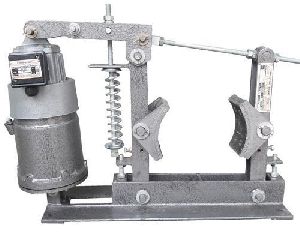

Electro Hydraulic Thruster Brake

Get Price Quote

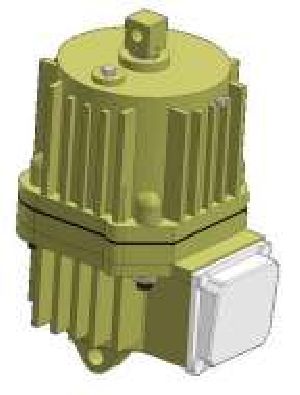

ELOPHY Thrusters

Get Price Quote

Product Code : ELOPHY-1 Short Decription Thrust Capasity:- 23 Kg; Stroke Length: 50mm Availability : In stock

Best Deals from Thrustor Brake

Electro Hydraulic Thruster

Get Price Quote

A wide range of Electro Hydraulic Thruster that we are offering is precisely designed and developed by adroit professionals at our sophisticated manufacturing unit. Our Electro Hydraulic Thrusters work on a principle of hydraulics. They are easy to mount and dismount. Also, they require low maintenance and power consumption. We are an eminent Electro Hydraulic Thruster Manufacturer and Supplier from Delhi (India). We are backed by a huge distribution network that ensures safe and time delivery of our product. Working On supply of electric power, motor driven centrifugal impeller draws the oil from the low pressure end of the chamber to the high pressure upper end. The piston mounted on the same shaft moves to the upper end with full thrust, till its movement is stopped by the stopper shoulder at the end of the stroke. Pressure build up stops when power is discontinued. Radial blade design of the impeller enables it to rotate both in clockwise and anticlockwise direction. Therefore power supply to star connection can be in any R-Y-8 phase sequence. Features Gentle application & release of brake without jerks & shocks Compact unit Constant magnitude Self-aligned movement Low power consumption Minimum maintenance Easy mounting and dismounting Detail Thruster - ST 520 : A compact 90 watt, 415 Volts, 50 Cycles, 3 Phase Electric motor is directly mounted on the top of a piston. The piston is housed in the C.L tank filled with fluid. The piston moves the fluid from low pressure area to high pressure area. The specially designed impeller which is mounted on the motor shaft produces required fluid pressure. Thruster - ST 535 To ST 13300 : This range of thruster has two thrust rods and a common piston. The motor is mounted on the top cover of the tank. A separator plate divides the tank in two partitions- low pressure side. The spacer bushes control the thruster. The models are suitable for large capacity, higher motor rating and larger thruster forces.

Thrustor Brake

Get Price Quote

The brake is applied by the tension of the compressed springs mounted vertically between the thrustor and brake lever. The thrustor rods are connected with the brake by means of an angle lever. As the piston travels upwards the angle lever turns, pushes the brake rod and compresses the brake spring. Simultaneously, the brake lever on the other side of the wheel (Brake Drum) is retracted. The brake lever at the thrustor begins to move when the first lever reaches the stop on the brake base member.

Crane Hydraulic Thruster Brakes

1,300 Per Piece

Thruster Brake 100-18

Get Price Quote

Thrustor Brake

8,000 Per Piece

Thrustor Brakes

Get Price Quote

Since our commencement, we are known for offering a remarkable array of Thrustor Brakes available with us in various specifications. These brakes are a device to hold up the speed of moving machinery and to stop it accurately to the desired position. The braking force is applied to the brake shoe by a pre-stressed compression spring. The shoes press on the rotating brake drum retarding its speed and finally stopping it. The releasing of the brake and compressing of the spring is done by this brake.

Thruster Brakes

Get Price Quote

Thruster Brakes, Cable Carriers, cable trolley, Electric Wire Rope Hoists

Electro Hydraulic Thruster

Get Price Quote

Electro Hydraulic Thruster, air circuit breaker parts

Thruster Brake

Get Price Quote

Thruster Brake, Limit Switches, 240 VAC High Limit Switches

hydraulic thruster

Get Price Quote

hydraulic thruster, Pendant Push Button, radio remote, Current Collector