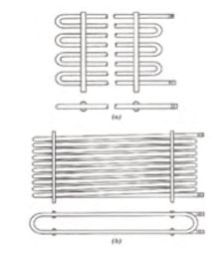

Ammonia Shell, Tube Condensers

Get Price Quote

With the help of our efficient workforce, we are able to offer a comprehensive range of ammonia shell & tube condensers that is designed at par with international quality standards. Our range of shells and tubes are manufactured using premium quality material, components and spares to ensure durability, and are appreciated by the clients due to their robust construction, corrosion resistance and dimensional accuracy. Moreover, we also provide customization as per the specifications detailed by our clients to meet their requirements. features robust constructiondimensional accuracycorrosion resistanthigh performance available in various sizes

Variable Refrigerant Volume System

Get Price Quote

Our company is a specialized Manufacturer & Supplier of Variable Refrigerant Volume System. The Variable Refrigerant Volume System is an air-condition system for commercial building applications. Clients can also avail large Variable Refrigerant Volume System from us that heat and cool the areas simultaneously. The Variable Refrigerant Volume System is often used in office environments where several rooms can be connected to a single external unit. Highlights Rigid construction Accurate designing Excellent performance Long service life

Best Deals from Industrial Refrigeration Systems

DIN Rail Mounting Thermostat

100 Per Piece

1000 Piece (MOQ)

Features: Compact Design Wide Adjustment Range Colour Coded Temperature knobs Din Rail Mountable Thermostat (NC): Thermostat opens on temperature rise – for regulating heaters or for switching signal devices. Comes with red temperature knob. Thermostat (NO): Thermostat closes on temperature rise – for regulating filter fans and heat exchangers or for switching signal devices. Comes with blue temperature knob.

Industrial Condenser

Get Price Quote

1 Piece (MOQ)

Glass Coil Condenser

Get Price Quote

Coil Condensers Coil Condensers are commonly used for the process of vapor condensation as well as examines the cooling of liquids. Condensers are manufactured by binding many parallel coils together in a glass shell. These coils are built of different diameters using various bore tubes. Design of Coil Condenser The Coil condensers are commonly used to separate or remove heat from refrigeration or an air-conditioning system. Occasionally they are accustomed to the intention of heating the air streams. Coil condensers are among the four essential components in an air-conditioning or the refrigeration cycle. The refrigerant then enters the system as a superheated gas and gets condensed in the coil tubes. The refrigerant then leaves the coil in the form of a liquid. Methods of Using the Coil Condensers Vapors from bottom It is effortless to install the Vapor method over a reactor. However, it may result in the condensate to return at its condensing temperature. You must be careful while working with this method that the condensate must not be in excess, and it must not lead to the blocked coils and create back pressure. Usually, the use of a reflux divider is advised to be installed below the condenser that will take the distillate out. Boilers Boilers are usually used for the evaporation process carried out for various liquids by passing the hot steam through the coils. Boilers are manufactured by combining many parallel coils in a glass shell. The coils in the boilers are specially designed to provide you with a much bigger cross-section than Condensers. Angled Hose Connector Assemblies Angled hose connector assemblies are usually made from either metal or plastic and must connect the condensers to the flexible hose. These can be provided with a rubber gasket, a mating flange, and nut bolts. Immersion Immersion-type heat exchangers are generally used to control the exothermic reaction happening in the glass vessels. Immersion-type heat exchangers can be used along with the vessels that have a bigger and wider bottom outlet. Such heat exchangers come with a central hole in the coil battery so that a stirrer can be mounted at the bottom of the heat exchanger. In most of the applications, the cooling water is usually used in the coils with a maximum pressure of 2.7 bar g; you can also use them along with the hot steam having a maximum pressure of 3.5 bar g. In the latter case, all the coils are entirely immersed in the liquid. Immersion procedure is not advised to use with the products having crystallization tendency. Product coolers Product coolers are generally used to cool various types of liquids that are used for the process of cooling the distillates in the distillation system. Unlike other coil condensers, among the product coolers, the product passes through the coil battery, and the coolant passes through the shell. This transfer process will give the product more time to get cooled. Preventive measures while using coil condensers Let the vapors pass via shell only. Keep the maximum coolant pressure to 2.7 bars. Coolant flow must be adequate for the process. The use of steam in the coil is prohibited. Coolant must be heated but not to its boiling point. Turn the coolant control valve slowly. Let the coolant drain freely. You can use coils made from brine in a closed circuit. Connect the water main to a flexible hose. Ensure water left in the coil doesn’t freeze. Condensers must be mounted only in a vertical position Final Thoughts Ablaze Export Pvt. Ltd. is one of the leading Coil condensers manufacturers in India. We are into the production of many standard chemical process equipment as well as we also provide customized process equipment. We have years of experience serving customers across India as well as delivering our products across the world.

air conditioner condenser

25,600 Per Piece

1 Piece (MOQ)

Shell and Tube Type Evaporator

30,000 - 80,000 Per Piece

1 Piece (MOQ)

energy regulator

Get Price Quote

10 Piece (MOQ)

Evaporative Condenser

Get Price Quote

1 Piece (MOQ)

Features : Lowest operating hp \ kw Higher system efficiency Environmentally friendly Lower annual operating costs Reliable, simple operation and maintenance

Ammonia Atmospheric Condensor

Get Price Quote

brine chiller

Get Price Quote

Liebig Condenser CORNSIL

Get Price Quote

50 pcs (MOQ)

Marine Refrigeration and Air Conditioning Condenser

Get Price Quote

1 Piece (MOQ)

Trafag Mechanical Thermostat for ESP Hopper

6,000 Per Piece

100 Piece (MOQ)

Steam Iron Covers

Get Price Quote

Being one of the leading names in the industry, we are instrumental in offering Steam Iron Covers to the clients. We are based in Haryana, India. Our clients can avail them in various specifications. Owing to their brilliant features like seamless finish, dimensional accuracy, durability, and long life, these are highly appreciated by our clients. We have enough capacity to deliver them in bulk quantities, within the promised time frame.

Vehicle Refrigeration System

200,000 Per Piece

1 Piece (MOQ)

Mild Steel Chemical Condenser

600,000 - 800,000 Per Piece

1 Piece (MOQ)

Sub-Zero Refrigeration Controller

Get Price Quote

10 Piece (MOQ)

Shell and Tube Condenser

Get Price Quote

1 Piece (MOQ)

Shell and Tube Condenser, Heat Exchanger used for industrial, Herbal Extraction Plants, Pharmaceutical Plants and Chemical Plants. Condenser used in Herbal Extraction Plant, Phyto Extraction Plant for cooling vapors of product.How it worksA shell and tube exchanger consists of a number of tubes mounted inside a cylindrical shell. Vapor runs through the tubes, and water flows over the tubes (through the shell) to transfer heat between the two.These Shell and Tube Condensers are manufactured from high-grade quality material and are easily available at affordable prices. Various Sizes Stainless Steel Options Custom Configurations Highly efficient Easy to install. Leak-Proof. Highly durable. Low maintenance. Operate trouble-free.

Stem Type Thermostat

Get Price Quote