Semi Auto Batching System

400,000 Per Piece

1 Piece (MOQ)

Automatic Batching system

Get Price Quote

1 Piece (MOQ)

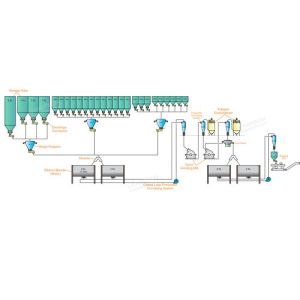

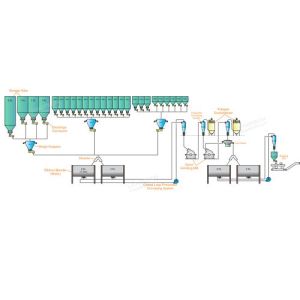

A Sample Process flow of the system Silo of 1 Ton (1 unit): This Silo would be mounted on the load cell and would indicate the weight of the material filled in it. A complete batch including different ingredients would be made here manually by checking the weight of each item while filling. Vibratory Feeder (1 unit): This Feeder would be placed each at the bottom of the Silo to feed the material in the Z Type Elevator. Z-Type Elevator: This would carry the material from the discharge of the Vibratory feeder and will convey it to the Mixer via the Diverter. Y – Diverter: This would be mounted at the outlet of Z Elevator. It would be pneumatically operated by a manual solenoid valve and would alternately feed the 2 Mixers Mixer 750 Kg (Twin): This would thoroughly mix the Ingredients received from the weigh hopper. It has a 10HP main motor Mixer. The discharge valve below it is of Flap type operated by pneumatic cylinders, which while in closed condition doesn’t allow any material to get accumulated over it. Collection Hopper (1 Ton): This would be mounted below the 2 mixers and would take the discharge from both of the mixers Screw Conveyor (1 unit): This would convey the material from the outlet of the Collection Hopper and would feed at the inlet of the Bagging Station. Bagging Station (1 Unit): The bags of 50 Kg each would be filled here it consists of two outlets for each where the material would come alternately. While one bag is getting filled in the 1st outlet, the 2nd would be stopped and will be replaced with a new bag manually. The Weight scale is placed below the two outlets which would automatically weigh 50 Kg and then switch the discharge to the other outlet.

Best Deals from Auto Batching System

Automatic Batching system

Get Price Quote

1 Piece (MOQ)

A Sample Process flow of the system Silo of 1 Ton (1 unit): This Silo would be mounted on the load cell and would indicate the weight of the material filled in it. A complete batch including different ingredients would be made here manually by checking the weight of each item while filling. Vibratory Feeder (1 unit): This Feeder would be placed each at the bottom of the Silo to feed the material in the Z Type Elevator. Z-Type Elevator: This would carry the material from the discharge of the Vibratory feeder and will convey it to the Mixer via the Diverter. Y – Diverter: This would be mounted at the outlet of Z Elevator. It would be pneumatically operated by a manual solenoid valve and would alternately feed the 2 Mixers Mixer 750 Kg (Twin): This would thoroughly mix the Ingredients received from the weigh hopper. It has a 10HP main motor Mixer. The discharge valve below it is of Flap type operated by pneumatic cylinders, which while in closed condition doesn’t allow any material to get accumulated over it. Collection Hopper (1 Ton): This would be mounted below the 2 mixers and would take the discharge from both of the mixers Screw Conveyor (1 unit): This would convey the material from the outlet of the Collection Hopper and would feed at the inlet of the Bagging Station. Bagging Station (1 Unit): The bags of 50 Kg each would be filled here it consists of two outlets for each where the material would come alternately. While one bag is getting filled in the 1st outlet, the 2nd would be stopped and will be replaced with a new bag manually. The Weight scale is placed below the two outlets which would automatically weigh 50 Kg and then switch the discharge to the other outlet.

auto batching system

1 - 5 Per L

Solvent and Chemical Batching System

Get Price Quote

When transferring liquids, delayed flow rates or erratic operation can stall processes and drive an entire day's timetable off-schedule. Lower the downtime and experience the extended hours of stable operation Fluidyne's tanker unloading system can provide. These systems are extensively used in industries while unloading fuel from tankers as an improvement over traditional dip rod measurement standard. We present a wide range of liquid and solvents loading and unloading systems for preventing the wastage of fuel as well as accurate unloading for audits. Assembled with positive displacement flowmeters, our systems ensure a high level of accuracy in their measurements. These oil and chemical tanker unloading systems are most suitable for liquid fuels like diesel, petrol, kerosene and other solvents. Solvent and chemical batching-Fluidyne Fluidyne's dispensing and batching systems are flexible and highly dependable. As they come with a small footprint, they are also easy to integrate within existing systems. Our Series 6730 Preset Batching systems can function independently or can be used with existing machines. They completely substitute batch mixing and facilitate on-demand metering, giving a carefully mixed product and decreased waste. Each chemical batching system offers a customized turn-key engineering design, created for specific liquids and designed to handle shifting ratio mixing, varying viscosities, and many other scenarios. The Configuration of Chemical Batching System: The Series 6730 Batching System is created for dispensing exact preset quantities of liquids into storage tanks, reactors, batch reactor vessels, etc. With the choice of pneumatically or electrically-activated ON/OFF valves, our weatherproof or flameproof batch controller presents a system ideal for solvent and chemical batching applications with automatic cut-off action coupled with high accuracy. Benefits: Automated batch dispensing utilizing Fluidyns and platforms. Application: The batch process is a manufacturing process that works in short bursts of time, in situations the size or scale of production does not warrant a continuous operation. Nearly all chemical and solvent production is carried out in batches, especially in the food and pharmaceutical industry. The system is also used at plants for batch solvent extraction. Fluidyne's dispensing and batching systems can be employed for solvent and chemical batching and transferring, including in the production of: Stainless steel AISI 316 / Teflon wetted parts. High accuracy positive displacement flowmeter. Pneumatic / Electrically operated on/off valves. Weatherproof Batch Controller for nonhazardous areas. 100% CMRS Dhanbad certified Flameproof and Weatherproof batch controller for hazardous areas Zone IIA and IIB Batching accuracy better than ± 0.5% of reading. Stainless steel AISI 316 / Teflon wetted parts. Remote mounting of batch controller possible. Diagnostic alarm for empty pipeline condition. Flow Range Options 1" size - 2400 LPH 1.5" size - 6000 LPH 2" size - 12,000 LPH Fluidyne P.D. flowmeter with oscillating piston Rotary Piston - PEEK Wetted Parts - SS316 ON/OFF Valve Pneumatically Actuated - 1",1.5",2" size Audco Ball Valve threaded/ANSI 15O Flanged Avcon actuator Single or double acting Electrically Actuated Avcon pilot operated Diaphragm SS construction 230 VAC, 24 VDC coil voltage Batch Controller MCU based with 8x2 dot matrix backlight LCD Parameters displayed Preset batch qty in litres Delivered batch qty in litres Cumulative totalizer in litres Instantaneous flowrate in LPH/LPM Relay ouptuts for 3 phase pump motor control Enclosure Weatherproof to IP54 Flameproof/weatherproof to IS2148 1981 (suitable for Gr IIA and Gr IIB) Weatherproof to IP65 option available

Automatic Batching system

Get Price Quote

Preset Batching System

27,000 - 35,000 Per piece

We have Preset Batching Systems using Positive Displacement Flow meter or, Insertion Paddle Wheel type Flow Meter.Batcher with PD meter has high accuracy almost 0.5% of the batch quantity, but those would not be portable. These type of Batchers are recommended fro high value fuels, Solvents and oils.The Batcher with Insertion Paddel Wheel Sensor type Meter has accuracy of 1% of the batch quantity, and those can be Portable as well as stationary - depending up on the capacity.Both systems can also be provided in Flameproof housings and SS 316 contcat parts.Batching Systems are designed for dispensing exact preset quantities of liquids to reactors, storage tanks, batch reactor vessels as well as at Civil Construction sites for Concrete Mixers (Ready Mix Cement Plants).

auto batching system

Get Price Quote

To produce desired quality feed, Proportion of each ingredient is must. every batch weighing application is unique with its own capacity requirements, plant specifications, our batching system has proven this need in all technical aspects, even is auto or manual control system with semi auto control and it is user friendly. The plant mimic on the PC screen displays the status of the batching section & operations can be continuously monitored. PLC based computerized batching system. software acquires various data & reports from the machines, quantity of the material in batch hopper is sensed by load cells & transmits the information to PC which controls the batching operations as per the recipe.

Auto Weighing and Batching System

250,000 - 400,000 Per Unit

250000 Unit (MOQ)

auto batching system

Get Price Quote

Weighing & batching solution for complete process automation Independent & ratio metric flow rate control, heating & cooling profile control, agitation control Automation through reputed make PLC & HMI for complete process over viewing and control. SCADA for remote control & report generation with time trend.

Automatic Batching system

100,000 - 500,000 Per Sets

1 Set(s) (MOQ)

We are a noteworthy organization in the domain, engaged in offering Automatic Batching System. This system is designed and developed in compliance with international standards using high grade components and sophisticated technology to ensure high level of accuracy. The entire range of Automatic Batching System is in high demand in the market for its optimum performance, high strength, reliability and durability. The offered system is stringently monitored on various parameters to meet set industry norms. Specifications: Single point or multiple point batching done. Liquid can also be dosed through the system. Speeds up the production. Reports per shift & per day available. Can be upgraded to improve the total system.

auto batching system

Get Price Quote

ABP20MR Automatic batching plant by Jaypee® provides a cost effective complete concrete producing solution. The innovative design of the plant with pan mixer and also reversible type provides easy and low cost transportation and mobility for the complete unit. Automatic Batching plants employ computer-aided control to assist in speedy, precise measurement of input elements as well as tie together the various parts and accessories for coordinated, secure performance for longer functional life. The sturdy construction of the concrete processing equipment helps in maintaining low cost of production and least usage of labor requirement by our clients. With our automatic batching plant, you can effectively get rid of the unexpected construction problems and sudden cost overruns that could delay your project start-up dates and raise the planned budget. The batching plant is pre assembled and factory tested before shipment; thus, the guaranteed way to rapid on site set up and start up. Automatic Batching Plant is used to transport the ingredients for making concrete or to prepare concrete for further processing. Operated automatically, the output of these plants can be up to 20 cum per hour. For better mobility, this plant is provided with pneumatic wheels.

auto batching system

Get Price Quote

backed by the assistance of our experienced professionals, we have been the prominent manufacturer and supplier of a qualitative range of automatic batching system. These systems are provided with 2 no’s of screw conveyors for cement and lime which are taken into hopper according to mix design. Offered systems are widely appreciated by our clients owing to their long working life and minimum maintenance features. Moreover, our clients can avail these systems from us at most affordable prices.

auto batching system

175,000 Per Piece

auto batching system

Get Price Quote

At Weighing Solutions & Instrumentation, we provide solutions for automatic batching system. Be it a new automatic batching system requirement or automating the existing manual batching system. Fulfilling Both the requirements. Batching is one of the major and vital part of many industries. It plays a very very vital role in maintaining the quality as well as quantity of the output of a plant. Batching is actually taking different materials in different quantities and mixing them together to make a raw mix or a final product.

auto batching system

Get Price Quote

Control Feature:- The Control Panel is latest Technology PLC or PLC-SACDAMicroprocessor based Controlled Operation. User Programmable recipes are available up to 999 numbers. A printer is attached which gives complete record in user definable format. It weights aggregate, cement, sand, water and Additive and the weights can be set in cores and fine steps.

auto batching system

325 Per Bottle

We are the main supplier of this product.

auto batching system

Get Price Quote

Auto-Weighing and Batching System, as the name suggests, is used for precise weighing of multiple products to prepare a batch which is then further mixed and then packed.The system can be used for Powders, Cakes and Liquids. The system is a completely pre-engineered system with instruments provided for automation. Fully automatic and semi-automatic versions of this system are available.

Auto Batching Proportioning System

Get Price Quote

For the production of quality feed, it is of utmost importance that all the ingredients and micro ingredients (vitamins, additives and trace elements) are measured in weight with high precision so that the desired percentage of each can be ensured in final feed.As the no. of ingredients and volume of production increases, it necessitates that the automatic weighing of all the ingredients is carried out. It generally consists of two set of proportioning bins with individual weighing hopper scale, one for major ingredients and second for micro ingredients. There may be any no. of bin from 2 to 20 for each set with suitable capacity and higher accuracy of weighing is required for micro ingredients. Auto weighing of liquids, fat, and oil can also be incorporated to the mixer.

auto batching system

Get Price Quote

This is fully automatic batching plant for material feeding in Mixer or tank. Operator will decide to how much material will feeding depends upon quantity set point can be set in the HMI panel and just press the start button from panel. Automatic material will start feeding in mixer after checking all interlocks. If any fault in system feeding will not started and alarm will generate in the control panel display.

auto batching system

Get Price Quote

Three or Four Bin Batching System for sand and aggregate. Loading of sand and aggregate can be done in the bins. The batching system uses conveyor belts and electronic load cell for accurate weight-based transfer of materials to the skip bucket.

auto batching system

Get Price Quote

auto batching system, textile machinery spare part, Rubber Sleeve

Automatic Batching system

Get Price Quote

We design and develop the world renewed technology based DIGITAL MULTI INGREDIENT AUTOMATIC BATCHING SYSTME (DMIABS) with fully automatic features with industry unmatchable accuracy, reliability, repeatability and quality. Our state of art design computation and control device in conjunction with the precise load cell mounting modules gives the side load and vibration tolerance features that are highly appreciated by various industrial and engineering analysts. Automatic Batching System is used in industries like Sugar, Tea industry, Fertilizers, Asbestos, Food processing, Solvent Extraction, Pharmaceuticals, Chemical, Pulp and Paper, Steel, Animal feeding, Poultry feeding, Animal and Birds food preparation, etc. The Automatic Batch Blending System offered by us is available in different specifications and grades. We are reckoned s one of the leading Automatic Batch Mixing System Exporters from India. Let Us Know, How Sweet this Recipe! We develop the tailor made design to suite entire customer range from vast production areas. Automatic batching, Auto discharging, Batch counting, Recipe Counting, Preset timing option. Printing of 24 character format batch report and recipe report with user specified format and Label print option. We designed weigh module (load cell and their mounting apparatus) such that no reaction against side loading and vibration effects. Selection of World class sensor (load cell) with our own design specification to full file the optimum and precise results. Avoided intermediate signal conditioners and amplifiers between load cells and computation & control device. Easy to install and commission the system (approximate time take to install the system will be 3 hours). Digital computation and control device will feed the sensor excitation voltages, with out any ripple or deviations so; life of the sensors will be well protected as well optimum result can be taken from the sensors. Entire programming through membrane keypad, no potentio metes or dip switches selection or any other manual operation. We develop the computation and control device with 24 bit �System on Chip� technology with resolution of 16,000,000 counts. Say good bye to multi card system, all operations performs with single and compact design with 24 bit �System on Chip� technology computation and control device. We proudly announcing the accuracy level start from, better than + /- 0.001% for design capacities. System having self maintainable features means system operating with self supervisory software. Our computation and control device can communicate any of external device like PLC, DCS or Host Computer by mean of 4 / 20 mA, STATUS RELAY OUT PUTS, RS485, RS232, PROFIBUS AND DEVICE NET Available Capacities : 500grms and above Application Area : Sugar, Tea industry, Fertilizers, Asbestos, Food processing, Solvent Extraction, Pharmaceuticals, Chemical, Pulp and Paper, Steel, Animal feeding, Poultry feeding, Animal and Birds food preparation, etc.

auto batching system

Get Price Quote

auto batching system, Load Cell Type Bagging Machine

auto batching system

Get Price Quote

auto batching system, batch mixer, feed mill plant, full circle hammer mill

rubb-auto4-bh11 auto batching system

Get Price Quote

rubb-auto4-bh11 auto batching system, Vent Tube, Holder Cap, Engine Block

Auto Batching Systems

Get Price Quote

Auto Batching Systems, Sensors, UV Visible Scanning Spectrophotometer

auto batching system

Get Price Quote

auto batching system, bagasse handling systems, Metal Trough Belt Conveyor

Automatic Batching system

Get Price Quote

Automatic Batching system, Magnetic Separator, Hammer Mill

Poultry Auto Batching System

Get Price Quote

Poultry Auto Batching System, Poultry Feed Hopper