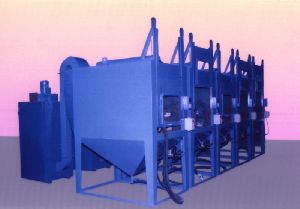

Belt Conveyor Sand Blasting Machine

Get Price Quote

1 Piece (MOQ)

Mini abrasive Blasting Machine

20,000 Per Piece

1 Piece(s) (MOQ)

Best Deals from Abrasive Blasting Machine

Portable Abrasive Blaster Machine

Get Price Quote

portable abrasive blaster

50,000 - 150,000 Per Piece

1 Piece (MOQ)

Abrasive Blasting Machine

Get Price Quote

We are pioneers in offering Abrasive Blasting Machine that is extensively used for surface making. We fabricate a wide range of Abrasive Blasting Machine using quality material and the latest technology. Our Shot Blasting Machine Manufacturer is available in different capacities as per the requirements of the clients. Highlights Sturdy constructionCompact designReliable operationCompetitive prices

Abrasive Pressure Blast Machine

1,550,000 Per piece

1 piece (MOQ)

Cabinet Type Abrasive Blasting Machine

Get Price Quote

MEC offers an environment friendly cabinet type abrasive blasting machine for generating anchor pattern on components that can be handled in a cabinet enclosure and operator maneuver the blasting nozzle from hand holes provided at the front of cabinet. To view the blasting operation, a vision window is provided at front side.3 variants are available in the cabinet type blasting machines, viz., Suction blasting, Pressure Blasting & Wet Blasting.Suction Blasting : Works on Injection Suction principle of blasting. Uses the venturi principle to draw abrasive from a non-pressurized hopper to the blast gun where it is combined with the compressed air stream and propelled against the work surface. Suction blast machines are most easily distinguished by having two hoses (one for air and one for abrasive) running to the blast gun.Pressure Blasting: Works on Direct Pressure principle of blasting. Uses a pressurized vessel or "blast pot" that holds the abrasive media. In a pressure blast machine the air pressure in the vessel and in the "pusher" line is the same. This means that there is no pressure differential between the blast pot and the blast line – this allows the abrasive media to meter into the air stream at the blast pot and then run the length of the blast hose out to the nozzle. Pressure abrasive blast equipment has a single hose running to the blast nozzle.Wet Blasting: Works on Injection Suction principle of blasting. Uses a slurry pump to draw the wet slurry of very fine abrasive and water to the blast gun where it is combined with the compressed air stream and propelled against the work surface.

abrasive blast equipment

Get Price Quote

abrasive blast equipment, shot peening equipment

abrasive blasting machines

Get Price Quote

abrasive blasting machines are fabricated out of thick gauge crc sheet metal, sharing and bending and welded to perfection. It can work continuously without stopping for media refills . The surface finish are extremely good as compare to suction sand blasting. It has unique feature of in build dust collector are of its own kind, keeping floor clean and fresh ambient, reduce maintenance and greater productivity.application: used for cleaning engine components like cylinder head, crank case ,tappet cover, manifold and turbochargers parts.

Abrasive Blasting Machine

125,000 Per Piece

Cabinet type abrasive blasting machine we are manufacturer of all types of abrasive blasting machines.

Pressure Abrasive Blasting Machine

150,000 Per Piece

portable abrasive blasting machine

Get Price Quote

1 Piece (MOQ)

If you are searching for a abrasive blasting device that is portable yet highly functional, select Aerowheel Portable Abrasive Blasting Machine.Therefore, if you also want to get a Portable Abrasive Blasting Machine that can assist you to increase the production quantity of your business, order Aerowheel Surface FinishingPortable Abrasive Blasting Machine. The Machine we offer is prepared with stainless steel and weight 100-1000 kg. The Aerowheel Portable Abrasive BlastingMachine use 220volts unit electricity to work properly. AerowheelPortable Abrasive Blasting Machine is completely run by electricity and no manual labour is required for operating this device because it’s fully automatic. The power usage of this device is 1-3 kilowatt. You don’t need to get concerned about the order quantity of Aerowheel Portable Abrasive BlastingMachine since the minimum order quantity is 1 piece. As Aerowheel Surface Finishing is one of the massive Portable Abrasive Blasting Machine manufacturer, you can get this incredible machine by Aerowheel anywhere in India. You can get Portable Abrasive BlastingMachine in foreign countries too because we export too. Aerowheel Surface Finishing offers Portable Abrasive Blasting Machine at an affordable price that is more cheaper than the other trademarks. Therefore approach to Aerowheel Surface Finishing for receiving the best offers on Portable Abrasive Blasting Machine.

Abrasive blast cleaning machines

Get Price Quote

Portable Abrasive Sand Blasting Machine

Get Price Quote

Salient Features : We have in store with us an impeccable spectrum of Portable Abrasive Blasters. Customers can make use of varied media as an abrasive for different activities and finishes. Fabricated in accordance with the set industrial guidelines, our range is available in standard and customized specifications. Recommended for high output on big components like vessels & structures and our P7-501RSPL recommended for Components made of Stainless Steel & Sheet thickness before 4mm.

portable abrasive blasting machine

Get Price Quote

1 Unit (MOQ)

portable abrasive blaster

Get Price Quote

portable abrasive blasting machine

45,000 Per Piece

1 Piece(s) (MOQ)

TECHNICAL SPECIFICATIONS Model KI-P7 300R KI-P7 500R KI-P7 1000R Special Contractor Abrasive Capacity Metallic (Kg.) Sand (Kg.) Volume (Ltrs) 300 130 85 500 230 142 1000 460 284 600 276 170 Overall Dimensions approx Height (mm) Diameter (mm) Weight (Kg.) 1175 465 142 1375 620 192 1615 765 247 1515 620 205 Blast Nozzle Tungsten Car bide lined Office (mm) (standard size) 6 8 10 10 Blast Hose ID (mm) Blast Hose Length (mtr) Recommended Air Hose ID (mm) 19 5 19 25 10 25 32 10 32 32 10 32 Approx. Cleaning Rate (sq.Mtr/hours) 5-9 11-15 15-19 15-19 Compressed Air Requirement (M3/min) at6.33kg/Cm2 2.4 3.8 7.1 7.1 Recommend Abrasive Size (BSMesh) 25-80 16-80 16-80 16-80 Remote Control Operation Yes Yes Yes Yes

portable abrasive blaster

29,500 Per Piece

portable abrasive blasting machine

Get Price Quote

1 Piece (MOQ)

DBS-100 RC REMOTE-CONTROLLED Abrasive blasting machine

Get Price Quote

DBS-100 RC, REMOTE-CONTROLLED Abrasive blasting machine with RC, 100-liter, standard delivery Areas of useHigh performance abrasive blasting of metal constructions and buildings, bridges, reservoirs, piping, concrete surfaces.Cleaning up to grade SA-3,0.Performance up to 37 m2/h.Designed for working with any dry abrasives, max. grain size 3,5 mm. STANDARD DELIVERY100-liter capacity tank, screen, cap, sand valve, high-performance moisture separator, inspection door, quick hose couplingsRemote control device (RC) with a pneumatically-operated RC main valve, deadman handle, 40-meter twin-line hose, hose fittings.CAF-3All Contracor ® abrasive blasting machines are equipped on standard delivery with a highly efficient CAF-3 moisture separator to prevent the entry of moisture and oil from the compressor into the tank.