Diaphragm Pump

Get Price Quote

1 Piece (MOQ)

Diaphragm Pump

20,000 Per Piece

1 Piece (MOQ)

Best Deals from ARO Diaphragm Pump

Diaphragm Pump

Get Price Quote

Hydraulic actuated double diaphragm pumps our wide range of comprises of hydraulic actuated diaphragm pumps which have been manufactured adopting superior quality raw material. These can be customized as per the specifications of our clients and have a long performing life.

Diaphragm Pump

20,000 - 25,000 Per No

1 Piece (MOQ)

We specialize in manufacturing and trading of Diaphragm Pump. We mainly offer Teflon / Viton Diaphragm Pumps. Our Diaphragm Pumps are used for passing the sample gas through the gas analyzers if the gas pressure at the sampling point is too low. It is an electricity propelled pump. The product is an outcome of our own development, using imported Knf pump. The product is ideal for Process Industries like Cement, Thermal Plants, Steel Plants, Chemical Industries etc. Specifications Capacity : 250 LPH at Atmospheric PressurePower Supply : 220 V 50-60 Hz. KNF make mini Diaphragm Vacuum Pump Model N 86 KNE Performance Capacity : 6 LPM Ultimate Vacuum : 100 mbar abs Operating Pressure : 2.4 bar g Motor : AC Motor 230V / 50 Hz / IP00 MoC Pump Head : Ryton Diaphragm : EPDM Valves : Viton

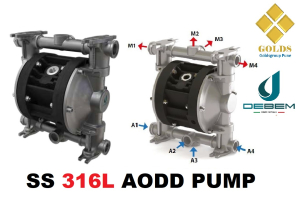

air operated diaphragm pumps

50,000 Per Piece

air operated diaphragm pumps

20,000 - 22,000 Per Nos

1 Nos (MOQ)

Model- RWP300PTT Inlet/outlet:- 1" PTFE Diaphragm

Diaphragm Pump

15,000 - 250,000 Per piece

5 Piece (MOQ)

Diaphragm Pump

38,000 - 95,000 Per Piece

Diaphragm Pump

42,500 - 45,000 Per Piece

1 Piece (MOQ)

Diaphragm Pump

20,000 Per Piece

10 Piece (MOQ)

Pneumatic Diaphragm Pump

16,100 Per Piece

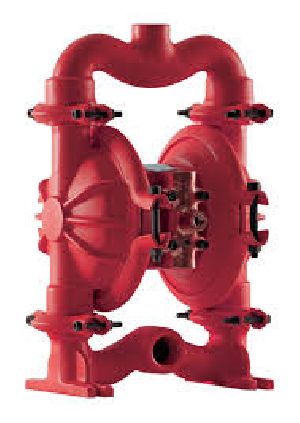

Aro Diaphragm Pump

Get Price Quote

Specifications Max Flow Rate900Lpm (238gpm)Port SizeInlet : 76.20mm (11/2" BSP)Discharge : 76.20mm (3" BSP)Air Inlet : 12.70mm (3" BSP)Air Exhaust : 19.05mm (3/4" BSP)Suction LiftDry : 6.09m (20')Wet : 7.62m (25.)TeflonDry : 3.05m (10')Wet : 6.09m (20')Max Particle Size (Dia)19.10mm (0.750")

Diaphragm Pump

1,200,000 Per Piece

Diaphragm Pump

Get Price Quote

air operated diaphragm pumps

Get Price Quote

1 Piece (MOQ)

air operated diaphragm pumps

9,850 Per Piece

Diaphragm Pump

Get Price Quote

We have hired a team of professionals who take care of the entire lot and make sure that it remains protected from air, dust, water and other damaging factors. Our team experts are capable of maintaining database containing complete transactions made by our customers and thus, you can trust us for the online or offline payments made.

Diaphragm Pump

Get Price Quote

The Murzan PI 50 is the only diaphragm pump specifically designed to meet the special requirements of the sanitary industry. High efficiency oil free air valve, maintenance free check valve systems, and total visual inspection of all wetted parts give the user a safe and efficient transfer of foods, cosmetics and pharmaceuticals.USDA listed, FDA Approved, the PI 50 series is manufactured to meet general 3-A standards. Our unique design allows for total visual inspection of all wetted parts. There are no blind spots or hidden areas for bacteria to grow. Simply remove the manifold clamps and chamber clamps for complete disassembly and cleaning. Easy to sterilize and to clean in place (CIP).

Pneumatic Diaphragm Pump

36,800 - 280,000 Per Piece

1 Piece (MOQ)

Diaphragm Pump

Get Price Quote

We are offering diaphragm pump. Our diaphragm pumps are double acting type. We make two types of double acting pump, one is suitable for working in 12 kg centimeter square pressure and capacity of free displacement is 3800 litres per hour and the other type is suitable for working in 15 kg centimeter square and capacity of free displacement is 7600 litres per hour.

Pneumatic Diaphragm Pump

Get Price Quote

To handle viscous chemicals,slurries To transfer explosive liquids,solvents,acids. Pharmaceutical liquids creams and compounds. Semi solid foods, flavours, drinks, wine, beer, alchohols. Waste water, sewage effluents, coal and lime slurry. Hydrocarbons, petrol diesel, lubrication oil, vegetable oil. Paints emulsions,pigments, thinners, resins. Ceramics, Slip Gazes, Clays.

Diaphragm Pump

35,000 Per Piece

1 Piece (MOQ)

air operated diaphragm pumps

Get Price Quote

Pneumatic Diaphragm Pump

10,000 Per Piece

Diaphragm Pump

Get Price Quote

Diaphragms made from a highly elastic elastomer material have the role of forming a sealed yet easily mobile partition between two volumetric areas. As regulator diaphragm they transform the preset pressure from a control medium into a rod force for the activation of switchgear, of control and regulator instrument or of indicator equipment. As pump diaphragms they inversely convert a rod force into a pressure within the medium to be conveyed. Finally, they form as a separator diaphragm a sealing barrier with the lowest intrinsic resistance between two spaces having pressure at virtual equilibrium in an accumulator. A diaphragm is commonly installed in pneumatic brake cylinders as a sealing component, between piston and housing. DISADVANTAGES The universal application of diaphragms is governed by certain limitations owing to technical reasons regarding production and for design reasons: The maximum possible operating pressure and the attainable stroke length are restricted The effective diameter is always smaller than the housing diameter and in certain cases is not constant in the working range Diaphragms offer advantages over conventional sealing systems : Technically, they are absolutely tight. Lip seals always need a film of lubricant in the contact zone and as a result certain leakage occurs Diaphragm's work is practically maintenance-free No breakaway forces are needed when starting up or with a change of direction of movement. No rest point appears in the working area when the design is correct Diaphragms distinguish themselves by their rolling motion, thus low wear and a correspondingly long working life Diaphragms essentially place lower demands on dimensional stability and surface quality of the surrounding metal parts than do lip seals, and they often enable substantial cost savings This versatile, flexible engineering component comes into use in nearly all sectors of industry. Aerospace technology, foodstuffs, automotive and ancillary industry, general mechanical engineering and water fittings are only some of the business areas in which a diaphragm gives useful service. The main applications are pumps, compressors and valves as well as accumulators and bladders. Requests which we encounter daily: Pumps should transport a medium without leaking and should be able to meter this medium to the most precise extent. Actuating processes in valves have to flow as much as possible without large resistance. Braking processes are controlled via pressurized air in heavy goods vehicles. Actuating pressures from controlling media govern display equipment, switchgear and regulating apparatus. Various types of media should transmit precise pressures separately from one another. Hydraulic accumulator has to maintain pressures at the same level and dampen vibrations. The solution : Elastomeric diaphragms as the problem solver! Pumps, Actuators, Brakes, Regulating, Separating, Accumulators? Diaphragms made out of elastomer help with the solving of these complex tasks; as, for example, environmental regulation being complied with through the use of diaphragms in pumps. Also, even aggressive media in industrial valves can be controlled, without leakage, by the employment of diaphragms using high quality materials. Innovative technology (ABS, EBS etc.) for heavy goods vehicles braking systems function with diaphragms. Likewise, space craft are kept on the right course with diaphragms. Finding the solution: How are diaphragms used? You can put your enquiry to our experienced product developers. They are specialists in design and in the layout of diaphragms made from elastomer. We are on your side, not only with the finer points of design but also with the selection of the correct elastomer as well as the composite system. You can trust a Comprehensive-Know-How of diaphragms having already been developed and manufactured. We can make it easier for you to accelerate your development, and with that a reduction in costs, through the use of modern methods. Take advantage of our assistance in order to develop the diaphragm suitable for your application. Be it a pure elastomeric diaphragm, a fabric-reinforced diaphragm, one with a foil covering or additionally a diaphragm equipped with an inlay part. We supply you with a made-to-measure solution to your problem. Theoretic knowledge in the production of diaphragms has already been successful in practical action for over 25 years. We manufacture technically high-quality products for our customers. Our processes correspond to the latest quality standards. Our highly motivated team are only too happy to solve your problems quickly, and if need be, those of an unconventional nature also.

Diaphragm Pump

10,000 - 50,000 Per Piece

Diaphragm Pump

Get Price Quote

We are the main supplier of this product.

Diaphragm Pump

Get Price Quote

1 Piece (MOQ)

Diaphragm Pump

Get Price Quote

Diaphragm pump Flow rate upto 150 LPM

air operated diaphragm pumps

Get Price Quote

The largest Air-Operated Diaphragm Pump in the world (DP 125) with a flow rate of up to 2400 kg (5291 lb/h) at a bulk weight of 60 g (0.1 lb)/l, was developed and manufactured by Crane in cooperation with process industry partners. Until now, no other pump type has been able to fulfil the specific task settings of the industry in an economical and functional way. All DEPA diaphragm powder pumps are fitted with specially formed suction and discharge manifolds for favorable flow conditions. The high flow rate is achieved by good fluidization of the products. Regarding the discharge of granulates and crystalline media, special requirements have to be met. Various materials for body, diaphragms, valve seats and valve balls are available.