Pizza Pasta Sauce making Machine

100,000 Per unit

1 unit (MOQ)

The process of making pizza pasta sauce involves larger-scale equipment and standardized procedures to ensure consistency and efficiency. Here is an outline of the typical process in a factory: Ingredient Preparation: Gather the necessary ingredients in bulk quantities, including canned tomatoes, tomato paste, olive oil, minced garlic, chopped onions, dried herbs, salt, pepper, and any other required ingredients. Ensure that all ingredients are properly stored, labeled, and readily available for the production process. Mixing and Blending: Use industrial-scale mixing equipment, such as large vats or tanks, to combine the ingredients in the required proportions. Automated systems can be used to measure and add the ingredients accurately, ensuring consistency in each batch. Cooking: Transfer the blended sauce mixture to large cooking vessels, such as industrial kettles or steam jacketed kettles. Heat the sauce mixture to a controlled temperature and cook it for a predetermined duration to develop the flavors and ensure food safety. Stirring mechanisms within the cooking vessels help prevent scorching and ensure even heat distribution.

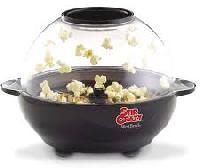

Popcorn Maker

Get Price Quote

Popcorn Maker, Bread Toaster, Home Appliances, oven toaster grillers

Best Deals from Snack Machine

seviyan

Get Price Quote

seviyan, Corn Flakes, chocos power chocolate flakes, Oats, Poha

noodles machinery

Get Price Quote

noodles machinery, Screw Conveyors, Pressure Cookers, plastic blenders

Fryums Making Machine

Get Price Quote

Fryums Making Machine, Fryums

pasta machine

Get Price Quote

pasta machine, Papad Making Machine

Noodles Making Machine

Get Price Quote

Noodles Making Machine, Ro Plant, Fruit Juice Plant

Sweet Corn Machine

Get Price Quote

Sweet Corn Machine, hot dog roller, Cone Baker, Vapa Burner