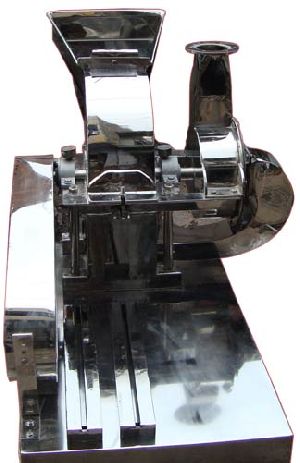

PP Cap Sealing Machine

Ypm offers motorized p.p. Cap sealing machine. motorized p.p. Cap sealing machine is used for pilfer proof capping of bottles. It has a capacity to seal 1500 to 2000 bottles hr. Depending upon the efficiency of the operator, and is complete with bottle resting tray and dies for sealing 22, 25 & 28mm neck bottles. The motorized p.p. Cap sealing machine can be adjusted easily according to the client`s requirement. The body of the machine is cladded with stainless steel sheet. The unit is complete with â½ hp motor and starter, etc.

...more

Volumetric Bottle Filling Machine GMP Model

90,000 Per Piece

The YPM Semi Automatic Volumetric Liquid Filling Machine is precision Built on sturdy Welded frame completely enclose in stainless steel sheet and doors Are provided to facilitate the servicing of machine. Working on volumetric Principle. The unit is made compact, versatile and enclosed in stainless steel Elegantly matt finish body Operation : Containers have to place manually below the filling nozzle at platform of Machine. Where motor operated syringe fill desire pre set volume in container, Bottle guide are provide for precisely match for centering of container below Nozzle, to avoid spillage of liquid on container. The dosing block with a hexagonal Bolt fitted below syringe. This means fill size can be easily set. Motor Required : 1 HP Three Phase motor /415 Volts / 50 Hz. Filling Range : 100 ML -1000 ML Net Weight : 120 Kg. Gross Weight : 275 Kg. Machine Dimension : 650mm (L) x 900 mm (W) x 950mm (H) Salient Features : Semi-Automatic with filling range. ± 1% Filling accuracy on single dose. Three different speeds depending upon capacity of bottles. Body covered with SS304 sheet. All contact parts SS 304 / 316 A unit to fill variety of liquid and can be used for various type of containers. Minimum change over time from one size to another container or fill size. Optional Features : Change parts Extra Storage Tank Extra Utility Requirement : Electrical Supply:- Single Phase + Neutral + Earthing.

Weight : 100-500kg

Type : GMP Model

Warranty : 1 Year

Application : Industrial

...more

Vibro Sifter Machine GMP Model

75,000 Per Piece

Vibro separators are circular unitary gyratory screens used to separate mass composition of solids from solids, liquid from solid and for gradation of materials as per particle size, having a very wide range applications. This is accomplished by vibrating the screens in three different planes along the vertical axis by means of a specially designed vibratory motor having off centered weights at the top and bottom end of the motor shaft. The top weight causes vibration in the horizontal plane which causes the material to move across the screen towards the periphery. The lower weight acts to tilt the machine which causes vibration in the vertical tangential axis. The angle of lead of the lower weight with relation to the upper weight provides variable control of the screening pattern. Thus the material moves across the screens and also in the vertical and tangential planes enabling maximum screening. YADAV PHARMA MACHINERY’ Vibro sifter are available with a wide range of possible screen sizes (mesh) Option for multiple deck separation is also possible. The unit consist of Specially designed vibratory motor to run on 400 / 440V, suitable HP, 3 phase, 50 cycles electric supply ,with adjustable eccentric weights at the top and bottom of the motor shafts mounted vertically at the centre of the base plate of screening unit. Screening unit consists of SS 304 screen sandwiched between SS 304 hopper and bowl with the help of special clamp with gasket. Rugged Springs placed over the circular motor base amplify the vibration and at the same time restrict the vibration from being transferred to the floor.Salient Features : Noiseless, Maintenance free & high speeds Details Available in various models providing screening diameter of 12”, 20”, 30” , 36”, 48”, 72” etc Portable and compact Electric power requirement less than other machine of the kind in the industries & lower energy consumption compared to reciprocating vibratory system Standard machine are with TEFC motor explosion proof / flame proof motor material. All contact parts and screen of SS 304/316 AISI stainless steel material. SS 316 quality contact parts optional. Easy dismantling and cleaning facility for contact parts. Wide range of screen sizes 4-200 Mesh. Double & Triple deck screens with outlet and hopper for bottom deck available on request.

Certification : CE

Weight : 100-1000kg

Color : Metallic

Automatic Grade : Automatic

Power : 1-3kw

Warranty : 1year

...more

Tray Dryer GMP Model

150,000 Per Piece

1 Piece(s) (MOQ)

Model available: 12 trays, 24 trays, 48 trays, 96 trays and 192 traysConstruction The YPM Tray dryer is of robust construction built on formed angles of 3 mm thick sheet and suitably reinforced with angles and sections. The dryer’s external walls are manufactured from 1.6mm thick Stainless Steel sheets of 304 qualities. The internal of the dryer is built of 1.6 mm thick S.S 304 quality sheets. The internal structure is fully TIG welded and all the internals have ground smooth surfaces. It is insulated with minimum 50 mm thick glass wool insulation and Cladded with S. S. Polished sheets. The dryer is having a fresh air inlet through 20 Micron PP cloth filters and an adjustable air outlet flap and a door at the front. The door is explosion proof and is locked with the help of spring loaded ball latches with suitable pressure. Door lips are having Neoprene rubber Gasket to prevent leakages.FinishingThe design and manufacture of the dryer is of high standard of GMP and has an aesthetic look. It is buffed externally to 150 grit matt finish and internally buffed to 220 grit mirror finish.Electrical heatingThe Air inside the Tray Dryer is heated by "U" tube S.S.304 air heaters each of 1 KW.The heaters are fitted on the sides of the dryer to facilitate uniform heating. Maximum temperature attained inside the dryer is 100' C and will be indicated and controlled by a Digital Temperature indicator cum controller over full range of heating load.Total heating load for it will be 12 Trays Dryer - 4 KW 24 Trays Dryer - 6 KW 48 Trays Dryer - 12 KW 96 Trays Dryer - 24 KW 192 Trays Dryer – 48 KW Air Circulation Air inside the dryer is circulated by one heavy duty axial flow S.S.304 or aluminum blower fitted on a shaft of and driven by l H.P. through belt. The special design of the Blower ensures uniform air circulation so that there is uniform air current over the entire charge loaded in the Trolley inside the dryer. The working of the motor is indicated by lamps in the control panel. Trays Trays will be manufactured from 1.6 mm SS 304 sheets. Its dimensions are 32" x 16" x 1 l/4". The Trays have rounded corners with' mirror finish from inside and outside. SS 316 quality is available on demand.Racks And Trolleys Racks are provided for trays inside the Dryer. They are of fixed type for 12 and 24 Trays Models. For 48 and 96 Trays and 192 Trays Models. Racks are provided with wheels to slide them in and out of the Dryer. An additional S.S, trolley for Racks for outside movement can be provided on request.

...more

Transfer Pump

45,000 Per Piece

We are offering transfer pump.capacity 500 liters. - 10000 These pumps are made from ss-304 or ss-316 sheet.

...more

Tablet & Capsule Counting Machine GMP Model

The YPM Stainless steel scrambler & un scrambler, size 48", 36", 30" & 24" diameter, with variable pitch pulley drives OR direct geared motor driven with variable speed drive, to ensure uniform flow of containers to suit different machines and purpose on line. The unit is built on M. S. Square pipe frame or optional S. S. Square pipe and totally encompassed with S. S. Coverings. The S. S. Cladded aluminum cast disc, soiled guide rails; helical gear housing provides a serials and noiseless performance for a long time. The variable pitch pulley ensures total and finer synchronization for incoming and out-going containers. Salient Features : Design as per cGMP – Current Good Manufacturing Practices compliance. Available different model with 20”, 30”, 36”, 42” diameter of turn Table. Construction AISI S.S.304 quality. Three step pulley for different speed. Special self-aligning bearings ensure smooth and trouble free operation. Suitable for different type of container. S.S. elegantly matt finished body. Reduction gears ensure jerk free and noiseless operation. Matt Finished body. Optional Features : Castor Wheel with lock A/c Frequency Drive(VFD) Acrylic Cover Tray for loading or unloading of container

...more

Starch Paste Kettle GMP Model

YPM Starch Paste Kettle GMP Model will be made out of S.S. 304 Rectangular Pipes and will be an independent resting type frame work where no foundation will be required. The Kettle will be a hemispherical type bowl with either steam / Oil / Water heating Jacket will be provided. The Kettle will be manufactured from 2.5 mm thick S.S. 304 Sheet and The Jacket will be of 2.5 mm Mild Steel (In case of steam Jacket the thickness will be 4 mm) There will be oil / water heated fitted at the back bottom side of the Kettle. The Kettle having a worm type arrangement for tilting. A temperature controller & a temp Indicator will be provided for temp control & Indication. The Kettle will be Insulated with 50 MM thick glass wool Insulation & Cladded with 16 SWG S.S. 304 Sheet. Starch Paste Kettle will be buffed to 150 grit matt finishes externally and Internally the Kettle will be buffed to 220 grit mirror finish. Functions : Basically YPM Starch Paste Kettle is used for preparation of Starch Paste. Hemispherical shape ensures that the Heating of the Starch Paste is Uniform & gets more Surface area. The tilting type arrangement Ensures ease in unloading the Paste into any container or vessel. The Starch Is put in the kettle and water is added till desired thickness is achieved. The Kettle is jacketed & is heated till the Starch Melts an Thick Paste is achieved. This Paste can be agitated either manually or with The Help of an Anchor Type agitator which will constantly stir. The Paste so that there will no lumps formation and proper mixing is achieved. Temperature can be set to desired temp by adjusting the thermostat provided. Optional Available : Starch Paste Kettle is built in stirrer arrangement with lifting & lowering device Our Starch Paste Kettle is equipped with Steam fittings with all connections factory fitted Non Tilting type with bottom discharge models is also available. Capacities Available : Our Starch Paste Kettle is available From 50 Liters to 1500 Liters Capacity. We Also Manufacturer Capacity 3000 Liters & Above. Needless to say, it also provides the benefits of the effective manpower utilization.

...more

Stainless Steel Tank

25,000 Per Piece

Stainless steel tank manufacturing capacity 5 ltrs. To 5000 ltrs. As per your requirement complete tank with castor wheel

...more

Coating Pan Machine GMP Model

175,000 Per Piece

YPMCoating Pan designed by keeping in mind needs of universal conventional coating requirements such as rotational speed, angle of inclination of pan, inside finish of pan, total volume, temperature of air and exhaust arrangements. Special Features : Coating Pan Drive can be available with VFD for pan speed variation which required in both film as well as sugar coating. Spraying systems is also available with the unit. Polishing pan is made suitable on the same drive of coating pan drive. Hot air / Cold air blowing system is used for tablets. Model available in sizes 12", 24", 30", 42", 48", 60" and 72". Hot air blower system with mobile trolley and filter housing will be provided with TIC or PID type temperature controller for control of air temperature within the range of 50 degree C to 80 degree C. HEPA filter unit (optional) can be provided along with inlet ducting lines. Other options such as FLP motor and panel, steam heating unit can be provided. Pan : SS 304 / 316 semi ellipsoidal size pan with a circular mouth for charging & discharging of tablets Pan mounted at an inclination of 45 degrees to the horizontal.Drive Assembly : Consists of a suitable HP 3 Phase, 440 V, 1440 RPM TEFC motor with suitable worm reduction gear box and cone pulley arrangement to give three speed output.Hot Air Blower : The unit is provided with a hot air blower consisting of suitable HP 3 Phase 440 V, 2880 RPM TEFC electric motor & centrifugal blower with damper delivering required CFM. The air is heated by means of suitable electric heater to give air at 30 to 90 degrees Heater with thermostat control and flexible hose pipe. Control Panel : Unit provided with suitable control panel with starters and push button to actuate the Drive and for blower the circuits consists of MCCBs, relays and contractors in series Ample overload protection is provided by the MCCB and the relay Wires coming out of the Connections are numbered for easy recognition. Mounting : The motor and gear box is mounted inside sturdy MS frame and the pan mounted on the Gearing housing fitted in the stand. Blower mounted by the side of the stand or placed in remote Location if required. Finish : All joints argon Arc welded and all SS Parts polished to suitable finished required of Pharmaceutical equipment MS parts painted to smooth finish. Options Available : Unit with FLP motors and FLP push button station but non FLP panel to be mounted outside FLP area, Unit in SS 316 quality contact parts, Unit with SS304 cladding / for GMP model and Steam heating for blower.

Type : GMP Model

Warranty : 1 Year

Material : Metal

Packaging Type : Packed in Box

Finishing : Polished

...more

Scoop

950 Per Piece

Scoop manufacturer in all s.s. 316 quality and one pic also available in different sizes 250 gm to 5 kg

...more

GMP Model Ribbon Blender

175,000 Per Piece

OperationThe YPM RIBBON BLENDER is an efficient and versatile blending machine for mixing of dry granules & powders homogeneously. Approximate two third of the volume of the container of Ribbon Blender is filled to ensure proper mixing. The Ribbon Blender gives best result for mixing of dry powder & granules due to the design and shape of the mixing ribbon and product container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. Material should be charge from the top side. There are port/ports should be provided on the top cover to charge the material as well as for air vent. One discharge valve provided at the bottom side at center of the container. The discharge height could be adjusted as per the requirement, so that material gets discharge in the other container directly, so that material handling time for discharge is nil and the operation is dust free.In YPM Ribbon Blender the powder moves from center to the end of container and end of container to the center of container. Hence requirement of total mixing time is very less and the RPM required are also very less.The dry material gets sufficient continuous movement due to the shape & movement of ribbon & shape of the container. Which moves material for good quality of blending? The unit is consist of one electrical motor, one worm reduction gear, belt drive between motor and gear, couple drive between gear to ( ribbon ) mixing stirrer. Container having four nos. of legs with discharge valve & top cover. Both end of mixing shaft is sealed with bush & PTFE gland housing & safety guards are provided on all moving parts.Special Features The shape of container and mixing stirrer gives sufficient continuous movement to the powder / granules result in good quality. All contact parts are made out of SS304/SS316 quality material. Maximum care has been taken to ensure safe operation of the unit. Inching facility for stirrer for discharge of material. Full cover on top side of the container. Discharge height must be adjusted, if confirm with order. Operating panel provided for safe operation of blender. Centrally located material Discharge valve. ( Butter fly / Sliding Valve ) Dust proof top cover with window provided. General structure completely made out of mild steel & painted in Standard Model & the same is cladded with SS304 in GMP model. Safety Guards & Covers made out of SS304 in GMP Model & made out of mild steel in Standard Model. Legs made out of M.S & painted in Standard Model & same will be cladded with SS304 in GMP Model. Panel provided with following facilities in 500 Liters & bigger model. In Small model only D.O.L. starter provided for On-Off operation of the motor. Three phase indication facility. D.O.L. starter for on-off operation of motor. Emergency stop provided in panel. Digital timer for batch time setting. Ampere meter to indicate load of motor in ampere. Limit switch provided at top cover for safety purpose. Inching push button with selector switch for inching operation during discharge of material.

Type : GMP Model

Warranty : 1 Year

Material : Metal

Feature : Durable

...more

GMP Model Pulverizer Machine

IMPACT Pulverizer Machine :Since our inception, we are fully involved in manufacturing and supplying high quality YPM Impact Pulverizer. These equipments are precisely designed to install in pulverizing machine. In accordance with set industry norms, these equipments are manufactured by utilizing optimum quality raw materials. Moreover, this YPM Impact Pulverizer Machine is highly acclaimed due to their perfect finish and easy installation.We manufacture, supply and export different models of impact pulverizer machine. All its wide range is made using superior quality raw materials. It is featured with very smart functions and is dimensionally very much accurate. This machine will offer you maximum output with minimum power consumption. It is very easy to clean, operate and it has multipurpose use as you can grind food items, spices, chemicals etc.Features : Optimum strength Enhanced durability Corrosion resistant body Output up to 300 mesh. Cyclone Pulverizer Machine :he unit is to reduce the size of the hearbals; medicine powder etc.All contact part of the pulvrizer is made of the Mild Steel or Stainless Steel. The machine is driven by motor of three Phases, With Starter etc. The unit is provided with provision for affixing mesh of different size as per requirements and nature of materials to be provided The pulvrizer shall reduce the Powder size up to 100# mesh.Features : Optimum strength Enhanced durability Corrosion resistant body Output up to 100# mesh.

...more

Powder Mass Mixer GMP Model

150,000 Per Piece

IntroductionThe YPM Mass Mixer Machine is basically mixing a assembly wherein the mixing stirrer is in horizontal position in the container & have a single speed, simple rotation. The stirrer rotates around itself at a very slow speed inside the bowl and thereby achieving intimate mixing of dry or wet materials of Tablet Granulation, Powder, Chemicals, and Food & Confectionaries Materials. Because of a special design feature of machine & stirrer, the mass mixer can be mix the sticky materials & also uniformly and intimately mix the materials which are to be difficult to mix.Application : YPM Mass Mixers are Ideal for mixing of Pharmaceutical powders, chemicals, food and confectioneries etc.Special Features: Range of YPM Mass Mixers models to suit working volume 50,100,200,500 and1000 Kgs. At bulk density of 0.50 gms/cc. All contact parts of mass Mixers are made out of S.S.304 quality material.(SS316 provided on demand on extra cost) Compact design requires comparatively smaller floor space. Single stirrer with single speed for dry & wet mixing. All non contact parts in the mass mixers (general structure) are made out of mild steel and cladded with SS304 or chrome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. All moving parts are enclosed with safety guards. All moving parts are enclosed with safety guards. Thrust bearings are provided to carry out rigid thrust load. Easy for cleaning & operating. Simply designed SS304 dust cover provided with one port for material charging & inspection. Interlocking system with top dust cover, to avoid accident, during process. The container tilting system provided for easy unloading of material and easy cleaning. Specially design all moving parts provided with provision of easy lubrication. Shell : Consisting of 'U' Shape of suitable dimensions. Construction of S.S. and side plates duly M.S. stiffened from outside and from inside with S.S.Mixing Mechanism : Paddle type blades welded to the main shaft provide for efficient mixing of thick heavy material. PTFE gland mechanism provided at shaft ends prevents ingress of external powder into the trough and prevents leakage.Charging : From the top charging can be done through a hinge able lid; hopper or Nozzle can be provided for additional spraying of additives.Discharge : By bottom discharge slide Iris or Butterfly valve of suitable diameter, for regulated discharge.Drive : Consisting of suitable H.P. TEFC 3 phase ac 415v / 50 cycles motor coupled to suitable worm gear, with driving shafts mounted on suitable Plummer block.Mounting : Mounted on suitable ISMC Section Stand, with protective covers for belts and couplings.MOC : All contact parts in S.S. Constructions. Complete unit with S.S. cover and all surfaces polished to mirror dull finish. MS parts dull painted to smooth finish.Options Available: The control panel is mounted on platform and is provided with Unit with FLP Unit in S.S. 316 GMP Model with M.S. parts cladded with S.S.

Application : Industrial

Color : Silver

Warranty : 1year

...more

GMP Model PP Cap Sealing Machine

70,000 Per Piece

The YPM semi automatic cap sealing machine is precision built on sturdy Welded steel Frame completely enclose in stainless steel sheet and doors are Provided to facilitate the servicing of machine. Machine is motorized, Incorporating rotating Threading & sealing rollers, for threading & sealing of ROPP cap. Operation : Require manually feeding & unloading container, where the body and the neck Of the container are positioned below the rotating head, and sealing head is Performing perfect operation of threading & sealing. Technical’s Detail: Motor - 1/2 HP Three face motor/ 415 Volts / 50 Hz. Machine Dimension - 1000mm(L) x 720mm(W) x 1400 mm (H) Approx Net Weight - 200 Kg. Gross Weight - 300 Kg. Quantity - 01 Nos. Salient Features : The unit is made compact & versatile. S.S. Elegantly Matt Finished Body. Quick setting. Motoriesed head movement. Complete machine with one dia 22, 25, 28 any one as per your requirement. No change parts require for different container diameter. Low noise level, low power consumptions. Adjustable bottle height gauge for easy and quick setting. SS cladding or hard chrome plating of all exposed parts to ensure long life and resistance against corrosion. Sealing pressure can be varied to suit different gauges and size of caps.

Packaging Type : Packed in Box

Warranty : 1 Year

Material : Metal

Finishing : Polished

...more

Planetary Mixer GMP Model

Application The YPM Planetary Mixer is ideal for mixing of Pharmaceutical powders, ointments, creams, lotions, pastes, tooth paste, cosmetics, food and confectioneries, rubber and rubber compound, colors and pigments, PVC & plastic material, ceramics, pesticides, insecticides, adhesives, metal powder, resins etc. etc. For Ointment - Cream - Lotion - Paste etc. Manufacturing With Double Stirrer, Scrapper & Centrally Located High Speed Emulsifier Special Feature Range of models to suit gross volume 50, 100, 150, 200, 350, 600, 1000, 1500 Liters for OINTMENT - CREAM - LOTION - PASTE - TOOTH PASTE. All contact parts are made out of S.S.304 quality material. (SS316 provided on demand on extra cost) Compact design requires comparatively smaller floor space. Lowering and lifting movement achieved through motorized drive in 140 & 200 liters model & hydraulic lifting system from 350 liters to 1500 liters size models. (In 50 & 100 liters models product container moving up & down manually. Motorized system can be provided on demand on extra cost, if required.) In all other bigger size models product container remain fixed and mixing drives comes up and down by means of mechanical or hydraulic system. Castor wheel mounted product container for the ease of mobility. (This facility available from 50 liters to 350 liters model only.) Container with fixed legs above 350 Liters model. Hence no facility of mobility of container. A high-speed emulsifier (Homogenizer) will be provided at the center axis, in 150 liters model and above capacity model only. (It can be interchangeable with disperser & necessary assembly provided with m/c) In-Line Homogenizer also provided on demand, if required. Double stirrer & SS scraper with PTFE blades for better mixing of the material. (In 150 Liters & above model only) Single stirrer with scrapper in 50 & 100 Liters model. Planetary motion of the stirrer (beaters) enables faster and better mixing of the material at a considerable lesser time. As stirrer is a top driven and sealing doesn't come in contact with product, there isn't any black particle contamination problem. Water / steam circulation jacket for mixing bowl, to heat or cool the mix during operation in OINTMENT MIXER only. (Water jacket recommended only in 50 to 350 liters model. Steam heating recommended in 600 liters to onward all models. Jacket also made out of mild steel in Standard Model & SS304 in GMP Model.) All non contact parts (general structure) made out of mild steel and cladded with S.S. 304 or chrome plated or made out of SS304 in GMP Model. Contact parts are polished to the mirror finished and non contact parts are polished to the matt finished in GMP Model. All safety guards & covers made out of SS304 material in GMP model & made out of mild steel & painted in standard model. General structure & all non contact parts are made out of Mild Steel & same wil painted in Standard Model : Fixed type product container in 600 liters and above capacity models. Heater with temperature controller for heating facility. (For 50 / 100 / 200 / 350 liters OINTMENT MIXER only) 100 % utilization of machine can be possible due to facility of change of extra product container. (In 50 to 350 liters model only) Insulation will be provided on jacket of container. (For OINTMENT MIXER only) as a optional facility. Material discharge from bottom. Flush bottom valve provided for material discharge in 350 liters and above model only. (For OINTMENT MIXER only) M/C provided with Light glass, Sight glass, material inlet, air suction valve for vacuum, CIP port facility. (For OINTMENT MIXER only) All connection of valve, light glass, sight glass will be triclover ended. Sampling port provided in 600 liters & above model. Flush bottom type valve in 600 liters & above model. All moving parts are enclosed with safety guards. Optional SS316 product contact parts instead of SS304. Variable speed drive for main agitators motor and emulsifier motor. Vacuum Pump Set. Flameproof model "PLC" based operating panel for automation. Hydraulic lifting system in 60 to 200 liters model, instead of mechanical lifting system.

...more

Multi Mill GMP Model

95,000 Per Piece

Application : Multi Mill is widely used for wet and dry granulation; pulverization etc. in Pharmaceuticals, Chemicals, Cosmetics, Ceramics, Colors, Dyestuff, and Food products etc.It also finds application in Pesticides, Fertilizers, Spices, Detergents, Insecticides, Plastic and Resins Industries. Description : Unit consists of S.S. 304 quality hopper and processing chamber (can be provided is S.S. 316 quality at extra cost) With beaters assembly, motor, reversible switch, DOL starter, four speed step pulley, Suitable screen with painted pillar mounted on base plate, with castors wheels. Operation : It operates on the principle of variable force swing beaters having both knife and impact edges rotating within a selected screen to get the required size reduction. Material fed in the hopper, goes down to the processing chamber where it moves to the periphery and passes through the screen radically and tangentially. Finally the processed material gets collected in the container kept below the processing chamber. Output and quality of the final product depends on three main factors: Shape of beaters (knife/impact edges), Speed and Screen. Salient features : Direction of beaters can be changed by reversible switch from knife to impact forward and vice-versa. All contact parts can be easily and quickly dismantled and cleaned. Machine is designed for continuous operation. Cylindrical screen for higher output. Castors wheels provided for mobility. Flame proof electrical can be provided at extra cost. Beaters and Scrapper blades of SS 304/316 quality are provided.

...more

Packing Conveyor Belt GMP Model

75,000 Per Piece

The YPM Packing Conveyor belt is having stainless steel table top with moving endless sandwich belt in the center. Tabletop is fixed to the same structure made out of SS square pipe and supported on adjustable bolts. Tabletop is of 12 inches working space on both side of the conveyor belt for final visual inspection packing. Operation: The conveyor belt brings the container or products from the labeling/blister/strip machine, operator in turn pickup these bottles/products and visually inspect the bottles/products and doing necessary action like primary packing, secondary packing, picking and placing at proper place. Multi track conveying system either of S.S/denim slats. S.S. light canopy with black and white background is placed above conveyor. Three track having either side un-inspected & center inspected goes for further labeling. Manual pick up from un-inspected track & found ok, place in center track for further process. Salient Features Structure is made of S.S. 304, 30mm sq. pipe, 16 SWG with matt finish. A/c frequency variable drive. Belt alignment system for long life and straight running of belt. Direct gear drive. Length can be made as per customer requirement. S.S. elegantly matt finishing. Adjustable height of conveyor belt, to align with other machine of the line. Self-alignment bearing for easy maintenance. Rigid vibration free construction for trouble free performance. Optional Features : Castor wheel with lock. Extra and table at end of conveyor. Special type adjustable angle at initial of conveyor for strip or blister packing S.S. chain instead of PVC belt. Optional Features : Electrical supply - Single Phase + Neutral + Ear thing Electrical load - 0.5 KW We Also Manufacturer SS Belt Conveyor SS Chain Conveyor SS Screw Conveyor

Type : GMP Model

Material : Metal

Packaging Type : Packed in Box

Finishing : Polished

...more

Oscillating Granulator Machine

We are counted among one of the eminent manufacturers and suppliers of oscillating granulator,which is fabricated using superior quality stainless steel raw material. The products are suitable for wet and dry granulation process and are complete with suitable electricity. Further, the machines areequipped with motor, reduction gear box, quick opening and locking arrangement, for changing thesieves, machine duly painted and finished. Oscillating granulator, plays an important part in the process of granulation in tablet making. All contact parts made of stainless steel 304316 quality. Gmp model is also available.

...more

GMP Model Octagonal Blender

Operation The YPM OCTAGONAL BLENDER is an efficient and versatile blending machine for mixing and lubrication process of dry granules homogeneously. Two third of the volume of the Octagonal Blender is filled to ensure proper mixing. The Octagonal Blender gives best result for granules due to very slow speed and octagon shape of container. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. In YPM Octagonal Blender the granules comes from all sides due to the octagonal shape of the product container, hence requirement of RPM is less. Suitable mainly for Crystalline & Granular type material. This type of material gets sufficient continuous movement due to their shape if containers have only slow movement and will results in good quality of blending / lubrication of granules. Special Features of Octagonal Blender : Octagonal Blender is Suitable for dry mixing of products in granule form. Easy for loading and unloading of material. Easy for cleaning. All contact parts of the Octagonal Blender are made out of S.S. 304 / S.S. 316 quality material, as per customer requirement. The octagonal shape & slow speed of rotating gives sufficient continuous movement to the granules result in good quality. Simple design Octagonal Blender requires minimum maintenance. General structure & safety guards made out of mild steel & colored in Standard Model and made out of SS 304 & polished to the matt finish in GMP Model. Maximum care has been taken to ensure safe operation of the unit. Manual rotating facility with hand wheel for inching. Bigger size batch at low power consumption. Option (Will be provided on extra cost on your demand) Contact parts of the Octagonal Blender made out of SS316 instead of SS304. Flame proof drive motor along with flame proof starter. Vacuum Loading facility for material charging. Cylindrical container with cone for material discharging.

...more

Mixing Tanks

50,000 Per Piece

yadav pharma machinery(india) manufacture stainless steel mixing vessels and asme vessels for pharmaceuticals, biotech, cosmetics and other liquid processing industries.

...more

Liquid Syrup Manufacturing Plant GMP Model

500,000 Per Piece

Ideal solution to the pharmaceutical industry for the production of oral liquids. The process consists of Sugar syrup preparation. Ingredient Mixing and Storage with product distribution piping. Range of plant covers from 50 L to 3000 L with various options in top and bottom entry agitators for mixing and homogenizing of syrup & suspensions. Product contact parts are S.S.304 / 316 with option of jacketed vessels and heating system suitable for steam as well as electrical. Yadav Pharma Machinery (India) Liquid Manufacturing Plant Consist the Following equipments and accessories : Sugar Syrup Vessel Filter Press Manufacturing Vessel Transfer Pump Storage Vessel Transfer Pump Piping To Connect All Above Equipments Working Platform Control Pump This system consists of a closed circuit manufacturing facility from feeding of Sugar / Water Phase to loading the Volumetric Liquid Filling Machine. The Sugar and Water, are load with vacuum system or by mechanical system or manually. The Sugar Syrup Vessel is supplied with high speed stirrer & electrical heating ( In small model ) / steam heating facility (In bigger size model ) . The sugar syrup is prepared at required temperature & are transferred to Manufacturing Vessel by vacuum or by transfer pump. The product during emulsion formation is re-circulated through In-Line Homogenizer or Liquid Transfer Pump.( Optional Facility ) The Pump also discharges the product in the Storage Vessel. The Storage Vessel is then taken to the filling area (if it is small capacity) and is connected to again Liquid Transfer Pump. Or Storage Vessel remains fixed (In bigger size) & pump transfer the Liquids in the float tank which is connected with filling machine. The entire Plant can be operated by centralized operating panel by one operator. The plant is equipped with an electrical control panel with digital temperature indicators / controllers and digital timers. Salient Features of Liquid Syrup Manufacturing Plant : The Plant is designed to be operated only by one operator and one helper. All material transfers are done by vacuum or by transfer pumps. All the vessels are CGMP (paint free construction) The gaskets used are of silicon (food grade). All contact parts are of S.S. 304 quality material (SS316 provided on demand) & finished to class 4B (Mirror) finish and are crevice free. The entry of stirrer & high speed emulsifier are from top. In-line Emulsifier ( as per customer choice ) provided on demand. ( Optional ) All vessels are suitable for internal pressure of 1 Kg. / Sq. cm. and hence can be sterilized. All pipes, pipe fittings and valves are of SS304 / SS316 (as per customer requirement) seamless quality, internally electro polished, with tri-clover ended joints. The entire plant is equipped with CIP & SIP connections, so that customer can use this facility, if have CIP & SIP equipment. All values of temperature & time of the plant are indicated digitally on the control panel. Ampere indicates on Ampere meters. A micro processor based automatic operating plant can be designed as per requirement. (Optional ) All the inlet & outlet connections are provided with tri clover joints, which are very easy for cleaning & replacement.

...more

Turntable Machine GMP Model

70,000 Per Piece

The YPM Stainless steel scrambler & un scrambler, size 48", 36", 30" & 24" diameter, with variable pitch pulley drives OR direct geared motor driven with variable speed drive, to ensure uniform flow of containers to suit different machines and purpose on line. The unit is built on M. S. Square pipe frame or optional S. S. Square pipe and totally encompassed with S. S. Coverings. The S. S. Cladded aluminum cast disc, soiled guide rails; helical gear housing provides a serials and noiseless performance for a long time. The variable pitch pulley ensures total and finer synchronization for incoming and out-going containers.Salient Features : Design as per cGMP – Current Good Manufacturing Practices compliance. Available different model with 20”, 30”, 36”, 42” diameter of turn Table. Construction AISI S.S.304 quality. Three step pulley for different speed. Special self-aligning bearings ensure smooth and trouble free operation. Suitable for different type of container. S.S. elegantly matt finished body. Reduction gears ensure jerk free and noiseless operation. Matt Finished body. Optional Features : Castor Wheel with lock A/c Frequency Drive(VFD) Acrylic Cover Tray for loading or unloading of container Utility Requirement : Electrical Supply - Three phase + Neutral + Earthing Electrical load - 0.5 KW

Driven Type : Electric

Warranty : 1 Year

Application : Industrial

...more

Hot Air Dryer

150,000 Per Piece

The major concern of our firm is to deliver a quality content, thus, we check the product quality on several counts at all stages. Headquartered in Delhi(India), we are making available high quality products to every nook and corner of the country.

...more

heating tanks

Yadav pharma machinery(india) manufacture stainless steel mixing vessels and asme vessels for pharmaceuticals, biotech, cosmetics and other liquid processing industries.

...moreOpening Hours