VERTICAL SEAL LESS PUMP

Heavy duty engineered polypropylene sump-pump for primery effluents / corrosive liquids and scrubbing systems. Zero maintenance pumps, eliminates the need for gland packing and seal Leak proof and can run dry without damage of rotating parts Pumps to be mounted out side the suction tank in vertical position and not to be submerged Vertical gland less pump, similar in hydraulic design to any conventional centrifugal pump, it differs in, so far as restriction is provided, escape by way of an overflow connection in the upper pump body & return to the suction line Preferred selection for E.T.P. Plant because of seal less design Pump is seal less hence can run dry Minimum component makes maintenance easy Low maintenance cost and prolong life Ideally recommended for transfer of treated effluent No mechanical seal / glands, hence pump can run dry Low maintenance cost and easy to maintain M.O.C. PP - UPTO 550- 600 C PPH - UPTO 90 01000 C PVDF - UPTO 100 0 - 1100 C We are fully committed to providing the finest pumps, the best engineering, the most effective customer service & the greatest after sales support possible.

...more

Tower Packings

Tower packings is available in Polypropylene, PVDF & HDPE material of construction in various types ( like Hackette, Tellerette, Dinpak & Envipac) and sizes. Tower Packings find wide applications in wet scrubbers, cooling towers, entertainment separators, absorption & stripping columns and air-washers. They are uniquely designed to increase mass transfer & process capacity; to reduce pressure drops, energy consumption & hence operating costs. Tower Packings are an ideal replacement for the existing ring or saddle packings to increase throughput, improve efficiency and conserve energy. ADVANTAGES High mass and/or heat transfer rate Extremely low pressure drop Free of plugging , fouling, nesting & wall channeling Highest flooding point & lowest wetting point Even gas and liquid distribution. No Interlocking or meshing. Better particulate collection by inertial impaction Greater liquid surface availability. More interstital hold-up points Renews liquid surface at no extra cost in energy Continuous exposure of fresh liquid surface to gas flow Non wetting surface High column stability Higher absorption efficiency enables to conserve energy Used as mist eliminator also Reduces energy consumption & hence operating cost

...more

solvent pump

High head low capacity pump, Available in S.S.-316 INVESTMENT CASTING and Cast Iron with all wetted parts of S.S.-316, Excellent for handling solvents from barrels and from tank farms to the charging vessels, Seal leakage can easily be detected from window in priming chamber, Pump can take negative lift from 3 to 5 meters, Life lubricating bearings, covered from both the ends so minor leakage from pump side does not affect bearings, Being a low speed (1450 RPM) pump, Less Maintenance is needed, Maintenance is easier, Drain arrangement is standard, Low overhang shaft arrangement giving minimum deflection at the seal faces, Installation is easier since motor required is vertical flange type and is directly coupled to the pump, coupling alignment is simpler, Biggest advantage from installation point of view is that since it is an "in line" type pump, it can be fitted as a valve and hence it will not require any suction or delivery piping efforts.

...more

Sewage Pumps

Ideal for sewage, industrial waste, liquids containing solid suspension, such as mash, pulps, beet shreds, etc. & muddy fluids of high consistency. Vertical Dry pit Sewage pumps These pumps are most suitable for :- Drainage and irrigation installations Sewage disposal for housing colonies basement, toilet blocks etc. Marine installations The basic advantages of these pumps are :- Economy in floor space Prime mover can be mounted at an elevation as shown or at a higher elevation. Higher elevation of prime mover is possible by adding extra adaptors, transmission shaftings and intermediate bearings. This reduces the risk of submerging the electric motor in case of accidental flooding of the dry pit. Ease of maintenance. To dismantle, the mounting cover is to be unbolted from the casing after motor has been removed. The rotor assembly is drawn out upwards complete with stuffing box, bearing housing etc. This rotor assembly can then be completely dismantled at a convenient location. Due to the back pull out design, choking of the impeller can also be similarly, removed easily. Automatic Self priming sewage pump is a highly precise and yet a very rugged unit.The operation of the pump is as follows:A. vacuum pump starts.B. Water level in float chamber rises. Float rises and operates the level switch.C. Vacuum pump shuts down and main pump starts. Whilst main pump is in operation and pump looses prime then the priming pump restarts to automatically maintain the prime. As soon as priming is completed, the vacuum pump shuts down and main pump goes on operating. In case the level of product in the suction tank goes below the level of the suction line and pump looses its prime, the vacuum pump cuts in. The main pump continues to function for a predetermined time limit-approximately 2.5 minutes. After the predetermined time limit is over, the electric control panel shuts down the main pump motor. The whole system is absolutely automatic and has been developed after long research, to give outstanding performance under arduous service conditions. Multistage Centrifugal pumps For high heads at relatively low speedsFor fire fighting servicesHigh rise building Boiler feedWater worksBooster serviceMine drainage Design Features Rugged and simple in design Maximum dimensional interchangeability Wide choice of materials Dynamically balanced impellers Vibration free performance The distinguishing features of these pumps are High Efficiency, Long Bearing Life and Adaptability to various operating conditions.The pumps are built as multistage pumps upto 10 stages with horizontal suction and vertical delivery branches. The intermediate stages are designed to lead water from the outlet of one impeller to the inlet of the adjacent impeller with minimum of friction, resulting in high efficiency. Special Designs Twin Outlet and Triple outlet multistage pumps are also available. The intermediate delivery housings are of special design and can be arranged after any number of stages depending on the head required at the intermediate delivery outlet. Hence a single multi stage multi outlet pump can perform the function of two or even three separate standard multistage pumps. These pumps can also be made self priming by the addition of a primary stage.

...more

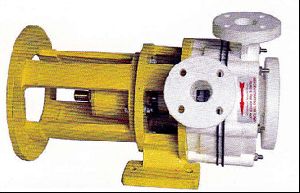

Pvdf Pumps

The Fluorinated Polymer are widely appreciated for their remarkable chemical inertness and their excellent resistance to ageing.POLYVINYLIDENE FLUORIDE (PVDF) offers the specific advantage of easy processing in accordance with all the convection methods used in the plastic industry. PVDF, polymerized, according to its own special process, offers a high degree of crystallinity to that by other processes, resulting among other things, in superior thermomechanical properties. The intrinsic technical superiority is one of the reasons for the success which PVDF has achieved on the world market for more than 20 years. Easy processing by : extrusion, injection, compression, rotational moulding, blow moulding etc. Chemically inert to most acids, aliphatic and aromatic organic solvents, alcohals etc. Very high purity. Excellent mechanical properties over a wide range of temperatures : tensile yield strength up to 55 MPa at 23°C and 10 MPa at 150°C. Abrasion resistance comparable to that of polyamides, and relatively low coefficient of friction. Continuous use at temperatures as high as 150°C for the homopolymer grades (without mechanical stress). Excellent thermal aging resistance : tensile yield strength retention over 90% after 25,000 hours at 150°C in a ventilated oven. Unaffected by UV (>232nm) and good resistance to gamma radiation. Excellent intrinsic fire resistance. Very easily joined by welding and good capability for thermoforming. Physiologically harmless and approved for contact with food products (FDA). Advantages at a Glance Tried and tested chemical process pump design for rough conditions. Thick-walled vacuum-proof plastic housing in one piece. Therefore no additional sealing points in the pump housing. Plastic housing completely encapsulated in a metal armour of tough material. Pipeline forces are absorbed by the metal armour. Also suitable for high system pressures. Flanges with through holes meeting the requirements of the chemical industries. Semi-open PVDF impellers reinforced by large metal inserts. Smooth running and long service life of the mechanical seal, thanks to the particularly heavy duty bearing pedestal. Modular system ensuring economical spare parts stocking. External corrosion protection of pump and base plate by an epoxy paint Pump Casing Linear & ArmourPVDF liner is completely encapsulated in the metal armour (shell). All sealing points are metal supported and "flowing" of the PVDF is thus limited. The robust armour absorbs all the loads in the system and from the suction.Slide in UnitPump without casing with semi-open PVDF impeller and solid injection moulded PVDF back plate.Shaft SealingExternal mounted teflon bellow-type single mechanical seal and high alumina ceramic stationery sealing face.

...more

Priming Pot

Suitable for 3 to 5 mtr. negative suction lift. Fabricated from PPH for higher strength. Top cover makes maintenance easy. Fabricated with in-buift strainer to arrest coarse impurities. Inlet & Outlet size to match pump suction flange size. SPECIAL SIZE AND HIGH CAPACITY POT ON REQUEST.

...more

Portable Submersible Pump

Dewatering Pumps are perfectly suitable for non clog operation to handle sandy and muddy & sea water from the lowest level and are used in Building Construction sites, Ship yards, Dam sites, Narrow trenches and Pits, Shafts, Mines, Disposal of flood water and Waste water in Thermal Power plants, Hydro Electric power projects, Atomic Power Stations, Recirculation of water in process and Heavy Industries-like steel plants Sugar Mills, Lift irrigation and also for Screened Sewage.

...more

MOULDED POLYPROPYLENE GAUGE SAVER

For measuring corrosive fluid line pressure with accurate readings from 0 to 10 kg/cm2 This engineered, all plastic Pressure Gauge Saver consists of a moulded cylinder incorporating a top and bottom chamber. It is an effective means of eliminating the corrosion problem and the necessity for utilizing a costly high alloy gauge in the measuring of line pressure in pipes carrying corrosive chemicals. WORKING A moulded flexible diaphragm incorporating double "O" rings separates the top and bottom chambers and provides for positive sealing as well as complete isolation of the corrosive fluids to the inert materials. The top chamber is filled through a 1/4" BSP threaded hole, with any compatible fluid such as water or oil. This liquid simply serves to the hydraulically transfer line pressure. A pressure gauge indicator, of the user's choice, is then threaded onto the 1/4" BSP Connection. In the lower chamber a 1/2" BSP thread ( or other pipe size) inlet is provided and when connected to the pressure line, provides the required channel for the fluid to enter and activate the flexible diaphragm, and a true and accurate reading ( to 10 kg/cm2) will be recorded on the pressure gauge. This action also has the effect of dampening line pulsations, surges and shocks which are normally imparted to an indicator not protected with a Guage Saver. The moulded flexible diaphragm is Neoprene. Polypropylene is rated for kg/cm2 service. Polypropylene is suitable upto 85º C.

...more

Motorised Barrel Pumps

SALIENT FEATURES : Seal less design Self Priming type Light weight & hence portable Barrel pumps with their versatility help to provide a complete solution to your fluid management needs Modular design construction for easy maintenance All components are interchangeable Saves considerable time, labour, spillage High standards of quality and safety ensures reliable performance for handling aggressive corrosive & flammable liquids. BARREL PUMPS ARE AVAILABLE IN STAINLESS STEEL SS-316/POLYPROPYLENE/TEFLON MATERIAL OF CONSTRUCTION

...more

LOW CAPACITY PUMPS

Standard Pumps filled with Ceramic Sleeves and FEP/ PFA ( FEP/PFA Lined Pumps) Bellows Mechanical Seals. Excellent for handling corrosive chemicals like HCL, dil HrSO4, HNOs, FeCIs, CUSO+, HE HBr, CH.CoOH, NaOH, HsPOa, NaCletc Applications Alkalies Transfer Recirculation of Electrolyte Scrubbing of Corrosive Gasses like Clz, Brz, lz, Soz, Co. Effluent Treatment For Descaling of Tubes Filtration lndustries Chloro - Alkali lndustries Chemical & Pharma lndustries Food lndustries Electronic lndustries ETP/WTP/STP Electro Plating lndustries Models ATOM-100 ATOM-120 ATOM-130 ATOM-130H These Pumps are recommended for lntermediate duty of 8 to 10 hours per day running. Occupies less space, easy to handle & economical. Electroplating solution circulation & etching solution for electronic circuit board. Available with PVDF impeller & silicon carbide mech. seals for high temperature ancj aggressive acids. Pumps are available with lnternal Mechanical Seals (lMS). Pumps are available in Gland Packing construction Above pumps are also available in PTFF lined construction. Pumps are also available in Gland Packing Pumps are supplied with special Mech.Seals for applications like Slurries, thicker liquids, rnixing fluids etc.

...more

High Speed Pumps

These Pumps are high head (upto 45 mts) with different capacities coupled to 2900 RPM motors. These Models Are Highly Recommended for : Excellent for scrubbing corrosive and aggressive gases like Cl2, Br2,12, SO2, CO3, etc. Used in transfer of chemical in batch process. Recommended for use against filter press in dyes and intermediate industries. For recirculation of chemicals in electroplating industr All Models.- are available with PVDF impellers for high temp. upto 90oC. ALTRA-190 Model is high head (upto 50 mts) low capacity pump coupled to 2900 RPM motor. Excellent for vaccume ejectors. Pumps are available with Internal Mechanical Seals (IMS). Pumps are available in Gland Packing construction. Above pumps are also available in PTFE lined construction. Pumps are also available in Gland Packing Pumps are supplied with special Mech.Seals for applications like Slurries, thicker liquids, mixing fluids etc. Pumps are available in special material on request.

...more

High Capacity Pumps

SEEMSAN Moulded Polypropylene High Capacity Pumps are specially designed and developed for high capacity and high head application. AKRON- 220 Model is designed to transfer ACID / ALKALI/ Effluent at higher head & high flow rate. This pump can operate at 1450 RPM as well as 2900 RPM. AKRON - 230 High Capacity 2900 RPM Pump AKRON - 265 High Capacity 1450 RPM Pump AKRON - 320 High Capacity 1450 RPM Pump AKRON - 360 High Capacity 1450 RPM Pump These Pumps are recommended for: AKRON series pumps are high volume / flow transfer pumps. Recommended for acidic efffuent transfer for large scale industries. Scrubbing acidic fumes in steel industries. Pumps are also availabl'e in Gland Packing Pumps are supplied with special Mech.$eals for applications like Slurries, thicker liquids, mixing fluids etc. PUMP Available with PT.F.E. Glandpackings.

...more

gas scrubbing systems

For various hazardous, toxic and corrosive gases like HCL, Cl2, SO2, NH3, H2S etc., dust particulates and various solvent vapours. For large surface area wetted by a liquid over which the gas stream flows, wet packed scrubbers are used to absorb pollutant solute from the gas stream. Customised packages available for removal & recovery of different gases and recovery of solvents and by-products.

...more

Frp Scrubbing System

For Toxic, Corrosive & Hazardous fumes. Are designed, manufactured, installed & commissioned as per customer's requirements. Made of Fibreglass reinforced plastics, Engineering plastics, Composites and Metals as per customer's needs. Work for absorption, recovery & removal of HCL, SO2, NH3 , H2S, NOx, flue gas, solvents, odours etc. Highly useful for pickling plants, pesticide formulation units, bulk drugs, pharmaceuticals, dyestuffs, chemical processing industries etc.

...more

Filtration Units

In Electroplating, it is necessary that certain corrosive chemicals in the electroplating bath are required to be continuously agitated or operated at high current densities. In such cases, solid particles remain suspended rather than settle at the bottom. These suspended particles cause roughness in plating. In order to remove these suspended particles, continuous filtration of the bath is necessary which is done by Plate Filtration Unit. Plate Filtration Units are engineered to provide absolute and economical removal of suspended solid or organic impurities from the corrosive chemicals. Filtration units are provided with resuable PP filter Cloth along with Filter Paper. Filter Units are also available with PP Filter Cartridges. MODELS AVAILABLE : PFU 200, PFU 300, CFU 300 DUPLEX

...more

Effluent Transfer Pump

Suitable for 3 to 5 mtr. negative suction lift. Fabricated from PPH for higher strength, Top cover makes maintenance easy, Fabricated with in-buift strainer to arrest coarse impurities, Inlet & Outlet size to match pump suction flange size, SPECIAL SIZE AND HIGH CAPACITY POT ON REQUEST.

...more

Dosing Pumps

Accessories : LDPE Tubling Spring loaded injection valve Self balanced Root valve HDPE tank with level swifter Antisiphoning / Back pressure valve Automatic flow controller Applications : Water and Effluent treatment Cooling water treatment Controlled sampling of liquids Antiscalent dosing All pumpable chemicals in processes Positive MeteringThe vital parts in the SC- Series pumps are» HousingThe robust, sturdy housing of our pump is made out of stainless steel, Hastalloy, Cast iron, Titanium etc. The selection of the material depends upon the liquid Characteristics.» StatorIt plays a very important role in the overall performance & life of the pump It is made out of Natural rubber, Neoprine, Nitrile, Viton, PTFE, Hypalon.» RotorNormally hardened and chrom plated or stainless steel. Also rotors can be made out of Hastalloys, PTFE, Titanium depending upon the liquid to be handled.» Universal jointIts a very specially designed so as to offer increased service life with absolutely low replacement cost.Our SC- Series pumps are tested in a highly sophisticated testing arrangement to check the efficiency of each pump.

...more

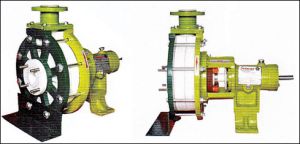

Diaphragm Pumps

Air-operated double diaphragm pumps can move anything from fine chemicals (gentle, non-shearing action), to abrasive and viscous slurries (no close-fitting parts, low internal velocities), and almost any other product that can move. Versatile Performance Can run dry indefinitely without damage. No shaft seals or gland packing. Infinitely variable flow & discharge pressure from 0 to pump's maximum by adjusting air pressure. Gentle non-shearing action. If discharge is clogged or closed pump stops immediately; no power consumed, no heat, no wear. By opening discharge, flow starts automatically. Operates submerged or with flooded suction. Self-priming from a dry start. Pressures up to 100 PSI (7 bar). No close fit, sliding or rotating parts. Low internal velocity reduces wear. Quick assembly/disassembly with split clamp bands. Capable of pumping at high temperatures. Quiet, steady discharge flow without use of pulsation dampener. Safe for use in explosive environments. No electrical hazards or costly motor and control equipment needed. No pressure relief or bypass piping required because pump pressure never exceeds air inlet pressure. Pollution-free operation. The pump even improves air environment in confined areas. Air Operated Double Diaphragm Pumps The air valve directs pressurized air to the back side of diaphragm 1. The compressed air is applied directly to the liquid column separately by elastometric diaphragms. The diaphragm acts as a separation membrane between the compressed air and the liquid. Driving the diaphragm with air instead of the shaft balances the load and removes mechanical stress from the diaphragm, dramatically extending diaphragm life. The compressed air moves the diaphragm away from the center block of the pump.The opposite diaphragm is pulled in by the shaft connected to the pressurized diaphragm. Diaphragm 2 is now on its air exhaust stroke; air behind the diaphragm has been forced out to atmosphere through the exhaust port of the pump. The movement of diaphragm 2 toward the center block of the pump creates a vacuum within chamber 2. Atmospheric pressure forces fluid into the inlet manifold forcing the inlet valve ball off its seat. Liquid is free to move past the inlet valve ball and fill the liquid chamber. Why these Pumps Work Best The heart of the Double Acting Air Operated Diaphragm Pump is the air valve which shifts the air supply to both diaphragms alternately with complete reliability under all conditions of head and flow. The air valve performs this function with a simplicity in design and serviceability. Top Performance in the most rugged pumping jobsPumps give dependable, top performance in the most rugged pumping jobs. Up to 50% solids and over 30 m. are no problem for the Pump.Material of construction Polypropylene Cast Iron Cast Aluminium S. S. 316 FEP/ PFA ( FEP/PFA Lined Pumps) (PTFE) Diaphragms & NRV Balls are offered in different elastomers.Neoprene / EPDM / Nitrile / PTFE / Hypalon Accessories: 1) F.R.L : Air Filter, Regulator and Lubricator are required in Air line to provide clean, moist free air at constant pressure to the pump. FRL also helps to lubricate air valve assembly (connecting shaft and piston). 2) Needle valve in brass.Size available 1/4", 3/8", 1/2".

...more

Corrosive Chemicals Tanks

Fabricated from various thermoplastic, thermoset and composite materials Equipment designed in various sizes as per various international standards Extensively used for storing/processing various toxic, hazardous & corrosive chemicals Expertise available in designing complete acid handling systems with minimum pressure drop required.

...more

Corrosion Resistant Centrifugal Fans

For Processing industries Made of Fibreglass reinforced plastics, Engineering plastics and composite materials as per customer's needs Volumetric flow rates upto 1,00,000 m/ hr and static pressures upto 600 mm WC. For special applications and extreme operating conditions special designs can be developed.POL

...more

Butterfly Valves

Moulded PP Butterfly Valves available with choice of Elastomer Liners like Neoprene, Nitrile, Hypalon depending on application. Excellent for handling acidic effluent. Sizes Available : 3" (75 mm), 4" (100 mm), 6" (15mm), 8" (200mm) Test Pressure : 7.5 kg/cm3 Temperature : upto 65ºC Working Pressure : 4-5 kg/cm2 (G)

...more

Butterfly Dampers

Excellent for ON/OFF Service For Volume Control Balancing For controlling gas & fumes from fume cupboards in chemical laboratories For gas scrubbers and pollution equipment

...more

Basket Strainers

Moulded PP Basket Strainers are available with choice of Elastomer Liners like Neoprene, Nitrile, Hypalon depending on application Excellent for handling acidic effluent. Sizes Available : 3" (75 mm), 4" (100 mm), 6" (15mm), 8" (200mm) Test Pressure : 7.5 kg/cm3 Temperature : upto 65C

...more

Ball Valve

SALIENT FEATURES: Full Port Blow Our Proof Stem Low Torque Floating Ball Mirror Finish Ball Quarter Turn Shut Off 100% Interchangeability Variety of Material of: S.S.ASTM, A 351, GR CF8 (304), CF3 (304L), CF 8M (316), CF3M (316L), CF8C (321) CN7M (ALLOY 20) ASTM 216, GR WCB (CAST STEEL) APPLICATION STANDARDS Mfg. Std. - BS 5351 Testing Std. - BS 5146 Product Range - 15 to 50 mm End Connection - BSP Female End / BSPT / NPT / BSP Female Ends

...moreBe first to Rate

Rate ThisOpening Hours