Vented Extruder Line

We have developed efficient Vented Extruder Line. Our Vented Extruder Line has many salient features to give long & hassle free operation. Our Vented Extruder Line is specially designed for assured high output at low operating costs. The Vented Extruder Line that we offer can be obtained at market leading prices. Attachments With Our Vented Extruder Line : Vented Extruder Line with Die Face CutterVested Extruder with Air Ring and Water Ring Die Face CutterAutomated Pelletizing Lines with Air or Water ring Die Face Cutter, Internal Mixer (Kneaders)Modified Automated Pelletizing Lines with air & Water ring Die Face Cutters for Heat Sensitive Pelletizing Die Face CutterAutomated Die Face CutterPolymers like Ethylene Vinyl Acetate (EVA Injection compound)Automated Pelletizing Line with Die CutterHydraulic Screen ChangerPlastic Compounding MachinesPlastic Recycling MachinePlastic Recycling EquipmentsVented Plastic Extruder LineThermoplastic ExtrusionsRubber Compounding MachinesTwin Screw ExtruderHydraulic Screen ChangerSigma KneadersHigh speed and Slow Speed MixersAgglomeratorsChemical KettleSingle Screw Vented Extruder for NylonScreen ChangersVibratory ClassifiersStrand Palletizers

...more

Twin Screw Extruder

Single Screw Machinery

We are offering a wide a range of Single Screw Machinery, which are known for their many unique features such as :Lines for rigid and flexible pipes and electrical conduit, telelink cable covering sprinkler system, agricultural purpose, water sewage supply chemical gas application in PVC/ PE etcLines for suction hoses, putta pipes, channel small sleeves and tubes in PVC, PE, PP, ABS, Nylon etcAdopt special software for extruderOptimized design of screw to more application raw material characterForced feeding groove, design with reason, temperature adjustableCoupling connect drive unit offer higher powerLowest stress, melt with equality temperature, stability processing condition Extruder & there Attachment are : Single screw extruder 25mm to 150mm screw diameterDie heads in various designsCooling / vacuum tanksCater pillarsAuto Cutting sawAuto chutes High speed mixers, Heating and cooling mixersScrap grindersBi color extruderFeeding extruderAuto coilersTwin screw extrusion lines

...more

screw machine

Rotary Die Film Blowing Machine

Our clients can avail from us cutting edge Rotary Die Film Blowing Machine. Our Rotary Die Film Blowing Machines have the screw and cylinders stems of the extruder made from high quality alloy steel that has nitrogen treatment and precision finishing resulting in optimal hardness and strong corrosion resistance. Our Rotary Die Film Blowing Machines are offered at competitive prices. Characteristics : The auxiliary machine has a plat from working table for easy operation and has bubble stabilizing ringDouble rolling and double-cutting coiling unit adopt torque motor to keep appropriate tension and make even and roll-changing easy Used For Blowing : Various plastic film of low density polyethylene (LDPE)High density polyethylene (HDPE)Linear low density polyethylene (LLDPE) etc used for packing liquid, industrial products garments and textile etc Technical Specifications ModelVLM-55VLM-65VLM-75VLM-90VLM-100Screw Diameter55mm65mm75mm90mm100mmL/D Ratio of screwL/D 26:1L/D 26:1L/D 26:1L/D 26:1L/D 26:1Screw Speed 10-100r/min10-100r/min10-100r/min10-100r/min10-100r/minMax Output50kg/h70kg/h86kg/h100kg/h180kg/hPower of Main Motor15 KW22 KW30 KW35 KW40 KWRotational Mode of Machine HeadContinuous RotationContinuous RotationContinuous RotationContinuous RotationContinuous RotationMax Folding Width of Film800mm1200mm1500mm2000mm2000mmGross Power26 Kw42 Kw56 Kw88 Kw100 Kw

...more

Pvc Wire, Cable Machinery

we are the highly acknowledged manufacturer and exporter of pvc wire and cable machinery, which is the prime manufacturing product of our company. traits : the output specified is on approximate basismade from special alloy steelnitride and honed designed for bearing the pressure of maximum barspiral grooved barrel forced feedingincrease outputguaranteed remarkable stabilitylinearity over the entire speed rangewe can get the 30% to 35% extra on the grooved screw and barrel.semi automatic plant is only with the helical gearbox and ac drives.fully automatic plants included with plc systems, automatic material loading systems, drives synchronizations and many other automatic features.also deals in complete turnkey projects hqes : extruders up to 150mm screw diameter applications at : telephonepowerinstrumentationcontrolbuilding cables etc

...more

pvc pipe machinery

pvc extrusion machine

PVC Blown Film Plant

We are offering of PVC Blown Film Plant, we are offering a featured range of them in the global markets. All PVC Blown Film Plants are designed, and developed to work from raw materials directly to ready film rolls in final sizes lengths and thickness. Lines Main Features : Haul-off unit with a rubber and hard chromium plated cooled rollsWinding unit composed of two hard-chromium plated cooled rollsSingle-screw extruders with special screws designAll cylinders moved individually controlled by frequency invertersInverters linked and synchronized for optimal process controlSpecific blown film dies for PVC, with rotary systemThree phase electric motor controlled by a frequency inverterAir ring specific for PVC blown film Projects for PVC Blown Film Plant : Fully automatic PVC Cling Film PlantFully automatic PVC Stretch Film PlantFully automatic PVC Rigid Film PlantFully automatic PVC Sheet manufacturing plantAutomatic slitting and rewinding systemsAutomatic winders for the PVC film Thickness From : 7 to 100 microns Film Width : Up to 1.500mm Production : Up to 120 kg/

...more

Polypropylene TQ Blown Film Plant

Our Polypropylene TQ Blown Film Plants are highly demanded in the market due to their optimal quality and performance. These TQ Blown Film Plants are used for the manufacturing of Polypropylene films. Our Polypropylene TQ Blown Film Plants are highly efficient and demand low maintenance. Our Polypropylene TQ Blown Film Plants are available at affordable prices. Used For Packaging Of : Readymade garmentsHosieryKnitwearStockingsBlanketsBed-SpreadsSareesTable ClothsBreadCakeBunsDry-fruitsPapadsWafersNutsPopcornsBiscuitsFlowersNursery Seeds Technical Specifications ModelVLM-40VLM-50VLM-50-HVLM-65VLM-65-HScrew Dia (mm)4050506565L/D Ratio26:01:0028:01:0028:01:0028:01:0028:01:00Output (kg/hr)18-2225-3535-5040-6555-80Film Width Range (mm)25-25075-450100-550150-650200-750Film Thickness Range (Micron)18-8018-8018-8018-8018-80Main Drive (kw)3.757.511.251522Nip Roller (mm)400550600700800Roll Winder2 Station Winder AC Motor2 Station Winder AC Motor2 Station Centre Winder Torque Motor2 Station Winder AC Motor2 Station Centre Winder Torque Motor Total Connected Load (KW)1117.5212432Overall Dimension (LxWxH) (Mtrs.)4.5 x 2 x 3.55.5 x 2 x 45.5 x 2.5 x 1.56 x 2.8 x 56 x 2.8 x 5

...more

Plastic Products for Pipe Fittings

We provide premium quality Plastic Products for Pipe Fittings which are manufactured with complete precision. These Plastic Products for Pipe Fittings are made using specially engineered polymers that can endure high temperature and pressure. The Plastic Products for Pipe Fittings come with BSP threads for easy installation and removal. Our range of Plastic Products for Pipe Fittings is resistant to chemicals and other acidic liquids. Our Plastic Products for Pipe Fittings can be customized as per the clients̢۪ specification. Why Our Plastic Products for Pipe Fittings? Made from high quality engineered polymersResistant to abrasive chemicals and acidic liquidLow thermal conductivityCan withstand high temperature and pressureLight in weightEasy to install and removeNon toxic

...more

Plastic Products for Electrical Industry

We offer a wide range of Plastic Products for Electrical Industry that is used in electrical industry. Plastic Products for Electrical Industry come with intricate and complex shapes are designed for household or electrical insulation. Manufactured from the best grade of engineered polymers, our Plastic Products for Electrical Industry have less thermal conductivity and do not melt even at a high temperature. Features : Low thermal conductivityCritical dimensions to avoid assembly issueEasy to install Resistant to abrasive chemicals and acidic liquidResistant corrosion & abrasion

...more

Plastic Products for Commodity Goods

We expertise in manufacturing, supplying and exporting Plastic Products for Commodity Goods and the sizes range from small to medium. These Plastic Products for Commodity Goods are cautiously machined to the precise tolerances with the use of modern machines. Best grade of engineering polymers are used for guaranteed quality and durability. We can design and develop plastic products as per the specifications and drawings provided by the clients. Features : High impact strengthEasy to install and removeLight in weightResistant corrosion & abrasionLow thermal conductivity

...more

Plastic Products for Automotive Light Industry

We bring forth a wide range of Plastic Products for Automotive Light Industry. Our Plastic Products for Automotive Light Industry have various components that make it special. Plastic Products for Automotive Light Industry have back lights, headlight tail lights, parking lights and indicators. These lights are meant to provide better visibility on the roads. The special design of the light allows for easy installation and removal. We make sure that every light is designed to make driving safer. Features : Uniform curvesLow thermal conductivityLight in weightEasy to installBetter illuminationResistant to corrosion & abrasion

...more

Plastic Products for Automation Industry

We specialize in manufacturing, supplying and exporting high quality Plastic Products for Automation Industry. The broad range of Plastic Products for Automation Industry has automatic garage shutter doors that are widely used in factory buildings and garages. Every Plastic Product for Automation Industry is designed to guarantee perfect balance, high dimensional stability and safety of the user. Components of Shutter Door : Control Box: Open, close, stop three buttons control the door separately. The control system is fitted with wiring terminals for photocell, air chamber etcEmergency Stop: Press the emergency stop button on the control box can cut off the power of control unit immediately during emergency and protect people as well as machineRemote Control: Hopping code technology prevents thieves from guessing your remote codeAuto Brake System: It has auto brake system in motor and can achieve fast braking Disengage the release handle (rotate 1800 ãnti clockwise), release the door from the door operator immediately

...more

Plastic Extrusion Machine

P.P. T-Die Sutli Plant

We are the major Manufacturer, Exporter and Supplier of P.P. T-Die Sutli Plants in New Delhi. These P.P. T-Die Sutli Plants are easy to install and are known for high performance. The P.P. T-Die Sutli Plants that we offer are suitable for PP synthetic jute. This P.P. T-Die Sutli Plant has 'T' Die system which is responsible for high production of sutli. There is Auto cheese winder is given in different width of coil as per the requirements. Coil Width : 40 mm50 mm60 mm100 mm150 mm200 mm Screw Diameter : 40 mm50 mm65 mm75 mm Used For : Loose packagingTying of bags as a substitute for jute sutliTwisted rope making Features : Strap sizes from 6 mm to 19 mmModels for manual & heat sealable strapsHydraulically operated embossing unitHigher production plants (min. 20 kg. /hour to 100 kg. /hour)Helical gear box with inbuilt thrust bearing Technical Specifications Plant Model VLM 250 VLM 350 VLM 500 VLM 700 Screw Size (mm) 40 50 65 75 Screw L/d Ratio 26 26 26 26 Feed Section Type Smooth Feed Smooth Feed Smooth Feed Smooth Feed Die Width Type 250 350 500 700 No. of Station Winders 8 12 18 24 Max Production Capacity(kgs per Hour) 15 35 50 70 Total Connected Load(kw) 25 31 43.5 63.8 Main Drive (kw) 7.5 10 15 20 Polymer to Be Processed PP Dimension of Plant in Feet LWHLWHLWHLWH 408845886010870128

...more

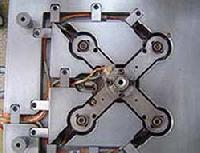

Injection Molding Machine (SHARK PLC Series)

We present efficient Injection Molding Machine (SHARK PLC Series) which has special design that makes the mold process more economical. Our Injection Molding Machines (SHARK PLC Series) are made with the use of modern technology and are easy to operate. These Injection Molding Machines have different features that make them highly demanded in the market. Features : Dual injection cylinders and lower energy consumptionManual mold height adjustmentFrequency conversion technology for low operation cost with best quality of outputBenefit in terms of quantity required for sampling, testing, prototyping, new product design and development or be low-volume batch production Technical Details : The Clamping Systems :Mechanical Structure - Mould Platen & Toggle SetTie Bars- High tensile steel that is hard chrome platedFitted with mechanical ejectorMold Height Adjustment - ManualThe Injection System :Nitriding screw & barrelDual injection cylindersScrew motor fitted is of high torqueDouble Carriage CylinderHopper - Swivel typeInjection unit - Swiveling typeHydraulic & Other Systems :Yuken / Boshch make hydraulic accessories for optimum efficiencyPressure Gauge Reading is done of all FunctionsQuiet operation due to large bore hydraulic hosesYuken/Boshch make hydraulic accessories for optimum efficiencyPre-heating Zone - Pyrometer ControlledPyrometers have digital displayMachine with frequency conversion technology Major Highlights : The frequency conversion technology of the machine allows it regulate the system pressure and flow as per the required working pressure and flow at different stages of molding. The flow & pressure is controlled to match the motor output and its loading capacity. Some of the major effects of the system are : No throttle energy loss and overflow loss is considerably reduced. The noise level lowered by 3-5 decibel25-75% of power savingLonger Hydraulic oil change intervals and enhanced life of the hydraulic sealing parts Longer motor life due to less heating caused by the change from constant high speed running to intermittent running of the motorLower starting power current also plays in important role in dipping the required power supply transformer capacity and stabilizes the power network well

...more

Injection Molding Machine (SHARK FA Series)

We present an advanced model of operationally-proven Injection Molding Machine (SHARK FA Series). These Injection Molding Machines provide larger return on investment with improved productivity and performance. The centralized lubrication system of the Injection Molding Machines ensures proper functioning, whereas the mold height adjustment provides manual adjustment for complete control over the process. Injection Molding Machine (SHARK FA Series) features Yuken / Bosch make hydraulic accessories for a consistent operation. Why Our Injection Molding Machine (SHARK FA Series)? Quality outputLow energy consumptionEnergy efficient variable displacement pump system Technical Details : Mechanical Structure - Mould platen & toggle setThe Clamping SystemInternal Double Toggles - Balanced at 5 pointHigh tensile steel tie bars made up of hard chrome platedCentralized lubrication system for smooth functioningWide space between tie bars & mold height acceptance rangeShot Counter - AutomaticHydraulic Ejector – Branded makeFixed with adjustable boot under moving plateMould Height Adjustment – Manually doneThe components of Injection System includesDual injection cylindersScrew Motor is of higher torque for efficient functioningInjection unit is swiveling typeQuality nitriding screw & barrelHas double carriage cylinderEnergy efficient suck back functioningHydraulic & Others AttachmentYuken / Bosch make hydraulic accessoriesDimensionally accurate swivel hopperAll functions read by pressure gaugeHeating zone controlled by pyrometerPyrometer & timers has digital display for ease of readingLess sound emission due to large bore hydraulic hosesVariable displacement Pump attached for efficient energy saving Major Highlights of the Series : Effective control system for pressure and flowComputer - controlled proportional variable displacement pump system to regulate the pressure and flow in accordance to needed working pressure and flowPressure is adjusted as per the motor output and the loading capacity Major Effects : 25% - 70% of energy savingDelivery cost benefit mainly due to power efficiencySophisticated computer control- no throttle or overflow resulting in loss of energyLower system heating and oil temperature maintenance of the system for prolonged hydraulic oil and seal life Less consumption of cooling water

...more

HM Blown Film Plant

We have developed HM Blown Film Plants through our more than 30 years of experience in extrusion technology. These HM Blown Film Plants are equipped with a number of features like for enhanced functioning and longer service life. Our HM Blown Film Plants have unique design which enables easy handling. These HM Blown Film Plants are available at economic prices. Known For : DurabilityEfficiencyEasy operationHigh output at less operating cost

...more

Dies & Moulds for Pipe Fittings

We have come up with high quality Dies & Moulds for Pipe Fittings with quick connect assembly. These Dies & Moulds for Pipe Fittings are designed with the use of the latest 3D software to get great precision. Every mold is tested under strict industry norms to guarantee enhanced productivity and excellent surface finish. We offer our Dies & Moulds for Pipe Fittings at competitive prices. Available In Different : Dimensional specificationsMaterial specifications Our Dies & Moulds for Pipe Fittings Are Appreciated For : Special cavity surface permits no after treatmentOptimized mold designMinimum eccentricityStrong dimensional stabilityConsistent weight

...more

Dies & Moulds for Pet Preform

Our Dies & Moulds for Pet Preform are made to high standards using the latest technology. These Dies & Moulds for Pet Preform are designed to have a long service life and easy handling. Hardened mold parts with deeply engaging tapers support the lifetime of the mold and reduce maintenance. We provide Dies & Moulds for Pet Preform in different material and dimensional specifications as required by the client. Features : No scratchesHigh surface qualityNo crystallinityFlashless split-linesLow acetaldehyde (AA) levelsStrong dimensional stabilityMinimum eccentricityConsistent weight

...more

Dies & Moulds for Household Appliance

We offer a wide range of Dies & Moulds for Household Appliance. These Dies & Moulds for Household Appliance are widely used for making household appliances like television, refrigerators, washing machine, etc. These Dies & Moulds for Household Appliance have unique design which improves critical distribution of the pressure for excellent finishing. Our Dies & Moulds for Household Appliance can be made a per the client̢۪s specifications. Features : Precision groundWell balancedExpertly honed and finely polishedExcellent dimensional stabilityCNC (Computer Numerical Control) 4 axis machiningCavity surface coated with thin layer of heat resistant material

...more

Dies & Moulds for Hot Runner

We are reckoned as the prominent Dies & Moulds for Hot Runner Manufacturer, Exporter and Supplier in New Delhi. Our Dies & Moulds for Hot Runner are two plate molds with heated runner system in the one half of the mold. Our Dies & Moulds for Hot Runner delivers molded parts of uniform density, which is free from all flash, runners, and gate stubs. We design and develop both insulated and heated runners molds. Our Dies & Moulds for Hot Runner is customized to any dimensions in accordance to the clients̢۪ requirements. Why Our Dies & Moulds for Hot Runner? Low cost / piece - least expensive for large volume productionReduction of energy costsAutomated processing - runners do not need to be separated from the partsGates at the best position for economical designMaterials cost savings - no runner to regrind or reprocessShorter, faster cycle times - no runners to coolSmaller machines - reduced shot volume into runners

...moreBe first to Rate

Rate ThisOpening Hours