Underseal Protection

Get Price Quote

204 Anti Corrosive Primer

Get Price Quote

300 Litre (MOQ)

Best Deals from Anti Corrosive Coatings

Bronco Cemcoat P Membrane

Get Price Quote

100 Kilogram (MOQ)

BRONCO® CEMCOAT P is a cold applied heavy bodied bitumen protective coating Area Of Application Primer on steel or concrete substrates. Protective coating of concrete structures. Protection of galvanized iron in corrosive environment. Advantages Safe as internal protection of potable water tanks. Long pot life Economical Excellent resistance to corrosive elements Single Component, easy to use and cold applied.

Task Anti Corrosive Glass Flake Coating

1,500 - 1,800 Per Kilogram

5 Kilogram (MOQ)

Features : Highly Durable Industrial Purpose Low Maintenance

Anti Scale Protective Coatings (ESPON-SR)

Get Price Quote

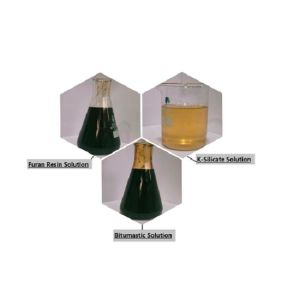

Our Anti Scale Protective Coatings (ESPON-SR) help in preventing of scaling and decarburization during heat treatment of components. After heat treatment, unproductive process of shot blasting, machining, grinding can be either substantially reduced or eliminated by using our Anti Scale Protective Coatings (ESPON-SR). The Anti Scale Protective Coatings (ESPON-SR), we offer, allow the rejection of components due to pit marks formed by scaling during heat treatment is avoided. Attributes : Preventing of scaling and decarburization during heat treatment of components. A fortune in capital investments can be saved as existing furnace can be used for scale free heat treatment. This is otherwise possible only by use of highly capital intensive controlled atmosphere furnace. After heat treatment, unproductive process of shot blasting, machining, grinding can be either substantially reduced or eliminated. Rejection of components due to pit marks formed by scaling during heat treatment is avoided. Quench cracks on components after heat treatment are prevented. Surface finish and aesthetic appeal of heat treated components is greatly improved. ESPON-SR anti scale compound is easily removable after heat treatment.

NPG Gelcoat

Get Price Quote

Zqtb Protective Coating Compound

Get Price Quote

ZQTB is a newly developed high temperature, erosion / corrosion resistant ceramic refractory coating compound. It can withstand high temperatures and also control erosion / corrosion of refractory linings, monolithic, ceramic fibre boards, modules and steel shells. ZQTB is to protect refractory from heat or chemical reactions and to increase the life span of ladles in iron rolling mills or metal processing units. Main Characteristics & Advantages: Easy to apply by toweling, brushing or spraying Good adhesion to metals, refractory bricks, monolithic, cast-able and ceramic fibre modules etc. Excellent dry strength, Excellent resistance to powdering Good adhesion, Chemical resistance, Easy to mix, Gas-tight surface without spalling or cracking at 1800oC, Reduction in slag adhesion Considerable increase in service life of refractory linings and heating systems Resistant to the influence of steam, acids, alkalis, fumes of sulphur and Vanadium compounds and molten metal, Odourless and non-hazardous Porosity approximately 22% at service temperature 1350oC Resistant to severe attack and sand blasting effect of burning fuel oil Considerable increase in service life of refractory linings and heating systems ZQTB Compound – The Versatile Refractory Coat ZQTB Compound resists harsh chemical attacks at high and low temperatures. Around 3mm thick ZQTB Compound coating can work wonders at ambient to 1800° C temperature. 5mm thick ZQTB Compound coating offers as good a protection and insulation as a 130mm thick fire brick. ZQTB Compound prevents leakage of hot gases from heating chambers, thus maximum heat energy is preserved, wear and tear on the ZQTB Compounded surface is minimized and coating lasts longer. ZQTB Compound has unlimited applications and is used in the following areas where continuous and high temperature heating is found hazardous, especially in the heating chambers constructed with conventional materials. Ceramics / Glass Aluminium, brass and other nonferrous metals Chemicals and fertilizers, Pulp and paper, Iron and steel, Marine and shipping, Cement, Sugar, natural and other gases, Petroleum and hydrocarbon Coating of kiln furniture, graphite and carbon crucibles. ZQTB Compound coating will be of great benefit to use in the above areas as well as in domestic boilers, induction furnaces, rotary kilns, chimneys, ducts, etc., where fuel oil, gas or electricity are used for heating purpose.

Fire Protective Coating

Get Price Quote

10 Metric Ton (MOQ)

Anti Corrosive Coatings

500 - 600 Per Litre

50 Litre (MOQ)

Epoxy floor coating Base coat are the derivative of Epoxite conjuction with Amine/ amide Adducts,. They create high degreeof bonding with concrete surface for anti-carbonation alongwith di electric insulation to floor ,itgives air drying, Chemical Resistant finish.

Anti Corrosive Liquid

Get Price Quote

Avail from us, the best quality Anti Corrosive Liquid that is used for Joint less Monolithic Screeding. Anti Corrosive Liquid offered by us, has excellent quick setting properties and can withstand various chemicals. We are a trusted Manufacturer and Supplier of Anti Corrosive Liquid. Anti Corrosive Liquid for all major acid/akaline conditions are Silica Base & Carbon Base. Demanded for Chemical resistant Good adhesion property Longer working life High strength

Brick Coatings

1 Per Kilogram

5 Kilogram (MOQ)

Greetings from Advent Polymin Pune . Available Water Repellent Breathable Coating to Prevent Growth of Moss, Algae, Dampness and Black marks on Exposed BRICKS, Cladding , Stone's, Compressed Mud Walls, , Rammed Earth Wall, Laterite. 🧱🧱🧱 Terracotta Tiles, Lime Plaster, Cob Walls, Cow Dung Plaster, Coloured Concrete, Any kind of stone and mortar wall.

HS Stone Chip Protection (Grey, Black) (1L)

Get Price Quote

Synthetic resin-based stone chip protection of vehicle underbody and lower body. The coating can be primed or overpainted in any color within 30-40 minuted after drying. The coating ha high durability and excellent resistance to abrasive wear. it also ha sound deadening and vibration absorbing properties.

Enviropeel Compounds

Get Price Quote

Enviropeel is reusable, non-toxic and contains no volatile organic compounds (VOCs). When inspection or replacement is required, it can quickly be cut and peeled away to reveal the protected surface. Removed material can be returned to the unit for re-application. The material is a sprayable thermoplastic containing inhibitors for active corrosion protection. It protects against galvanic, pitting and atmospheric corrosion. Prevents water, dust, and contaminant ingress and isolates vulnerable components from corrosive environments. The material is supplied grey as standard but can be made any colour to order.Benefits of Use : Stops corrosion immediately Reduces wear & tear Prevents ingress Long-term active protection Reduced labour costs and maintenance-related accidents Extended component life Environmentally friendly Easy to remove Re-usable and waste free Multiple Applications Bearing housings Protective Mechanisms : Passive Protection :Ingress of moisture and contaminats prevented by perfectly fitting Enviropeel barrier. Active Protection L Inhibiting oil coats all internal surfaces under preventing corrosion process.

Heat Protective Coating

Get Price Quote

Heat protective coating all the materials used for construction of building absorb and transfer heat inside of the building all the day. Heat always flow from the warmer side to cooler side and cooler to warmer side. 80% to 95% of heat gain during summer and about 70% of heat loss during winter trasferred through the walls, ceiling and roofs of the building by way of conduction and radiation. The conventional insulation only slows down the rate of heat transfer which after saturation cannot stop radiant heat. Monarch’s ozoprotect heat solar reflective coatings reflects up to 98% of heat back to its source. Monarch's ozoprotect specialized coating containing ceramic microspheres and or glass microspheres keeps you cooler in the summer and warmer in the winter reducing cooling cost during summer months and heating cost during winter months. The load reduction of air conditioning or heater and corresponding electrical consumption saves energy cost up to 40% all round year. The payback period is less than 6 months. Ozoprotect significantly contributes to green building certification as solar reflectance index (sri) is 116 and prevention of global warming besides reducing evaporation loss in petroleum storage tanks. Features • reflects 98% of heat in roofs ceilings walls. • reduces internal temperature of building up to 15°c. • reduces evaporation losses, pollution, smog, the urban heat island effect and global warming. • quick payback period - saves over inr 5200 year for every 1°c temperature reduction – saves over 40% in energy bills for air conditioner heaters. • conventional insulation system only slows the rate of heat transfer - cannot stop radiant heat. • resistant to acid rain, uv rays, saline atmosphere & condensation. Application • buildings • steam pipelines • oil & gas storage tanks • refrigerated cold storage facilities • mobile & modular homes • roofs • wall facade coatings • commercial buildings • pipes

Protective Coatings

Get Price Quote

We are an eminent name as Manufacturer, Importer and Supplier of Protective Coatings. The Protective Coatings that we offer you are prepared under the guidance of experts and are totally reliable. Suiting the budget of each buyer, our Protective Coatings are extensively demanded by the buyers. We have the ability to make available even the bulk orders within the promised span of time. Acquire from us a range of pocket-friendly Protective Coatings!

Protective Coatings

Get Price Quote

Cable fire suppression coatings fire suppression coating especially designed for protecting electric power cables, communication cables, junction boxes - against ignition, propagation of fire, smoke emission. High solids intumescent firestop coating with ultra high density, heat insulation. Expands upto 65 times when exposed to heatfire.

Protective Coating

Get Price Quote

Performance Protective Coatings

Get Price Quote

Clients can avail from us premium Performance Protective Coatings available under the brand name Multi Crete. Performance Protective Coating (MULTI CREATE) is a two component hydraulic binder based product which is very effective for solving sealing problems on porous substrates. Performance Protective Coating is composed of a "Powder" consisting of hydraulic binder, chemical inert aggregates and waterproofing additives as one part and Resin Emulsion as the second part. The two components are mixed together to obtain a plasticized cement rendering. Once applied, Performance Protective Coatings constitute perfectly leak tight coating resistant to strong water pressure. Performance Protective Coatings work even against the normal negative pressure. The cured coating has the appearance of white, slightly rough rendering. Benefits Reacts in contact with water by crystallization.Bonds strongly to most of the building materials.Can be applied on a damp substrate.Forms micro porous coating which allows breathing of the substrate.Can be applied both indoor-outdoors, horizontal vertical surfaces in uniform thickness. Unaffected by UV light.Does not corrode reinforcing steel.Resists high positive water pressure and normal negative water pressure. Acts by perfectly plugging pores in concrete and masonry. Highly durable even in continuous contact with water. Resistant to water, dilute acid and alkali solutions.Non - dangerous and odorless.Resistant to fungus and microrganism growth. End Uses MULTICRETE is used as a protective performing coating in building - terraces, toilets & bathroom basements. It also acts as protection against corrosion and salt. It is used for sealing under positive water pressures in water reservoirs, water tanks, built up pits of all kinds, agricultural silos, swimming pools, sea water pools etc. Direction For Use Surface Preparation: Surface preparation is very important to get the best results and to avoid failure. The substrate must be clean and free of dirt, grease, sludge, fungus, cement coating blistered and loose plaster etc. Moisture is necessary for the effectiveness of MULTICRETE, therefore the substrate must be dampened with water, However, streaming water must be diverted by creating drains.Do not apply in rain. Before application of MULTI CRETE, seal the crack with any suitable sealant.Sealer / Primer Coat The concrete or cementitious substrates are highly porous. It is necessary to make the substrate less absorptive so that the top coats film thickness remains same. Krishna SEALER is highly elastomeric acrylic emulsion polymer without filled system has extra ordinary penetrating power which seals the porosity. Microcrevices of the substrate. It provides strong adhesion to the substrate and top coating. Due to non-filled system it overcomes the problem of linear stress and strain created in the substrate. Apply one coat of SEALER as a primer coat by brush. Apply the topcoat after one hour but within four hours of drying of SEALER coat. MixingAdd the powder (part 1) in to the liquid (part II) and mix manually until a homogenous semi - liquid without lumps, is obtained. The consistency of the mixture should be enable to give a good and smooth application by brush. ApplicationApply the first coat of MULTICRETE generously in order to plug the pores and shrinkage cavities. Within 24 hours, dampen the surface and then apply the second coat. Apply a third coat in the same way, if necessary. Moisten or wet the surface frequently for three to four days. Cleaning : Tools and equipments to be cleaned with water. Storage & Shelf Life : Store in cool dry place. Shelf life of the unmixed material is one year from the date of manufacture. Packing : 10, 20, 70 kgs duel packs. Precaution Do not apply over hot or dry substrate.Do not apply in rain.

Anti Corrosive Coatings

Get Price Quote

We are main supplier of this product.

Insulation & Waterproofing Protective Coating

375 Per Kilogram

500 Kilogram (MOQ)

We are the main supplier of this product.

ProKoat Heavy Duty Protective Coating

Get Price Quote

100 Litre (MOQ)

Easy application 5-year protection warranty Provides a tough durable protective coating with a sheen Gives a natural aesthetic look of the previous surface Water-based and Eco-friendly

Protective Coatings

Get Price Quote

These are a range of high performance 100% solids specialty coatings designed to protect various industrial structures, equipments and civil structures against corrosion, heat, chemical attack, fungus, ultraviolet radiation, fire, seepage etc.

Protective Coating

Get Price Quote

500 Meter (MOQ)

We are Coating and Laminating Company Doing High End Tpu Breathable film Lamination On Different Fabric like Polar Fleece, Cotton, polyester Cotton, Terry Fabric Etc. also We Do Various Treatments like anti Bacterial, Anti Microbial, Fr, Wr and other Protective Coating as per Customer’s Requirements. We also Do Pu Coating, Carbon Coating etc. we Do 3 Layers, 2 Layer Lamination like Fabric to Fabric Lamination, fabric to Poly Wad Lamination, Fabric to Tpu Film to Fabric Lamination. we have Ready Stocks of Special Fabrics like Gas Mask Fabric, Bed protector (100% Waterproof No Noise, No Vinyl & Acrylic Contains), child Care Product, Hygiene Product Etc. we also Do Hot Melt Lamination. we Cater to Various Industries like Hotel, Hospitals, Jacket, Sports, shoes, Horse & other Animal Clothing, Child Care, Fashion Etc. protective Coating- We Do Various Types of Fabric Protective Coatings as per Customer Requirements.

britex acc-ez electroplating chemical

Get Price Quote

Two Component Epoxy Zinc Base Anti Corrosive Coating ACC epoxy zinc , is supplied as a Two component coloured liquid based, Metallic zinc and epoxy resins. Used as a blast or holding primer in new construction structural steel and as a lining in water tank. The product offers excellent anti-corrosive performance, good wetting properties andoutstanding adhesion to blasted steel. Recommended as a tie-coat over inorganic zinc silicate coatings.

Anti Corrosive Coatings

Get Price Quote

Leveraging on our rich industrial experience, we make available in the markets anti corrosive coatings. anti corrosive coatings are high on demand by diverse industrial segments such as chemical factories, oil & gas installations, fertilizer plants etc. Among others. These anti corrosive coatings are obtainable at leading market rates. variety daccros & puromma : top performance weather and chemical resistant finishesruustgone : surface preparatory rust converterstarpel : coal tar based coating & lining systemsmidlecoat : high build barrier intermediate coatingsmaxal, maxprimer, maxozin : range of high performance primers attributes solvent and chemical resistantresistant to erosion and corrosionwater proof acid and alkali resistant ability to withstand extreme weather conditions eco friendlyhighly adhesivestrong physiochemical bonding.

Protective Industrial Epoxy Coating

Get Price Quote

With us, clients can stay assured for the premium quality of the offerings as we keep them in healthy conditions. For this, we have developed a large storage unit. We make use of quality packaging material to circumvent loss while shipping. The kind of packaging we do is done under the supervision of veteran professionals. This is done to ensure that the product is completely safe.

Anti Corrosive Coatings

350 Per Kilogram

1000 SQM (MOQ)

Anti Corrosive Coatings

Get Price Quote

We offer anti-corrosive primers & hi-speed enamel paints.

Metal Guard - Water Based Anti-Corrosive Coatings

560 - 580 Per kilogram

1 Kilogram (MOQ)

Rust Protective Coatings

Get Price Quote

Rust Protective Coatings are formulated to provide long term protection to metal parts against corrosion. They prevent oxidation and curb the formation of rust in metal objects like pipes and machine parts. Our Rust Protective Coatings are highly durable and resilient. They can tolerate harsh conditions and provide uninterrupted service. We are one of the prominent Manufacturers, Suppliers and Exporters of Rust Protective Coatings from Maharashtra. Availability : MCON RR : Rust remover is an effective cleaning aid for completely removal of rust from rusted surfaces. clean corroded reinforcement steel surfaces by wire brushing, remove loose particle and apply Rust Remover by brush. Next day remove the loose rust particles by brush. Used to remove rust of old and new steel reinforcement, water tanks, effluent plants, MS Pipes, etc. MCON RC : Single pack water based rust converter,non flammable, non poisonous and emits no harmful fumes. convert rust into inert iron complex, long term protection, reduces moistures vapor transmission, low VOC content, fast dry. Use in structural steel machnery, vehicles, railings furniture etc. Availabe in 1, 5, 10, 50, 100 ltr. containers. MCON CR : Protective, anto corrosive coatings for steel & reinforcement provides active corrosion protection of steel & reinforcement. Easy application by brush or spray. Pre-weighted pack. Excellent bonding with rebars and concrete. MCON ZRP : Two components, epoxy zinc rich primer for use in maintenance and new construction. It provides sacrificial protection for exposed steel including steel reinforcement. It resists corrosion by electrical and chemical means. Used as anti corrosive coatings for exposed steel, all mild steel strusture like bars, reinforcement, pipelies, water tanks, bridges, arches in marine enviroment etc. Coveage - 6-7m2 / Ltr @ 50-60 misrons thickness for single coat.