Axial Fan is designed to ensure minimum power consumption, noise level and operating costs. The Fan is totally free from the kind of problems posed by belt & gear drives.DRIFT ELIMINATOR: Multi blade rotary drift eliminator specially designed to reduce carry over losses. Drift loss, in maximum case is never beyond 0.3% to 0.5%.WATER BASIN: The F.R.P. water collection sump is leak proof and avoids spillage.MULTIPLE ARM ROTARY SPRINKLER: Water distribution highly efficient & Not easily compromised by orifice blockages.CONTACT AREA & HEAT TRANSFER: Honey comb fills provide more contact area by breaking air & water into several segments uniformly.LONG LIFE: Three to four times more life as compared to ordinary towers.FUNGUS FREE: No wood no fungus & hence less bioload.EASY PLUMBING: Our Towers come with ready connections.LIGHT & COMPACT: Occupies much less space. Floor area is abour 0.5 sq. ft per ton & weight is 15 to 20 kg/RT. Elegently profiled, modular construction fire & corrosion retardant FRP Cooling Towers are ideal for any industry.

...more

CO2 Test Bench

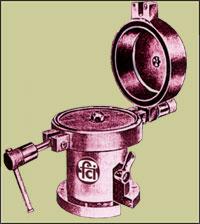

We supply a complete cylinder testing equipment as per the international regulations, apart from cylinder testing hydro pressure pump and measuring apparatus/fixtures measuring the expansion of the cylinder at the maximum pressure and then seeing whether the expansion is within the allowable limit. For seeing the inside condition of the cylinders we have a special torch arrangement, which can be hung in the cylinder itself and the internal condition can be seen. We have a special design test vice which is hydraulically/mechanically/manually operated and which holds cylinder securely without damage. SALIENT FEATURES: 1. TEST Pressure 350kg/cm2 & above 2. Sturdy Bulldozer type construction 3. Heavy duty Gear Box 4. Self oiling arrangement 5. Totally enclosed Mechanism 6. Large Pulsation Dampener 7. Leakproof-Long Life 8. Dependable 9.Economical ANCILLARIES: Tipping Jig Robustly constructed and designed for easy tipping and emptying of cylinders after test. APPLICATIONS: Testing of: Gas Cylinders, Pressure Vessels. Boilers, Pipes, Tubes, Rubber Hoses, Valves, Casting, Castings and many others parts.Test Vice:Hydraulically operated the test vice holds cylinders securely without damage. Cylinder valve removal spanner to gently remove tight valves also available. The standard SSFCI cylinder test station will have the following:1. Hydraulic Pump for cylinder testing2. Measurement gauges3. Cylinder vice4. Weighing machine5. Cylinder6. B.N Valve Socket gauge7. Cylinder trolley8. Blower with heating arrangement9. Cylinder drying Rack10. Stretch Board with glass and brass tubes11. Water tank12. Cylinder inspection lamp13. Other requisites, tools and tackles etc.

...more

CO2 Purity Tester

Special purity measuring burette forgasseous CO2 .Exactitude of measuring upto 1% by volume.

...more

CO2 Gas Plant

Technology to generate whealth from waste:Gaslabs has developed a new technology of EXTRACTING CO2 FROM BIOMASSES. It has set up serveral plants running on Biomasses and demands are pouring. while introducing this technology for the first time in the world Gaslabs Asia is constantly working on design innovations of its plant based on fertilizer gases, breweries and distilleries to extract even more wealth from waste. Gaslabs' flue gas plant uses boiler or any furnace flue gas as a raw material thus doing away with costly liquid fuel which is generally costlier in Asian contexts. The flue and biomass gas plants can be designed in the different capacities ranging from 30kg per hour to 2000kg per hour depending on the available input and client requirement.Other options may be the plants that run on waste hard coke, nut coke, breeze coke and pearl coke. Bye- Product based, Pollution free, Low priced Plant, Delivery more than purest CO2Gaslabs Asia plants are designed to use industrial bye products as their raw material, which works as a boon for DISTILLARIES and BREWERIES where fermented gases are produced in plenty and otherwise would go waste. GASLABS ASIA PLANTS RECOVER ODOUR-FREE, FOOD GRADE CO2 FROM THEM. Plants themselves are 100% POLLUTION-FREE causing no environmental imbalances, instead they capture CO2 which otherwise would have been mingled with the environment.Gas quality is guaranteed to be food grade and 99.99% pure in most cases. These plants are not only cost-effective in running but they are MOST REASONABLY PRICED to install too!-as they comparative study vis-a-vis to their features will revealIn our CO2 production plants based on any fuel burning we can co-produce N2 and DISTILLED WATER as well.Concept: Easy, Cheap Maintainence and Right AutomationUndoubtedly Europe was first to use CO2 for industrial purposes. It's countries designed various plants and innovated new technologies, spreading them out to the world.But unfortunately, in design Western Industry even now supports the 'Disposable' tag. A good reason for this may be the cost of repair & maintainence though. While the opposite is true for Asia. Though Gaslabs Asia makes widest range of plants ( from semi-automatic to full PLC computer controlled) it supports the Asian line. All Gaslabs' plants are MODULAR IN DESIGN with JUST RIGHT AUTOMATION, thus making maintainence and repair easy & cheap. Gaslabs' plants also have plenty of space in their floor plan which is relatively less costly in Asia.JUST HOW MUCH AUTOMATION does a client need? Many times a total automation, for an Asian environment may not prove to be as effective and hassle-free as manual or semi automated processes. At Gaslabs Asia, our first concern is plant uptime, productivity and automation-in that order.Our own running production plant becomes test bench of our new ideasWe believe that New Ideas should prove their dependability and we implement it with conviction. Our own CO2 plants work as testing ground to our innovations before they are commercially made available to our clients. This also gives us an opportunity to understand their problems which they might encounter in future. We make every attempt to eliminate them at design level itself.At Gaslabs Asia new ideas get into practical shape only when they have withstood our rigorous testing measures and have proven their dependability.For example our Biomass Plant took 5 long years to see the light of the day.

...more

CO2 Cylinder Manifold System

Big consumers have to use many cylinders. SSFCI CO2 manifold system enables a consumer to draw CO2 gas at one place and avoid mishandling of CO2 cylinders at different places at the workfloor. The battery system of using the cylinders at one place eliminates the carriage of individual cylinders at different locations where MIG welding sets/user systems are located. The SSFCI manifold system incorporates a special system, through the pipeline laid across machine on the shop floor. With our Pressure Reduction Station the pressure of the gas is reduced so that low pressure gas (as required by the user) is sent through the pipeline. With proper instrumentation and inter-locking, safe system is designed for trouble free service.Features:1. No internal freezing.2. No pressure oscillation.3. Clean CO2 as the impurities get filtered off.4. No interruption in CO2 supply during cylinder change. Saving of energy, CO2 and time are the main advantage.5. No outside heater/steam required. 6. Neat surroundings.7. No full time operator required.CO2 is transported in liquid phase either in cylinders or in storage tankers but it is used in gaseous state in beverages and other uses. CO2 is evaporated and expanded to lower pressure. In the expansion operating cooling occurs which can choke the entire system, resulting in pressure oscillation and thus CO2 losses can take place. SSFCI manifold system makes it possible to supply gaseous CO2 at any desired outlet pressure. We can install up to 4 outlets with 4 different outlet pressure as required. Gas outflow pressure can be varied between 1 to 16 bars. The quality of required determines the number of CO2 cylinders to be connected per hour. Our engineers will erect the complete system for you. The time for installation is minimum as the entire system is pre-assembled and tested at our site.CO2 supplies are done in the cylinders of different sizes, heights & capacities, therefore, the SSFCI manifold system, is modified to suit such conditions. It must be understood that the system is designed to handle pure, moisture free CO2 gas as per IS/BS/ASME Standards. If the gas is not of proper specifications and contains moisture or oil etc, extra features like Dryers and Oil Filters can be incorporated at extra cost.Alarm System can be provided to indicate low pressure in cylinder when these are exhausted.

...more

CO2 Cylinder Filling Unit

For filling CO2 gas two types of systems are available. Manual and Semi-automatic. In semi-automatic the CO2 supply is cut of the moment pressure reaches pre set limit. The top quality of our cut off valves ensures precision fillings and exact cut off timings. The cylinder is then removed from the balance. In the manual option cylinders are removed when the pre-determined volume/weight of CO2 is reached and this is seen by eye.

...more

CO2 Cylinder Filling Pump

These days cylinders are filled more and more with the help of a special liquid pump which pumps the liquid from the liquid source to the cylinder filling system. The pumps is of special design to handle liquid CO2 at extremely low temperature at pressure (approx, 22kg/cm2) and pumping the same to 80 kg/cm or more in cylinders. The entire piping circuit is made that the pumps run continuously and the excess liquid is returned back to the storage system. Application:* Cylinder Filling* Pumping Cryogenic liquid from Mobile tanks* Tank containers* Liquid cylinders* Pipe Line backup* Process feedingSpecial Features:* Extremely low NPSH requirement, Only 0.1 to 0.5 m.* Gland Packing specially developed for leakless operation, hence reduced gas loss.* Indigeniously developed, High eliability.* Minimal maintenance, all parts available off the shelf.* Quick cool down.* Designed for continuous operation.World Class pumps are supplied which are already in operation for several years.

...more

carbon dioxide storage tanks

Carbon Dioxide Recycling Plant

Voltage : 220 V

Storage Tanks

Totally safe for bulk CO2 storage. Designed with most modern safety devices, refrigerants and insulants which prevent even the smallest loss of gas by evaporation and liquid CO2 remains liquid for maximum period of time.Best kind of Low Temperature Steel is selected for construction and the tank is fabricated under internationally approved inspection agencies. Valves & fittings are approved by Controller of Explosives.Polyeurathene insulation and aluminium cladding is provided along with magnetic level indicator. Refrigeration system is logic controlled and maintains the temperature inside the tank to the set standard.

...more

Lorry Mounted CO² Tankers

Generally Tankers are placed on lorry chasis and we have designed and supplied lorry tankers of various capacities suitable for the existing chasis available. Since generally (unless asked for) there is no refrigeration system in the mobile tankers therefore the PU insulation is of higher thicknesses given. The material of construction is carefully selected low temperature steel which is stress relieved. After insulation is done there comes the Alluminum cladding. The tanker is provided with suitable piping arrangement on which safety valves, inlet-outlet pressure gauges and other safety of standard and approved make fittings are mounted. To suit local stipulation of Explosives Directorate required chasis modifications are also done. We provide:(a) height barrier.(b) barrier around the tank.(c) modification in the position of battery and rear red light and providing rear bumper are a few of the modification undertaken by us on the chasis.Fabrications and drawings are approved and supervised by international inspection agencies.

...more

Long Distance Transportable Tankers

Transportable tank is a storage tank, which is ISO housed in a frame and can be put into a container. All such containers are made to BS-5500. Tanks are suitable for transportation by road, ship or rail. These are vacuum insulated rigid tanks.TECHNICAL DATAOPERATING PRESSURE: 22/g/cm2TEST PRESSURE: upto 30 kg/cm2MATERIAL: Low temp. steelTEMPERATURE RANGE: +20 to -50oCCAPACITY RANGE: 1 to 500 tons

...more

Demineralizer System

Water is one of the most naturally available elements. It is also one of the most contaminated ones. A number of minerals readily dissolve into water. These have to be removed from the raw water, before it can be used for any industrial applications. a demineralizer (dm) removes these minerals from the raw water by an ion-exchanges process. The process first exchanges the cations of the salts for hydrogen ions and then, exchanges the anions of the salts for the hydroxyl ions our dm systems use the most modern ion-exchange technology to produce chemically pure water. Our dm systems :- give chemically pure water-instantly and continuously, year after year.have durable resins of the highest quality.comes with the convectional conductivity meter.are easy to operate and needs practically no attention after it is installed.can be connected directly to any water supply mains.is delivered promptly.is available in a wide range, and of low – rates to suit all type of customers. wide range of applications chemically pure, demineralized water is an ideal substitute for distilled water in a wide range of applications in industries like pharmaceuticalscosmeticssurface cleaningchemicalselectronicspaintsour softeners have the following advantages over convectional softeners- battery manufacturinghigh pressure boilerhospitalslaboratoryresearches technologydistilleries

...more

carbon dioxide purity tester

Electrical Panels

Be first to Rate

Rate This