Namibind Drum Type Wood Chipping Machine

1,115,000 - 1,650,000 Per piece

Introducing Namibind’s NB 20 Drum type wood Chipper, with its robust design and precision engineering, this wood chipper stands at the forefront of efficiency and reliability in the industry. Measuring 1450mm in width, 1660mm in length, and 1540mm in height, this machine boasts a sturdy construction, weighing between 3.5 to 4 tons. It's built to handle various raw materials, including palm trunk branches, bamboo, pine wood, eucalyptus, sawmill waste, and more. The NB 20 wood chipping machine offers impressive throughput, capable of churning out 2 to 3 metric tons of chips per hour with moisture content, or 1 to 2 tons without moisture. These chips range from 25mm to 35mm in length and 7mm to 10mm in thickness, with customization options available. Efficiency meets power with a 36.5 kW power consumption, driven by a 40 HP drum rotor with direct V-belt drive, a 3 HP feeding belt/infeed roller, and an additional 3 HP pinch/press roller and discharge belt.

Cnc Wood Router Machine

Get Price Quote

1 Piece (MOQ)

Salient Features Integrally Cast Iron Bed Structure, Robust and without distortion. Y axis Double Motor Driving System ensures Stable & Smooth Movement. High Precision Rack Gear Transmission ensures fast speed & High Accuracy. T-slot Alluminium Table with Dust Collector. Leadshine Stepper Motors & Drives. Lubrication System. High Precision Taiwan TBI ball screw. Easy to maintain, cutting surface is smooth, saving time and labor. Standard Accessories Leveling Pads-6 Nos. Tool Kit-1 Set,

Best Deals from Wood Working Machines

sliding table Panel saw machine

30,000 - 120,000 Per Piece

1 Piece (MOQ)

Key Features : Table Saw – WOOD LOG SLIDING TABLE SAW Wood log cutting saw Wood log for pallets and furniture's Log upto 6 x 6 inch can easily cut Slider plate for holding firmly Easy smooth slide Thick MS plate on top with slot for slider

Wood Fired Khoya Machine

65,000 - 75,000 Per piece

1 piece (MOQ)

A Khoya Making machine is a specialized piece of equipment designed to effieciently produce khoya (Aslo known as mawa/milk boiling machine) A dairy product used extensively in Indian sweets. Heating System: Can be powered by various fuels like diesel,gas. Stirring Mechanism:Continuously stirs the milk during the cooking process. Prevend the milk form sticking to the vessel bottom. Ensures even heating and faster evaporation. Working principal: Milk addition Heating Khoya Formationg Cooling and shaping Benefits of khoya making machine :- Increased Efficiency Improved Quality Enhanced Hygiene Cost Efficetiveness Versality khoya making machine in delhi mawa/khoya making machine in delhi mawa making machine in delhi milkboiling machine in delhi

Cnc Wood Cutting Machine

550,000 Per Unit

Cnc Wood Cutting Machine

380,000 - 450,000 Per Piece

1 piece (MOQ)

We are trader of wood router cutting machine, MDF wood router cutting machine, acrylic router cutting machine available Model. Kr1325 single Head

Wood Splitter Machine

150,000 Per piece

Wood Working Machinery

38,000 Per Piece

We are a topmost manufacturer and exporter of quality approved assortment of Wood Working Machine. These products are appreciated for their high performance and long service life.

Wood Working Machines

45,000 Per Piece

Wood Working Machinery

50,000 - 100,000 Per Piece

1 Piece (MOQ)

wood working combined machine for multi purpose function available from 8" - 18".

Plywood Brush Sanding Machine

25,000 Per Piece

Woodworking Spindle Moulder Machine

882,000 Per Piece

Wood Finger Joint Making Machine

65,000 Per Piece

We are accredited for providing faultless array of products. This has become possible owing to the efforts of our quality auditors who strictly check the inputs before procurement. Keeping in consideration the latest standards, we are involved in supplying only high quality Wood Finger Joint Making Machine at reasonable prices.

plywood cutting machine

Get Price Quote

Our clients can avail from us Plywood Cutting Machine, which are manufactured from high grade superiority raw material. Our Plywood Cutting Machine can be availed at industrial leading prices and are extremely demanded in the market.

Cnc Wood Router

Get Price Quote

Stone Carving Cnc Router Machine

Get Price Quote

Wood Chipper Machine

250,000 - 2,000,000 Per piece

1 Piece (MOQ)

CNC Marble Carving Machine

650,000 Per Piece

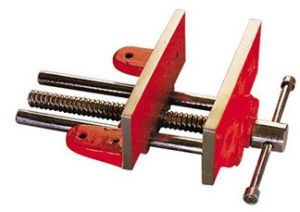

Woodworking Vice WITH STEEL HANDELS

Get Price Quote

Wood Laser Engraving Machine

230,000 - 250,000 Per piece

1 Piece (MOQ)

Get the fully automated co2 laser engraving machine for fast and efficient laser engraving over the leather, acrylic, MDF, wood and similar other non-metallic mateials with higher accuracy.

Wood Turning Lathe

Get Price Quote

Our company is positioned with leading Suppliers in the market, serving customers with the best and finest Wood Turning Lathe. Based in Delhi(India), our organization caters to the numerous requirements of the customers related to our products.

power feeders

24,000 Per Unit

Hydraulic Vacuum Molding Press

600,000 Per Piece

1 Piece(s) (MOQ)

wood screw making machine

Get Price Quote

These cold heading machines are fully automatic and easy to operate with little training, fitted with Solid Die to produce blank for Bolts, Screws, Rivets and other similar components. Cut off and knock out mechanism have safely devices that will stop any major accident if any abnormal function occurs in machines.A positive knock out provision had been made on the 1st and 2nd punches to eliminate the possibility of parts sticking to these punches during the operations. The maximum parts of the machines are ground and all the Cames and Rollers from H.C.H.C. ( Hardened & Ground ).

CNC Pin Router Machine

185,000 Per Piece

Woodworking Multi Boring Machine

Get Price Quote

Associated with a diligent professionals and smart packaging facility, we are capable to undertake standard as well as tailored packaging requirements of the clients. Making available the finest assortment of products, we make sure that the range is kept safe in our inventory in Ahmedabad(India).

wood surface planer machine

Get Price Quote

hydraulic clamp carrier

1,737,000 Per Units

Wood Sanding Machine

Get Price Quote

Wood Chipper Machine

Get Price Quote

Drum chipper is specialized equipment for high-quality biomass sheet processing, which is applied to all paper mills, particle board plants, fiber plants and wood chip production base, wood chip export base. Advantage Available raw material:Wood logs, branches and twigs with moisture more than 15%. Sperical material blade, with high strength and anti-abrasion. Free of any professional tool sharpener, low maintenance cost. Knife roll is wholistic processing and is undertaken dynamic balance test to improve accuracy and stable operation. It can process larger diameter wood with its special structure. Low power consumption, with is 20-30% lower than similar product in market. Feeding system consists of feeding and squeezing parts: Squeezing part is automatic controlled by hydraulic system; PLC controls the whole feeding system to guarantee the smooth feeding. Forging dead plate, with high strength and long service time. Product introduction Production capacity : 4-70 m3/h Range of Application : Wood logs, branches and twigs with moisture more than 15%. Drum chipper is specialized equipment for high-quality biomass sheet processing, which is applied to all paper mills, particle board plants, fiber plants and wood chip production base, wood chip export base. The slicer can cut logs, small diameter wood and other material into high-quality industrial wood chips with uniform length and thickness and flat cut. It can also cut branches, plates, etc.. Working principle The slicer can cut logs, wood branches, slab, waste veneer, bamboo, cotton stalks and other non-wood fiber stalks into certain specification sheet material, which can be material of particleboard, fiberboard, non-wood-based board and paper. It has advantages such as advanced structure and high quality sliced product, strong materials adaptability and easy operation and maintenance. This machine is composed of base, blade roll, upper and lower feed rollers, conveyor belts, hydraulic system and other components. The welded base that made of high strength steel is support of the whole machine. Two fly knives are fixed onto the blade roll by specially manufactured fly knives and pressure blocks. According to different raw material thicknesses, the upper feeding assembly can up and down within certain range by means of hydraulic system. Qualified flakes falling down through the mesh sieve and large flakes will be re-cut in the machine. Technical Parameters