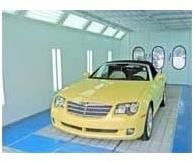

Wood Painting Booth

Buy robust, dimensionally accurate, properly finished and durable Wood Painting Booths from us at market leading prices. Made from corrosion resistant materials, our entire range of Wood Painting Booths is reliable and food-grade. We are one of the eminent Manufacturers and Suppliers of a variety of Wood Painting Booths in India. We provide them in varied specifications and offer customized solutions as well.

Size : 55x40ft, 60x40ft, 65x40ft

Type : Liquid Painting Booth

Thickness : 0-10mm, 10-20mm, 20-30mm

Color : Available in Many Colors

Position : Commercial, Exterior, Garden

Surface Finishing : Polished

Feature : Magnetic Screen, Waterproof

Warranty : 1year

...more

Spray Phosphating Plant

We are reckoned as reliable Manufacturer and Suppliers of Spray Phosphating Plants in India. Compact in design, our Spray Phosphating Plants are widely appreciated for having features like separate weighing of material, rust resistant and high mechanical properties. We manufacture the plants in varied specifications and offer individually tailored solutions as well. Hence, buyers can get Spray Phosphating Plants customized as per requirement.

Type : Phosphating Plant

Application : Keeps Corrosion Free Steel

Certification : CE Certified

Weight : 100-1000kg

Color : Blue

Voltage : 110V, 220V, 380V

Automatic Grade : Automatic

Power : 1-3kw, 3-6kw

Driven Type : Electric

...more

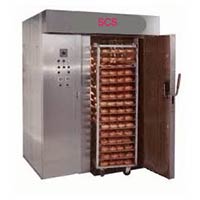

Rotary Ovens

We are leading Manufacturer manufacturer of Bakery Ovens Roatary types and Automatic Chain conveyor Type. We have installed approx. 1000 of the Ovens in Food industries of India Markets like Biscuits, Toasts, Rusks etc.

...more

Pre Treatment Plants

We are engaged in the manufacturing & supplying of Pre Treatment Plants. The Pre Treatment Plants are in great demand at various industries for Powder Coating or Painting process. All the materials, which have to be Powder Coated / Painted, have to be totally cleaned and free from dust, oil, rust, scale and any other impurity on the surface. The process, which is adopted for the above, is known as Pretreatment Process. The process comprises of the seven or eight tank system, the material is to go through different chemical process, and the result is the much-cleaned surface of the metal with protective coat. Details Batch (Hoist Type)/Automatic (Overhead Conveyor/Transporter Type) Complete with Heating Systems and all other accessories Both Type Deep and Spray Type The Seven Stages Are As Follows <liDegreaseing Water Rinse Derusting Water Rinse Phosphating Water Rinse Passivation What is Pre Treatment Process? Pretreatment process is one of the most important and essential part of the Powder Coating or Painting process. As all the materials which has to be Powder Coated / Painted has to be totally cleaned and free from dust, oil, rust, scale and any other impurity on the surface. The process which is adopted for the above is known as Pretreatment Process. The process comprises of the seven or eight tank system and the material is to go through different chemical process and the end result is the totally cleaned surface of the metal with protective coat. The seven stages are as follows : Degreaseing : For removing of oil, dust and any greasy substances. The chemical is basically alkaline and made as 15% Strength in water. The chemical is heated up-to 60 degree. The jobs are then dipped in solution for 5 min and due to Chemical reaction all the dust, oil and greasy substance is removed. Water Rinse : For cleaning and removing the excess detergent. The plain water is in the tank and when the components are dipped, excess detergent is removed and the Components are washed. Derusting : For removing the rust and scale on components. The chemical is basically acidic and a solution of 15% in water is made. The components are dipped for 5-7 min depending on the amount of rust. The components then become virgin and ready for next process. Water Rinse : The excess chemical is washed in the water Phosphating : For giving a adhesive coat on metal. The solution is made of 10% in water. The components are kept in the solution for 5-10 min depending on the Coating required on the jobs. The solution is generally heated up-to 60-70 degree. Water Rinse : For removing excess solution Passivation : For giving a protective coat on the phosphated job. The solution is made of 5% strength. The chemical is heated up-to 60 degree C. The jobs are then dipped in solution for approx 2-3 min and a protective coat comes on the job. After the above process the metal is ready for Painting or Powder Coating. For Aluminium & Brass Components The pretreatment process of the Aluminium and Brass components are different from the MS In above components cleaning procee is is of three stages as follows : Degreasing : To clen the extra oil and grease on the components Water Rinse : To wash out and remove the excess degrees material from the Components Passivation : To make the surface active for the acceptance of Powder However a short cut for the cleaning of MS components are as follows : Degrease Water Rinse Dip in Three in One solution for phosphating and passivation. Then the components are taken , dried and Powder Coated. / Painted For casted or forged components generally they are shot/sand blasted and then powder coated/ painted. However these components are to be coated within one hour of being shot/sand blasting as they are prone to catch the moisture from atmosphere and turn yellow.

Type : Effluent Treatment Plant

Application : Water Recycling

Certification : CE Certified

Weight : 100-1000kg

Color : Available in Many Colors

Voltage : 220V

Automatic Grade : Automatic

...more

Powder Spray Equipment

We are offering powder spray equipment. Acked by a technically trained team of employees, we are engaged in the production & distribution of electrostatic powder spray equipment. Designed & developed by adopting cutting-edge technology, the electrostatic powder spray equipment is much demanded in the global market. We provide the electrostatic powder spray equipment in assorted specifications to cater to the assorted needs of the clients. Highlights in built hv charging systems in barrel assures quick, easy and efficient process enhanced transfer efficiency and reduced wastage due to 100kv built-in electrostatic high voltage generator a powder pathway constructed from wear-resistant material, specially rounded to prevent impact fusion and thus provide a smooth uninterrupted flow. A most easily maneuverable, well balanced and efficient powder coating gun made in a high impact-unbreakable plastic body. We use most advance technology for high voltage generation so that we get : maximum transfer efficiency uniform coating electrostatic powder spray equipment no faraday cage effect trouble free operations the control panel provided on the machine controls the charging voltagepowder out-putair velocity and fluidization of powder. The powder container made in stainless steels, free from the trouble of rusting. The total system is mounted on a movable trolley, so that it can be easily operated any where in the shop. Technical specifications input voltage 230 v + 10 v, 50 hz+ 2% air consumptions 8 cfm at 5 kgcm2 hv out-put 100 kv solenoid voltage 220 v ac hopper capacity 20 kg., 1 no. Fluidizing pressure 3.5 kgcm2 gun 1 no. Gun in-put voltage 220 v ac (max.) polarity negative powder delivery 450 gmmin. (max.)

...more

Powder Spray Booths

The Powder Spray Booths have smooth interior wall surface and anti static panels to minimize the attraction of powder coating, making it more efficient and easy to clean. The Powder Spray Booths allow adequate flow of clean air at breathing level of the operator. We can manufacture, erect, and commission any type of Painting System and Powder Spray Booths on turnkey project basis. We also undertake projects for pre-treatment plant, both- Dipping Type and Spray Type, as well as for Conveyorised and Batch Type Ovens for paint. Powder Spray Booths are manufactured from Mild Steel and Stainless Steel. Why Our Powder Spray Booths? Powder Spray Booths are fitted with quality spray guns and the paint tank The processes such as water wash, dry back, and down draft can be easily carried out in the Powder Spray Booths These booths are used for spray coating different parts with liquid paint The capacity of Powder Spray Booths can be customized as per the client's need The Powder Spray Booths are widely used in plant and machinery industry The durable, efficient, and economical Powder Spray Booths are environment-friendly as well.

Type : Spray Booths

Material : Aluminum

Application : Industrial

Voltage : 110V, 220VC

Finishing : Polished

Heating mode : Electric

...more

Powder Coating Plant

We are a trusted Manufacturer & Supplier of Powder Coating Plant. The Powder Coating Plant is extensively used as surface finishing technique used for Plant and Machinery industry. The precise make of the Powder Coating Plant supports flexible and tough powder coating systems on different equipment. Addition to these, we can also offer Painting soultions on turn key basis to the clients. Details Batch (Monorail/Trolley Type)/Automatic (Overhead/Inverted Conveyor Type) Complete with Spray Equipments, Spray Booths and Curing Ovens Ground and Elevated Type. (Diesel, LPG, CNG, LDO, Electrical, IR Fired Type etc.) Highlights Provided with smooth interior wall surface and anti static panels that minimizes the attraction of powder coating making the booth more efficient and easy to clean Designed to offer adequate flow of clean air at breathing level of the operator Powder Coating Solutions : SFS is best powder coating solutions for spray booths which are been made with the mild steel and stainless steel. Powder coating spray booths are been fitted with the quality spray guns and the paint tank. The processes that can be carried out in these booths are water wash, dry back and down draft. These booths are been used for spray coating the parts with the liquid paint and the capacity can be customized as per the client's need. Powder Coating Systems : SFS offer a wide range of powder coating system for booths plants, which is offered in various specifications as per the different industrial requirements. These effective and efficient systems are durable and cost-effective. Providing the pollution free environment.

Type : Coating Plant

Certification : CE Certified

Weight : 1000-2000kg

Voltage : 110V, 220V

Automatic Grade : Automatic

Power : 1-3kw, 3-6kw

...more

Powder Coating Equipment

Before the final dispatch, we ensure that the products are in accordance to the pre-defined quality standards. Backed by an efficient network and trustworthy resources, we have emerged as a dominant supplier of Powder Coating Equipment in the market.

...more

Painting Plant

To meet varied requirements related to the painting process, we have come up with reliable Painting Plant. A team of skilled professionals puts in the expertise to develop high quality Painting Plant. Offering a highly functional system, we have become one of the leading Painting Plant Manufacturers and Suppliers. The Painting Plant is made available at affordable prices. What We Offer? Spraying equipment Powder coating/spray painting booths Ovens and allied equipment like ASU, conveyor etc. Details Batch (Monorail/Trolley Type)/Automatic (Overhead/Inverted Conveyor Type) Complete with Spray Equipments Spray Booths (Wet/Dry/Down Draught/Side Draught/Water Wash/Water Screen Type) and Curing/Paint Baking Ovens Ground and Elevated Type. (Diesel, LPG, CNG, LDO, Electrical, IR Fired Type etc.)

Type : Liquid Painting Plant

Certification : CE Certified

Weight : 1000-2000kg

Color : Available in Many Colors

Voltage : 110V

Automatic Grade : Automatic

Power : 12-15kw, 15-18kw

Driven Type : Electric

...more

Paint Spray Booths

Buy precision-engineered, optimally functioning and high performance Paint Spray Booths from us at market leading prices. We offer a wide range of Paint Spray Booths. Compact in design and robust in construction, these booths are low maintenance and guarantee high output. Our company makes available Paint Spray Booths as per specifications provided by customers. Interested buyers can purchase Paint Spray Booths from us as per requirement and expect on time delivery of consignments.

Type : Spray Booths

Material : Aluminum

Application : Long Life Span

Application : Car Painting, Furniture Painting, Metal Fabrication

Voltage : 110V, 220VC

Finishing : Polished

Heating mode : Electric

...more

Paint Shops

We are offering paint shops. To meet varied requirements related to the painting process, we have come up with reliable painting plant. A team of skilled professionals puts in the expertise to develop high quality painting plant. Offering a highly functional system, we have become one of the leading painting plant manufacturers and suppliers. The painting plant is made available at affordable prices. What we offer? spraying equipment powder coatingspray painting booths ovens and allied equipment like asu, conveyor etc. Details batch (monorailtrolley type)automatic (overheadinverted conveyor type) complete with spray equipments spray booths (wetdrydown draughtside draughtwater washwater screen type) and curingpaint baking ovens ground and elevated type. (diesel, lpg, cng, ldo, electrical, ir fired type etc.)

...more

Industrial Ovens

We bring forth a range of industrial ovens in india. The industrial ovens are manufactured using hi-grade material as per the international standards. The industrial ovens of the company are known for their compact design, superior quality, and efficient performance. We are counted among the leading manufacturers and suppliers of industrial ovens. The range of industrial ovens includes curing oven and drying oven. The cost-effective and high performing industrial ovens are highly demanded in various industries. We offer industrial ovens at affordable prices.

...more

Lacquering Plant

Buy structurally robust, excellently finished, durable and highly reliable Lacquering Plants from us at competitive prices. Made using premium raw materials that are rust proof, our entire range is of unmatched standards. We are ranked among eminent Manufacturers and Suppliers of Lacquering Plants in India. We offer them in a variety of designs, styles and sizes to meet varied requirements of customer. We offer customized Lacquering Plants for the same as well.

Material : Metal

Application : Industrial

Feature : Durable

Finishing : Polished

Warranty : 2 Years

...more

Industrial Ovens

We are offering industrial ovens. The company is engaged in manufacturing and supplying curing oven in india. Though curing ovens are available in multiple configurations, yet these curing ovens are attuned to set industrial standards. We have the facility to manufacture curing ovens as per the client's specific requirements. The curing ovens are available at affordable prices. Application areas painted components semi-conductor chemicals food pharmacy automobile ancillaries

...more

Garment Dryer

We are counted among renowned Manufacturers and Suppliers of Garment Dryers in India. Available in a variety of specifications, our Garment Dryers are high performance, energy efficient and render long service. They are easy to operate and wash. Buyers can get Garment Dryers from us at market leading prices and place bulk orders as well. Buyers can get customized Garment Dryers from us as well.

Material : Metal

Finishing : Polished

Warranty : 2 Years

...more

Electrostatic Powder Spray Equipment

Backed by a technically trained team of employees, we are engaged in the production & distribution of Electrostatic Powder Spray Equipment. Designed & developed by adopting cutting-edge technology, the Electrostatic Powder Spray Equipment is much demanded in the global market. We provide the Electrostatic Powder Spray Equipment in assorted specifications to cater to the assorted needs of the clients. Highlights In built HV Charging Systems in barrel Assures quick, easy and efficient process Enhanced transfer efficiency and reduced wastage due to 100KV built-in electrostatic high voltage generator A powder pathway constructed from wear-resistant material, specially rounded to prevent impact fusion and thus provide a smooth uninterrupted flow. A most easily maneuverable, well balanced and efficient powder coating gun made in a high impact-unbreakable plastic body. We use most advance technology for high voltage generation so that we get : Maximum Transfer efficiency Uniform Coating Electrostatic Powder Spray Equipment No Faraday Cage effect Trouble Free Operations The Control Panel provided on the machine controls the Charging Voltage/Powder out-put/Air Velocity and Fluidization of Powder. The Powder Container made in Stainless Steels, free from the trouble of rusting. The Total System is mounted on a Movable Trolley, so that it can be easily operated any where in the Shop.

Material : Aluminium

Certification : CE Certified

Application : Industrial

Color : Available in Many Colors

Power : Electric

Feature : Corrosion Resistance, Crack Proof

...more

Dust Proofing System

We offer high quality Dust Proofing System in India. The Dust Proofing Systems are used for purifying the air, surrounding an area, by removing the dust particles, and ventilating the ambient air in the area. The cost-effective Dust Proofing System is highly demanded for industrial use. We offer Dust Proofing System at affordable prices. Highlights Superior quality Compact design Smooth operation Cost-effective

Application : Dust Proofing

Weight : 100-200kg, 200-300kg

Color : Available in Many Colors

Voltage : 110V

Automatic Grade : Automatic

Driven Type : Electric

...more

Drying Ovens

We are offering drying ovens. The company is engaged in manufacturing and supplying curing oven in india. Though curing ovens are available in multiple configurations, yet these curing ovens are attuned to set industrial standards. We have the facility to manufacture curing ovens as per the client's specific requirements. The curing ovens are available at affordable prices. Application areas painted components semi-conductor chemicals food pharmacy automobile ancillaries

...more

Drying Oven

With great pleasure, we offer high quality Drying Oven. The Drying Ovens are known their efficient performance at low production cost. The Drying Oven capably dries and recycles the hot air back to the sealed air chamber, saving time and electricity. We offer Drying Oven at reasonable prices. Attributes High productivity Power-efficiency Low operating cost Easy to install Demanded In Chemical plants Food sector Textile industry

Type : Drying Ovens

Color : Available in Many Colors

Voltage : 220V

Driven Type : Electric

Warranty : 2years

...more

Curing Ovens

For those wishing to purchase reliable and high performance Curing Ovens, we are the best place. Our company is one of the reputed Manufacturers and Suppliers of a comprehensive assortment of Curing Ovens in India. Well-known for their energy efficiency and high capacity, our Curing Ovens are the best. We provide them in bulk and provide exemplary after sales support for it.

Type : Curing Ovens

Certification : CE Certified

Color : Available in Many Colors

Voltage : 110V

Power : 1-3kw

...more

Curing Oven

The company is engaged in manufacturing and supplying Curing Oven in India. Though Curing Ovens are available in multiple configurations, yet these Curing Ovens are attuned to set industrial standards. We have the facility to manufacture Curing Ovens as per the client's specific requirements. The Curing Ovens are available at affordable prices. Application Areas Painted components Semi-conductor Chemicals Food Pharmacy Automobile ancillaries

Type : Curing Ovens

Certification : CE Certified

Color : Available in Many Colors

Voltage : 220V

Power : 3-6kw, 6-9kw

Driven Type : Electric

Warranty : 2years

...more

Ced Plant

Making the judicious use of all the available resources & credentials, we bring forth CED Plant. The Cathodic Epoxy Electro Coating Plant electrically deposits the paint on the metal part or a component by assuring the organic finish. This works on the simple principle of Opposites Attract. Process A DC charge is applied to a metal component immersed in a bath comprising of oppositely charged paint particles. The paint particles deposit on the component to a point where the coating reaches the desired thickness and an even, continuous film is formed over every surface, crevice and corner. On attaining desired thickness, the film insulates, resulting in stopping of attraction between paint particle and the component, thus completing the process. Depending upon the end use, you can choose either protective, decorative or a combination electro coating. What is CED / Electrophoretic Deposition? Electrophoretic deposition (EPD), is a term for a broad range of industrial processes which includes electrocoating, cathodic electrodeposition, and electrophoretic coating, or electrophoretic painting. A characteristic feature of this process is that colloidal particles suspended in a liquid medium migrate under the influence of an electric field (electrophoresis) and are deposited onto an electrode. All colloidal particles that can be used to form stable suspensions and that can carry a charge can be used in electrophoretic deposition. This includes material classes such as polymers, pigments, dyes, ceramics and metals. The process is useful for applying materials to any electrically conductive surface. The materials which are being deposited are the major determining factor in the actual processing conditions and equipment which may be used. Due to the wide utilization of electrophoretic painting processes in many industries, aqueous EPD is the most common commercially used EPD process. However, non-aqueous electrophoretic deposition applications are known. Applications of non-aqueous EPD are currently being explored for use in the fabrication of electronic components and the production of ceramic coatings. Non-aqueous processes have the advantage of avoiding the electrolysis of water and the gas evolution which accompanies electrolysis.

Type : Ced Coating Plant

Certification : CE Certified

Color : Available in Many Colors

Voltage : 110V, 220V, 380V

Driven Type : Electric

...more

Bakery Ovens

We are leading Manufacturer manufacturer of Bakery Ovens Roatary types and Automatic Chain conveyor Type. We have installed approx. 1000 of the Ovens in Food industries of India Markets like Toasts, Biscuits, rusks etc. Biscuit ovens are available for direct and indirect heating, heating by gas, oil or electricity, or as hybrid versions.

Application : For Baking

Weight : 15-20ltrs, 20-25, 25-30ltrs

Voltage : 220-250v

Automatic Grade : Automatic, Fully Automatic

Power : 1-3kw

Driven Type : Electricity

temprature : 0-100°c, 100-200°c, 200-300°c

...more

Bakery Oven

We are ranked among responsive and responsible Manufacturers and Suppliers of a wide range of Bakery Ovens in India. Reckoned for their high-performance and smart sensor technologies, our entire range of Bakery Ovens is precision-engineered, functions optimally and guarantees long service life. It provides uniform heating even after extensive use. Buyers can get Bakery Ovens from us at completive prices and expect timely delivery.

...moreBe first to Rate

Rate ThisOpening Hours