TOILET ROLL MAKING MACHINE WITH EMBOSSING

Special Features Consistent Functioning Energy Efficient Operation Longer Functional Life Perforation Unit Slitting Unit Embossing Unit (Optional)

Brand Name : Sarvada Engineering Corporation

Phase : Single Phase or Three Phase ( As per customer requirement )

Warranty : Yes

...more

Rotogravure Printing Machine

1 Piece (MOQ)

otogravure Printing Machinery is so versatile that it can be used for myriads of printing works spanning from small labels to large photographs and Vinyl Roll. It is not circumscribed to only paper but is efficient to engrave images on surfaces of varied materials like foil, plastic and so on. About two decades of experience in printing industry and comprehensive expertise along with sophisticated production facilities empower us to manufacture a range of small, medium, high end Rotogravure Machines which offer optimum performance, resulting in higher productivity.We design the Rotogravure Printing Machine [ 1 to 10 colors ], incorporating fine quality of constituents and high-test associated components besides, employing high technology, that testify to the great value for the customers investment. Being a leading name in the industry, we also develop custom-made machines according to specific requirement of individual client that enable them to suffice their diverse market needs.

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

...more

Paper Plate Making Machine

The products have many advantages and are hence preferred as compared to standard utensils/crockery for serving eatables. Additionally, because of the disposable nature, they save a lot of labor as far as cleaning/drying of utensils is concernedQuick Details Model – Single Die or Double Die Fully Automatic Machine Crank Model or Hydrayllic Model Production – 45 pcs / per min. Power Load – 1/2 KW (Single Phase) Capacity of plate – 4’ to 12’inches Paper Thickness – 100GSM to 180GSM Weight of Machine – 450 kgs (approx) Motor – 1hp Power Consumption—2 Unit (Per Hour

Power : 2Hp Motor

Usage : Paper Plate Making, Dona Making

Brand Name : Sarvada Engineering Corporation

...more

Paper Lamination Machine

Driven Type : Electric

Warranty : 5 Years

Feature : Superior Performance, Rust Proof, Durable, Easy Maintenance, Easy To Operate

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

...more

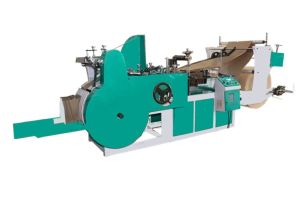

Paper Handle Pasting Machine

Certification : CE Certified, ISO 9001:2008

Application : Paper Handle

Automatic Grade : Automatic

Driven Type : Electric

Country of Origin : India

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

...more

Spiral Paper Tube And Paper Core Making Machine

In this Machine we have all ranges ,i.e 6 layers,12 layers,18 layers, 22 layers, 32 layers and so many as per customer’s demand. This whole plant consist of 5 to 6 machines as per requirement.We are an acclaimed name to offer a wide range of quality proven paper tube making machine that is used comprehensively in textile and packaging industry.The offered paper tube production line is designed and manufactured using optimum quality materials and highly advanced technology to meet the international quality standards.These paper tube production lines are available with us in various specifications to meet the requirements of various clients.Being a customer oriented organization we always try to timely deliver high-quality paper tube production lines to our valued clients at leading market price.Paper Tube Making Plant for making Paper Tubes in Different sizes the Machine is complete with 15 HP AC motor with AC Drive (3 phase 440v),reduction gear box & Capacity detachable reel stand.Glue Station- 2 HP AC Motor and knives for glue adjustment (cascade type, rotodel pump)Auto Rough Cutter to Cutting the Cores in different Sizes.Operated by accombined pneumatic and electric power. 2HP AC Motor (Tube length can be adjusted by the limit switch or photo cell.Fine Cutting Machine.-Fine Cutting Machine (working width 60") for Cutting the Tubes in Fine Size as per your requirement. 8 Holders with Knives and Machine with 2HP AC Motor.Parchment station- Parchment paper stand for pasting the finishing paper on out side of paper tubes. Light weight easy to operate. Paper speed is synchronized with winder speed.Sliting Machine-Sliting Machine with 1000 mm. Working 5 HP DC Motor with DC Drive. With 10 Cutter Sets with Top and Bottom, Heavy duty casting body Duplex rewinding, Single Shaft LoadingAir Compressor ( optional)-200 LBS Air Compressor with 2 HP AC Motor Single Or Three Phase. Branded Co. make. Wall thickness as per cutomer requirement.Features High functionality Higher output Extra strong tubes Electronic proportional control system for winding speed adjustment Rapidly interchangeable mandrels Pneumatic control of winding belt tension Built-in control panel with remote station

Automatic Grade : Automatic

Country of Origin : India

Application : Paper Tube Making, Paper Core Making, Spiral Paper Tube Making Composite camp.

Weight : 6000-7000kg or more.

Brand Name : Sarvada Engineering Corporation

...more

Kraft Paper

45 Per Kilogram

100 Kilogram (MOQ)

Color : Brown

Pulp Material : Other

Country of Origin : Made in India

...more

HEAVY DUTY PLATEN PUNCHING MACHINE

Our Machine can also provide half cuts for stickers. The perfect sticker cutting is ideal thus, the die blade should cut through the face paper & the adhesive should come to stop just before the release of paper. We make it 100% percent possible by introducing these features in our Platen Die Punching Machine. In addition to this, the Platen Die Punching Machine that we offer complies with the set industrial standards. Our valued clients can avail the Platen Die Punching Machine manufactured by us in various sizes as per their needs.Features Our Heavy Duty Platen Punching Machine is designed for Die Cutting, Creasing & Embossing on Paper, Card Board, Corrugated Board, Leather, Plastic and P.V.C. etc Totally standardized (i.e. all parts are inter-changeable) All shafts are from EN Grade steel and pins are grounded & bushes from Phosphorus Bronze Alloy. All bearings are of SKF/NBC/NACHI only. Fail-safe combination clutch brakes system with adjustable system (up to microns). The main driving shaft is equipped with two sets of double helical self-lubricated imported polyamide/steel pinion . Main electric panel (operation and control) are equipped with Detachable Socket System with international standardized components i.e. Siemens/L&T/Schneider (France) etc. Self diagnostic system software with visual indications Main flywheel is locked with check-nut system. Fully Automatic Centralized Lubrication System is provided. Quick and simple adjustment of impressions is made through two worm gears and eccentric bushes in the cam for left-right and up-down of platen to make the four corners equal. Machine is having quite silent running and outlook is excellent with best quality paint and powder coated fitting. “Friends” Fastest Platen opening 87” to provide press Operator Increased Time to feed delivering greater productivity. All features that make the “Friends” Platen Punching Machine most simple, reliable and maintenance free.

Certification : CE Certified, ISO 9001:2008

Weight : 4000kg Or More

Automatic Grade : Automatic

Warranty : Yes

Brand Name : Sarvada Engineering Corporation

...more

Flexographic Printing Machine

1 Piece (MOQ)

We are a prominent Flexo Printing Machine Manufacturer, Exporter and Supplier in India. The Range Includes Flexographic Printing Machine, Woven Bag Printing Machine, Multi Color Flexo Printing Machine, PP Woven Bag Printing Machine, Non-Woven Bag Printing Machine, HDPE Bag Printing Machine, PP Bag Printing Machine in modulate design with arched bridge Stack Type. With many years of worthy experience let this model stand out for its economic efficiency and high precision printing, flexographic printing machine as the most successful one in the world markets. Printable Materials includes PP, WOVEN, NON-WOVEN,HM, HDPE, LD, LLDPE, B.O.P.P, Polyester, Polypropylene, Foam Sheets, Paper, Aluminium Foil etc.Our robustly constructed Flexographic Printing Machine has an excellent speed range of 50 -100 meter per minute most suitable for 2, 4, 6, & 8 colour for Paper, LD, Non-Woven, Woven Sacks & other Substrates. Our machine is easy to install and operate. It gives high speed with great accuracy. Our elegantly designed machine also ensures reduced wastage as it has tolerance free format. It also has reverse printing arrangements and gives uniform impression.A flexographic print is made by creating a positive mirrored master of the required image as a 3D relief in a rubber or polymer material. Flexographic plates can be created with analogue and digital plate making processes in our Flexo Printing Machine. The image areas are raised above the non-image areas on the rubber or polymer plate. The ink is transferred from the ink roll which is partially immersed in the ink tank. Then it transfers to the anilox roll (or meter roll) whose texture holds a specific amount of ink since it is covered with thousands of small wells or cups that enable it to meter ink to the printing plate in a uniform thickness evenly and quickly (the number of cells per linear inch can vary according to the type of print job and the quality required). To avoid getting a final product with a smudgy or lumpy look, it must be ensured that the amount of ink on the printing plate is not excessive. This is achieved by using a metal scraper, called a doctor blade. The doctor blade removes excess ink from the anilox roller before inking the printing plate. The substrate is finally sandwiched between the plate and the impression cylinder to transfer the image. The sheet is then fed through a dryer, which allows the inks to dry before moving on. In the case a UV ink is used, the sheet does not have to be dried, but is dried from UV rays. Basic Parts of the Press Unwind and Infeed Section.

Brand Name : Sarvada Engineering Corporation

...more

eyelet punching machine

Salient Features Automatic feeding eyelet Hole eyeleting together 100 no. to 600no. eyelet size 1300 to 1600 punch/hour Easy to operate Expart not required Heavy duty designed Leas Space required Foot operated clutch system 1/2 HP AC motor Specially designed for Paper Bags Tags, Files Plastic Bags any other Products

Certification : CE Certified, ISO 9001:2008

Driven Type : Electric

Country of Origin : India

Type : Single Head And Double Head (As per Customer Requirement)

...more

Die Punching Machine

Our Machine can also provide half cuts for stickers. The perfect sticker cutting is ideal thus, the die blade should cut through the face paper & the adhesive should come to stop just before the release of paper. We make it 100% percent possible by introducing these features in our Platen Die Punching Machine. In addition to this, the Platen Die Punching Machine that we offer complies with the set industrial standards. Our valued clients can avail the Platen Die Punching Machine manufactured by us in various sizes as per their needs.Features Our Heavy Duty Platen Punching Machine is designed for Die Cutting, Creasing & Embossing on Paper, Card Board, Corrugated Board, Leather, Plastic and P.V.C. etc Totally standardized (i.e. all parts are inter-changeable) All shafts are from EN Grade steel and pins are grounded & bushes from Phosphorus Bronze Alloy. All bearings are of SKF/NBC/NACHI only. Fail-safe combination clutch brakes system with adjustable system (up to microns). The main driving shaft is equipped with two sets of double helical self-lubricated imported polyamide/steel pinion . Main electric panel (operation and control) are equipped with Detachable Socket System with international standardized components i.e. Siemens/L&T/Schneider (France) etc. Self diagnostic system software with visual indications Main flywheel is locked with check-nut system. Fully Automatic Centralized Lubrication System is provided. Quick and simple adjustment of impressions is made through two worm gears and eccentric bushes in the cam for left-right and up-down of platen to make the four corners equal. Machine is having quite silent running and outlook is excellent with best quality paint and powder coated fitting. “Friends” Fastest Platen opening 87” to provide press Operator Increased Time to feed delivering greater productivity. All features that make the “Friends” Platen Punching Machine most simple, reliable and maintenance free

Certification : Iso 9001:2008

Width : 50mm, 60mm, 70mm

Machine Weight : 1000-2000 Kg

Usage : Paper & Duplex Paper Die Punching Machine

Brand Name : Sarvada Engineering Corporation

Phase : Single Phase or Three Phase ( As per customer requirement )

Warranty : Yes

...more

Half Sticker Cutting Machine and Perforation Creasing Machine

Country of Origin : India

Creasing and cutting machine

Features Easy to operate Hassle free performance Rugged design Technical Specification Motorized Paper Creasing Machine Accurate & soundless working Machine No maintenance All steel body Size : 22", 30" Most useful for cover creasing Power : 1/4 hp AC

Country of Origin : India

...more

Automatic Corrugation Box Making Plant

Certification : CE Certified, ISO 9001:2008

Driven Type : Electric

Country of Origin : India

Warrenty : Yes

Weight : 5000kg or more( Depend on Machine)

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

...more

Automatic Slitter Rewinding Machine

We use very good quality raw material to produce excellent quality Slitting Machine Centre Drum. It has web width ranging from 300 mm to 2000mm. It is most efficient in slitting material such as paper, PVC, Aluminium Foil, other substances. Our machines are in great demand and for their attributes like long service life, high reliability and competitive price. We have been catering to the needs of various printing and packaging players across the country.Specifications Web Width-300mm To 2000mm Speed-100mtr To 250mtr Material-Paper, Polyester Film, Bopp, PVC, Aluminum Foil & Other Substrates Drive -Single Motor, 3Motor Synchronized Drive

Certification : CE Certified, ISO 9001:2008

Rated Power : 3-6kw, 6-9kw, 9-12kw

Driven Type : Elecric

Country of Origin : Made In India

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

...more

Automatic Shopping Paper Bag Making Machine

1 Piece (MOQ)

We Have Four Models of Paper Bag Making Machines but for Shopping Bag Our Large Model will be more suited . Large Model Paper Bag Making Machine Medium Model Paper Bag Making Machine Standard Model Paper Bag Making Machine Baby Model Paper Bag Making Machine We design & Manufactures the Machine as per Customer’s demand. So in all four Models we have option of with printing or without printing.Paper bag making machine is designed to manufacture Flat and satchel paper bags from kraft paper, greaseproof, white paper and poster Paper etc. in different size for packing confectionery, food stuff, ready-made Garments, tobacco, tea powder grocery, dry cleaners etc.Advantages Of Shopping Paper Bag Making Maching /Paper Bag Making MachineWith rapid advancement in innovations and utilization of components, manufacturing measures have gotten simpler. This has prompted to an agreeable large-scale manufacturing of any item. At the early phases of the introduction of paper bag machines, the process towards making them was manual. Individuals were expected to perform temporary jobs like cutting, straying off edges and corners, and so on. It took a great deal of time, exertion, and cost to make the paper bags. With the headway in innovation and advancement, it has prompted the improvement of paper bag making machines. Let's talk about the advantages and scope of these machines.Scope of a paper-bag machineThe ecological safety awareness has expanded all over the globe. This awareness made by individuals has improved sensationally at different levels today. Because of this, there is a decrease in the utilization of plastic bags. Likewise, there is an improvement in the use of paper bags also. Requests for paper bags are very high in the present-day situation. Paper bag-making machines assist with making the market's enormous requests from different sources, for example, retailers, clients, sellers, and so forth simpler.Faster Production and Saves TimePaper bags made out of hand can be exceptionally perplexing and excellent, though it requires some investment to create one. Regarding catering to a mass request, manual techniques and workforce are inefficient in gathering client's requests. Paper bag making machine's plan and improvement help in quicker creation rates. Here the entirety of the cycle associated with bag making happens consecutively in a continuous movement. This plan for bag creation guarantees an authoritative creation yield for a given time. Paper bag machines utilize a PLC control framework that empowers no delay between the whole creation time's ensuing items. In this angle, paper bag making machines are a lot quicker than the manual techniques. It empowers continuous creation and decreases the time engaged with design to a few folds.Reduced Production CostsIf there should be an occurrence of manual paper bag creation, each cycle includes cutting, collapsing, and joining that are performed physically. Limit of human processes are restricted somewhat and furthermore shifts from individual to individual; hence the efficiency of the business for a predetermined time is additionally restricted. With regards to catering to a mass request, paper bag machines becomes easy to build the creation and meet the necessity. Paper bag machine, then again, can deal with the mass creation prerequisite.

Certification : CE Certified., ISO 9001:2008

Weight : 4 Tones Or More

Power : 3-5kw, As Per Machine Model

Driven Type : Electric

Capacity : 8000-9000/hr

Country of Origin : India

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

...more

Automatic Reel to Sheet Cutting Machine

Features Machine is having special feature of oil bath gear system with oil lubricating pump Machine is fitted with heavy duty excel makes P.I.V. Gear Box Imported chain to adjust the length of the sheet to be cut with Gear Ratio 1:5 Machine is driven by A.C. frequency drive with provision for synchronization of speed between Sheet Cutter with Corrugating Machine With A.C. Motor & Starter Feeding section with concealed gears Cutting section with Blade workable at four edges Delivery conveyor with endless Belts Electronic sheet counter Paper cutting capacity is 200 feet per minute Specifications Body: This strongly design machine can be used as an independent unit or can be synchronized to a corrugation Machine for direct and accurate sheet cutting It minimizes the percentage of wastage Setting Action: PIV gear box is provided for adjusting of sheet to the required length from 20" to 80" PIV gear box 1:5 ratio shall be provided Design: The machine is robust in design & in grade casting Strong in construction and easy to operate Nylon sandwich belt shall be provided as a delivery conveyor to carry the sheets out Electric motors of 3 phase A/C 1440 RPM / 440 V ISI mark ISO 9001:2008 certified All moving parts are protected by safety guards

Certification : ISO 9001:2008 Certified

Cutting Capacity : 100mm, 200mm, 300mm

Overall Length : 6-10 Inch, 20-30 Inch, 40-50 Inch

Effective Cutting Width : 5mm, 10mm, 15mm, 20mm

Max Cutting Thickness : 30mm, 40mm, 50mm

Maximum Working Height : 200mm, 250mm, 300mm

Overall Diameter in mm : 50-100mm, 100-150mm

Brand Name : Sarvada Engineering Corporation

Phase : Single Phase or Three Phase ( As per customer requirement )

Warranty : Yes

...more

Automatic Paper Napkin and Tissue Paper Making Machine

1 Piece (MOQ)

Each Printing Unit Consits ofTwo / Four Colour of Flexo graphic Printing EACH PRINTING UNIT CONSISTS Forward & Backward adjustment one Ink Roller Dipped in Duct One Ink Carrying Roller Could be adjustment fir the required ink.Embossing UnitOne Female Embossing unit ( Desinge as per your requirement)Folding Unit Rotary Cutting Unit Two Vetical Drum for ¼ th Folding Digitally variable counting with Totaliser AccessoryExtra Band Saw Blade, Toll Kit, 2 ps Grinding wheel

Brand Name : Sarvada Engineering Corporation

Capacity : 400-500sheets/min

Machine Weight : 25000 Kg Or More

Driven Type : Electric

Phase : Single Phase And Three Phase ( As Per Customer Requirement )

Warranty : Yes

...more

Automatic Paper Bag Making Machine

1 Piece (MOQ)

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

Application : Paper Bag

...more

Automatic and Semi Automatic Paper Cutting Machine

Certification : CE Certified, ISO 9001:2008

Brand Name : Sarvada Engineering Corporation

Phase : Single Phase or Three Phase ( As per customer requirement )

Warranty : Yes

...more

Aluminum Kitchen Foil Rewinding Machine

Certification : CE Certified, ISO 9001:2008

Type : Automatic and Semi-automatic

Phase : Single Phase or Three Phase ( As per customer requirement )

Country of Origin : India

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

Warranty : Yes

...more

Aluminum Foil With Cling Film And Butter Paper Rewinding Machine

2 Per Piece

1 Piece (MOQ)

Special Features High Efficient HighOperational Fluency Superior Performance Power Brake Machine Works in Meter

Type : Automatic And Semi-automatic

Certification : CE Certified, ISO 9001:2008

Weight : 100-500kg, 1000-2000kg

Country of Origin : India

Warrenty : Yes

Brand Name : Sarvada Engineering Corporation

Warranty : Yes

Brand Name : Servada

...more

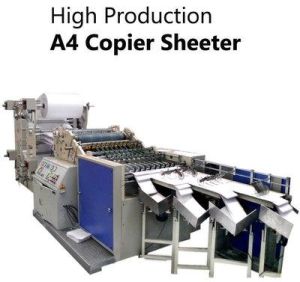

A4 paper making machine

Certification : ISO 9001:2008 Certified

Machine Weight : 1000-2000kg, Or More

Country of Origin : India

Size (mm) : As per Customer Requirement

Width : As per Customer Requirement

Power : 1-3kw (As per Customer Requirement)

Brand Name : Sarvada Engineering Corporation

Phase : Single Phase or Three Phase ( As per customer requirement )

Warranty : Yes

...more

Paper Bag Making Machine

Opening Hours

About us

Established in the year 2017, we at Sarvada Engineering Corporation is a reputed organization busy in Manufacturing and Supplying wide-ranging array of Cutting Machine, Making Machine, Punching Machine, Rewinding Machine, Paper Lamination Machine, Paper Handle Pasting Machine, Karft Paper, Half Cut Creasing Perforation Machine, Flexographic Printing Machine, Carton Box Making Plant, Automatic Corrugation Plant, and Rotogravure Printing Machine, etc.

The available collection is designed and manufactured in compliance with global quality standards using quality-approved components and pioneering technology in our technically advanced manufacturing unit under the direction of our experts. These products are broadly acknowledged for sturdy building, optimum functionality, superior presentation, high efficiency, and longer service life. Furthermore, we offer our product range in different technical features to accomplish the different needs of the industry.

Additionally, these units are handled by a team of professionals which in return gives us a spirited edge over our close-up competitors. With widespread market understanding and widespread domain associate, we have managed to reach an insuperable position in the business.

Our packaging experts deliver efficient consignments to our clients securely and securely. For making our complete product range defect-free, we make sure that the entire range is manufactured using the best quality elements that are procured from the reliable vendor of the business.

With the assistance of our quality testing unit, our complete product range is inspected on diverse parameters of quality to destroy all the flaws from the collection.