Zirconia Ball

We are well reckoned as one of the major Ceramic Hybrid Ball Bearings Exporters based in India. Our Ceramic Ball Bearing is comprised of an outer and inner ring that is manufactured from high quality steel. Providing excellent performance, our Full Ceramic Ball Bearing is anti abrasive and non corrosive in nature. Ceramic Ball (Product Introduction) Material: silcon nitride (Si3N4), zirconia (ZrO2), and alumina (Al2O3) Specification: 1/64"~ 3/2", with different gauge. Precision : G3 ~ G20 Usage: for bearing, inspection, and other rolling conditions. Capacity: 3 million pcs/month for 5/32" silicon nitride ball Ceramic ball specialties compared with steel ball : Lighter than steelLarger clastic modulusLower friction coefficient, rolls more freelyLower coefficient of thermal expansionSuperior surface finishHigher high-temperature hardnessNever rust, and can roll without oil or greaseCorrosion resistant than steel Bearing Class We produce FULL CERAMIC BEARING and CERAMIC BALL BEARING Full ceramic bearing means the inner ring, out ring, and ball are composed of ceramic materials including zirconia and silicon nitride. Ceramic ball bearing, also named hybrid bearing, means the ball is ceramic, while the out ring and inner ring are steel. Ceramic ball bearing could have identical structure with steel bearing. Properties advantage, compared with metal bearing Higher limit speed: ceramic is lighter than steel, and can effectively restrain the centrifugal force, therefore enhances the limit speed.Higher precision usage: ceramic has higher hardness and elastic modulus than steel, which means ceramic bearing is stiffer, more rigid than steel bearing, thus can be used in higher precision condition.Longer life: lighter ceramic leads to lower centrifugal force, thus extends bearing life. Furthermore, friction coefficient of ceramic is lower than steel, which also extends bearing life.Higher temperature usage: ceramic is more mechanical stable at elevated temperature, thus could be used under higher temperature.Temperature-variation usage : ceramic has a lower thermal expansion coefficient, thus the clearance and the tolerance variation is lower than those of steel bearing, which leads to a large temperature-variation range usage of ceramic bearing.Better seizure resistance: ceramic has smaller thermal expansion coefficient, indicating less thermal deformation, thus enhance seizure resistance.Could run without oil or grease : ceramic never rusts and is self-lubricated, thus can be used in situation that requires no oil or greasc.Resistant to acid, alkai and salt: chemical industry is the largest potential application industry of ceramic bearing to eb exploited.More suitable for maganetic application: our ceramic bearing is non-magnetic, which means it is diffucult for magnetic particle to adhere on the race, thus reducing particle-abrasion. Ceramic ball bearing is especially outstading in above first three items, while full ceramic bearing is outstanding in other items. Full silicon nitride bearing is more superior than full zirconia bearing. It can endure higher temperature, and is more resistant to acid, alkai and salt. Usage For rough service environment, such as chemical, metallurgy, food, electric, medical industry etc. Our bearing products have been used as high-speed motor spindle bearing, high-precision machine spindle bearing, dental drill bearing, high speed wheelhead bearing, fishing bearing, etc. Retainer Material: PTFE, NYLON, PEEK, stainless Steel or without retainerPrecision: PO for full ceramic bearing and PO~P4 for ceramic ball bearingMajor bearing series: deep groove ball bearing, angluar contact ball bearing, and thrust ball bearing.

...more

Warning Light

1,500 Per Piece

Universal Joint Cross Shaft

We are instrumental in the manufacturing of premium quality Universal Joint Cross Shaft. Our Universal Joint Cross Shaft is known for its efficient and reliable transmission. These Universal Joint Cross Shafts exhibit great strength and render long life. It also withstands high tensional pressures, while rendering maximum performance. Technical Specifications

...more

Universal Joint

The assistance of our sophisticated packaging system and skilled personnel, we are able to meet the standard as well as customized packaging requirements of the clients with ease. For the convenience of customers, we issue an invoice to them including details of transaction. Moreover, we maintain transparency in our payment procedure and dealings.

...more

UC-205-Ball Bearings

We are well reckoned as one of the major Ceramic Hybrid Ball Bearings Exporters based in India. Our Ceramic Ball Bearing is comprised of an outer and inner ring that is manufactured from high quality steel. Providing excellent performance, our Full Ceramic Ball Bearing is anti abrasive and non corrosive in nature. Ceramic Ball (Product Introduction) Material: silcon nitride (Si3N4), zirconia (ZrO2), and alumina (Al2O3) Specification: 1/64"~ 3/2", with different gauge. Precision : G3 ~ G20 Usage: for bearing, inspection, and other rolling conditions. Capacity: 3 million pcs/month for 5/32" silicon nitride ball Ceramic ball specialties compared with steel ball : Lighter than steelLarger clastic modulusLower friction coefficient, rolls more freelyLower coefficient of thermal expansionSuperior surface finishHigher high-temperature hardnessNever rust, and can roll without oil or greaseCorrosion resistant than steel Bearing Class We produce FULL CERAMIC BEARING and CERAMIC BALL BEARING Full ceramic bearing means the inner ring, out ring, and ball are composed of ceramic materials including zirconia and silicon nitride. Ceramic ball bearing, also named hybrid bearing, means the ball is ceramic, while the out ring and inner ring are steel. Ceramic ball bearing could have identical structure with steel bearing. Properties advantage, compared with metal bearing Higher limit speed: ceramic is lighter than steel, and can effectively restrain the centrifugal force, therefore enhances the limit speed.Higher precision usage: ceramic has higher hardness and elastic modulus than steel, which means ceramic bearing is stiffer, more rigid than steel bearing, thus can be used in higher precision condition.Longer life: lighter ceramic leads to lower centrifugal force, thus extends bearing life. Furthermore, friction coefficient of ceramic is lower than steel, which also extends bearing life.Higher temperature usage: ceramic is more mechanical stable at elevated temperature, thus could be used under higher temperature.Temperature-variation usage : ceramic has a lower thermal expansion coefficient, thus the clearance and the tolerance variation is lower than those of steel bearing, which leads to a large temperature-variation range usage of ceramic bearing.Better seizure resistance: ceramic has smaller thermal expansion coefficient, indicating less thermal deformation, thus enhance seizure resistance.Could run without oil or grease : ceramic never rusts and is self-lubricated, thus can be used in situation that requires no oil or greasc.Resistant to acid, alkai and salt: chemical industry is the largest potential application industry of ceramic bearing to eb exploited.More suitable for maganetic application: our ceramic bearing is non-magnetic, which means it is diffucult for magnetic particle to adhere on the race, thus reducing particle-abrasion. Ceramic ball bearing is especially outstading in above first three items, while full ceramic bearing is outstanding in other items. Full silicon nitride bearing is more superior than full zirconia bearing. It can endure higher temperature, and is more resistant to acid, alkai and salt. Usage For rough service environment, such as chemical, metallurgy, food, electric, medical industry etc. Our bearing products have been used as high-speed motor spindle bearing, high-precision machine spindle bearing, dental drill bearing, high speed wheelhead bearing, fishing bearing, etc. Retainer Material: PTFE, NYLON, PEEK, stainless Steel or without retainerPrecision: PO for full ceramic bearing and PO~P4 for ceramic ball bearingMajor bearing series: deep groove ball bearing, angluar contact ball bearing, and thrust ball bearing.

...more

UC-204 Ball Bearings

We are Well Reckoned as One of the Major Ceramic Hybrid Ball Bearings Exporters Based in India. Our Ceramic Ball Bearing is Comprised of An Outer and Inner Ring that is Manufactured from High Quality Steel. Providing Excellent Performance, Our Full Ceramic Ball Bearing is Anti Abrasive and Non Corrosive in Nature. ceramic Ball (product Introduction) material: Silcon Nitride (si3n4), Zirconia (zro2), and Alumina (al2o3) specification: 1/64"~ 3/2", with Different Gauge. precision : G3 ~ G20 usage: for Bearing, Inspection, and other Rolling Conditions. capacity: 3 Million Pcs/month for 5/32" Silicon Nitride Ball ceramic Ball Specialties Compared with Steel Ball : lighter Than Steellarger Clastic Moduluslower Friction Coefficient, Rolls More Freelylower Coefficient of Thermal Expansionsuperior Surface Finishhigher High-temperature Hardnessnever Rust, and Can Roll Without Oil or Greasecorrosion Resistant Than Steel bearing Class we Produce Full Ceramic Bearing and Ceramic Ball Bearing full Ceramic Bearing Means the Inner Ring, Out Ring, and Ball are Composed of Ceramic Materials Including Zirconia and Silicon Nitride. Ceramic Ball Bearing, also Named Hybrid Bearing, Means the Ball is Ceramic, While the Out Ring and Inner Ring are Steel. Ceramic Ball Bearing Could have Identical Structure with Steel Bearing. properties Advantage, Compared with Metal Bearing higher Limit Speed: Ceramic is Lighter Than Steel, and Can Effectively Restrain the Centrifugal Force, Therefore Enhances the Limit Speed.higher Precision Usage: Ceramic Has Higher Hardness and Elastic Modulus Than Steel, Which Means Ceramic Bearing is Stiffer, More Rigid Than Steel Bearing, Thus Can Be Used in Higher Precision Condition.longer Life: Lighter Ceramic Leads to Lower Centrifugal Force, Thus Extends Bearing Life. Furthermore, Friction Coefficient of Ceramic is Lower Than Steel, Which also Extends Bearing Life.higher Temperature Usage: Ceramic is More Mechanical Stable At Elevated Temperature, Thus Could Be Used Under Higher Temperature.temperature-variation Usage : Ceramic Has a Lower Thermal Expansion Coefficient, Thus the Clearance and the Tolerance Variation is Lower Than Those of Steel Bearing, Which Leads to a Large Temperature-variation Range Usage of Ceramic Bearing.better Seizure Resistance: Ceramic Has Smaller Thermal Expansion Coefficient, Indicating Less Thermal Deformation, Thus Enhance Seizure Resistance.could Run Without Oil or Grease : Ceramic Never Rusts and is Self-lubricated, Thus Can Be Used in Situation that Requires No Oil or Greasc.resistant to Acid, Alkai and Salt: Chemical Industry is the Largest Potential Application Industry of Ceramic Bearing to Eb Exploited.more Suitable for Maganetic Application: Our Ceramic Bearing is Non-magnetic, Which Means It is Diffucult for Magnetic Particle to Adhere On the Race, Thus Reducing Particle-abrasion. ceramic Ball Bearing is Especially Outstading in Above First Three Items, While Full Ceramic Bearing is Outstanding in other Items. full Silicon Nitride Bearing is More Superior Than Full Zirconia Bearing. It Can Endure Higher Temperature, and is More Resistant to Acid, Alkai and Salt. usage for Rough Service Environment, such as Chemical, Metallurgy, Food, Electric, Medical Industry Etc. Our Bearing Products have Been Used as High-speed Motor Spindle Bearing, High-precision Machine Spindle Bearing, Dental Drill Bearing, High Speed Wheelhead Bearing, Fishing Bearing, Etc. retainer Material: Ptfe, Nylon, Peek, Stainless Steel or Without Retainerprecision: Po for Full Ceramic Bearing and Po~p4 for Ceramic Ball Bearingmajor Bearing Series: Deep Groove Ball Bearing, Angluar Contact Ball Bearing, and Thrust Ball Bearing.

...more

Twin Shaft Concrete Mixer

Signet International is a well acclaimed Manufacturer, Exporter, and Trader of Twin Shaft Concrete Mixer. Our Twin Shaft Concrete Mixer is equipped with sturdy Hopper, Guardrail, Railway, Discharge mouth, Supporting leg etc. It delivers impressive performance over period of time.

...more

Tower Crane Limit Switch

5,000 Per Piece

Brand Name : Telemecanique

Material : Aluminium

Switch Type : Rotary Gear

Voltage : 220/ 225 V

...more

Tower Crane HRCV Block

60,000 Per Piece

1 Piece (MOQ)

Tower Crane Brake Disc

10,000 Per Piece

Brand Name : Signet

Material : Cast Iron

Packaging Type : Carton

...more

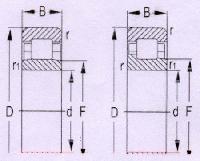

Tapered Roller Bearings

We are staffed with the most up to date machines and cutting-edge technology for the testing of raw material and thus, with without fail we carry out stern quality examinations of the same at the initial stages. From traditional payment methods to modern ones, we are familiar with all of these payment methods. According to the suitability of patrons, we ensure the payment for an order is done conveniently.

...more

SWL Series Worm Gear Screw Lifter

As a pioneering Manufacturer, Exporter, and Trader, Signet International presents superior quality SWL Series Worm Gear Screw Lifter. Our Worm Gear Screw Lifter is ideal for low speed and low frequency. Its main components are precision trapezoid screw pair and high precision worm-gears pair. The product is quite economical, compact in design, easy to operate, and needs low maintenance. Due to its low speed and low frequency, the product is suitable for heavy loads. The trapezoid screw has self-lock function, it can hold up load without braking device when screw stops traveling. Note : The braking device is equipped for self-lock, and it can malfunction due to large jolt & impact load

...more

Spherical Roller Bearings

We are enumerated among distinguished Spherical Roller Bearings Manufactures in India. Our vision has made us a world-leader in the delivery of value creating technology to the Spherical Roller Bearings industry. We offer spherical roller bearings at very reasonable prices. The FAG spherical roller bearing is well known for its heavy duty capabilities. It incorporates two rows of symmetrical barrel-shaped rollers which can align themselves freely in the sphered outer ring raceway, thereby providing compensation for shaft deflection and bearing seat misalignment. FAG spherical roller bearings are produced in E-type design depending on their size and series. Bearings of this design have no centre lip on the inner ring. The delivery range of the E-type design bearings can be seen in the tables. The other bearings have a centre lip on the inner ring. FAG spherical roller bearings incorporate a maximum number of large diameter and extra long rollers. The high degree of roller raceway conformity ensures even load distribution and a high load carrying capacity. In cases of exceptionally high loads, for examÂple vibratory applications, FAG manufacture special spherical roller bearings with reduced dimension and radial clearance tolerances. These bearings are suffixed F8G. FAG spherical roller bearings are manufactured with cylindrical or with tapered bore. China Wafangdian GWG Bearing Manufacturing Co., Ltd. are specialized in manufacturing bearings, roller bearing, spherical bearing with strong design capability. GWG Bearings have four factories and three sales offices. The are bearing factory, roller factory, cage factory, forging factory and sales office in Dalian, Wuxi and Ningbo. Wuxi and Ningbo offices mainly serve the domestic markets, and Dalian office serves the international markets. We mainly make medium and large rolling bearings, capability range from medium bearings with inner diameter of 120mm to large bearings with outer diameter of 3000mm. In addition to our GWG brand, GWG Bearings also provide OEM service and supply non-standard products, roller bearing, spherical bearing, bearing spherical, spherical roller bearing, spherical plain bearing, Large Spherical roller bearings, Large diameter Spherical roller bearings, Custom Spherical roller bearings, Large size Spherical roller bearings for special applications. Feature Spherical rollers are put between the spherical raceway on the outer ring and the two grooves on the inner ring for there bearings. Since the center of the arc raceway on the outer ring is the same as the center of the whole bearing arrangement, there bearings are self-aligned and automatically adjust the bending of the shaft and housing and the eccentricity. The bearings can carry radial load and axial load in double directions. The especial radial load carrying capability makes there bearings suitable for heavy load and shock load carrying.

...more

Slewing Drive

25,500 Per Piece

Material : SS

Slewing Bearing

80,000 Per Piece

Material : Stainless Steel

Shape : Round

Outside Diameter : 852 mm

...more

Single Row Taper Roller Bearing

Single Row Taper Roller Bearing

Single Row Cylindrical Roller Bearing

Single row cylindrical roller bearing

Single Row Cylindrical Roller Bearing - 02

Single row cylindrical roller bearing

Single Row Cylindrical Roller Bearing - 01

Single row cylindrical roller bearing

Single Row Angular Contact Ball Bearings

Feature When the single-row angular contact ball bearing is carrying the radial load, they will be a component of force in the axial direction. Therefore it is suggested that two of there bearings be applied in back-to-back or face-to-face arrangements. Single row bearings can carry radial load and axial load in one direction. Double-row angular contact ball bearings have two designs of one outer ring and two inner rings and one outer ring and one inner ring. For the design with one outer ring and two inner rings, the axial clearance is easy to control during machining. Applications These bearings are mainly applied in the machine tool spindles, high-frequency motors, gas turbines, oil pumps, air compressors, printing machines and other installations.

...more

Self Aligning Ball Bearings

1,200 Per Piece

Number of Row : 2

Thickness : Upto 10 mm

Outside Diameter : Upto 220 mm

Shape : Round

...more

SB-02-Slewing Bearings

We have carved a niche as one of the supreme Large Diameter Slewing Bearings Manufacturers based in India. Construction and function of a Slewing Ring Bearing Slewing Bearing consist of an internal external ring (1) and (2) with an integrated raceway system and optional internal or external gear (3). A functional seal (4) protects the raceway system on the upper and lower sides. Slewing Rings are designed for grease lubrication which is carried out via grease nipples (5). In Slewing Rings, the rolling elements (6) carry the loads between the inner and outer ring. The load capacity of the raceway system is determined predominantly by the raceway design, the hardening depth, and the number and size of the rolling elements. Spacers (7) separate the rolling elements and minimize friction and wear. The rolling elements are inserted during manufacture through the filling plug hole (8), retained by the filling plug which is then secured by a pin (9). The force is transmitted to the mounting structure by bolts. Through holes or threaded holes (10) can be provided in the inner and outer rings for these bolts. Inner and Outer Rings (1) (2) The bearing consists of an inner and outer ring made of medium carbon steel. Such as: 42CrMo, 50Mn, C45 and so on. Each includes at least one precision raceway arranged to transfer loads and relative motion from one structure of equipment to the other, the raceways are selectively hardened to the required surface and depth necessary to transit high stresses imposed during operation of the equipment. In one location around the raceway, there is an unhardened area referred to as the hardness gap or soft spot. This area is relieved to minimize the ability of the rolling element to apply stress on it. Only one side of each ring is manufactured to be mated with the supporting structure. One or both rings may include an integral drive mechanism such as gear or sprocket teeth to enable the mechanical advantage necessary to overcome rotational resistance and provide relative motion through the bearing. Gear (3) Slewing ring can be supplied with gear teeth as an integral part of either the inner or outer ring. They are typically a standard full depth or stub involute spur gear having a 20°pressure angle with provision for backlash and confirming to AGMA Q6 quality. However, where required, modifications of the basic tooth forms, pressure angels, and quality can be provided. For assembly purposes, the maximum point of gear runout is identified with paint. Alternative methods may be applied upon request. Seals (4) A seal is included on each side of slewing ring for retention of lubricant and protection of the bearing from dust and small particle contamination. The seals are made of an elastomer material compatible with most general purpose lubricants having mineral oil and greases using lithium or calcium thickeners. If conditions require different sealing, NBF can provide details of additional options upon request. Grease Nipple (5) At least one grease nipple is supplied in one of the slewing ring for periodic lubrication of the raceway and internal components. On designs with integral gear teeth, it is located in non-geared ring. The number supplied typically increases with bearing diameter. More or less may be included upon request. Rolling Element (6) Precision rolling elements enable relative rotation and transmit load between the inner and outer rings. Hardened chrome alloy steel balls or rollers may serve as the rolling elements. They are sized appropriately for the anticipated stresses and closely matched to provide uniform load distribution between the rings and minimize rotational resistance. Spacers (7) Spacers separate the rolling elements and are designed to minimize friction, skidding, and jamming during rotation. These conditions occur as a result of load distribution and distortion of the mounting structures and bearing rings during operation of the equipment. Spacers are generally made of a plastic material compatible with typical lubricants and operating environments. Filling Plug and Pin (8) (9) The rolling elements in slewing rings may be inserted through a hole drilled radially through the non-geared race and then plugged. The plug is retained mechanically with a pin to assure proper orientation is maintained. Mounting Holes (10) The ideal hole pattern for attaching both rings of the slewing ring is a full circle of uniformly spaced through holes. It is recognized, however, that the equipment designer cannot always accommodate this type of arrangement and may require tapped holes and even special bolt patterns in one or both rings for assembly and maintenance reasons. Click Here for More Details

...more

Planetary Concrete Mixer

Signet International brings forth Planetary Concrete Mixer that are the only ones of their type designed and manufactured in India The patented design produces a unique "counter current" mixing action, resulting in a fast, homogeneous mix in as little as 30 seconds. Features Mixing Tank :Steel all welded construction. Floor is 3/8� thick. Drum wall is 3/16� thick. Tank is welded to an I-beam frame with mounting holes. Frame also has lifting lugs for unloading and handling mixer.Liners :Replaceable bolted wall and floor liners of abrasion resistant AR225 (225 Brinell hardness) steel. Floor and walls are 3/8� thick. Optional AR360 (360 Brinell hardness) floor liners are 1/2� thick.Planetary Mixing Cover :Hinged access doors with neoprene rubber gaskets. Six hinged access doors. Doors equipped with over-center draw latches of malleable iron with corrosion resistant coating. Cover is bolted to outside of mixer drum and is rotatable 360 degree.

...more

Nylon Tower Crane Pulley

5,000 Per Piece

Application : Lifting

Material : Plastic

Capacity : up to 10 Ton

...moreBe first to Rate

Rate ThisOpening Hours