2000 Extractor Feeder

Get Price Quote

1 Piece (MOQ)

Shown mounted over the Bajaj 161 Saw gin with metal guards and Polycarbonale Windows The 2000 extractor/feeder is the economical design for fine trash removal and single locking of seed cotton fed into a gin stand. The 2000 extractor/feeder has shown excellent feeding and trash removal in field tests and in cotton High Volume Instrument testing. The model 2000’s one piece unit design will fit under most existing conveyors and in the same mounting footprint as most gin stand models. Replacement of your old feeder or any new installation with the 2000 extractor/ feeder will ensure the most economical way to feed your gin stand. A touch screen control panel, mounted on the feeder, is used for display and changing PLC control parameters. This panel contains several touch screen displays to control every aspect of 2000 EXTRACTOR / FEEDER BAJAJ MODEL BAJAJ STEEL INDUSTRIES LTD. S I N C E 1 8 3 2 IN COLLABORATION WITH , USA Shown mounted over the Bajaj 161 Saw gin with metal guards and Polycarbonale Windows FOUR SPIKED CLEANING CYLINDERS FIVE ADJUSTABLE CLEANING GRIDS SEGMENTED HEADS FOR CYLINDER REMOVAL POLYCARBONATE GUARD WINDOWS POLYCARBONATE LINT SLIDE COVER the ginning operation. A touch screen display. with adjustable setpoints, controls capacity of ginning based upon current load on the gin motor, An AC inverter drives the 3/4 hp feed motor for ease of control and operation, The gin and feeder operations are synchronized to prevent over feeding or under feeding. Motion detectors on the feeder and lint cleaner auto¬matically stop the ginning operation if the cotton flow is interrupted. *not included As seed cotton enters the 200, feeder through two 6 vane feed rollers, it is first exposed to four spiked cleaning cylinders. The cotton is passed over the top of these cylinders and is then conveyed between them and the inclined grid section which allows for improved fine trash removal and single locking. Once through the inclined grid two section, cotton is carried to two 6-1/2” channel saw cylinders, one of which functions as a reclaimer. The flow of cotton through a combination of brushes, a control bar, and adjustable grid sections allows tor hull, stick. and fine trash removal and enhances the opening of seed cotton locks for improved ginning. A saw dotter cylinder improves single locking and transfers the seed cotton from the cleaning cylinders to the feeder apron and into the gin.

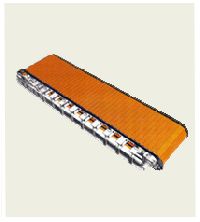

GBZ Type Heavy Duty Apron Feeder

Get Price Quote

GBZ Type Heavy Duty Apron Feeder is based on a sophisticated technology and widely used in building material, chemical plant, metallurgy, coal industries. NHI China are nonpareil Suppliers of GBZ Type Heavy Duty Apron Feeder in China. Our GBZ Type Heavy Duty Apron Feeder can work with materials having different size, density and hardness. To ensure 100% customers satisfaction, the GBZ Type Heavy Duty Apron Feeder reaches them only after strict quality checks.

Best Deals from Apron Feeder

apron feeders

1,000,000 Per Piece

Apron Feeder

Get Price Quote

BWZ series heavy duty apron feeder designed by Mining is one new type high-efficiency conveying equipments. It absorbs Mining decades years’ experience in designing &manufacturing conveying machines and the advanced technology of the world. This apron feeder is especially suitable for short-distance transmission. Pretreatment: Using the hydraulic hammer to crush the big stone into smaller one, and arrange the worker to cut through the long reinforcement to prevent damaging the belt conveyor. Use alloying-steel plate, the machine has long service life and requires no maintenance. It has high tension and it is have very stable performance by using track. For its simple structure, it is easy to maintain. BWZ series heavy duty apron feeder has wide application and the temperature, moisture and the environment have little or no effect on it.

Apron Feeder

Get Price Quote

apron feeder for material conveyong steel pand to handle bolders , coal limestone , additives etc

Apron Feeder

Get Price Quote

Rullitech apron feeders are custom designed for each application. They are of heavy duty construction suited for rugged conditions encountered in the mining and quarrying industries. They come with large diameter headshaft and tailshaft. Head and tail shaft roller bearings are sealed to prevent dust intrusion. The chains are crawler tractor type and are closely spaced to withstand shock loading of large lumps from the hopper. The steel flights are ribbed and overlapping and made of Manganese steel.

Automation Apron Feeder

299,000 - 300,000 Per Piece

apron feeders

Get Price Quote

Our wide range of apron feeders is the answer to packaging, conveying, hearing, cooling, feeding, batching and various other applications. Our apron plate feeders are manufactured using the best raw materials which make them resistant to heat and other extreme climatic conditions. They are highly flexible and are capable to carry fragile items. As one of the major large apron feeders manufacturers and suppliers in India, we make our products available as per customers� requirements

Apron Feeder

Get Price Quote

Being one of the prime Manufacturers and Suppliers in India, the company offers world class Apron Feeder. Fabricated using the best grade raw materials, our Apron Feeders are required for heavy-duty operation and for primary or subsequent application stages. Designed to perfection, these industrial grade Apron Feeders are very strong and sturdy. Owing to some of the features like precise designing and smooth operation, these Apron Feeders are highly demanded by the clients across the world. Made available in varied requirements of capacity, size and material handled, our Apron Feeders are very affordable. Why Our Apron Feeders? Precision engineeredSuperior qualityHigh performanceLonger functional life Features Of Our Apron Feeder Impact loads are absorbed by pans of rolled alloy/ cast alloy/ manganese steel material depending on application and are similar to heavy-duty track-type undercarriage shoes.Pans are bolted to forged link chains supported on heavy-duty lifetime lubricated rollers.High strength pans resist abrasion and withstand heavy impact loads.Short pitch and precision-machined chain provides noise-free discharge of material with negligible impact on receiver.Chain and roller flanges maintain rigid alignment of pans in relation to skirt.

Apron Feeder

Get Price Quote

Features: Apron feeders are available in a wide variety of designs for both horizontal and inclined travel. They help in feeding of material at controlled and continuous flow rates. These are mainly used to handle large sized lumps. The typical design is a series of pans mounted between two strands of roller chain, with pans overlapping to eliminate dribble, and often equipped with end plates for deeper loads. Pan design may vary according to material requirements. Apron-feeder applications range from fairly light-duty applications with light-gauge steel pans up to extremely heavy-duty applications requiring reinforced manganese steel pans with center supports.

Apron Feeder

Get Price Quote

Techno Power engineering is best apron feeder manufacturers, exporters and suppliers in ahmedabad. The Techno Power surface feeder extracts bulk materials directly from the truck, but is also used for wagon unloading as well as in bulk material handling with front-end loaders. A frequent application is the conveying of corrective materials, additives or alternative fuels. Owing to its flexibility, it is a technically and economically good solution in many areas of bulk material handling.Functions & Features Controlled discharge of bulk materials from trucks Suitable for dry and dusty, heavy and abrasive as well as for wet and sticky materials No expensive bunker necessary High flexibility No bridge formation or blockages Low dust generation owing to modest drop height and volume controlled discharge

Apron Feeder

Get Price Quote

Apron Conveyors are particularly useful as feeders and for handling bulk material built to resist high temperature and high impact. MASYC also offers you Heavy Duty Apron FeedersWide Conveyors with latest technology in outboard roller support and centre load support.

Apron Feeder

Get Price Quote

Suitable for most robust applications and for absorbing heavy Impact Loads. ELECON has supplied appron feeders with capacity upto 3000 TPH and pan width upto 2.5 Meter.

Apron Feeder

Get Price Quote

We make available the optimum quality Apron Feeder to the clients. Our Apron Feeder consists of aprons in varied lengths for carrying the objects from one place to another. These Apron Feeders are suitable for carrying heavy-duty materials without any chance of damage. Our Apron Feeder is also suitable for carrying hot materials which need to be transported with care. Highlights : High strengthLong usable lifeSuitable for heavy-duty materialsLow maintenance needs

Apron Feeder

Get Price Quote

Apron Feeder

Get Price Quote

Apron Feeders are provided for extraction of material from hoppers and bins and for applications having high impact loads. In addition, these are also used to control the feed rate of more abrasive, heavy and lumpy materials. Apron feeders are used in mines & minerals, steel plants, coal fields, cement plants, thermal power stations, quarries and ports & harbors. In addition, they are also extensively used in aggregate making, crushing screening, heavy chemicals and paper mills. Teknik has supplied an Apron Feeder with a capacity of 2000TPH and 20 Meters Length for controlling the feed rate of Iron ore in a ship loading system. Teknik has also supplied Apron Feeder to Star Cement, Meghalaya for 1200 TPH for limestone handling.

Heavy Duty Apron Feeder

Get Price Quote

BWZ series heavy duty apron feeder designed by SCM is one new type high-efficiency conveying equipments. It absorbs SCM decades years’ experience in designing &manufacturing conveying machines and the advanced technology of the world. This apron feeder is especially suitable for short-distance transmission. BWZ series heavy duty apron feeder designed by SCM is one new type high-efficiency conveying equipments. It absorbs SCM decades years’ experience in designing &manufacturing conveying machines and the advanced technology of the world. This apron feeder is especially suitable for short-distance transmission. Features Use alloying-steel plate, the machine has long service life and requires no maintenance. It has high tension and it is have very stable performance by using track. For its simple structure, it is easy to maintain. BWZ series heavy duty apron feeder has wide application and the temperature, moisture and the environment have little or no effect on it. Application The BWZ series heavy duty apron feeders are widely used in metal-mining, construction, cement industry and coal industry and so on. For its corrosion resistance and crushing resistance, most of materials can be transported by this machine. Technical Data

BWZ Heavy Duty Apron Feeder

Get Price Quote

Bwz series heavy duty apron feeder designed by sbnith is one new type high-efficiency conveying equipments. It absorbs sbnith decades years experience in designing &manufacturing conveying machines and the advanced technology of the world. This apron feeder is especially suitable for short-distance transmission.

BWZ Heavy Duty Apron Feeder

Get Price Quote

Features use alloying-steel plate, the machine has long service life and requires no maintenance. It has high tension and it is have very stable performance by using track. For its simple structure, it is easy to maintain. Bwz series heavy duty apron feeder has wide application and the temperature, moisture and the environment have little or no effect on it.

Apron Feeder

Get Price Quote

In several industrial sectors, the need to extract bulk material, of any type and size, from hoppers, silos and storage chambers can be satisfied by the various types of extractors feeders designed and manufactured by AEW. Apron Feeders are generally used for used for extracting small medium and large lumps of material for feeding other lifting or processing machines, crushers or other sections of the plant