Weather Proof Pressure Gauges

Weather proof gauges provide resistance to corrosive media and environment. Chemicals and petrochemicals, Power generators, pollution control equipment, Oil exploration and any other application requiring fine quality, long lasting pressure measurement instrument etc.

Dial Size : 63 mm/100 mm/150 mm/ 200 mm

...more

Water Pressure Reducing Valve

"YASH” make pressure reducing valve (also termed a "Pressure Regulator") is a "Throttling" device, its function is to effect a reduction in pressure of the fluid-(Steam, Air or Gas) - passing through it. Correctly designed and installed to the user’s definite and detailed specification, the Regulator gives a constant reduced pressure irrespective of fluctuations, within reasonable limits within the inlet pressure, the incoming high pressure There are various types of Self Actuating Type Pressure Reducing Va... upon the working Pressures, Flow Rates and Fluids.

Feature : Maintains Constant Outlet pressure, irrespective of change in upstream pressure. High Turn down Ratio. Full to % (10:1). Very ideal for Low and Medium pressure, Steam, Gas and Air Variety of Spring Range For better Down Stream Pressure Control

...more

Utility Pressure Gauge

Utility gauges are designed for long and reliable service under rugged conditions where gaseous and liquid are not highly viscous or do not attack copper alloys or crystallize.

...more

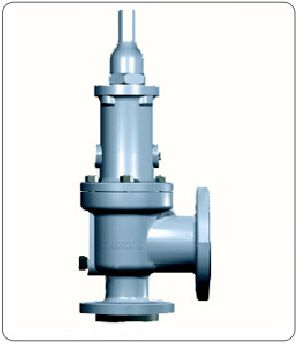

Relief Valves

YASH” Please Install Flash PlayerDownload from here make Safety valve provides protection from over-pressure in steam, gas, air and liquid lines. The valve "lets off steam" when safe pressures are exceeded, then closed again when pressure drops to a preset levelThese can also be defined as Pressure relief valve, which are made by appropriate metal for specific parts. We take utmost care of manufacturing procedure to ensure safety measures. The main function of a safety valve is to prevent an undue rise in pressure in the vessel, to which it is fitted. Materials used in making are of higher quality such as G.M. confirming to IS 318 Gr.2 & Brass confirming to IS 319. Low pressure system can be protected from overpressure by spring – operated valves. Weight – loaded valves or pilot-operated valves. Technical Specification End Connections : Screwed NPT / BSP / BSPT, Ends Flanged to ANSI B16.5 Table D / E F other Material & Specifications are Welcome Body & Bonnet : One piece, SS 316/ SS 316 L/SS 304/ CS or any special material Usage : For all kinds of medium/low pressure applications. OD Size : ½” to 4” (15 mm to 100 mm) Working Pressure : Suitable upto 450 PSI Maximum Temperature: - 65° to 450° F. (-54° to 232° C.) Material : SS 316/ SS 316 L/SS 304/ CS or any special material Quality : Highest standard in Visual, Materials, Dimensional Accuracy, Operation, Leak-tightness, Finish and Workmanship Operation : Smooth, Easy, Low-Torque, Long life Testing : Each valve is 100% tested on Nitrogen medium to ensure leak-tightness at Shell, Seat Application Industries : Petrochemical, Power, Energy, Thermal, Refineries, Fertilizers

...more

PinchValves

The secret is in the rubber sleeve - the valve's only wetted part. Actuation of the valve, the pinching action, is accomplished by air or hydraulic pressure placed directly on the elastomer sleeve. A rubber sleeve also known as rubber muff or tube is protected under a cast iron or aluminum body. The inside of this rubber sleeve has no crevices or indentations to allow slurry compound to collect and dry into hard, sharp material.

...more

Monoflanges Valve

The valve vents line pressure either to atmosphere or to containment when used with optional barbed vent tube. Bleed valves are used whenever an instrument is removed from a system or to assist in the calibration of control devices.

...more

Master Gauges

Test Gauges are extremely sensitive and highly accurate with adjustable knife - edge pointer and mirror bands on the dial to assure precise readings and to climate parallax error. Also suitable for gaseous and liquid media, particularly for testing and calibration.

...more

Lubricated Plug Valves

"YASH” make Plug valve is used primarily for on--off service and some throttling services. It controls flow by means of a cylindrical or tapered plug with a hole in the center that lines up with the flow path of the valve to permit flow. A quarter turn in either direction blocks the flow path. Plug Valve is lined non corrosive polymer and can resist any type of chemicals at various temperatures. It is available from 25 mm NB to 150 mm NB. Valves are virtually unaffected by changes in processing temperature or chemical concentration. In-fully-line valve, the fluorocarbon lining is locked into the valve body.

...more

High Pressure Globe Valves

These valves are designed for least possible obstruction to free flow by providing curvature turns in the body, thereby minimizing stresses & turbulences also. Discs are plug type and held together with stem by disc nut & allow the perfect seating arrangement on the seat. Carbon steel & cast Iron valves have renewable seats while stainless and other higher grade materials have integral seats. All the valves have back seat arrangement as an additional sealing under full working pressure which facilitates replacement of packing with the valve under fully open condition

...more

Electrical Contact Pressure Gauge

These gauges can be used for different monitoring, measurement and control of line pressure by switching “on or off” electrical equipment. Pumps, Motor, Turbine electrical & Electronics Instruments etc.

Dial Size : 100 mm/150 mm

...more

Electric Contact Thermometer

Electric contact thermometers are made of bulb, transmitting capillary and flat bourdon tube that are pressure filled with Mercury or gas filling. Contacts are mounted on mechanical dial Gauge to “Make or Break” an electronic control cycle depending on the position of the Instrument's pointer. SS 204 Capillary is also used to measure temperature on the application which is at a distance. It is an economical, rugged, reliable and precise temperature measuring instruments. These gauges can be used for different monitoring, measurement and control of line pressure by switching “on or off” electrical equipment. It is one of the most versatile and widely used devices in industrial temperature measurements.

...more

Double Block Bleed Valves

The development tendency of the valve in the future. These new assembly of the double block & bleed valve provides great savings in weight, space and installation times especially in cage isolation. Double Block and Bleed valves have evolved to replace the process of bolting together individual valves to provide dual isolation

...more

Non Return Valves

“YASH” Please Install Flash PlayerDownload from here make offers check valve, which are ideal to reduce flow resistance and pressure drop to the minimum possible level. They are perfectly engineered, lapped and screwed in seat to ensure tight shut-off and long life. A Check valveis a mechanical device that normally allows fluid (liquid or gas) to flow through it in only one direction & the other for fluid to leave. It’s a two-port valves.Function of Check Valve is to prevent the reverse flow of fluid/gas/air in case of failure or sudden brake-down occurs in Piping Systems. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, many check valves are very small, simple, and/or cheap. The bodies (external shells) of most check valves are made of plastic or metal. CHECK VALVES ARE AVAILALE IN SINGLE / DUAL PLATE DESIGN/WAFER/SWING TYPES. "YASH” make Swing Check/Non-Return Valves are designed and manufactured according to BS1868 / API/BS/DIN STANDARD. Check Valves as popularly known in the Piping System in all fields are considered very critical in its application. Valves are provided with properly guided Swing Disc through a Hinge for High Temperature and Pressure, Soft Sealing for Pneumatic and Vacuum applications. The design ensures the Valves function smoothly with a very nominal differential pressure from either side. The disc is designed so compact and light weight to ensure minimum pressure drop across the Valve.Available in varied materials like Cast Iron, Cast Carbon Steel, Cast Stainless Steel of all Grades, High Alloy Steels, Hastelloy etc. Manufacturing range commences in size from 50NB through 600NB; in Pressure Rating from ANSI 125# through 1500#. We offer a range of precision check valves that are designed to be self cleaning, quick opening, and positive sealing. These can be customized on the basis of client’s specifications. Therefore, they are available in various dimensions and designs. They are mainly used to make liquid or gas flow in only one direction. These check valves used in a wide variety of applications in many industries Technical Specification Size Range: 50NB – 600NB Range: ½” to 24” Trims: stellited, 316, 304, Monel, Ali bronze, duplex Pressure Rating : ANSI - 150#, 300#, 400#, 600#, 900#, 1500#, 2500# Standard : Generally conforming to BS1868 / API/BS/DIN STANDARD End Connections : Screwed Ends to BSP / BSPT/ NPT (F) Socket Weld Ends to ANSI B 16.11 Type : Swing / Lift Gasket& Packing : Optional PTFE/ Graphite/ Asbestos/ Spiral wound/ Ring joint Disc : Solid Seat : Integral/ Renewable/ Seal welded Material: SS 316/ SS 316 L/SS 304/ CS or any special material Quality : Highest standard in Visual, Materials, Dimensional Accuracy, Operation, Leak-tightness Operation : Automatic Testing: Each valve is 100% tested to ensure leak-tightness at Shell, Seat and Gland Application Industries : Petrochemical, Power, Energy, Thermal, Refineries, Fertilizers

...more

CAPSULE GAUGE

Capsule Pressure gauges are designed for measuring lowvery low pressures and vacuum. The pressure medium needs to be gaseous. The capsule consists of two diaphragms joined and sealed around their circumference. Several such capsules may be combined to enable measurement of very low pressures.

...more

Bleed Valves

"YASH” make Bleed valves are designed for use on products such as multi-valve manifolds, or gauge/root valves. Functionally, the valve vents line pressure either to atmosphere or to containment when used with optional barbed vent tube. Bleed valves are used whenever an instrument is removed from a system or to assist in the calibration of control devices.Bleed Valves are also called Double Block & Bleed valve generally, as this valve is made up by two ball valve and one needle valve or two ball valve and a globe valve.Double Block and Bleed valves have evolved to replace and add the process of bolting together individual valves to make the valves in one body. it saved a lot of space and material, it is the development tendency of the valve in the future. These new assembly of the double block & bleed valve provides great savings in weight, space and installation times especially in cage isolation. Double Block and Bleed valves have evolved to replace the process of bolting together individual valves to provide dual isolation. This new assembly provides great savings in weight, space and installation times especially in instrument & can be seen in the reduction of leak paths to atmosphere MONOFLANGES OR SINGLE BLOCK & BLEED VALVES One Piece Ultra Slim line Forged Body combines a compact design with strength and reduced potential leak paths compared to conventional designs. Flanged Connections available on inlet or inlet and outlet in a choice of sizes and ratings to suit each particular application. Gauge Adaptors allow flexible positioning of gauges and instruments with a choice of designs available. Technical Specification Size Range : 15mm to 600mm Pressure Rating : ANSI - 150#, 300#, 400#, 600#, 900#, 1500#, 2500# Standard : Designed and manufactured to conform API/BS/DIN STANDARD End Connections : Flanged connections to ANSI B 16.5 Type : NYLON SEAT PACKING BLOCK VALVES BALL TYPE, BLEED VALVE NEEDLE TYPE, WITH BOLTED BONNET DESIGN Max Temperature: -52 degree C to +250 degree C depend on different material. Material : Stainless Steel, CS A105, Brass, Alloy steel Operation : Pneumatically controlled, electrically controlled - Smooth, Easy, Low-Torque, Long life Quality : Highest standard in Visual, Materials, Dimensional Accuracy, Operation, Leak-tightness Testing: Each valve is 100% tested to ensure leak-tightness at Shell, Seat and Gland. Application Industries : Petrochemical, Power, Energy, Thermal, Refineries, Fertilizers, Chemical, Pharmaceutical

...more

Needle Valves

"YASH" make Needle valves come in bar stock as well as in forged construction various sizes, sealing styles, end connections and stem types. Main feature of Needle valves is that its stems are interchangeable with any of its valves of the similar configurations thus resulting in low cost and less inventory

...more

Relief Valves

"YASH" make Safety valve provides protection from over-pressure in steam, gas, air and liquid lines. The valve "lets off steam" when safe pressures are exceeded, then closed again when pressure drops to a preset level

...more

Gate Valves

"YASH" make Gate valves are designed to provide minimum turbulence & resistance to flow when in fully open position. These gate valves ensure accurate control & alignment of wedge while operating. The gate valve is a general service valve used primarily for on--off, non-throttling service. The valve is closed by a flat face, vertical disc, or gate that slides down through the valve to block the flow.

...more

Globe Valves

"YASH" make Globe valve is used in industry to regulate fluid flow in both onoff and throttling service. Globe valves offer precise throttling and control and have high-pressure limits. These valves are designed for least possible obstruction to free flow.

...more

Ball Valves

"YASH" make Ball Valves are quarter-turn, straight through flow valves that have a round closure element with matching rounded seats that permit uniform sealing stress. Ball Valves are available in a variety of body styles, including one-piece, two-piece, three-piece and flanged body construction.

...more

Check Valve

"YASH" make offers check valve, which are ideal to reduce flow resistance and pressure drop to the minimum possible level. They are perfectly engineered, lapped and screwed in seat to ensure tight shut-off and long life. A Check valve is a mechanical device that normally allows fluid (liquid or gas) to flow through it in only one direction & the other for fluid to leave. It�s a two-port valves.

...more

Non Return Valves

"YASH{" make Swing CheckNon-Return Valves are designed and manufactured according to BS1868 APIBSDIN STANDARD. Check Valves as popularly known in the Piping System in all fields are considered very critical in its application.

...more

Control Valves

"YASH" make Control Valves offers a self Actuating Pilot Operated Automatic Control Valve specially design for Liquid Service, Also called as a 'Multifunction' Control Valve.These type of Valves are designed to provide different combination of Pilot Arrangements that can be used for various types of functions like : OnOff, Pressure Reducing, Pressure Relief, Flow Control, Pump Bypass, Non Return & many more.

...more

Butterfly Valves

"YASH" make Butterfly valves are the most efficient and reliable sealing, Maintenance Free, Tight Shutoff Isolation valve mechanism under high vacuum working conditions. Butterfly Valves are of small in terms of thickness which ensures easy and faster passage for air and gases and are ideally suited for "In-line" isolation purpose.

...moreBe first to Rate

Rate ThisOpening Hours