Wet Scrubbers

Wet Scrubbers are effective air pollution control devices for removing particles and/or gases from industrial exhaust streams. Wet scrubbers operate by introducing the dirty gas stream with a scrubbing liquid – typically water. Particulate or gases are collected in the scrubbing liquid. Wet scrubbers are generally the most appropriate air pollution control device for collecting both particulate and gas in a single system. TECOR Group offers a variety of Wet Scrubber systems specifically designed for your process application. Many important operating variables are considered when evaluating the size and type of scrubber for any specific application. We will work with you and use our experience and knowledge to provide the proper solution for your process.

...more

Water Wall Panels

Water wall panels are used in modern day Boilers in place of Steam Generating Tubes to reduceheat loss due to their gas tight nature and reduce insulation costs. We fabricate Water Wall Panels using automatic Fin to tubes welding machines and large Tube Panel Benders to achieve desired shape of panels which can have Swaged Ends, Stub Welded to Headers. We supply Panels with integrated manhole openings in the panels. Water wall panels are used in Waste Heat recovery boilers. We can manufacture 100 MT /Month of panels with required accuracy.

...more

Trima Cyclones

We are a prominent entity, engaged in manufacturing and supplying a comprehensive assortment of Trima Cyclones, which is fabricated at our well-equipped manufacturing unit with the use of modern machines and sound technology. In order to meet the various requirements of clients, we offer our products in various specifications and dimensions. Clients can avail these products from us at market leading prices.

...more

super heaters

Super heater coils are used in a boiler to generate saturated steam. The super heater coils are specially used in Boilers of Power plant. We manufacture Super heater coils in various grades of Alloy steel – T1, T9, T11, T22, T9 & T91 and in stain less steel tubes SS 304, SS310, SS316 and SS 347H with or without support & Header as per customer’s drawing,

...more

Storage Tanks

Storage tanks are available in various specifications & according to customers' requirements we deal with processing storage tanks which includes dairy, food & pharmaceutical hygiene standards. Our storage tanks are highly durable and needs very less maintenance. They are also used in connection with boilers or other independent water heating sources to provide storage capacity to meet peak and normal system demands. Tanks are designed and constructed in accordance with all major codes and standards.

...more

Steam Distribution Headers

We manufacture Steam Distribution Headers of various capacities and temperatures in accordance with steam requirements as specified by our customers.These are customized and IBR or 3rd party inspections required are carried out after the fabrication. Our range includes boiler steam distribution headers, which are of immense importance for various industries like Paper Mills, Sugar Mills, Breweries, and Hotels etc. Our dedicated team has made it possible for us to be a company, which specializes in the manufacture of Steam Distribution Systems over the past 15 years. Steam Distribution Headers Steam distribution headers are fabricated out of carbon steel or alloy steel seamless tubes. Customised or tailor made items are offered. Headers, after fabrication, are stress relieved to make the Steam distribution headers free from stresses. IBR or 3rd party inspection undertaken. Specifications of TECOR STEAM DISTRIBUTION HEADERS:- Made with Seamless pipe/Carbon Steel/Alloy steel etc. as per customer requirement. All material used in production is IBR Certified. Headers manufactured as per customers requirement of steam. Product approved thoroughly by the IBR Department with all the Documents provided to the costumer. These are designed to offer effective and swift solution to steam pressure reduction that matches up with the specific requirements of the customers.

...more

Smoke Tube Boiler with Water Wall Furnace

With a sustained effort, we have become a prime manufacturer, exporter and supplier of a wide assortment of Smoke Tube with Water Wall. These tubes are designed and fabricated keeping in mind all the set quality norms of the industry. The offered smoke tube is made with ultimate precision by making use of top quality factor inputs which are procured from genuine vendors of the markets. Available at reasonable rates, our range of Smoke Tube with Water Wall is best known for features such as high performance, low maintenance, energy efficiency, and so on. Product Features » Horizontal three pass multi tubular boiler. » Manually Fired » Large Grate Area » Large Furnace Volume to ensure proper combustion. » Suitable for all types of industries like Rice, Rubber, Food Processing etc. Operating Range » Capacities: Right from 1 TPH. to 10 TPH » Pressure: 10.54 to 17.54 Kg/cm2 (g) » Firing fuels: Groundnut Shells, Wood chips, and Wood bark, Cow Dung. » Efficiency: Efficiency from max. 82%.

...more

Short Radius Bends

Pressure Vessels

These Pressure Vessels are manufactured as per various codes like ASME, PED, IS, BS, DIN or any other standard as per customer requirement. TECOR Group have excellent welding facilities which include GTAW / FCAW/SMAW & SAW. The entire welding is carried out under expert supervision using world best consumables. All the welding procedures and welders have been approved by renowned inspection agencies We have skilled work force to manufacture quality equipments in different material of construction like carbon steel, stainless steel, duplex steel, Hastelloy, Titanium, Inconel, & many others. the range of pressure vessels manufactured is as follows. At TECOR we have a capacity to fabricate Pressure Vessels as per strict norms of I.B.R in accordance with the requirements of our customers. We offer a wide range of Pressure Vessels. These Pressure Vessel are widely demanded for better quality and effectiveness in various process industries like pharmaceuticals, Chemical producing Units, Solvent Producing Units.

...more

pressure reducing stations

We also offer pressure reducing stations with pressure control systems. High quality components are used which ensure reliability of the system. These are also engineered, designed and fabricated at Forbes Marshall and duly hydrotested before dispatch. Assured accurate consistent downstream reduced pressure irrespective of fluctuations at inlet. Gives more latent heat, which is heat used in industrial equipments resulting in lower fuel consumption.

...more

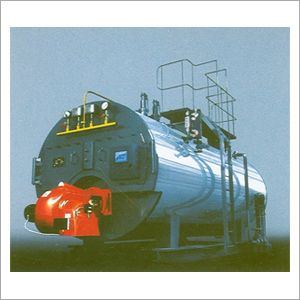

Oil Fired Boiler

We have a well-equipped works to design and manufacture Oil Fired Boilers. These boilers are designed and manufactured with the modern technologies and high quality raw materials, which are procured from the known vendors of the industry. Product Features » Fully automatic three pass packaged Boiler in Dry Back / Fully Wet Back Construction. » Capable of firing fuels like L.D.O/H.D.O/C.N.G and other various oils and gases. » Highly Efficient – 85-90%. » High water holding capacity. » Highly efficient safety alarms. » Suitable for all types of industries like Hospitals, Rubber, Tyres etc. Operating Range » Capacities: Right from 1 TPH to 20 TPH » Pressure: 10.54 to 17.54 Kg/cm2 (g) » Temperature: Up to 75ºC » Firing fuels: LDO, H.D.O, C.N.G, L.P.G, Propane etc. » Efficiency: Maximum efficiency from 85-90%.

...more

Multi Cyclone Dust Collector

We are offering Multi Cyclone Dust Collector that consists of a number of small-diameter cyclones, operating in parallel and having a common gas inlet and outlet. Multi Cyclone Dust Collectors operate on the same principle as cyclones - creating a main downward vortex and an ascending inner vortex. Multi Cyclone Dust Collectors are more efficient than single cyclones because they are longer and smaller in diameter. The longer length provides longer residence time while the smaller diameter creates greater centrifugal force. These two factors result in better separation of dust particulates. Applications : Sugar industry Paper industry Processing industry Food industry Workshops Pharmaceutical industry

...more

Moisture Separators

The compressed air coming out from an After Cooler, contains large quantities of water vapour condensed as a result of cooling of the compressed air. If this is not removed, much of it will be carried to the distribution system and cause extensive damage to all the equipment and processes, which use the air.Apart from water vapour, there is also an appreciable quantity of oil vapour that is formed due to heat and pressure carried along with the air stream is also removed by the separator. Wet steam is steam containing a degree of water, and is one of the main concerns in any steam system. It can reduce plant productivity and product quality, and can cause damage to most items of plant and equipment. Whilst careful drainage and trapping can remove most of the water, it will not deal with the water droplets suspended in the steam. To remove these suspended water droplets, separators are installed in steam pipelines. The steam produced in a boiler designed to generate saturated steam is inherently wet. Although the dryness fraction will vary according to the type of boiler, most shell type steam boilers will produce steam with a dryness fraction of between 95 and 98%. The water content of the steam produced by the boiler is further increased if priming and carryover occur. There is always a certain degree of heat loss from the distribution pipe, which causes steam to condense. The condensed water molecules will eventually gravitate towards the bottom of the pipe forming a film of water. Steam flowing over this water can raise ripples that can build up into waves. The tips of the waves tend to break off, throwing droplets of condensate into the steam flow.

...more

Flash Tanks

At Tecor, We bring forth a comprehensive range of Flash Tanks which is available in assorted specifications and dimensions. Offered products are used to transfer steam from very high temperature condensate prior to introducing into a low pressure lines and to pass condensate prior to returning to the boiler or condensate tank. These products are designed using premium quality raw material and sophisticated technology under the supervision of skilled professionals. Our precious clients can avail the offered products from us at market leading prices.

...more

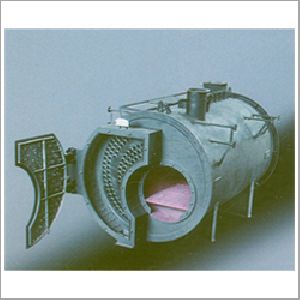

External Furnace Water cum Smoke Tube Boiler

External Furnace Water cum Smoke Tube Boiler with FBC. Banking upon cutting edge technology, we have become a prime manufacturer, exporter and supplier of a wide gamut of Water Wall with FBC. These walls are designed and fabricated under the strict supervision of our adept manpower. These products are widely used in all process industries like textile, rubber, oil, refineries, dyes and intermediates, and food industries. Our range of Water Wall with FBC is best known for features such as highly reliable, efficient, easy to use, cost-effective, and so on. Product Features » Multi Fuel Fluidized Bed Technology. » Membrane design furnace to ensure maximum absorption of radiation heat. » Shell and Water Wall FBC. » Designed with/without Bed coils. » Suitable for all types of industries like Rice, Paper Mills, Solvent Extraction, Food Processing etc. Operating Range » Capacities: Right from 2 TPH. to 15TPH » Pressure: Up to 21 Kg/cm2 (g) » Firing fuels: Rice Husk, Pet coke, Coal Sawdust, Biomass and similar other fuels. » Efficiency: Efficiency from max. 82%.

...more

Economizers

In order to meet the diverse requirements of clients, we are offering a qualitative array of Economiser Casing Panels. Our offered products are fabricated in compliance with the set industrial quality standards. Offered Products are precisely fabricated using the finest grade raw material and advanced techniques. In addition to this, the offered products can also be availed by clients in various specifications as per their varied requirements.

...more

Desuperheating Stations

Our steam pressure reducing station are pre-fabricated manufactured ready to install units for steam system management. The pre-assembled steam pressure reducing stations are individually sized to meet end-user's specific needs.lnlet and outlet piping & valve are sized as per best engineering practices. Each unit is custom engineered and designed to meet specific system requirements.

...more

Deaerating Tanks

We are among the distinguished names in industry, engaged in offering Industrial Deaerators. These systems are used to remove the dissolved gases efficiently from boiler feed water that is a required essential process in any of the steam systems. In the feed water, dissolved oxygen causes localized corrosion in boiler tubes. Carbon dioxide is dissolved in water, which results in corrosive carbonic acid production and low pH levels, which causes acid attack in whole the boiler system in feed water. While low pH levels and dissolved gases in the feed water are easily removed or controlled through adding the chemicals. This thermally and economically efficient system is best to remove the gases mechanically. This whole mechanical process is called deaeration and that help in increasing the steam system's life dramatically.

...more

Coal Wood Fired Boiler

These are high utility and top selling conventional boilers capable of firing various fuels to cater energy needs of many industries. This boiler occupies minimal space and is suitable for industries with space constraints. It is a premiumproduct for the industries looking to produce and utilize steam at low cost with easy operation. Product Features » Manually operated three pass packaged boiler in Dry Back/Fully Wet Back construction with internal furnace. » Capable of firing various solid fuels coal, wood chips, wood bark, bagasse and briquettes. » Highly Efficient » Provided with I.D Fan to induce and maintain the system pressure. » Branded mountings and accessories are provided with the boiler. » Suitable for all types of industries like Rubber, Tyres etc. Operating Range » Capacities: Right from 500 kg/hr. to 5 TPH » Pressure: 10.54 to 17.54 Kg/cm2 (g) » Firing fuels: Groundnut Shells, Wood chips, and Wood bark, Cow Dung. » Efficiency: Efficiency from 78-82%.

...more

Circulation Headers

Circulation Headers form an important part of all types of boilers. Steam from the generating tubes is collected in headers which are therefore always under pressure. This pressure may vary from 300 psi to 2000 psi. Since headers are always under pressure, the utmost care is taken by us while fabricating them. Depending on the generating capacity of the boiler the header sizes fabricated by us vary from 100 mm to 600 mm NB. The stubs of various sizes are very carefully welded to the main body of the header to provide the desired openings from the header.

...more

Boiler Pressure Parts

At TECOR we have facilities of providing our customers with both pressure parts and non-pressure parts. Our list of pressure parts can be seen below. In order to meet the diverse requirements of clients, we are offering a qualitative array of Economiser Casing Panels. Our offered products are fabricated in compliance with the set industrial quality standards. Offered Products are precisely fabricated using the finest grade raw material and advanced techniques. In addition to this, the offered products can also be availed by clients in various specifications as per their varied requirements.

...more

Boiler Drum

The Company is a regular exporter of Boiler Drums. Various Drums have been manufactured till now, with material thickness ranging upto 90mm. Types of Boilers: Process Boilers Waste Heat Recovery Boilers FBC Boilers Hot Air Generator Grate Fired Boiler Slop Fired Boiler

...more

Boiler Bank Tubes

Boiler bank tubes connect Steam and Mud drums in a boiler. Natural circulation occurs with out the aid of any external down comers. First 20-30% rows act as risers and the rest act as down comers. Membrane division wall separates the boiler bank and the furnace. Drum coil heaters are provided in the lower drum to preheat the feed water before sending it to Economizer. We manufacture Boiler bank tubes with or without fins with swaged (reduced diameter) ends are manufactured by us.

...more

boiler non pressure parts

While Non Pressure parts that are fabricated in our workstation are widely used in various industries and are available at most competitive prices. Moreover, these are widely acknowledged by the customers due to their dimensional preciseness, corrosion resistance, less maintenance. Our non-pressure boiler parts can be seen enlisted below. Soot Blowers Screw Feeders Rotary Feeders Grate and Grate Components Drum Internals Chevron type with demister pads Cyclone type

...moreBe first to Rate

Rate ThisOpening Hours