Aerosol Bottle Crimping Machine with Table

75,000 Per Piece

1 Piece (MOQ)

Aerosol Bottle Crimping Machine with table (Pneumatic) 12,000-15,000 bottles per day. Easy to operate. Double Cylinder used for high accuracy. With working table.

Aerosol contract filling job work

1,000 Per Set

all types aerosol filling job work

Best Deals from Aerosol Machine

aerosol filling machine

Get Price Quote

1 Piece (MOQ)

Automatic Aerosol Filling Machine

1,500,000 - 1,800,000 Per Piece 1

1 Piece (MOQ)

Semi Automatic Aerosol Filling Machine

650,000 Per Piece

1 Piece (MOQ)

aerosol filling machine

Get Price Quote

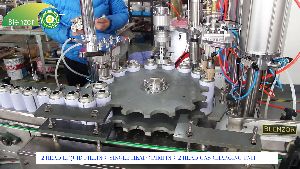

Rotary machine consisted of- Container Feeding Turn Table Indeed Conveyor. Automatic 2 Head Rotary Liquid Filling Unit. Single Head Crimping. Automatic 2 Head Gas Charging Unit. Technical Parameters : Pump Loading-Manual LPG Columns & Storage tank for Aerosol Containers Consisted of 6” dia. Column MS seamless pipe with pressure gauge & filtering unit & then after pass the filter 500Lit capacity of MS Storage tank to pass the filtered Gas. All Contact Parts-SS316 FLP Arrangement Filling capacity-10ml to 200ml Consisted of NO Container NO Liquid Filling & NO Container - NO Pump Loading (Pump loading by manually) as well as No Container No Crimping & No Container No Gas Charging. Consisted of Simple System for UHMW/CAST NYLON TURRET with Height Adjustment Any Change over for Varies as per dia. of the Containers in Crimping & Gas Charging unit. Gassing Head for Charging the LPG Gas which is applying with Booster Pump (Individually operation) & it’s operated with Two Stations ie. Initially filled with 40% & then after remaining 60% filled. Indexing with Pneumatic operation MANIFOLD separately for Rotary Liquid Filling as well as Crimping & Gas Charging Stations. Crimping Device-Pneumatic Operated Gassing Device-Pneumatic Operated Turn table Motor & Conveyor Motor with FLP (from Rotary Liquid Filling M/C to Gas Charging M/C) 0.5HP & 1HP respectively with Make - HINDUSTAN & with Suitable Gear Box Ratio Make - Bonfigloli as per requirement of Drive arrangement. LPG gas columns (will be kept at outside of the m/c) for molecules filtration before gas passing to the Gas charging stations via providing the storage tank. Operational Description : The Empty Containers Feed Manually onto the Feeding Turn Table which moves forward slowly up to the Filling Heads. It’s detect with FLP Sensors & after getting the feedback through the panel. Filling Nozzles will come down & filled the Containers as per settled Volume. This all operation will be done with Pneumatically operated. This Filled Containers moves forward & comes on to the further Line of Crimping & Gas Charging M/C Conveyor. During that time Pump Loading will be manually into the Filled Containers. It’s Moves forward to the Turret Cavity as per size of the Containers. This containers Index & rotate Clock wise with proper guiding & after indexing completion; Crimp the Pump with Pneumatic operated Cylinders. Crimping Setting will be done as per trial & error method which will set once a time with using Crimping & Checking the Depth Gauge as per standardise. After Crimping the pump; again Index the Turret with Crimped Bottle & Comes at Gas Charging station. At that time sense the container & give the signal to the Gassing Head. Gas will be fill into the Container which is pass through the Booster Pump ie. For Pressurize Gas filled into the Containers. For these operation we will provided Two separate Booster Pump due to easily filled the container with High Volume & for better accuracy as well as increase the productivity. These filled container moves forward to the next station & comes out at the Exit side conveyor. This whole assly. will be provided with Height Adjustable type due to Various Container sizes. Gas Charging will be operate as per requirement of Gas has to be charge & filled into the Containers ie. Either 2Nos OR 3Nos (As applicable) Gas charging will be applied as per depends upon the Filled quantity. These Gas Filled containers are moves forward from Gassing Exit Conveyor. This finish container comes out at the exit side of the Conveyor. This whole entire cycle repeat again & again with all sequence one by one & with Pneumatically as well as Electrically Logic operation (wherever applicable).

Aerosol Crimping Machine

45,000 - 50,000 Per

1 Box (MOQ)

Semi Automatic Aerosol Can Filling Machinery

650,000 Per Set

1 Set (MOQ)

aerosol filling machines

500,000 Per Piece

1 Piece (MOQ)

aerosol filling machine

Get Price Quote

aerosol filling machine

85,000 Per piece

1 piece (MOQ)

Aerosol Filling and Crimping Machine

Get Price Quote

The company has come up as a highly trusted Manufacturer, Exporter & Supplier of Aerosol Filling and Crimping Machine. The Aerosol Filling and Crimping Machine, offered by the company, are known for their feature-studded construction as well as high efficiency. The company offers the Aerosol Filling and Crimping Machines at the best prices and the consignment delivery is always on time. Working The filled containers, which are firstly filled at existing line, come on to the line & move forward to the turret cavity. The containers go through indexing and are rotated clockwise with proper guiding. After indexing is completed, the pump will be placed inside to the containers, with the operating pump and dispensing unit coming from the chute. These pump-loaded containers are oriented & passed to the next station for positioning & crimping the pump with pneumatic-operated cylinders. After crimping the pump, the gas will be filled into the containers with the help of booster pumps. For these operations, two separate booster pumps are provided to easily fill the container for better accuracy as well as increasing the productivity. These filled containers move forward to the next station & come out at the exit side conveyor. This cycle repeats again and again with all the sequences one by one and with the electro pneumatic operation. Details Consists of WP ARO - 40 High-speed 8 Stations MODEL GMP, Compact Rotary SINGLE HEAD AUTOMATIC Pump Loading & Crimping & Twin Head Gas Filling M/C for Aerosol Containers. Perfume filling at your scope of supply. Consists of All Contact Part SS-316 will be provided. Consists of Pump Loading will be Manually feeding arrangement. Consists of NO Container - NO Pump Loading as well as No Container No Crimp & also No Container No Gas Filling arrangement will be provided. Machine Speed 35 to 40 containers per min Max. Consists of Simple System for UHMW/CAST NYLON TURRET with Height Adjustment Any Change over for Varies as per dia. of the Containers. Consists of Pre Crimping Head for initially crimp the Pump at the time of Pump placing & Final Crimping will be done with Crimping Head. Consists of Gassing Head for Filling the LPG Gas with applying Booster Pump & its operated with Two Stations ie. Initially filled with 40% & then after remaining 60% filled. Consists of INDEXING DEVICE which is operated with Pneumatic operation MANIFOLD. Consists of CRIMPING DEVICE Pneumatics operated for compact design & up-to-date technology two sets, with the indubigely operation of pressing for initially Pre Crimping, and then Final Crimping will be done. SS Control panel Box with provided Pneumatic circuit operation Logic. All Pneumatic will be used Branded Make Festo / Janatics / SMC / Duncal as per suitable application. Consists of Conveyor Motor FLP 0.5 Hp, Make HINDUSTAN/REMI. And with Suitable Gear Box-24:1 Ratio Make Bonfigloli With Separate Drive System. Machine Tentative Dimensions : (Length 4500mm x Width 1500mm x Height 2000mm.) Machine Weight Approx : 750 Kg.

aerosol filling machine

Get Price Quote

LPG Filtrating Column is a four-column linear connected in series with rigid seamless high pressure tubes and Bite type fittings ( hydraulic grade ), OnOff valves, Safety valves and mounted on a sturdy powder coated stand, suitable for filtering industrial LPG for aerosol use.

electric semi automatic aerosol filling machine

500,000 - 1,700,000 Per piece

1 piece (MOQ)

For more details please contact

aerosol semi automatic crimping machine

Get Price Quote

Aerosol Crimping Machine

Get Price Quote

Used to apply sufficient pressure on valve-gasket before crimping to take care the variation up to +- 0.5 mm in can heights Helps in crimping 1” aerosol valves on aluminum or tin cans, foot pedal. FEATURES : We supply a semi-automatic crimping machines that provide 'Can push' operated-auto-return for positive crimping. Our crimping machines are known for their qualitative features like quick setting crimp-diameter, crimp-depth and auto-adjustment. Suitable for all type of aerosol cans these are offered at economic prices. Operating air pressure: 6 to 8 kg. Sq. cm. Capacity: Approx.4000 UnitsShift. (Depending on operator’s skil

aerosol filling machine

900,000 Per Piece

1 Piece (MOQ)

Automatic Aerosol Filling Machine

Get Price Quote

ONE Piece(s) (MOQ)

We are offering automatic aerosol filling with pump crimping & gas charging for deo containers model - wpm - aro - 40 this is suitable for deo spray containers with manually pump loading & automatically pump crimping as well as gas charging (provision with 2 heads) by overall pneumatically operational work due to avoid hazards. This type of machine getting output 40 containersmin max for 100 ml setting & accordingly reduce the volume will be increase. Ss control panel providing with overall pneumatic logic ie. No container no crimp as well as no container no gas charging (in 2 heads individually) operational work. Only providing conveyor geared motor with flp arrangement at other end of gas charging. Gas charging will be providing with boosting operation (2 separate booster will be provide for individual head). The overall pneumatic fitment will be providing with festo metal work as per suitable for logically operational work.

aerosol filling machine

Get Price Quote

Manufacturer of a wide range of products which include aerosol bottle filling machine.We are Manufacturer and Exporter of Aerosol Machine. User can make any type of gas bottle like Deoderant, Perfumes, Spray, Polish spray and many purpose.

Aerosol Line Machine

Get Price Quote