Salt Fog Chamber

85,000 Per Piece

1 Piece (MOQ)

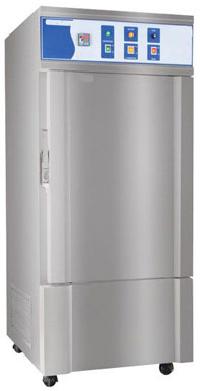

Salt Fog Test Chamber

Get Price Quote

The updated models of Salt/Cass Fog Test Chamber specially designed for evaluating the corrosion resistance of the surface treatment of metallic materials by Copper Accelerated Acetic Acid Salt Spray Test Method. It consists of following parts : Test Chamber : It consists of Cabinet and Lid and is constructed with insulated double structure made of FRP (Fiber Reinforced Plastic) Moulded Sheet. The Interior & Exterior Sides of the Chamber are Acid Proof, Alkali Proof, Impact Proof and easy to clean. The upper part (triangular shaped lid made of FRP with Acrylic Glass Window) has sufficient space for the mist to accumulate naturally on it and is so shaped that drops so accumulated do not fall on specimen being tested. A full top opening door will be provided for ensuring maximum working space inside the Chamber. Air-Saturator : It is provided to supply heated and humidified clean air, over 90% to 98% RH, for Atomization of the solution. It consists of Body (made of stainless steel), Heater, Bubbling Nozzle, Air Cleaner & Pressure Regulator. Air Regulator : The Air Regulator will maintain a constant pressure of air at 70 to 170 kpa Air Filter : The compressed air will be passed through a filter arrangement to remove all traces of oil and solid matters before sent to the saturation tower. Lid Sealing : Lid sealing through water seal method Mist Dispersion Atomizer : Atomizer made of Acrylic Glass will be equipped in the Chamber having property of non-choking. It produces a mist of atomized solution, which is distributed uniformly throughout the exposure zone by means of Mist Dispersion Atomizer incorporated with a baffle to prevent dispersion of large liquid droplets. Heating System : The temperature within the chamber maintained by heater with blower system, which provided in-between the exterior and interior walls. Solution Supply Tank : Solution Supply Tank will be provided to supply solution to Mist Dispersion Tower and will be made of FRP (Fiber Reinforced Plastic) Moulded Sheet. Solution Heating : Heating of solution in the Solution Tank by a special type of Glass Heating Element (two nos) fitted in the Solution Tank. Mist Collector : Two Mist Cylinders are provided for measurement mist quantity. Each has 80 cm² of horizontal area. The condensate is collected in individual graduated cylinders. pH Indicator : pH Indicator is inbuilt in Control Panel Control Panel : Separate Control Panel will be provided. The Control Panel will House : RH and Temperature Controller-cum-Indicator for Main Chamber. PID Temperature Controller-cum-Indicator for Air Saturating Tower. PID Temperature Controller-cum-Indicator for Solution Tank. Pre – Set Timer, ON/OFF Switches, MCB, Electronic Relays, Indicating Lamps & Time Totaliser pH Indicator. Safety DeviceAudiovisual Alarm start at the time of shortage of water in both the Saturating Tower and Solution Tank. WiringAll wiring will be as IS code. Channel type wiring will be done with suitable current rated copper wires.Standard Accessories SS Rod with PVC coating : 05 pcs Measuring Cylinder with Rubber Cork : 02 nos Glass Funnel : 02 nos S. S. Hanger : 15 pcs EPT Tube : 01 Mtr. Power Supply : 220/240 V, 50 Hz, Single Phase, AC Mains. Performance Test Temperature : Ambient to 50°C Temperature Accuracy : ± 1oC. Humidity Range : 95% to 98% will be maintained during the Salt Spray with saturation of Salt Solution. Humidity Indicator : RH Indicator will measure 90% to 100%. Mist Collection : 1-3ml/80cm²/hour at the same position as specimen to be tested. Mist Pressure : 0.8-1.8Kg/cm² (70-170 KPA). Heating System : Through hot air tower system. Standards : As per ISO 7253:1984, IS – 101 (Part 6/Sec 1 – June 1997), IS – 9000, IS – 6910, ISO – 3768 Part-I, ASTM – B – 117 – 73, ASTM – B – 368, DIN – 50021, JIS – 2371

Best Deals from Salt Fog Chamber

Salt Fog Chamber

Get Price Quote

Whether you are new to corrosion atmosphere testing or have been conducting testing for years, we present Salt spray chambers or Salt Fog Chambers that are not only easy to use and maintain but also provide the accuracy and flexibility necessary to meet today's demanding corrosion test procedures including Salt Spray Test, Condensation Water Test and Cyclic Corrosion Test. These machines create three types of manually adjusted environment; salt spray, high humidity and air drying at any given temperature within the chamber. Any combination of these environments can be programmed, in any order, to form a corrosion cycle. Such a corrosion cycle can be automatically repeated a predetermined number of times. Our models meet the requirements of basic, continuous salt spray tests conducted at a single temperature only, such as ASTM B117 and similar international test standards, and may be used with pH neutral salt solutions (NSS) or those acidified by the addition of Acetic Acid (ASS), Seawater Acidified Test (SWAAT) or Cupric Acid (CASS). Models above 480 Liters of capacity are ideal for Cyclic Corrosion Cabinet (Cyclic Corrosion Chamber). In Laboratories corrosion tests are used extensively for selection of materials and their surface protection. Our Corrosion box chambers are what you need to predict corrosion resistance of materials such as paints and coatings and are designed and developed to meet the widest possible range of industry standards:

Salt Fog Chamber

Get Price Quote

Salt Fog Chamber