Screen Exposing Frame

Get Price Quote

1 Piece (MOQ)

With the increase demand from the Textile Printers for high-density publishing and fine graphics on dark garment, we have successfully designed and delivered our "exposing System" for today's textile screen printers. An ideal equipment for transferring on the screen frame. This powder-coated frame has the following features: Special pump draws the elasticity that does not tear from frequent use with the edges of aluminium square pipe frame The suction pump draws the excess air fast and the vacuum pump makes the perfect bondage between the film and screen frame. Hence perfect sharpness. 1 Kw, 3 Kw, or 6 Kw Instant Start Halide light sources are recommended all over the world for reproduction of sharp graphic images. Different models are available according to the requirement and convenience of the end user. Micro Processor base light integrated electronic times has multiple memories and sequential operations. Optional : Drying Systems in frame with top exposure where Thermostatically controlled hot air is circulated for drying. The equipment is operator friendly. Self Tightening Screen Frame Cost- effective and user friendly. More accurate for achieving hi-tension for optimizing ink flow characteristics and mileage. Most required and used by Textile Screen Printers for four color, half tone and three dimensional printing with die-cut sharpness and print clarity. Used both on manual and automatic for smooth, faster production without wanton ink build-up. Operator takes 5-10 minutes to stretch the mesh for required job. Graphic Printers will save in coat upto 30% The performance and durability of the squeegee blade increase. Drier Thermostatically controlled drier for drying the screen frames.

screen printed stickers

Get Price Quote

With our capacious storage facility, urgent and voluminous requirements of the buyers are easily furnished by us. Rely on us for premium quality of the products as we make use of the finest grade raw material for preparing them. Also, we procure it from the reliable places after complete quality satisfaction.

Best Deals from Screen Printing Equipment

Screen Printing Material

Get Price Quote

Based in Delhi(India), We marked our presence in the nationwide market since our products are qualitative and cost effective. For those seeking to buy superior-grade Screen Printing Material, we are the best suppliers of it in the market.

Fixed Frame Narrow Screen

Get Price Quote

1 Piece (MOQ)

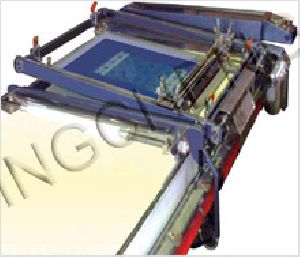

Large Flat Bed Screen Printing Machine

Get Price Quote

We are known for offering the best Large Flat Bed Screen Printing Machine for diverse printing applications with high accuracy. The Large Flat Bed Screen Printing Machine is designed in compliance with the set industrial quality standards. Our Large Flat Bed Screen Printing Machine is available at competitive prices. Details : Designed with horizontal guide wayCPU control system with manual and automatic operationsPrint head extension and elevation for clean upWith T type printing table with no vacuum/locking of jigsSqueegee skew angle, depth, leveling are adjustableOptional: Multi color printing registration device for curve printingPneumatic horizontal / vertical printing strokes, speed and strokes are adjustable

Industrial Model with Printer

50,000 - 60,000 Per piece

1 Box (MOQ)

screen printing mesh

400 Per Meter

Flat Bed Screen Printing Machine

220,000 Per Piece

Industrial Model with Printer

Get Price Quote

Industrial Model with Printer is designed especially for Canteen Management systems. This device comes with thermal printer for printing coupons. The Industrial Model with printer comes in heavy metallic body for dusty and harsh environments. It has 62,500 records storage capacity with 9,560 fingerprint templates storage capacity. The Industrial Model with printer features LCD display to show the information of the employees whereas 2 large lights (Red & Green) indicates the status of the attendance. The built in TCP/IP connectivity helps to get the data with a single click of the mouse. It features heavy duty battery back-up of up to 48 hours, which makes it more compatible with the industrial environments. This device works on multiple operational modes. Product Features: Large LCD display 62,500 recording capacity 9,560 fingerprint template storage Built-in Thermal printer Heavy duty metallic body Built-in battery back-up up to 48 hours Built-in TCP/IP connectivity

flat screen printer

Get Price Quote

INLINE SMT SCREEN PRINTER

Get Price Quote

Europlacer’s ep700 series printers combine the company’s commitment to high performance and reliability with outstanding value. The platform has been developed to cope with the rigors of high volume SMT production. Yet it incorporates the flexibility needed to deliver the fast set-up and product changeovers demanded by low and medium volume operations working in high-mix environments. Designed with ease of use, high-end performance and low cost of ownership in mind, the platform utilises the most advanced drive control technology available, including 1 micron resolution linear encoders on all axes. A suite of intuitive software enables total control of the printing process. The printers are fully equipped, as standard, with many features such as automatic rail width adjust, auto stencil loading, a fully programmable Under Stencil Cleaner and even automatic stencil paste inspection. In fact, everything you need to complete the SMT print process without exception or compromise. The vision system utilises a unique Dual Roving camera (DRc) method for automatic board and stencil alignment. Not only does this innovative vision system provide the highest level of alignment capability, it also incorporates SmartCal.

Flat Screen Printing Machine

Get Price Quote

Printing Carriage Rubber Squeegee System : Comprising of a Galvanized robust Steel fabricated Framework, supported on a series of Locating Carrier Wheels, and retaining the following: • A hinged Screen Holding Frame, suitably prepared with adapters for the Asian and European Type Flat Screen Setting/Locking systems, • Pneumatic operated Screen Lifting mechanism, • A Motorized Variable Speed Squeegee Drive system, complete with adjustable Travel Limiters, PLC Controlled for Multi-Stroke and Flood-Stoke Colour Application. • Sprung loaded Squeegee Retainers complete with calibrated settings for controlling the Colour Application by the Squeegee system. • A Motorized Variable Speed Print Carriage Drive system, PLC Controlled for Auto-engaging of the Print Carriage to the Repeat Settings, complete with related Electronic system for controlling the Print Carriage Auto / Alternate / Manual Travel Mode. • A Fabric Roll Support/Spreading attachment, useful for the Operator to apply the Fabric onto Print Table Surface The Electrical and Pneumatic Control Cabinet suitably connected to Printing Head Frame unit, housing all related Operational Switch-gear, together with Operator Control panel, all ready prepared for incoming Supply. PRINTING TABLEComprising of a Galvanized Steel Base-frame Structure, retaining a Reinforced Marine Plywood Table Surface, and covered with 2 layers of Polyester Under-Felt (for ~Soft~ Print Table System) and a Polyester/PVC coated Print Blanket, inclusive of necessary Print Carriage Runner Rails, a series of adjustable Repeat Blocks for Auto-engaging of the Print Carriage to the required Repeat settings, and Drainage side Channels. The Printing Table being equipped with a 3 Phase Electrical Supply Conductor Rail System, and a Retractable ~Drum~ Type Pneumatic Air Supply System for Operational Services to the Print Carriage and other related Optional Extra Accessories.TABLE HEATING SYSTEMAn Electrical Heated Under-blanket System is offered as Optional Extra, for maintaining the Print Table Surface heated up to 65 Deg Cent., comprising of a special Wire Mesh for enclosing between the 2 Layers of Under-felt, complete with Auto-Transformer for Setting the desired Temperature.

Yellow Screen Printing Mesh

Get Price Quote

wedding card printing machine

100,000 Per Piece

Flat Screen Printing Machine

Get Price Quote

screen printing mesh , bolting cloth

Get Price Quote

screen printing mesh is mainly used in screen printing and melting filtration, have the following advantages: precise opening, flat appearance, standard mesh and precise filtration value as colliery, food and medicine. General Specification of Polyester Screen Mesh: We provide 60meshinch,80meshinch,100meshinch,110mesh inch, 120meshinch,135meshinch,160meshinch,180meshinch,200meshinch,230meshinch,250meshinch,280meshinch,305meshinch,355meshinch,380meshinch,420meshinch. Width of polyester screen mesh: Max. Width: 3200mm. we may also take orders to produce polyester Screen Mesh with other special requirements

wedding card printing machine

125,000 Per Piece

Screen Printing Wooden Frame

300 Per Piece

Flat Bed Screen Printing Machine

1,200,000 Per Unit

Manual Screen Printing Table

75,000 Per Piece

Screen Printers

Get Price Quote

Offset Printing Solution, labels tags, Leaflets

screen printing stickers

Get Price Quote

screen printing stickers, Stationery Products, Stationery Products

glass screen printers

Get Price Quote

glass screen printers, printing presses, Screen Printing Machine

semi automatic screen printing machine

Get Price Quote

Screen Exposing Machine, Wire Twisting Machine

screen printing equipments

Get Price Quote

screen printing equipments, digital printing equipments

Screen Printing Material

Get Price Quote

Vinyl Printers, Printing Material, Screen Printing Bag

screen printing equipment

Get Price Quote

garments tags, Water Transfer Labels, box bar codes

screen printed stickers

Get Price Quote

screen printed stickers, stickers for electronic equipments

Screen Printing Material

Get Price Quote

Offset Printing Material

screen printing equipment

Get Price Quote

id card machine