Standard Centrifugal Pump Agitated Nutsche Filter

300,000 Per Piece

1 Piece (MOQ)

Agitated Nutsche Filters

Get Price Quote

Determined to present the utmost quality, we are involved in offering Agitated Nutsche Filters. Our capable staff keeps manufacturing process under stringent guidance to make certain our quality is in fulfillment with different quality grades set by industry. Hence, our customers can be certain of the excellence on offer. We offer a range of several designs and sizes. At their ease, customers can get them delivered. Details : Pressure Nutsches can handle a variety of flow rates and solids loading that can be discharged in dry or slurried form. They can be designed for pressures up to 75psi or full vacuum. Pressure nutsches are ideal for lab, pilot or batch applications and for easily filtered material such as carbon particles, salts and other products where a cake thickness of 6 inches or more can be attained.Pressure Nutsche Applications : Ideal for piloting of new or modified batch operation and/or processes requiring recovery of the cake. The Pressure Nutsche is excellent for lab, pilot or batch applications where cake thickness of 6” and above is achievable.

Best Deals from Agitated Nutsche Filter

pressure nutsche filter

100,000 - 1,000,000 Per Piece

1 Piece (MOQ)

Being a reliable name in this arena, we make sure that the payment procedures remain secured with us. In addition, we issue invoice to the clients stating all the relevant information of the products. To avoid any type of mechanical and biochemical harms, we pack our products in high-grade packing items that are sturdy as well. Moreover, we provide product details on it as well. Features: High-performance Robust construction Easy operations & maintenance

Agitated Nutsche Filter

Get Price Quote

1 Piece (MOQ)

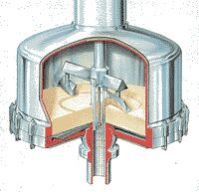

Details : Agitated Nutsche filters consist of a cylindrical shell with welded dished end at the top and either a flanged and bolted dished end or a welded dished end / flat welded end at the bottom depending upon process/customer's requirements By means of a perforated plate, provided with suitable filter cloth or porous cloth, the vessel is divided into two compartments An agitator of unique design is provided inside the vessel By manipulating movement in vertical and rotational directions simultaneously, the agitator can perform various activities with the use of push buttons switch/PLC The filter is capable of operating under pressure or vacuum or a combination of both The filter precludes any possibility of atmospheric pollution from toxic fumes/ obnoxious smell of slurry by working as a completely closed system ADVANTAGE : All operations can be handled by a single unskilled person with little training. Proper washing of cake due to re-slurrying resulting in thorough particulate washing. This reduces numbers of washes and volume of wash liquor. Reaction filtration, washing and distillation is possible in the same equipment. In some cases, drying operation can also be carried out in the same equipment. Heat transfer surface can be provided with the help of a jacket or limpet coils on the vessel walls. Indirect heating can be provided on the filter base and agitator. Available in special construction for sterile applications with high standard of particulate purity.

Agitated Nutsche Filter Dryer

750,000 Per Piece

1 Piece (MOQ)

pressure nutsche filter

Get Price Quote

1 Piece (MOQ)

Pressure Nutsche Filters

Get Price Quote

We hold specialization in manufacturing and supplying high quality Pressure Nutsche Filters that are widely used to separate solid and liquid by filtration under pressure or vacuum or in combination of both. It is a closed vessel designed that can be re-slurried and washed thoroughly with water or solvent. The discharge of wet cake is automatic. Drying of wet cake is also possible when drying features are incorporated. Pressure Nutsche Filters are constructed to perform a multitude of tasks including reaction, filtration, cake washing and thermal drying on a single unit. As such these are very sophisticated machines with tight process control on parameters such as pressure, temperature and PH. Components The Nutsche in its full configuration consists of four major components : The vessel The filter Plate and cloth, woven mesh screen or sintered metal plate medium The re-slurry arms for cake washing and smoothing The cake discharge mechanism Nutsche Filters are operating as part of a batch system hence the vessel's volume is designed to accept an entire charge of slurry from the upstream equipment. Therefore, so that the idle time of the filter is kept to a minimum, sufficient holding volume is required for fast charging and emptying of the vessel. The vessels are generally designed for an operating pressure of 2-3 bars but higher pressures may be specified if required. The vessel's cover supports the hydraulic system that controls the independent raising and lowering of the rotating auger and reslurry paddle arms as well as the various flanged connections and maintenance manhole. Applications Chemical Industry Food & Beverage Industry Bulk Drugs Fertilizers Pesticides Dyes Cosmetics Industry Petroleum Refineries Petrochemical Plants Natural Gas Processing Refrigeration Power Plants Space Heating Allied Industries Use : To separate solid and liquid by filtration under pressure or vacuum or in combination of both.Sizes Available : As per the Customer RequirementRaw Material Used : Stainless Steel (SS-316, SS-304, Alloy-2205).Price : Rs. 2 Lacs to 20 Lacs

Agitated Nutsche Filter

50,000 - 500,000 Per Piece

1 Piece (MOQ)

SS316L Sintered Plate for 1500Dia Nustche Filter

Agitated Nutsche Filter Dryer

Get Price Quote

Agitated Nutsche Filters

Get Price Quote

Associated with a diligent professionals and smart packaging facility, we are capable to undertake standard as well as tailored packaging requirements of the clients. Our products are subjected to the payment terms & conditions of our company. Patrons are provided with the terms & conditions, and can make purchases with a payment method best suited for them. Features : Quality tested Lightweight

Agitated Nutsche Filters

Get Price Quote

designed and manufactured to suit critical hygienic conditions of pharma and food industries. Detachable bottom is operated by hydraulic cylinders and held tightly with zero leakage. Offered in various materials of constructions, like stainless steel, carbon steel, rubber lined carbon steel and lead lined carbon steel. Offered in a wide range of filtration area capacities. Significant squeezing of filter cake is possible, there by resulting in considerably lower residual moisture in the cake, resulting in reduction in energy requirement for drying of filter cake by upto 40% depending on cake characteristics. Method of operation is totally enclosed, neat and hygienic. these conditions are excellent for solvent recovery, handling of toxic and hazardous materials without human intervention. Enables easy, non-manual and automatic cake/solid discharge. Scraper blade is provided to scrap the material which may stay on shell. The unit is designed with minimum maintenances feature. we provide gmp and non gmp in detachable and mono block agitated nustche filters . we manufacture capacities ranging from 0.5 kl to 10 kl.

Agitated Nutsche Filter

Get Price Quote

Agitated Nutsche Filter

Get Price Quote

Avoids cumbersome handling of materials, streamlines filtration process. Easy Operation, Easy Maintenance. Completely safe operation. Fail-safe protection devices are inbuilt for different operations. Saves labour up to 80%, filtration time up to 70% and filter space up to 50%; when compared to conventional filters like centrifuges, open filter nutsches and filter presses. NH filter is available in different designs to suit various products of Pharmaceutical, Dyestuff, Food processing and Fine chemical industries. Jacketed or limpet can also be provided on request. Pilot plant is available for trials at our factory

Agitated Nutsche Filters and Dryers

Get Price Quote

Agitated Nutsche Filters and Filter-Dryers: With more than 1000 installations across continents we are one of the largest ANF manufacturers in the world today We are pioneers in India for Stable Drive Systems, Sterile construction and special process features in filters and filter-dryers. We have manufactured and commissioned 10,000 Litre Hastelloy® Agitated Filters and Filter-Dryers – the largest in the country We have successfully commissioned more than 100 machines in Hastelloy® – C276, C-22 and C-2000 Our equipment are highly customizable for enhanced process flexibility Sizes ranging from 20 Litres to 20,000 Litres Large number of variants available with options for cGMP, Pharma and Sterile applications We offer a range of MOCs and also clad or polymer-lined construction We have supplied equipment for Food & Beverage, Pharmaceutical, Fine Chemical, Agrochemical, Chemical, Herbal Extraction and other related industries We also offer a range of Pilot plants in Stainless Steel and Hastelloy® with GMP construction

ANFD Agitated Nutsche filter

Get Price Quote

Agitated Nutsche filter (ANF) is a filtration technique used in applications such as dye, paint, and pharmaceutical production[1] and waste water treatment.[2] Safety requirements and environmental concerns due to solvent evaporation led to the development of this type of filter wherein filtration under vacuum or pressure can be carried out in closed vessels and solids can be discharged straightaway into a dryer.

AGITATED GLASS NUTSCHE FILTER

Get Price Quote

agitated glass nutsche filter agitated glass nutsche filter is a closed vessel designed to separate solid and liquid by filtration under vacuum. The closed system ensures odourless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated nutsche filters are extensively used in herbal products, chemical product development, kilo lab operation, pharmaceutical manufacturing, agro chemical and the food industry. general description a typical unit consists of a dish shape vessel vessel with a perforated plate. The entire vessel can be kept at the desired temperature by using a jacketed and stirrer (blade and shaft) through which heat transfer media can flow. The vessel can be made completely leak-proof for vacuum or pressure service. The base plate is having arrangement of bolting bar to hold the filter cloth. Suitable nozzles can be provided including manhole and side discharge nozzle. Ptfe lined stirrers are used for agitator shaft and solid ptfe blades are used to take high torque generation during solid discharge and re-slurring operation. process steps of agitated nutsche filter with agitator and discharge valve are:- 1) filtration2) washing of filter cake3) repeat mix or washing of the cake4) convection drying of the cake5) smoothing with compression of the cake6) discharge of the wet or dried cake. drive assembly consist of motor with vfd, mechanical seal is provided for vacuum application. Borosilicate glass vessel with different nozzles, manual/hydraulic system is provided for movement of agitator and discharge valve. Ptfe filter support plate. advantages of glass nutsche filter vacuum filtration possible. glass being transparent, offers visibility of processes. inert gas atmosphere can be maintained. minimal contamination of the cake. very high solvent recovery. solvents are in closed systems, so no toxic vapors are let off in the atmosphere. personal safety is maintained and heat transfer surfaces can be provided to maintain filtration temperature. garg offer glass anf from 10 l to 200 l for kilo lab operations with and without jacket , with and without stirrer. Our sales/technical team will be glad to assist you desinging the best suitable system for your process requirements.

Agitated Nutsche Filter

Get Price Quote

Agitated Nutsche Filter

Get Price Quote

5kl capacity, SS316 contact parts, GMP model, ultra drytech enggineering make, year 2005, with redcution gear box & motor - Worm reduction gear box ,Make-Shanti-Coimbatore, Type-WRD,8inch, Ratio-100:1 Motor -- 3 Phase415 v10 hp1450 rpm, Foot mounted induction motor, presently in excellent working condition for sale

Agitated Nutsche Filter .

150,000 Per Piece

1 Piece(s) (MOQ)

Agitated Nutsche Filter/Dryer is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed system ensures odourless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated Nutsche Filters are extensively used in Chemical, Herbal, pharma, agro, chemical and the food industry. Often found just downstream of a reactor or crystallizer, it has the important job of separating and isolating solids from a solvent.

Agitated Nutsche Filter

351,000 - 1,551,000 Per Piece

1 Set (MOQ)

Chemicals and API are frequently processed as powders, so that a crystallization of the solution after the reaction takes place and subsequently separation of solid and liquid materials becomes necessary. For such applications UD offers high quality filters for pilot plant facilities R & D Labs and for application in Kilo Labs as per their requirements of whether their primary purpose to clarify the liquid or to remove solids by filtration. Depending on solid particles in slurry different volumes of Filter cake Volume and filtrate is provided Nutch filter can be designed as per client’s process and GMP requirements The most crucial part is to remove solids and Filter cloth from top glass part. Our design is user’s friendly such that top cover or bottom cover can be easily removed and fixed by Operator Filter Cloth fixing is such that to change Filter cloth ,Bottom Part does require to dismantle or lower. It can be fixed or removed from Top Part only to make it Maintenance and User Friendly Agitated Nutsche Filter If process requirement needs to have Agitation-ANF ,UD Also offer top SS PTFE Sleeved Scrapper Stirrer which can be Operated Manually or by Electrical Motor . To make it ANF Large side Nozzle can also be provided so that after scrapping cake From Side Nozzle cake cal be removed Considering Modular Approach we also give transfer Pump and Skid Mounted Motor as per URS The contact parts are always 3.3 Expansion Borosilicate Glass and PTFE The equipment is designed in such a way that it can be easily dismantled for cleaning according to GMP regulations. Jacket can also be given in case of Hot filtration We offer Large Glass Agitated Nutch filter/Nutch filter with Motorised Lifting and lowering arrangement The dissipative PTFE is approved by FDA regulation too. Applications of Glass Nutsche Filters-Agitated Nutch Filter Acidic and other corrosive Media Filtration Light Sensitive Product Filtration Vacuum Filtration Competitive Advantages of the product Superior technical solution * No metal in contact with the product Movable skid on wheels Comfortable handling Easy cleaning Quick harvesting using top easily removable cover Simple substitution of the filter cloth Connection for Feed ,Solvent for Wash ,ventilation/ nitrogen on the top cover etc. Excellent corrosion-resistance Smooth, pore-free surface Transparency Catalytic inertness No effect on odour and taste Physiological acceptability