Battery Heating Shock Testing Thermal Shock Test Chamber

23,000 - 30,000 Per Set

1 Set(s) (MOQ)

automatic draught chamber

600,000 Per Piece

Best Deals from Thermal Shock Chamber

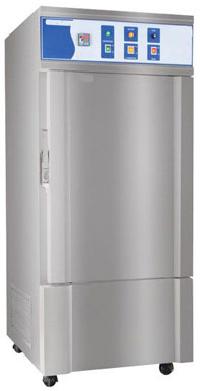

Thermal Shock Test Chamber

Get Price Quote

We are involved in offering an exceptional quality range of Thermal Shock Test Chamber. Our clients can avail these chambers in different grades and dimensions as per their requirement and choice. We offer these chambers the market leading prices. These chambers are designed for safe and hassle-free operations. These chambers offered by us features rugged construction, optimum performance, corrosion resistant finish, low power consumption, shock proof and durable nature.

Thermal Shock Chamber

Get Price Quote

Thermal Shock Test Chamber,Thermal Chamber,Thermal Shock Chamber for High-Low Temperature Rapid Change Test used to test the material structure or composite material in an instant by the extremely high temperatures and very low temperature continuous environment which can endure the degree of order in the shortest possible time to test its thermal expansion and contraction caused by chemical changes physical harm. The applicable the object material, including metals, plastics, rubber, electronic, etc., can be used as the basis of its product improvement of reference. FEATURES Equipment area is divided into three areas: high temperature, low temperature, the test area of three parts, the test product is placed in the test area, the temperature of the high temperature zone or low temperature impact area into the test area impact , test products for Static. Using touch graphic control interface, easy operation, stable, safety The way of impact:Application of air duct switching temperature into test area,do the thermal shock impact test. High temperature shock or low temperature impact, the maximum time up to 999H, the maximum cycle up to 9999 times. The system can be used for automatic cycle engine or manual selective impact shock and cold red hot red initiate and set two or three. Cooling adopt dual refrigeration system, the cooling effect of rapid cooling method for the water-cooled. Can test the impact of RT,perform to meet the standards and test method: GJB150.5;GJB360.7;GB/2423.22

LIQUID TO LIQUID THERMAL SHOCK CHAMBER

Get Price Quote

To observe the product characteristics and failure occurrences caused by different materials and their thermal expansion coefficients, thermal shock testing is subjected to the product. In thermal shock testing alternating high and low temperatures are fed in the chamber. "Liquid-to-Liquid" type thermal shock testing is now attracting attention for its ability to impose higher thermal stress on specimens than "Air-to-Air" type testing, and to deliver test results more rapidly. We offers several configurations of Liquid to Liquid Thermal Shock Test Chamber WEIBER Liquid Thermal Shock Chamber consist of separately controlled hot and cold baths. Designed for single & dual-fluid use. Either single liquid brine or double liquid brine can be selected by simply switching the valve. Automatic shutters at bath inlets. Smooth transfer of specimen Enhanced air tighteness to prevent vapour and brine leakage Microprocessor temperature/humidity programmer. Computer communications, networking, data-logging software. Colour touch panel.

Thermal Shock Chamber

360,000 Per Piece

1 Piece(s) (MOQ)

Description and Application: As we know that thermal shock occurs when a thermal gradient causes different parts of an object to expand by different amounts. This differential expansion can be understood in terms of stress or of strain, equivalently. At some point, this stress can exceed the strength of the material, causing a crack to form. If nothing stops this crack from propagating through the material, it will cause the object''s structure to fail. Normally we use thermal shock test equipment to test how much amount can a product withstand thermal shock. Thermal shock testing exposes products to alternating low and high temperatures to accelerate failures caused by temperature cycles or thermal shocks during normal use. The transition between temperature extremes occurs very rapidly, greater than 15 °C/min. Working Principle: There are three chambers used to perform thermal shock testing, high-temperature chamber, low-temperature chamber and test chamber. Sample is placed in the test chamber, more extreme temperature than test temperature can be set in high-temperature chamber and low-temperature chamber. When doing low temperature testing, cold chamber door open, and low-temperature chamber working together with test chamber. When converted into high-temperature test, cold chamber door closed, hot chamber door are opened, and test chamber working together with high-temperature chamber. Conversion of mechanical action (transferring from high temperature to low temperature or low temperature to high temperature) can be completed in less than 1second, and the temperature can be quickly stabilized. During the whole test, test sample is no need to be moved, and without any human intervention.

thermal shock test chambers

Get Price Quote

thermal shock test chambers, benchtop chambers, dust test chambers