ABS Sheet Rod Vaccum Forming Machining Components

Get Price Quote

10 Set (MOQ)

Although ABS polymers are resistant to alkalies, concentrated hydrocloric and phosphoric acids, aqueous acids, vegetable and mineral oils, alcohols and animal, but they are prone to get swollen by carbon tetra-chloride and aromatic hydrocarbons, glacial acetic acid. Concentrated sulfuric and nitric acids cause changes and deformation. They are soluble in acetone, esters, ketones and ethylene dichloride.ABS Properties High impact strength, also under cold High mechanical damping Good adhesive properties Outstanding electroplate ability Good thermoform ability Good weld ability Low moisture absorption Good sound damping properties ABS Fields Of Application Housings and control parts Transport containers Textile bobbins Musical instruments Chrome-plated trims Enclosures for electrical and electronic assemblies Protective headgear White water canoes Buffer edging for furniture and joinery panels Luggage and protective carrying cases Small kitchen appliances Toys Including Lego bricks Household and consumer goods are the major consumers. Battery boxes Radiator panels Golf club heads Automotive trim components Medical devices for blood access

Abs Sheets

Get Price Quote

500 Kilogram (MOQ)

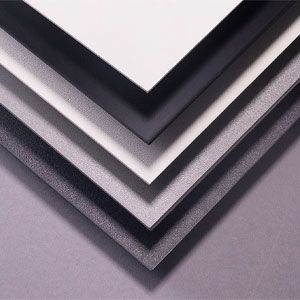

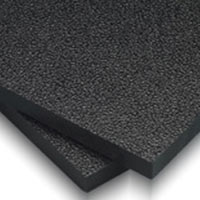

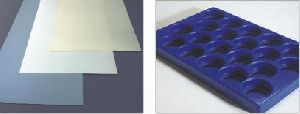

Our stock range of Acrylonitrile Butadiene Styrene (ABS) consists of different grades, such as virgin grade, economy grade, acrylic capped and flame retardant, in smooth and embossed finishes. ABS plastic sheets can be processed with ease and versatility. They can be machined, turned, drilled, milled, sawed, bored, die cut, routed and sheared using high-speed carbide-tipped tools. ABS can be machine finished by filing, grinding, sanding, buffing and polishing. ABS Plastic Sheet Characteristics High rigidity and impact strength Excellent chemical resistance Excellent abrasion resistance Excellent electrical properties, moisture and creep resistance ABS has good chemical and stress cracking resistance to inorganic salt solutions, alkalis and many acids (Except strong oxidizing acids) ABS is easily machined to close tolerances, is tough, dimensionally stable and may be thermoformed ABS Plastic Sheet Applications Automotive interior and exterior Aircraft interior trims Home appliances Architectural model buildings & Prototype Models ABS is easily machined to close tolerances, is tough, dimensionally stable and may be thermoformed Luggage Machine parts and rollers Pipes & Fittings Trays

Best Deals from ABS Sheets

Abs Sheets

Get Price Quote

The company is one of the major Manufacturers and Suppliers of ABS Sheets in Delhi. The ABS Sheets (Acrylonitrile Butadiene Styrene Sheets) are a widely used form of engineering thermo-plastic. The ABS Sheets are formed by the polymerization of styrene and acrylonitrile on to thermoplastic rubber. Then, the polymer is molten and combined with styrene acrylonitrile. The combination of the co-polymers gives the ABS Sheets an excellent surface appearance and makes it stronger, stiffer and tougher than the high impact polystyrene. The ABS Sheets are known for their resistance to high temperatures and chemicals.Features Of ABS Sheets High rigidity and impact strength Excellent electrical properties as well as moisture and creep resistance Good chemical and stress cracking resistance against inorganic salt solutions, alkalies and many acids (except strong oxidizing acids) Easily machinable to close tolerances Tough and dimensionally stable Easily electroplated Excellent scratch resistance Excellent weathering resistance Good wear and abrasion resistance Good thermoforming and printability Applications Bus Body Doors Automobile Vacuum Forming Automobile Chair backs Chair Backs (non-automobile) Housing Equipment’s Luggage Automotive interior and exterior Aircraft interior trims Laboratory equipment Luggage, Office accessories, Toys Machine parts and rollers ABS Thicker PMMA layer Bath tubs Vanities Hand basins Shower trays ABS Standard PMMA layer Shower-boxes/cabins/cubicles Shower trays Shower walls Panels for bath tubs Hand basins Steam cabins

Abs Sheets

Get Price Quote

Our stock range of Acrylonitrile Butadiene Styrene (ABS) consists of different grades, such as virgin grade, economy grade, acrylic capped and flame retardant, in smooth and embossed finishes.Details : ABS lends itself towards a great number of applications, such as cases, automotive applications, encasings and durable point of sale applications. Our products are available in stock in a wide range of popular sheet sizes, thicknesses, and colours. You may also benefit from our accurate cutting service, or our bespoke service for non stock sizes, colours and materials. Use our experience to help you meet your material requirements. ABS plastic sheets are available in two main grades, engineering grade ABS sheet and vacuum forming grade ABS sheet. ABS is the most widely used engineering thermoplastic today, and is formed by the polymerisation of styrene and acrylonitrile on to thermoplastic rubber which is then melt compounded with styrene acrylonitrile. The combinations of the copolymers gives ABS plastic sheets excellent surface appearance that is scratch resistant and available with smooth or textured surface. ABS plastic has stronger, stiffer and tougher properties than high impact polystyrene (HIPS). ABS plastic has superior resistance to high temperatures and chemicals compared to HIPS. ABS is a light and rigid material used in a variety of applications. ABS plastic sheets can be processed with ease and versatility. They can be machined, turned, drilled, milled, sawed, bored, die-cut, routed and sheared using high speed carbide-tipped tools. ABS can be machine finished by filing, grinding, sanding, buffing and polishing. ABS Plastic Sheet Characteristics : High rigidity and impact strength Excellent chemical resistance Excellent abrasion resistance Excellent electrical properties, moisture and creep resistance ABS has good chemical and stress cracking resistance to inorganic salt solutions, alkalis and many acids (Except strong oxidizing acids) ABS is easily machined to close tolerances, is tough, dimensionally stable and may be thermoformed ABS Plastic Sheet Applications : Automotive interior and exterior Aircraft interior trims Home appliances Architectural model buildings & Prototype Models Luggage Machine parts and rollers

Abs Sheets

Get Price Quote

Abs Sheets

300 - 350 Per Kilogram

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer widely used in the manufacturing of ABS sheets. These sheets are known for their strength, impact resistance, and versatility. ABS sheets exhibit good chemical resistance and are relatively easy to thermoform, making them suitable for applications like automotive components, luggage, electronic housings, and signage. They also offer a balance between rigidity and flexibility, contributing to their widespread use in various industries.

Abs Sheet

185 - 195 Per Kilogram

300 Kilogram (MOQ)

abs double color sheet

666 - 700 Per Piece

ABS Plastic Sheets

140 - 175 Per Kilogram

500 Kilogram (MOQ)

Our stock range of Acrylonitrile Butadiene Styrene (ABS) consists of different grades, such as virgin grade, economy grade, acrylic capped and flame retardant, in smooth and embossed finishes.Details : ABS lends itself towards a great number of applications, such as cases, automotive applications, encasings and durable point of sale applications. Our products are available in stock in a wide range of popular sheet sizes, thicknesses, and colours. You may also benefit from our accurate cutting service, or our bespoke service for non stock sizes, colours and materials. Use our experience to help you meet your material requirements. ABS plastic sheets are available in two main grades, engineering grade ABS sheet and vacuum forming grade ABS sheet. ABS is the most widely used engineering thermoplastic today, and is formed by the polymerisation of styrene and acrylonitrile on to thermoplastic rubber which is then melt compounded with styrene acrylonitrile. The combinations of the copolymers gives ABS plastic sheets excellent surface appearance that is scratch resistant and available with smooth or textured surface. ABS plastic has stronger, stiffer and tougher properties than high impact polystyrene (HIPS). ABS plastic has superior resistance to high temperatures and chemicals compared to HIPS. ABS is a light and rigid material used in a variety of applications. ABS plastic sheets can be processed with ease and versatility. They can be machined, turned, drilled, milled, sawed, bored, die-cut, routed and sheared using high speed carbide-tipped tools. ABS can be machine finished by filing, grinding, sanding, buffing and polishing. ABS Plastic Sheet Characteristics : High rigidity and impact strength Excellent chemical resistance Excellent abrasion resistance Excellent electrical properties, moisture and creep resistance ABS has good chemical and stress cracking resistance to inorganic salt solutions, alkalis and many acids (Except strong oxidizing acids) ABS is easily machined to close tolerances, is tough, dimensionally stable and may be thermoformed ABS Plastic Sheet Applications : Automotive interior and exterior Aircraft interior trims Home appliances Architectural model buildings & Prototype Models Luggage Machine parts and rollers

Abs Sheets

Get Price Quote

100 Square Meter (MOQ)

NovaTherm ABS Sheets are made from Acrylonitrile Butadiene Styrene (ABS), a polymerization of Acrylonitrile, Butadiene, and Styrene monomers. Chemically, this thermoplastic family of plastics is called "terpolymers", in that they involve the combination of three different monomers to form a single material that draws from the properties of all three. ABS Sheets have excellent impact & mechanical resistant. Owing to dimensional stability and electrical insulating properties, ABS Sheets are suitable for tough consumer products.Advantages : Weldability ultrasonic/thermo/chemically Excellent impact resistant High strength & durability Good machinability Good electrical properties Suitable to be used for thermo or pressure formed, sheared, sawed, drilled, cold stamped High mechanical Strength Applications : Suitcase Body Bus Body Building Storage cases Sanitary Ware Product holders & Containers Point-of-purchase displays Display components Models and prototypes Machine housings, guards, and covers Instrument panels Thermoformed trays and bins Grades : ABS, ABS Modified, ABS -FR ,ABS -UV Colours : Black, Custom Embossing : Egg Crate; Cracked Ice; Decorative; Flower; WaterCrush

Abs Plastic Sheet

Get Price Quote

Abs Sheets

3,000 Per Sheets

1 sheets (MOQ)

Abs Sheet

Get Price Quote

50 Piece (MOQ)

abs double color sheet

110 Per Kilogram

500 Kilogram (MOQ)

Abs Sheets

Get Price Quote

ABS Sheets (Acrylonitrile Butadiene Styrene) is the widely used engineering thermo- plastic and is formed by the polymerization of styrene and acrylonitrile on to thermoplastic rubber which is then melt compounded with styrene acrtylonitrile. The combination of the copolymers gives ABS excellent surface appearance, stronger, stiffer and tougher than high impact polystyrene and is also superior to it in its resistance to high temperatures and chemicals

Abs Plastic Sheet

Get Price Quote

These Novathene PE Sheets are made from Polyethylene, the best known volume plastic. PE Sheets have a relatively high molecular form with medium to high density. PE Sheets have excellent resistance against UV radiation, which increases life. PE Sheets that we offer are tough, sturdy and have resistance to stress cracking & chemicals. PE Sheets are non-toxic and non-staining & is demanded for their FDA approval and food contact suitability & machine-ability. The operating temperature of PE Sheets ranges from -30o C to 70o C.

ABS Fiber Sheets

Get Price Quote

ABS Double Color Sheets

Get Price Quote

ABS Laminate Sheet

2,700 Per Sheet

1 Sheet (MOQ)

ABS Plastic Sheets

455 Per Piece