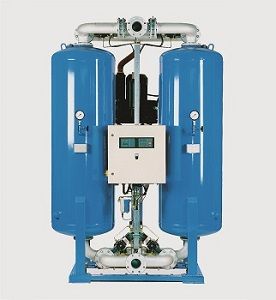

ECOTROC ATK-ECO Adsorption Dryer

Get Price Quote

The ECOTROC® ATK-ECO Adsorption Dryer that we bring forth is designed by our team of dexterous professionals under the experienced personnel. Plus, the ECOTROC® ATK-ECO Adsorption Dryer that we offer is made in line with the laid quality norms and standards. It is performance oriented and assured longer functional life.

engineered adsorption dryers

Get Price Quote

The compressed air coming from the compressor gets collected in the after cooler and passes through the pre-filter to a distributor. The distributor passes part of the air through a heater before going to one adsorber for regeneration. This compressed air is then passed through an after cooler for condensation and moisture separator for removal of moisture.

Best Deals from Adsorption Dryer

Heatless Adsorption Air Dryer 1

Get Price Quote

We are amongst the chief heatless adsorption air dryer manufacturers, importers and suppliers based in india. Our heatless adsorption air dryer is based upon the natural phenomenon of “desiccant”, which allows establishing equilibrium with the surroundings. In heatless adsorption air dryer, wet air (fluid) is cycled automatically between two desiccant towers. One tower adsorbs the moisture from the wet fluid, while the other being regenerated. The wet fluid enters the first tower and it passes through the desiccant bed where the saturated moisture is absorbed. Afterwards, a small portion of the dried air at ambient temperature and pressure is passed through the desiccant bed in the second tower for regeneration. At present interval, the towers changeover automatically and the cycle continues giving out a regular supply of fantastic dry air, which have dew points up to (-) 70oc (atm.) types embedded internal heat adsorption dryer. split flow no loss adsorption type dryer. heat of compression no loss absorption dryer. blower heat regenerated no loss adsorption dryer.

adsorption dryer

Get Price Quote

This is the simplest type of Air Dryer with Activated Alumina Molecular sieves Drying agent. Investment wise also this is the cheapest. This design is virtually maintenance free, fully automatic, and requires no attention for years. Cold regeneration type dryers do not require any heating for re-generation and therefore are very simple in design and smooth in operation.

Adsorption Air Dryer

Get Price Quote

Micro heat regenerated adsorption dryer works in a twin-tower alternative operation mode. Compressed air enters the dryer’s tower A through valve 1A (1B is closed), then is dehydrated and dried under the unique adsorption action of the adsorbent. Finished gas flows to the gas using point through valve 5A (5B is closed); meanwhile about 5% dry air source enters tower B through valve 4B (4A is closed) after being heated by the heater, the adsorbent in which is regenerated after a certain period of heating. Cold blowing begins when heating is stopped, which cools down the adsorption bed in the dryer’s tower B (for use in the next cycle). Finally, the air is discharged into the atmosphere through muffler. Before switching in the second half period, turn off valve 2B and open valve 1B to equalize the pressure in the two towers (to ensure pressure stability when using the gas and avoid the impact and jitter of the dryer), and the second half period work begins at the same time (the dryer’s tower B works and tower A regenerates). The process is similar to that of the previous half period. They save energy besides economising purge by reducing the loss of purge to a minimum of 50%. They have controllers with lucid functional displays that are programmable. They secure undisturbed operation despite tower changeovers. The moisture load is lessened by the auto drain valves in pre and oil filters. Therefore the desiccant life is secured without any extra cost. The inclusion of a unique purge economizer in the latest microprocessor based controller which facilitates manual setting up of the dryer load. This device can not only accept upto 3 compressor load/unload contacts but also compute the dryer load dynamically. According to these settings done, the purge can be set. Also, the purge air can be controlled according to the pressure input accepted by the controller.

Adsorption Air Dryer

Get Price Quote

Heatless adsorption dryers are used in certain applications where compressed air moisture can damage the process or products. With the use of activated alumina as the desiccant our heatless dryer can produce up to - 400C pressure dew point and can be raised to -700C by using molecular sieves.

adsorption dryer

Get Price Quote

FTIPL Customaries drying solution finally pays back to customer. We offer highly efficient drying by means of adsorption dryers & RefrigeratioCompressed air one of the most important source of energy within industry today. Insufficient treatment of this air leads to the build-up of aggressive condensate, which not only causes havoc in pipe work and pressure vessels but can lead to expensive downtime and paralysis of production processes. n dryers. Our Compressed air dryers are engineered components for complete systems, which outperform the requirements regarding their capability, operating reliability and efficiency.

adsorption dryers

Get Price Quote

ECOCLEAN® compressed air filters meet the strictest quality requirements and are extremely economical to purchase, operate and maintain. The housing is made of cast aluminium, with a chromebased protective coating on the inside and outside and an additional powder coating on the outside. Features: Optimized flow, due to the curved compressed air inlet Prevention of corrosion and bacteria formation The filter element is fastened securely by tie-rod Filter element with stainless steel cylinder for high strength The filter medium is wound up to 8 times, ensuring long life and lowdifferential pressure The dimensionally stable drainage layer made of needled felt prevents any deterioration in filter performance Fitted with automatic condensate drain as standard Easy to service and maintain, with hexagon nut flats on housing

adsorption dryer

Get Price Quote

The system consists of twin towers filled with desiccant of appropriate quality and quantity. Wet compressed air after being filtered by the prefilter and coalescing oil filter enters the distribution valve. An electrically operated valve with built in passages, which directs the air to one tower. The air is then passed through the tower and comes out in dry condition. The air is then passed through after filter to remove any carry over dust, via non-return valve. There is a by-pass arrangement with an orifice, to allow a fraction of dry compressed air to expand and pass through the other tower, here by regenerating it and making it ready for adsorption Cycle. The Regenerating air is passed out to the Atmosphere via muffler. At a preset time, the sequence control timer actuates the Distributor valve to reverse the tower function .

Adsorption Air Dryers

Get Price Quote

Heat of Compression Air Dryer [Series DC] Trident Refrigeration Compressed Air Dryer is an ideal solution for clean and compressed dry air. It is the result of extensive design and prototype testing and provides a consistent dew point of 3 c. Compared to other Air Dryers the HX Series of Trident has a very low running cost.No-loss Split Flow Air Dryer [Series DS] Trident make split flow dryers offers dewpoint of -40c depending on the requirements. These dryers utilise heated part of air for regeneration and there is no air loss in this type of dryer. These dryers are available for any capacity higher than 500 scfm. Internal Heated Type Air Dryer [Series DI] Trident make internal heated dryer offers good dewpoint.Heaters are kept inside the insulated tower and the tower is heated to the required temperature and pumped.These dryers are available for any capacity higher than 500 scfm. Blower Heat Reactivated Air Dryers Trident Blower Heat Reactivated Air Dryers offers a very good dew point of 50c or better depending on the requirement.These dryers are useful for instrumentation air meeting the quality requirement of ISA s7.34. Available for any higher capacity from 500 cfm to 4000 cfm. Operation The Blower Heat Reactivated Dryer works on the principle Thermal swing. The desiccant adsorbs moisture from the compressed air to deliver dry air. The desiccant bed saturates over a period of time. The saturated bed is regenerated by heating with hot air generated using a blower. Hence the dryer is called blower heat reactivated desiccant dryer. Since the temperature of the bed swings between the compressed air temperature and the regeneration temperature it is called Thermal swing type. The hot air from the blower passed through a heater. This makes the air very dry. The hot air then heats up the desiccant bed. When the bed is heated it gives up the moisture adsorbed and is ready for adsorption. The hot air carries this moisture to the atmosphere. After the regeneration, heated desiccant bed is cooled by the flow of air to suit the application conditions. Final Cooling is achieved by a no loss compressed air cooling method, resulting in a no Dewpoint spike system. Trident dryer comes with a dewpoint based control system as a standard. The tower changeover takes place only when the bed is saturated, resulting in energy saving and extended life. The dryer with its control valves and controller manages the drying, regeneration and repressurisation of the desiccant columns automatically and thereby delivering continuous dry compressed air.Blower Heat Reactivated Dryers are best suited for applications requiring large volume of compressed air at low dewpoint. For the above conditions the dryer works out very economical energy wise. Trident blower heat reactivated dryers are built from the start for customization. Since the air volume is large cusomisation delivers substantial energy savings.Salient Features Accordance with ASME or IS codes. Offered for 3rd party inspection. Typical operating pressures are 5 to 9kg/cm Micro processor based control panel.low dewpoint Low pressure drop Low energy cost for given dew point Compact Ready to use Reliable design and components Available to various standards Dew point based tower changeover controls Low total cost of ownership Extensive operation and maintenance manuals Contact us or visit our web site for the design input details to enable us to give you a correct solution.Application Power stations Plant air Instruments. Designed for Air Inlet Pressure 7 Kg/sq.cm Designed for Air Inlet temperature 38C Designed for Ambient temperature 35C Desiccant : Activated alumina with adsorption capacity 14%

Adsorption Dryes

Get Price Quote

adsorption dryer

Get Price Quote

Adsorption Air Dryer

Get Price Quote

Backed by the support of our dexterous team of experts, we are able to manufacture and supply a wide gamut of quality assured Adsorption Air Dryer. Used for a low dew point and easy regeneration, these air dryers are designed using top grade material and advance technology at our end. Our offered air dryers are quality checked on various quality parameters in order to deliver a flawless range. Features: Application specific design Smooth performance Low maintenance cost

Adsorption Air Dryer

Get Price Quote

The Adsorptive Air Drying has been specifically designed to enable the complex theoretical principles of adsorption processes to be conveyed clearly and comprehensibly. Moist air flows through the adsorbent (silica gel), which is placed in a transparent column as a packed bed, and the moisture is adsorbed. The adsorbent contains an indicator. The colour of this indicator shows the position of the mass transfer zone. Once the capacity of the adsorbent in this column is exhausted, the moist air is fed through a second column with regenerated adsorbent. The experimental setup allows simultaneous investigation of the adsorption process and the regeneration process for the adsorbent which uses heated air. Recordings of all relevant parameters enable both processes to be completely balanced.

Heatless Adsorption Air Dryer

Get Price Quote

Working Heatless Desiccant Air Dryers remove water vapor from compressed air through a process known as Pressure Swing Adsorption.A solid state controller automatically cycles the flow of compressed air between the towers, while the "online" tower is drying, the "offline" tower is regenerating. Regeneration, sometimes referred to as purging, is the process by which moisture accumulated during the "online" cycle is stripped away during the "offline" cycle. As dry low pressure purge air flows gently through the regenerating bed, it attracts the moisture that had accumulated on the surface of the desiccant during the drying cycle and exhausts it to the atmosphere. Our offered Heatless Adsorption Air Dryer is acknowledged among our clients its compact design, low maintenance cost and robust structure. Benefits Due to its inherent simple design, investment in this type of dryer is the cheapest and the payback on this investment is very quick. Low temperature operation reduces corrosion in towers and desiccant lasts longer. Power requirement is 60 watts only for solenoid valves operation.

Adsorption Air Dryer

Get Price Quote

Adsorption Air Dryer, Spray Dryers, Refrigerant type air dryers

Adsorption Air Dryer

Get Price Quote

Adsorption Air Dryer, Compressed Air Dryer, solar air dryers

Swing Adsorption Dryer

Get Price Quote

Swing Adsorption Dryer, Reliable Automatic Drain Valves

adsorption dryers

Get Price Quote

adsorption dryers, Micro Filters, acetylene cylinders, Steel Cylinders

engineered adsorption dryers

Get Price Quote

engineered adsorption dryers, automotive drain valves