Abrasive Cut Off Machine

Get Price Quote

1 Piece (MOQ)

Abrasive Cut Off Machine Automatic and in Manual Version is availane from cutting Capacity 30 MM to 120 MM Dia. Description: Absolute minimal deformation, cool & burn-free sample production. Effortless cutting by lever mechanism, counter balancing. Robust construction and rigid clamping minimizing wheel breakage. Large and Effective coolant delivery by unique design of casted wheel guard with focused vains Control Panel incorporates door limit switch, emergency stop, illumination on/off & machine-on, switches. Indications of door open, power on, pump on. Covering other safety norms. Dedicated wheels for very hard , medium hard , soft components and universal wheel, in 10 " , 12 " & 14 ",thickness 1.5mm,2mm,3mm,hole sizes 1" or 1.25",(Al2O3). Capacity : 60/80/100 mm Round Specimen. Table Top Version for Cutting Cap. 35 mm dia. Hardened peice / 50 mm dia solid stock (soft). Automatic heavy duty sectioning machine for large cross sections, irregular components. Cutting Cap. - 130 mm dia. (through hardened 42 HRc) Cutting motion - Cutting wheel swings down on the job (Chope type) or Reciprocating swinging, Automatic Clamping - T slotted bed clamping, fixed vice, Automatic filtration system. Automatic heavy duty sectioning machine for large cross sections, especially for taking longitudinal sections. Cutting cap. - 100 mm dia. ( hardened) / 200 mm longitudinal section of shafts ( 40 dia ) Component is fed to the cutting wheel Programmable cycle of clamping, cutting, de-clamping.

FCM-150 Abrasive cutting machine

100,000 - 200,000 Per piece

1 piece (MOQ)

FCM-150 Abrasive cutting machine designed to cut various metal and non-metal samples to optimum quality. Cutting Capacity 150mm,Operation Manual/Automatic,Dimensions 650mm X 800mm X 1450mm.

Best Deals from Abrasive Cutting Machine

Abrasive Cutting Machine

Get Price Quote

Abrasive cutter is rugged, sturdy and designed to cut Metallurgical Samples to optimal quality consistently and safely . Cutting Wheel spindle is connected with motor shaft by pulley and belt mechanism. The movement of cutting wheel towards the specimen is applied by handle fixed with motor base pivot spindle and the cutter unit is balanced by springs for smooth chop type movement. Corrosion resistant window. Cooling by two high flow water jets to provide optimum cooling. Large (25mm) drain, re-circulation coolant tank with 30LTR. Capacity Working on 440 volts, AC main supply with coolant tank of sufficient capacity. The chop type cut off wheel machine is suitable for quick and clean cutting of metallography specimen from rods & tubes etc. X-Y Movement Vice is made up of M.S, Specially designed. Coolant circulation System is provided with suitable filtering arrangement. Light attachments system is provided for clean and accurate cutting of samples Heavy Duty motor is provided 2/3/5 H.P , 3 Phase. Large Viewing window to monitor the cutting operation. Technical Data- Operation -Manually by moving motor to cut the sampl. Cutting Operation :- By manual cutt-off wheel in chop type procedur.

Abraclean Abrasive Removal Pump System

Get Price Quote

Product Details : Every Abrasive Waterjet Cutting Machine needs clearing to remove used abrasive from the catcher tank on regular intervals. A machine has to be shut down during this process resulting into loss of production. It is very difficult and risky to remove the sticky sludge manually as sharp edges of scrap can injure the person Due to metals scrap and other debris shevelling is also difficult. Our abrasive removal pump can be integrated with our Machine CNC to program it for scheduled ON & OFF cycles The sludge will be delivered via flexible pipe & can be separated via cloth filter bag. Thus water can be regained into the catcher tank. This entire system increases the uptime of the machine & saves money of manual removal.

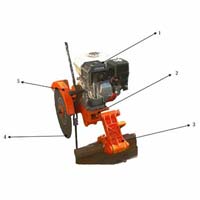

Abrasive Rail Cutting Machine

Get Price Quote

We are offering abrasive rail cutting machine engine - honda petrol engine power rate - 4.1 kw rpm - 3600.

Abrasive Cut Off Machine

145,000 Per Unit

Abrasive Cut Off Machine

Get Price Quote

We are offering abrasive cut off machine.an abrasive cut-off machine with complete operation for precision cutting of copper, brass, steel, alloy steel or non-metallic materials in cross sections range. A thin abrasive wheel can be used and highly accurate cutting length can be achieved. specifications of our abrasive cut off machine are as follows: sturdy floor model cutter for sectioning metallography samples rust proof construction steel vise cut-off wheel coolant tank coolant recirculation recirculation pumps

Abrasive Cut-off Machine

Get Price Quote

Our Abrasive Cut-off Machine are Used for Cutting Castings, Billets, Carbide Rods, Rock Samples, Ceramic Etc. of Varied Sizes. Abrasive Cut-off Machine are Available in Various Models, Sizes and Dimensions to Meet the Client’s Requisites. Machines for Cutting Several Rods and Components At a Time are also Possible.

405 mm Abrasive Cutting Wheel Making Machine

Get Price Quote

1 Set (MOQ)

Abrasive Cut-off Machine

Get Price Quote

The cast components have to be cut off at the in gate from the main sprue or runner bar. The abrasive gate cut off machine is used for this purpose. The ACM provides for a quick cut and is cost effective to use.

Abrasive Waterjet Cutting Machines

Get Price Quote

With An Experience over decade, Accurate Robotic Solutions Private Limited, Ghaziabad, is a leading supplier and manufacturer of Abrasive Waterjet Cutting Machines in India. Our quality and after sales services makes us unique among other manufacturers of Abrasive Waterjet Cutting Machines Abrasive Waterjet Cutting Machines With an increase proportion of technology, we are manufacturing, exporting and supplying high quality Water Jet Cutting Machine. Fabricated using superior quality raw material and advanced technology, these are designed with high precision in order to meet the set industry standards. These are widely appreciated among clients for their reliable performance, sturdy construction, longer service life and high tensile strength. Furthermore, our quality experts strive hard to provide flawless range of products at clients end. Used for Cutting Harder Materialse.g., Metals, Alloys & Super Alloys, Glass, Stone, Concrete, Glass composites, Ceramics and Hard Materials like Aluminum Oxide or Silicon Oxide etc. Lower Speed Compared to Pure Water Cutting But Hard Materials with Large Thicknesses and Complex Profiles can be Cut A Mixture of High Pressure Water and Abrasive Cuts the Material Superior Precision and stability are guaranteed by the Casting Beam and Y Axis Base Frame. Lathe Bed and water Tank are detachable which are designed to reduce the pressure from water with sands and machined parts to moving parts. X – Axis and Y – Axis : Rexroth/ABBA/HIWIN Or Equivalent ball Screw and Guide Linear Structure : Bridge Type

Abrasive Cut Off Machine

Get Price Quote

Abrasive Cutting Machine

Get Price Quote

Sofa Fabric Foil Transfer Bronzing Machine Application & Features The bronzing machine is suitable for bronzing, printing of fabric, plastic-skin, PU, PVC, cotton-hemp, silk, knitting etc. or colour changing of fabric, leather, PU,...

MMP-8 Abrasive Cut Off Machine

Get Price Quote

1 Piece (MOQ)

An abrasive cut-off machine with complete operation for precision cutting of copper, brass, steel, alloy steel or non-metallic materials in cross sections range. A thin 12” Dia abrasive wheel can be used and highly accurate cutting length can be achieved.Specifications of our abrasive cut off machine are as follows: Sturdy floor model cutter for sectioning Metallographic Samples Rust proof construction Steel vise Cut-off wheel Coolant Tank Coolant recirculation Recirculation Pumps

Manual Abrasive Cutting Machine

140,000 - 1,500,000 Per

Radicon Abrasive Cut Off Wheel Machine ( Model-RCM 948 )

Get Price Quote

Abrasive Cut Off Machine

Get Price Quote

1 Piece(s) (MOQ)

Metallographic Specimen Cutting Machine can be used to cut various metal or non-metal specimens (select different cutting disc according to different materials) so as to observe the Metallographic and lithofacies structure. The machine features high performance, low noise and high finish of specimen cutting sections, etc. The machine has nice appearance and it is easy to oprate safely and reliably. It is the ideal and nacessary specimen preparation instrument used in factories, scientific research institutes and colleges etc.

Abrasive Rail Cutting Machine

Get Price Quote

We are counted amongst the prominent Suppliers of Abrasive Rail Cutting Machine in Raipur, Chhattisgarh, India. Our vendors adopt the premium grade material and updated techniques for manufacturing it. It is completely in line with the set industrial standards and norms. We have enough capacity to deliver it in bulk quantities, within the given time frame. It is available in a high-quality packing material, to avoid the chances of mishandling during the transit.

Heavy Duty Abrasive Cutting Machine

Get Price Quote

1 Piece(s) (MOQ)

Abrasive Water Jet Cutting Machine

5,000,000 Per Piece

1 Piece(s) (MOQ)