Wind Driven Turbo Ventilator

As we are much more concerned about the safety of the products, we keep them under a secured environment of our capacious and well-structured warehousing unit that is supervised by experts. We assure you to deliver goods to the desired place, as we have strong distribution network and shipping facilities.

...more

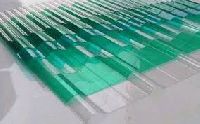

solid polycarbonate sheets

Polycarbonate Sheets are an excellent Roof glazing & cladding material with remarkable properties and performance making them one of the ideal choices for natural light transmitting for Roof glazing, Skylights, Pathways, Bus shelters, Shopping Archades, Canopies, Partitions, Greenhouses, Industrial glazing etc. Polycarbonate sheets are a perfectly ideal medium for use in the Industrial, Commercial, Domestic, Govt. & Leisure Segments. Range Polycarbonate sheets are available in 3 different types, which can be used for various roof glazing application. Transparent Plain Compact Sheets Transparent Plain Embossed Sheets Multi-Wall Sheets Profiles Solid Polycarbonate sheets are available in any matching Customised Profile to meet your requirements. Advantages Light Weight Design Flexibility U/ V Resistance High Impact Strength Excellent Light Transmission High Durability Rust Proof Eco-Friendly Applications Industrial Roofing North Light Parking Area Garages & Verandahs Porches & Walkways Stadium Partition & Window Glazing Domes & Canopies Note : FRP Sheets has all the above advantages with added feature of Shatter Resistance- (FRP Sheets are Hailstorm resistant), Excellent Light Diffusion & Less Heat Transmission with more Freedom in Color & Design.

Material : Polycarbonate

Thickness : 5-10mm

Application : Shedding

Pattern : Plain

Feature : Best Quality, Crack Proof, Easy To Install

...more

Puf Insulated Panels

140 Per Square Feet

Thickness : 50-100mm

Material : PU, Color Steel Sheet

Temperature : -180degC to +140degC

Type : Self extinguishing

Application : Construction Insulation

...more

PUF Panels

Pre-fabricated Composite Panels or Insulated Panels for Roofing & Cladding are Sandwich Panels manufactured with profiled Color Coated Metal - Zinc Coated / Galvalume Coated Steel Sheets or FRP / GRP Profiled Sheets duly Sandwiched with PUF (Polyurethane Foam) as the insulation material.The Panels are available in various colors and total thickness of panel range from 30 mm to 100 mm. The PUF Panels are ready-to-install and self supporting with high overall stiffness. Advantages & Essential Features Very high thermal insulation - Superb thermal efficiency & rigidity. Ready-to-Install and self supporting. Inner and outer skin in Pre-coated GI / Galvalume / FRP Sheets are resistant to extremes of Weather & corrosion. Very light weight to high strength ratio. Ease of handling & installation. For Roofmg & Cladding provision of specially designed overlap system to ensure water leak proof & airtight joints. Vertical & horizontal Panels are provided with Tongue & groove joints to ensure air tight assembly. Monolithically Constructed Panels, hence saving on support structure, no use of wire mesh or loose insulation / Glass wool to be fixed separately and ease of handling & installation with less of labour. Withstand against storm, heavy rainfall, wind. Sturdy enough for temperature (-180°C to +140°C). Fire retardant and Self extinguishing. Low maintenance. Applications Industrial Building & Sheds - Automobile, chemical, steel, cement, power plants, pharamaceutical, commercial building, godown, etc. Telecom Shelters Cold Storage & rooms. Pre-fabricated Shelters / Defense Shelters. Range of Insulated Composite Panels Insulated Roofing & Cladding Panels for pitched Roofs with minimum slope of 7 - 8%. Insulated Roofing & Cladding Accoustic Panels. Insulated Wall Panels with Tongue & Groove jointing system for use in Industrial, commercial, refrigerated rooms & Cold Storage. Fixing accessories like flashings, corner joints and customized fittings. Insulated Wall Panels with Tongue & Groove jointing system for use in Industrial, Commercial, Refrigerated Rooms & Cold Storage : Insulated with PUF and are self supporting panels for use in Industrial Building Partition, Telecom. Shelter, Cold Storage, Defense Shelters, Porta Cabins, High Altitude Cabins,' Commercial Buildings etc.The Panels are provided with tongue and groove systems for jointing Air tight system. Fixing accessories like flashings, corner joints and customized fittings : All the above panels are available in required thickness as per customers requirements and site conditions. All necessary standard accessories are provided for proper fixing & erection of complete system. Specification Density - 40 ± 2 Kgs m3 Compressive Strength at 10% deformation - 2.1 Kgs/cm3 Tensile Strength - 4.0 Kgs/cm2 Bending Strength - 4.2 Kgs/cm3 Adhesion Strength (Foam to Steel) - 3.0 Kgs/cm2 Dimensional Stability (48 hours) - -25°C 0.1% +38°C & 90% RH 0.1% + 100°C 0.4 Closed Cell Content - 90-95% Temperature Range - -180°C to +140°C Temperature Conductivity at 0°C (design value 0.020 k Cal/m-hr/°C or 0.023 w/m - 0.018k Cal/m-hm/°C k) Water Absorption - 0.2% volume at 100% RH Vapour Permeability (At 90% RH & 38°C) - 0.8/0.12 GMS/HR m2 as per IS 11239 Fire property extent to burn as per BS 4735 - Max. 100 mm Type - Self extinguishing

Material : PUF

Shape : Plain

Application : Roofing

Thickness : 0.5-1mm

Finishing : Polished

Feature : Corrosion Resistant, Durable, Good Quality

...more

multi wall Polycarbonate Sheets

Polycarbonate Sheets are an excellent Roof glazing & cladding material with remarkable properties and performance making them one of the ideal choices for natural light transmitting for Roof glazing, Skylights, Pathways, Bus shelters, Shopping Archades, Canopies, Partitions, Greenhouses, Industrial glazing etc. Polycarbonate sheets are a perfectly ideal medium for use in the Industrial, Commercial, Domestic, Govt. & Leisure Segments. Range Polycarbonate sheets are available in 3 different types, which can be used for various roof glazing application. Transparent Plain Compact Sheets Transparent Plain Embossed Sheets Multi-Wall Sheets Profiles Solid Polycarbonate sheets are available in any matching Customised Profile to meet your requirements. Advantages Light Weight Design Flexibility U/ V Resistance High Impact Strength Excellent Light Transmission High Durability Rust Proof Eco-Friendly Applications Industrial Roofing North Light Parking Area Garages & Verandahs Porches & Walkways Stadium Partition & Window Glazing Domes & Canopies Note : FRP Sheets has all the above advantages with added feature of Shatter Resistance- (FRP Sheets are Hailstorm resistant), Excellent Light Diffusion & Less Heat Transmission with more Freedom in Color & Design.

Material : Polycarbonate

Color : Multicolor

Pattern : Plain

Feature : Best Quality, Crack Proof

...more

GRP & FRP Roof Panels

BRIEF INTRODUCTION ABOUT (FRP) FIREGLASS REINFORCED PLASTIC FRp is a wonder composite material consisting of fiberglass reinforcement in a matrix of unsaturated polyester resin and outer protective coating with u/v stabilized in built color of your choice having exceptional strength to weight ratio.FRP is generally known for its high strength and resistance to high temperatures, chemicals, bacteria or termite and excellent acoustic insulation. Because of these outstanding properties unlike PVC or wood, it finds its application widely in all spheres of life-Aerospace, railways, chemical industry, marine industry, marine, industry , food industry, automobile industry, building and construction etc. FRP TRANSLUCENT ROOFING SHEETS “Roofing” Machine made FRP Sheets is produced in the most advanced State-Of The Art Continuous Automatic Production Line specially for manufacturing high transparency sheets in various profile. FRP Sheets are single moulded continuous sheets with both side smooth, glossy finish with inbuilt colour of your choice, which are duly “UV” Stabilized for protection against “UV” rays and colour fading .It is widely used for Industrial Roofingo or as Cladding and for covering of fencing of outer Boundary Wall of the building. The sheets provide the natural lighting as required, security & privacy to the enclosures. And the Building. It further provides acoustic insulation to the building/enclousers. FRP MACHINE MADE SHEET WITH ANTI AGEING FILM “Roofing” Made FRP Sheets also comes with Anti-Ageing Film embedded on thetop during online production process and become part of the Sheet Which can not be removed even with Force.This Anti-Ageing Film on the top gives extra protection to FRP Sheet from extremes of weather, UV radiation and protectsfrom any kind of abrasion. The life of FRP Sheet gets enchaced by 5-7 years with Application of with Anti-Ageing Film. Range Range of FRP Roofing Sheets Plain Sheets Crinckle/Textured Sheets Corrugated Sheets Industrial Sheets Curved Profile Sheets Note : Above sheets are available in translucent & gelcoated opaque in any colour of your choice and available in 0.6 mm thickness. FRP Sheets are chemical and weather resistant and are highly recommended for roofing & cladding in any Chemical Industry or building situated near to coastal areas. PRODUCTION INCNORPORATION-INDIAN RAILWAYS UNIFIED SOR -2010, CPWD DSR-2007 Applications : Industrial Roofing North Light Glazing Skylights-Industrial/Domestic Parking Areas Walk Ways Chemical Plants-Roofing/ Partition/Slide Cladding /Paneling Garages / Verandah /Proches Stadium /Swimming Pool / Railway Station Window Glazing Side Wall Cladding Green House Advantages Shatter Resistance Light Weight Maintenance Free Size Flexibility Environment Friendly Excellent Corrosion Resistance Excellent Light Diffusion & Light Transmission Excellent Weather & Temperature Resistance ADVANTAGES OF MACHINE-MADE FRP Roofing Sheet Uniform thickness,color,profile & any transportable length. .Anti-agening U/V Resistant film can only be provided in Machine-Made FRP Roofing sheets which enhance the life of Sheet and can give 15-20 years warranty. Flexible in Sizes and Thickness: FRP Sheeets are custom made sheets and can be made in various sizes, thickness and designs. Matching Profile: FRP Sheets can be made in any matching profiles as required by the customer. Durability : FRP Sheets have very ling life, as these are tough and flexible. Weather Resistant: FRP Sheets are resistant to extremes of weather , as these are waterproof , termite proof , and Acid proof. Provides Day Ligtht: FRP Sheets are translucent and hence provide essential daylight in long industrial sheds. Saves Electricity and Reduce Electricity Bill: FRP Sheets are used for natural day light in long Industrial sheds and provides day light for day work and reduces electricity consumption. No Wastage: A FRP Sheets can be made custom made sizes there is no wastage. Translucent: FRP Sheets are translucent and hence does not allow direct sunlight. However it diffuses light and gives more brightness. Freedom in Colour & Design: FRP Sheets can be made in any colour and in various designs. Fire Retardant: FRP Sheets can be made fire retardant if asked by the customer. Unbreakable: FRP Sheets are crash proof and unbreakable. Light Weight: FRP Sheets are light in weight when compared with weight to strength ratio. Easy To Maintain: FRP Sheets are easy to maintain & repair. FRP Sheets have good thermal & electrical properties. Dimension Stability: FRP Sheets have food dimension stability at high temperature. High Impact Strength: Resist very high impact strength , which is evident by its application in various fields of automobiles, railways, boats, aircrafts and defence etc. Glossy Finish: FRP Sheets can be made in single piece with both side smooth glossy finish and shining surface. No.Fadedness In Colour: FRP Sheets are U/V stabilized hence no or less effect on colors. Provision For Fitting: FRP Sheets have complete provision for fittings and fixtures. Design Versatility. ADVANTAGES OF FRP SHEET OVER OTHER ROOFING& POLYCARBONATE SHEETS FRP Translucent Roofing Sheets are chosen material for roofing, where controlled light transmission is requirerd. As FRP are much stronger & stiffer material duly reinforced with glass fiber compared to other plastics & polycarbonate sheets. The corrugated profile created in FRP is moulded process, whereas in other plastic & polycarbonate weak point . Due to this moulded process in FRP Sheet , it gives better flexural rigidity reducing the deflection under wind, extreme of weathers as well as other incidental loads. Polycarbonate sheets are made generally thicker and in smaller sizes due to les rigidity and they require closer frame supports made of M.S. etc. FRP roofing and domes can be moulded in bigger size covering large spans and are also cost wise competitive with polycarbonate. Most important, polycarbonate sheets being plastic material and co-effiecient of expansion/contraction are not compatible with PED/M.S. structure, hence over a period of ltime tends to warp & also become brittle in the extremes of weather conditions. Properties Excellent Corrosion resistant from all kind of water, alkaline, coastal environment, chemical fumes & extreme of weather temperature. Shatter resistance & hailstorm resistant sheet. High Impact Resistant Sheet. Light Weight Unbreakable Dimension Stability even during long period of use. Maintance Fre Thermal insulation:-FRP Sheets inherent advantage of inbuilt Thermal Insulation . Enviroment Friendly. Flexibility in sizes and thickness. Freedom in colour & design. Very long life (Warranty of 5 years against any manufacturing defect.)

Width : Max. 1500mm plain width and 1100 mm

...more

GRP & FRP Wind Driven Turbo Ventilator

Nomenclature : Providing & Fixing of "Rooffit" brand an ISO-9001 Certified Company Wind Driven Turbo Ventilators in desired neck size (21" /24") with anodized aluminum technically designed fins with stainless steel top plate and bottom fixing rings supported with double ball bearing system mounted on monolithically casted matching profile FRP Base Plate in 2 mm thick aerodynamically designedhood, with special UV stabilized inbuilt colour, gelcoat coating to take extremes of weather/ wind velocity and continuous ventilation complete to the satisfaction of Engineer-In-Charge. Application for Hot & Humid Areas : Industrial roofing, skylights buildings, green houses, garages / porches, commercial building, domes & canopy for industrial & commercial building, railways, school, warehouses & residential etc. WIND DRIVEN INDUSTRIAL TURBO VENTILATORS with Matching Fiberglass Reinforced Plastic (FRP) BASE PLATE. Ventilation is simply the process of replacing stale, hot air with clean & fresh air hence providing pleasant working environment. We are pleased to introduce ourselves as the leading manufactures of Wind Driven Industrial Turbo Ventilator with matching FRP Base plate, which enables the fixing & installation of turbo ventilator very convenient under various site conditions. Our Turbo Ventilator and the matching FRP base plate is technically designed to suit the various site conditions and provide maximum exhaust and rotation of air continuously, hence virtually providing pleasant and fresh air for healthy work environment.Our turbo ventilator is so designed having maximum fan blade hence providing optimal exhaust and at the same time is protective towards rain and dust. Features & Advantages No Electricity - Wind Driven Maintenance Free Fresh Air 24 x 365 Days Uniform & Continuous Ventilation Noiseless Installation & Operation Easy to install No Ingress of Rain Water Fits on Any Type of Roof Surface and Gradient Exhaust Stale, Hot, Humid Air and Fumes/ Pollutants Nonstop Healthy Living -Increase in Productivity Environment Friendly Payback Period is Extremely Low - Good Savings Rigid and Technically Designed Frame Construction to Withstand Cyclone, Storm, High Wind Velocity and Twister Turbo Ventilator are made in Aluminum and S.S. hence no Rusting Suitable for any size Industrial, Commercial, Warehouse, Godown building. Applications Automobile Industry Food Industry Textile (Spinning, Twisting, Sizing, Weaving, Dyeing, Knitting, Processing) Chemical Industry Engineering Industry Pharmaceutical Industry Boiler House Restaurants Foundry Generation House Commercial building Public Halls Residence And Many Other Places.

Shape : Round

Application : Industrial Use

Certification : CE Certified

Color : Silver

Voltage : 110V

Automatic Grade : Automatic

Power : 9-12kw

Material : FRP & GRP

...more

Frp Transparent Sheet

FRP is a wonder composite material consisting of fiberglass reinforcement in a matrix of unsaturated polyester resin and outer protective coating with uv stabilized in built color of your choice having exceptional strength to weight ratio. FRP is generally known for its high strength and resistance to high temperatures, chemicals, bacteria or termite and excellent acoustic insulation. FRP Sheets is produced in the most advanced State Of�The-Art Continuous Automatic Production Line specially for manufacturing high transparency sheets in various profile.

...more

Frp Rainwater Gutter

We have cemented our presence in the market by offering high quality lot that is prepared using the best grade material and modern work methodologies. Also, the material is sourced from the genuine vendors only. Only high-grade packaging material has been used for the safe packing of the products. Thus, we make sure that our customers will get only damage-free products from our end.

...more

GRP & FRP Rain Water Gutter

Scope of Work : Supply and sealing of Fiberglass Reinforced Plastic (FRP) Gutter 4mm thick with step jointing of 50mm at site. Nomenclature : Supply of 4mm thick FRP Gutter of "Rooffit" brand an ISO-9001 Certified Company, to be fabricated using two coats of Isopthalic grade UV stabilized Gel coat as top coating giving Glossy smooth surface on the top to take the extreme of weather and temperature followed by reinforcement of Chopped Strand Mat (CSM) and Woven roving (WR) duly impregnated with FRP GUTTERS unsaturated polyester Isopthalic exterior grade UV stabilized resin to form tough VALLEY GUTTER laminate with extra reinforcement of MS strip of size 25 x 3 mm at a distance of EAVES GUTTER 1000 mm c/c starting from one end of the gutter to be embedded with the gutter. The size of each gutter can be provided in 2.0 - 5.0 meters and color of your choice. Advantages of FRP Gutter Single Casted with no Joints: FRP Gutter are casted in one single piece (Monolithically casted) hence leaving no scope for any water, moisture, insects, dusts etc. to seep inside the gutter and pose problem towards maintenance, leakages or bad smell. Only FRP gutter can be made in single piece, unlike M.S., G.I. or asbestos. Maintenance Free - FRP gutter are made with inbuilt color, single piece casting and smooth glossy finish hence practically requires no maintenance except for cleaning with plain cloth once in a while or cleaning with soap water. Moreover, as the gutter is made with inbuilt color, it has very long live without fading of color and requires no repainting over regular interval, unlike M.S. or G.I. Very Long Life - FRP as a material is very tough & rigid and resistant to extreme of weather and there is no aging of the material as a result it retains the same luster, strength and rigidity over a very long period, unlike M.S. or G.I. Resistant to weathering & UV exposure as the FRP gutter are UV stabilized. Corrosion Resistant: Excellent water and chemical resistance - the gutter is constantly exposed to Water, Factory corrosive fumes and chemicals. Ease of Handling - FRP gutter are tough, light weight & scratch proof hence easy to handle, transport & install at site. Ease of Installation - FRP gutter is fabricated as per design and shape required and is provided with inbuilt step for ease of jointing at site. Ease of Repair - FRP as a material can be very easily repaired at site for any local or major damage, if any & more over repaired area is not visible. Good electrical & thermal properties Good aesthetic appeal, strength, durability, waterproof & are termite proof. Good dimensional stability at high temperature unlike MS or GI. Can resist very high impact strength, which is evident by its application in various fields of automobiles, railways, boats, aircrafts and defense etc. Excellent Mechanical, Physical and Biological properties. Advantageous strength / weight ratio and rigidity. Molding size virtually unlimited. Considerable design versatility. Choice of wide range of inbuilt color -maintenance free finishes. Fire Retardant-if required.

Color : Silver

Length : 0.5 - 4 m

...more

frp puf insulated panels

We keep the finished assortment of products in the highly developed and capacious storage unit. This helps us in keeping the products safe and sorted till the final dispatch. We are backed by a team of professionals who are proficient in their respective domains and ensure that the offered lot is meticulously packed. Also, we make sure that only high quality packaging material is used for packaging.

...more

frp plain sheets

Serving the customers with the exceptional range of frp plain sheets, we are well-recognized Suppliers in the field. We are a customer-focused firm and bring a solution that makes us capable to make safe and secure payments. Also, our payment procedure is verified and approved by the authority.

...more

GRP & FRP Opaque Cladding Panels

“Rooffit” offers Opaque FRP Panels for Casing & Covering of Cooling Towers, oater Treatment Plants Roofing/Cladding purpose in Industrial Sheds in replacement of Metal Sheets for Temperature Control as it gives cool working conditions, ideal for Coastal Areas/Mild Corrosive Areas also. Opaque Sheets are produced from advanced continuous automatic production line in required Plain, Trapezoidal or Corrugated Profiles. FRP Opaque Sheet offers excellent performance properties in terms of solar efficiency, exceptional strength to weight ratio, with low thermal expansions and ideal where mild chemical/salt water is used. FRP Opaque Sheets offers excellent acoustic insulation because of these outstanding properties unlike Metal, PVC or PC Sheets, it finds its application widely in Water Treatment Plants, Cooling Plants etc. FRP Sheets are produced in almost all profiles with modern high quality U/V absorbing surface protection which can virtually eliminate long term discoloration.FRP Opaque Sheets can also be produced with Fire Retardant Properties as per IS 6746 with Flammability Rating of UL 94, also as per ASTM E 84.“Rooffit” is one of the BIS (Bureau of Indian Standard) Licence holder for manufacturing of ISI Marked FRP Opaque Panel with licence No. CM/L 9512356116.Range of FRP Opaque Panels : Plain Sheets Embossed/ Textured Sheets Corrugated Sheets Industrial Trapezoidal Profiled Sheets Curved Profile Sheets Features: Length : Any Transportable length from 1.2 Mtr to 11.8 Mtr or more Width : Max. 1500mm Plain Width & 1100mm Profiled/Corrugated Width Thickness : 1.5mm to 4.0mm Color : Any Opaque Color Standards : As per Indian Standard IS : 12866 or Any other International Standard on demand High Mechanical Properties Advantages: Better Temperature control then Metal Roofing & Cladding Sheets Ideal for acoustic purpose Excellent Weather & Temperature Resistance Resistant to Mild Chemicals/Salt Water Fire Retardant Shatter Resistance Light Weight Maintenance Free Size Flexibility Environmental Friendly Hail Storm Resistant Sheets Durable & Long Life Dimensional Stability Applications / Uses For Casing of Cooling Towers and other areas where chemical/salt water is used For Industrial Roofing/Cladding Partitions Wall Panelings False Ceiling

...more

GRP & FRP Coating

Fiberglass Reinforced Plastics (FRP) lining is protective lamination on the desired surface (RCC, MS, WOOD, PLASTICS, etc.) to provide corrosion resistance against water, chemical proofing, high strength, dimension stability, and is known for its ease of application, maintain, and repair. FRP lining is widely used in chemical industries for atmospheric corrosion resistance, weatherproofing, water, chemical proofing, and to maintain the purity of the material stored inside the containers. Further, FRP lining is used for repair and maintenance of wide range of RCC, construction like over head storage tanks, pipe lines, building construction cracks, water/chemical proofing, bridges & flyover constructions cracks etc. which provide not only corrosion resistance but also high strength and dimension stability at low cost and ease of application. The desired reinforcement is given by use of fiberglass, which is available in various ranges and is applied as per requirement and utility. Ranges of fiberglass reinforcement are - CSM, Woven Roving, and Surface mat, Honeycomb mats. For corrosion resistance, water, chemical proofing wide range of resins like Isopthalic, Bisphenol, Vinyl Ester etc. are available and is applied as per requirement. Raw Material used in FRP Lining Glass Fiber-confirming to IS-11551-1986 Glass Fiber Rovings-confirming to IS-11320-1997 Unsaturated Polyester Resin confirming to IS-6746-1994 Cobalt Napthanate (Accelerator) MEKP (Methyl Ethyl Ketone Peroxide)-Curing Agents. N.C. Thinner - for cleaning and surface preparation. Steps for FRP Lining The desired surface to be lined is cleaned properly using iron paper, grinders or sand blasting as required and proper surface is prepared free of water, grease, foreign deposition etc. The surface is checked properly to ensure excellent bonding between the surface & the FRP lining. Once the surface preparation is done, as required, resin coat is applied and allowed to cure. This coat should fill up all the pinholes and the damaged area of the surface. After coating, as desired, fiberglass mat (CSM)- Chopped Strand Mat is then spread on the surface and is wetted with resin and properly brushed to ensure minimum air trapping and good bonding with the surface. Fiberglass layers are applied depending on the thickness to be given. The lamination is allowed to cure. Once the lamination is cured immediately one layer of surface mat (veil) is applied as final layer followed by one resin rich coat of resin for better corrosion resistance. During lining, precaution are taken for proper bonding and if required custom-made arrangements are made like provision of inbuilt M.S/Wooden/aluminum stripe / pegs are provided. Precaution is also taken at the time of surface finish as required and cracks; pits etc. are properly filled during surface preparation. Good workmanship and supervision is of prime importance during execution of job, which needs technical and specialized workers to do the same. FRP lining provides complete leak proofing, corrosion resistance, strength and very good life for virgin material lining as well as for old structures etc.

...more

FRP Gutter

We have cemFRP Gutterented our presence in the market by offering high quality lot that is prepared using the best grade material and modern work methodologies. Also, the material is sourced from the genuine vendors only. Only high-grade packaging material has been used for the safe packing of the products. Thus, we make sure that our customers will get only damage-free products from our end.

...more

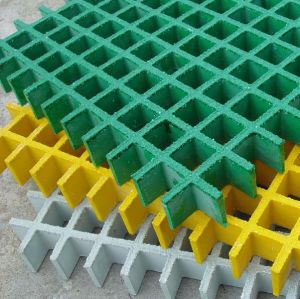

GRP & FRP Gratings

"Rooffit" FRP Grating as compared with other floor materials like Metal, PVC or RCC, provides a series of benefits, unmatched superior impact resistance, while the strength-weight ratio is only one fourth of that of steel gratings. Hence FRP gratings are easy to handle, cut and install and can be customized to customer's requirements as per site condition, utility application and weathering conditions. "Rooffit" FRP Gratings is the ideals solution for corrosion problem faced in industrial environments. The FRP grating is non-conductive of electricity and non--, magnetic, great appearance, ease of installation and Maintenance Free. Types of FRP Gratings Molded Gratings Pultruded Gratings Features Anti-skid top surface UV stabilised Dimensional stability. Excellent electrical insulation properties Easy to handle, store & Install Low thermal conductivity Total elimination of maintenance cost. Corrosion resistant and fire retardant. Suitable for horizontal & vertical layouts Self extinguishable with high level of safety. Excellent temperature & weathering properties. Light weight, Long lasting and maintenance free. Excellent strength weight ratio compare to steel. Minimal distortion and higher mechanical strength. Excellent insulation properties with high impact strength. Excellent physical, mechanical/chemical & atmospheric resistance properties. Applications Flooring Trench & Drain Covers Platforms & Walkways Electrical Cable Trays Stairways, Hand Rails & Ladders Chemical Pipelines Carriage Trays. FRP Cross Aims for Electric Applications. All Load Bearing Structures using FRP Pipe, Angle, Channel & Girders.

Material : FRP, GRP

Shape : Rectangular

Thickness : 5-10mm

Application : Floor Grating

Color : Multicolor

Surface Finishing : Polished

Feature : Fine Finished, Light Weight

...more

GRP & FRP Gel Coated Cladding Panels

Industrial Roofing and Cladding are exposed to extremes of weathering conditions, water, chemical fumes or chemical environment and constant exposure to humid conditions. Under these conditions Roofing & Cladding are prone to corrosion and selection of Roofing material should be done accordingly. Normally, Color Coated Profile Metal Sheets in 0.5 mm thickness are used for roofing in combination with FRP Skylights, FRP Gutter, Turbo Ventilator and Accessories under normal weathering and environmental conditions. In general, Mild Steel are highly corrosive material even under normal environmental conditions but the same is color coated with few microns of weather resistant paints which has very limited self life. But in presence of harsh weathering, chemical fumes or coastal environments, the M.S. Color Coated Profile Sheets are under constant threat of corrosion and not recommended for Roofing taking into consideration of minimum 10 years shelf life. FRP Skylight / Chemical Resistant Sheets is a Fiber Glass Reinforced u/v stabilized unsaturated Polyester resin system composite material consisting of a network of reinforcing glass fibers embedded in a matrix of thermosetting resin. FRP offers almost unlimited possibilities for shape, profile, size and color, which is known for its high resistance to wreathing & environmental corrosion, chemicals, fumes with inherent property of high strength, durability, water, chemical proof, light weight, dimensional stability, aesthetic appeal and easy to install and maintain. Properties & Advantages Excellent corrosion resistant from all kind of alkali, acid, chemical fumes, coastal environment, water and extremes of weather & temperature Superior Tensile Strength - FRP Sheets has very high tensile strength to weight ratio. c. Thermal Properties - FRP Sheets have a low co-efficient of thermal expansion with compatible co-efficient of expansion and contraction vis-a-vis PEB/M.S. Structure. \ Dimensional Stability - FRP Sheets do not shrink or stretch within the limits of their strength even during long period of use Electrical Characteristics - FRP Sheet has high di-electric constants. Considerable Design Versatility - Can be molded to match your profile in any transportable length. Available in Translucent & Opaque as required. Barcoal Hardness, water absorption, Fiberglass content & light transmission as per IS - 12866. Shatter and hail storm resistance sheet. High impact resistant sheet. Light weight and unbreakable. Environment friendly. Flexibility in sizes, color and thickness (as per span of Puffins) Maintenance free, easy to handle and install. Fire-retardant properties if required. Very long life -15-20 years with anti-ageing film.

Material : FRP, GRP

Shape : Rectangular

Application : Roofing Use

Thickness : 0.5-1mm

Feature : Corrosion Resistant, Durable, Good Quality

Finishing : Gel Cladded

...more

GRP & FRP Flashings

High-quality and certified inputs are used for the production of our finished goods. We, as a trusted name, only select the certified vendors for procuring quality raw materials. Assistance from skilled professionals and brilliant packaging unit has enabled us to meet specific requirements of the clients. Besides this, we make sure that the material used for wrapping them is of high quality.

...more

GRP & FRP Fire Resistant Cladding Panels

Industrial Roofing and Cladding are exposed to extremes of weathering conditions, water, chemical fumes or chemical environment and constant exposure to humid conditions. Under these conditions Roofing & Cladding are prone to corrosion and selection of Roofing material should be done accordingly. Normally, Color Coated Profile Metal Sheets in 0.5 mm thickness are used for roofing in combination with FRP Skylights, FRP Gutter, Turbo Ventilator and Accessories under normal weathering and environmental conditions. In general, Mild Steel are highly corrosive material even under normal environmental conditions but the same is color coated with few microns of weather resistant paints which has very limited self life. But in presence of harsh weathering, chemical fumes or coastal environments, the M.S. Color Coated Profile Sheets are under constant threat of corrosion and not recommended for Roofing taking into consideration of minimum 10 years shelf life. FRP Skylight / Chemical Resistant Sheets is a Fiber Glass Reinforced u/v stabilized unsaturated Polyester resin system composite material consisting of a network of reinforcing glass fibers embedded in a matrix of thermosetting resin. FRP offers almost unlimited possibilities for shape, profile, size and color, which is known for its high resistance to wreathing & environmental corrosion, chemicals, fumes with inherent property of high strength, durability, water, chemical proof, light weight, dimensional stability, aesthetic appeal and easy to install and maintain. Properties & Advantages Excellent corrosion resistant from all kind of alkali, acid, chemical fumes, coastal environment, water and extremes of weather & temperature Superior Tensile Strength - FRP Sheets has very high tensile strength to weight ratio. c. Thermal Properties - FRP Sheets have a low co-efficient of thermal expansion with compatible co-efficient of expansion and contraction vis-a-vis PEB/M.S. Structure. \ Dimensional Stability - FRP Sheets do not shrink or stretch within the limits of their strength even during long period of use Electrical Characteristics - FRP Sheet has high di-electric constants. Considerable Design Versatility - Can be molded to match your profile in any transportable length. Available in Translucent & Opaque as required. Barcoal Hardness, water absorption, Fiberglass content & light transmission as per IS - 12866. Shatter and hail storm resistance sheet. High impact resistant sheet. Light weight and unbreakable. Environment friendly. Flexibility in sizes, color and thickness (as per span of Puffins) Maintenance free, easy to handle and install. Fire-retardant properties if required. Very long life -15-20 years with anti-ageing film.

Material : FRP

Shape : Rectangular

Application : Roofing Use

Color : Metallic

Finishing : Polished

Thickness : 0.5 mm

...more

Frp Doors

NOMENCLATURE FRP Door Shutter - Panel Type : Supply & fixing of factory made 30mm thick Fiberglass Reinforced Plastic (FRP) paneled door shutter of required colour of "Rooffit" brand or equivalent an ISO-9001 Certified Company, made with fire-retardant grade unsaturated polyester resin, moulded to 3mm thick FRP laminate for forming hollow rails and styles, with wooden frame and suitable blocks of seasoned wood inside at required places for fixing of fittings, cast monolithically with 5mm thick FRP laminate for panels and conforming to IS: 14856 - 2000 including fixing to frames complete as per direction of Engineer-In-Charge. FRP Door Shutter : Flush Type Providing & fixing of factory made 30mm thick Fiberglass Reinforced Plastic (FRP) flush door shutter in different plain colour of "Rooffit" brand or equivalent an ISO-9001 Certified Company, made with fire retardant grade unsaturated polyester resin, moulded to 3mm thick FRP laminate all around, with suitable wooden blocks inside at required places for fixing of fittings and polyurethane foam (PUF) / Polystyrene foam to be used as filler material throughout the hollow panel, casted monolithically with testing parameters of FRP laminate confirming to table-3 of IS : 14856 : 2000, complete as per direction of Engineer-in-charge. FRP Door Frame : Providing and fixing of factory made Fiberglass Reinforced plastic (FRP) Door Frames of "Rooffit" brand or equivalent an ISO-9001 Certified Company, having three legged of cross-section 90mm x 45mm having single rebate of 32mm x 15mm to receive shutter of 30 mm thickness. The laminate door frame molded with fire retardant grade unsaturated polyester resin and chopped mat. Door frame laminate shall be 2 mm thick and shall be filled with suitable wooden block in all the three legs. The frame shall be covered with fiberglass from all sides. M.S. stay shall be provided at the bottom to steady the frame.

Material : Frp

Thickness : 20-25mm

Certification : ISI Certified

Application : Garage, Mall, Office, Shop

Grade : ASTM, DIN, GB

Color : Multicolor

Technics : Cold Drawn

Surface Finishing : Powder Coated

...more

Frp Door Frame

The Frp Door Frame, supplied by us, is produced using top-grade fiber-reinforced plastic, which is extremely strong. The door frame has a smooth and lustrous surface and is acclaimed for being waterproof. Our door frames are available in different sizes, as desired by the customer.

...more

Frp Corrugated Sheets

We are a quality-driven firm and make sure that our offerings are properly kept and processed. For this, we have installed all the in-house storage facility that helps us in meeting bulk and urgent requirements of the clients. Be cash payment or bank transfer, we are capable of making transactions using them all. Worry not! We have organized and maintained database to keep a stern check on the transactions made.

...more

GRP & FRP Corrosion Resistant Cladding Panels

Industrial Roofing and Cladding are exposed to extremes of weathering conditions, water, chemical fumes or chemical environment and constant exposure to humid conditions. Under these conditions Roofing & Cladding are prone to corrosion and selection of Roofing material should be done accordingly. Normally, Color Coated Profile Metal Sheets in 0.5 mm thickness are used for roofing in combination with FRP Skylights, FRP Gutter, Turbo Ventilator and Accessories under normal weathering and environmental conditions. In general, Mild Steel are highly corrosive material even under normal environmental conditions but the same is color coated with few microns of weather resistant paints which has very limited self life. But in presence of harsh weathering, chemical fumes or coastal environments, the M.S. Color Coated Profile Sheets are under constant threat of corrosion and not recommended for Roofing taking into consideration of minimum 10 years shelf life. FRP Skylight / Chemical Resistant Sheets is a Fiber Glass Reinforced u/v stabilized unsaturated Polyester resin system composite material consisting of a network of reinforcing glass fibers embedded in a matrix of thermosetting resin. FRP offers almost unlimited possibilities for shape, profile, size and color, which is known for its high resistance to wreathing & environmental corrosion, chemicals, fumes with inherent property of high strength, durability, water, chemical proof, light weight, dimensional stability, aesthetic appeal and easy to install and maintain. Properties & Advantages Excellent corrosion resistant from all kind of alkali, acid, chemical fumes, coastal environment, water and extremes of weather & temperature Superior Tensile Strength - FRP Sheets has very high tensile strength to weight ratio. c. Thermal Properties - FRP Sheets have a low co-efficient of thermal expansion with compatible co-efficient of expansion and contraction vis-a-vis PEB/M.S. Structure. \ Dimensional Stability - FRP Sheets do not shrink or stretch within the limits of their strength even during long period of use Electrical Characteristics - FRP Sheet has high di-electric constants. Considerable Design Versatility - Can be molded to match your profile in any transportable length. Available in Translucent & Opaque as required. Barcoal Hardness, water absorption, Fiberglass content & light transmission as per IS - 12866. Shatter and hail storm resistance sheet. High impact resistant sheet. Light weight and unbreakable. Environment friendly. Flexibility in sizes, color and thickness (as per span of Puffins) Maintenance free, easy to handle and install. Fire-retardant properties if required. Very long life -15-20 years with anti-ageing film.

Material : FRP

Shape : Rectangular

Application : Roofing Use

Thickness : 0.5 mm

Feature : Corrosion Resistant, Durable, Good Quality

Finishing : Polished

...more

FRP Cladding

We properly package our products using premium supplies and ultramodern technologies to make sure they endure shipping, handling, mechanical damages etc. We provide customized packaging solutions. Buyers can rest assured; the delivery of consignments will be done within the stipulated time. Our products can be ordered in bulk as well as in retail.

...moreBe first to Rate

Rate ThisOpening Hours