Aluzinc/Galvalume coils & sheets

Get Price Quote

• Aluzinc in MPA 550 Full hard Execution, as well as MPA 250 or soft.• Most common widths of 762mm/1000mm/1220mm, available.• Thickness from 0.18mm BMT till 1.0mm.• Coating from AZ 50 till AZ 150.• Drum Corrugated steel sheets in maximum length of 12 feet (3650mm).• Roll Profiled AZ sheets also upto 5500mm length

aluzinc sheet

126 Per Kilogram

Best Deals from Aluzinc Sheet

Aluzinc Steel Sheets

Get Price Quote

aluzinc galvalume sheets

Get Price Quote

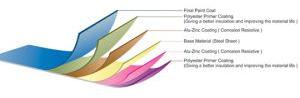

Aluzinc (Galvalume) Sheets & Coils(AS PER ASTM A792, CS TYPE B / EN-10326 / DX51D 55%AL / 43.6%ZINC & 1.3% SILICON AND OTHER ALLOYS) Production introduction : This alloy coating consists of 55% Aluminum and 43% Zinc and the balance contains majorly Silicon around 1.5% to affect excellent adhesion to the steel substrate. The metallic coating which is applied using a continuous hot-dip coating process, combines the galvanic corrosion protection of zinc with the barrier protection of aluminum. Aluzinc also displays excellent heat reflection properties, similar to aluminized steels and is more resistant to higher temperatures than hot-dip steel. It will maintain its bright appearance and reflectivity in prolonged exposures at temperatures of 320°C and is not heavily oxidized by continuous exposure to temperatures of upto 650°C. These high temperature oxidation and heat resistance attributes of ALUZINC enable the potential applications to be expanded beyond the traditional metal building market. In particular, Automotive exhaust systems, Furnace and Ovan hardware and white goods that require heat resistance (ovens, cookers, etc.) also used for Roofing and cladding, Pre-painted sheets, Air conditions, Refrigerators & Ductings etc. are potential applications of ALUZINC. Basic differenc in production of Aluzinc against Galvanize The most significant difference in process is the composition of the coating bath; the bath for 55% AlSi-Zi coated sheet production is comprised of a 55% AlSi-Zn coated alloy rather than near pure zinc for Galvanized sheets. The 55% AlSi-Zn coated bath is operated at a higher temperature (600°C 0r 1120°F) than the zinc bath used for galvanizing which is operated at about 450°C (840°F). The higher temperature for 55% AlSi-Zn coated is required because of the higher melting point of the 55% AlSi-Zn coating alloy. The melting point of the 55% AlSi-Zn coating alloy is about 580°C (1180°F) while that of the zinc coating is about 417°C (780°F) . Because of the higher bath temperature and the increased corrosiveness of the aluminum rich alloy, the 55% AlSi-Zn coated pot is lined with a special refractory and is induction fired. The general galvanizing principle of the strip heating the bath metal does not apply to 55% AlSi-Zn coated where the strip entering the bath considerably cooler than the bath (depending on base quality). Much of the bath’s heat is derived from the operation of the inductors. Prior to the strip entering the coating bath the hydrogen content of the protective atmosphere is increased for 55% AlSi-Zn coated compared to galvanized to provide maximum protection for the strip and to minimize oxidation of the bath surface. After coating in the ‘upleg’ as the strip rises in the cooling tower, air is blown onto the surface to cool the coating at a specified rate for generating the required coating microstructure for optimum corrosion resistance also fast cooling arrangement, resin coater, induction Furnace for resin coater. Product Advantage : Excellent long term durability Superior Cut Edge Galvanic Protection Superior standing water corrosion resistance Excellent Energy Efficiency Excellent Formability Excellent Paintability The coating has unique microstructure consisting of two layers, an aluminum-zinc overaly coating and an iron-containing inter-metallic or alloy layer. The alloy layer forms at the interface between the coating and the steel substrate and is very thin. The thickness of the alloy layer is minimized by the addition of silicon to the coating alloy. Varying amounts of aluminum, iron, zinc and silicon are contained in various phases of this layer. The overaly coating is composed of two main phases, an aluminum-rich dendritic phase and a zinc-rich interdendritic phase. The aluminum rich phase comprises about 80% of the coating volume, while the zinc-rich phase comprises about 19% of its volume the remaining 1% is taken up by the silicon particles. The unique microstructure combines the galvanic or sacrificial protection of zinc coatings with the barrier protection of aluminum (long tem protection into one product 55% Al-Zn coated sheet is produced in a variety of strength levels, from deep drawing to full hard. Product Specification & Size Range :

GI ALUZINC COTTED PROFILED SHEETS

100,000 Per

7500 Square Feet (MOQ)

GI sheet galvanized steel sheet , Marvell products are according to national standards GBT12459, GBT13401, U.S. standard ANSIASME B16.9, ANSIASME B16.5B16.47, ANSIASME B16.11, ANSIASME B36.19M B36.10M, ASME B16.20,British standard BS,Germany standard DIN,Japan standard JIS..., The purpose built nonstandard or special use products as per customer's demand, we will try our best to satisfy it.

aluzinc sheet

80 Per Kilogram

Aluzinc Steel Sheets

Get Price Quote

Offers aluzinc steel sheets. Supply condition: astmjisen and equivalent. In full hard, semi hard and soft quality (commercial grade, lock forming grade and structural grade) zinc coating: 50 azm to 185 azm thickness:hard coils – 0.18mm to 0.70mm soft coils & structurals – 0.23mm to 1.5mm width: 1250mm maximum coil wt: container: 8mt max. bulk : 12mt max. Surface finish: anti- finger print.

Aluzinc Roofing Sheet

Get Price Quote

100 Piece (MOQ)

aluzinc sheet

Get Price Quote

aluzinc sheet, Galvanized Roofing Sheets, Stainless Steel Coil

aluzinc sheet

Get Price Quote

aluzinc sheet

aluzinc galvalume sheets

Get Price Quote

aluzinc galvalume sheets, Aluminium Coils, Aluminium Sheets

Aluzinc Corrugated Sheet

Get Price Quote

Aluzinc Corrugated Sheet, Galvanized Coils

Aluzinc Steel Sheets

Get Price Quote

Aluzinc Steel Sheets, Hot Dipped Galvanized Steel Coils