Axial Flow Pump

45,000 - 100,000 Per piece

10 piece (MOQ)

In Line Axial Flow Transformer Oil Pump

Get Price Quote

Best Deals from Axial Flow Pump

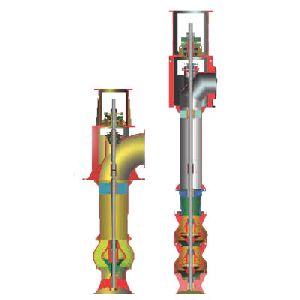

Vertical Axial Flow Pump

Get Price Quote

The VAF is a combination of vertical high efficiency & axial flow impeller pump . We have a complete range of this type of pumps which are suited for applications that require large quantities of flow with low head. Applications : Flood Control Water Treatment Shipping Ground Water Development and Irrigation Cooling Water (power) Dewatering and Water Supply (mining) Agriculture

Fre Flow PUMP

Get Price Quote

FreFlow horizontal, handles gas and particle content Max. head : 80 m (262 ft) Materials: cast iron, bronze, stainless steel

Axial Flow Pump

Get Price Quote

1 Set (MOQ)

The axial flow pumps we offer are of unmatched quality for which it has gained huge repute in the industry. It as has low head/high capacity pumping necessities, especially at the time when corrosive or abrasive solutions or slurries are concerned. These pumps are also appreciated for their extended service life, mechanical reliability, custom designs and available in wide range of materials. Our range allows the Model ATAF to pump practically any liquid.

Axial Flow Pump

75,000 - 500,000 Per Nos

Our Axial flow Pumps is Unmatched in the industry for high volume/ low head pumping requirements, Especially when Corrosive and Abrasive requirements, Especially used in the following application : 1. Evaporator and Crytilizer Circulation 2. Phosphate Soda ash, potash and sodium chloride processing 3.black liquor Evporator , chlorine dioxide generators Operation Data : Pump Size : 5" to 36"(DN125 to 900) flow upto : 20,000 cu.mtr Head : 9 Mtrs max temperature : 300 Degree Max Pressure : 10 Bar

Axial Flow Pump

45,500 Per Set

1 Set (MOQ)

vertical axial flow pumps

Get Price Quote

Our company is amidst leading Vertical Axial Flow Pumps Manufacturers and Suppliers in Panipat. These Vertical Axial Flow Pumps are used for transportation of large volume of water with low and medium heads. These Axial & Mixed Flow Vertical Pumps are provided with suction bells which drastically reduces the entrance losses. The Vertical Axial Flow Pumps provided by us are made in compliance with industrial standards. The Vertical Mixed Flow Pump which we offer can also be easily installed in the treated sewage plants. Range From 100 mm to 1000 mm

Axial Flow Pump

Get Price Quote

Axial Flow Pump

Get Price Quote

1 Piece (MOQ)

magnetic drive axial flow pumps

Get Price Quote

We introduce ourselves as one of the leading Manufacturers and Exporters of Magnetic Drive Axial Flow Pumps. These Magnetic Drive Axial Flow Pumps are skillfully designed in order to meet various industrial requirements. Our Magnetic Drive Axial Flow Pumps are made available in different specifications as per the clients needs at pocket friendly rates. Available In Alloy 20 Hastealloy Titanium CS Stainless Steel 316 Stainless Steel 304 Specifications Operating temperature of 80oC to +300oC Heads up to 10 Meters and Capacity of 50 m3/hr Capacity of 1000 m3/hr

Axial Flow Pump

Get Price Quote

The jec axial flow pump is unmatched in the industry for high volume low head pumping requirements, especially when corrosive andor abrasive solutions are involved. Mainly used in the following application: evaporator and crystallizer circulation phosphate, soda ash, potash and sodium chloride processing polypropylene reactors, xylene application black liquor evaporator, chlorine dioxide generators sewage digesters raw water pumping, flood control, marine ballast transfer.

Axial Flow Pump

Get Price Quote

creative engineers are manufacturers of agriculture vertical axial flow pump agriculture vertical axial flow pump.

Axial Flow Pump

Get Price Quote

We strongly believe in providing total customer satisfaction through excellence in our products and solutions. Radial Flow Centrifugal Pump in an Axial Flow Pump is of fabricated Elbow construction, with back pull out construction in valuable cost. This is a compact design with suction, delivery being interchangeable as per the site condition; accordingly the leading/ trailing tips are interchanged for the propeller. We are fully capable to provide replaceable wear ring as per customer requirements fitted in the casing: to ensure continues high efficiency; initially we keep 1 mm diametrical clearance which needs to be checked during preventive shut downs. With the help of our back pull type of design the dismantling of pump (rotating parts) can be done without dismantling the piping fitted to casing & since belt driven, angle spacer behind the pump to remove, rotating parts without dismantling motor. Our product is highly in demand in various industries like Textile Industries Chemical Industries Pharmaceutical Laboratories. Our vast experience coupled with the strict adherence to stringent quality procedures enables us to produce Magnetically Driven Axial-Flow Pump of the highest norms complying with International standards. A team of highly proficient professionals carefully plans the entire process and then proceeds accordingly. We are one of the leading Centrifugal Axial Flow Pump Manufacturers. Records of spares for one year services:- Propeller : -1Ball Bearing : -1Double row ball bearings : -1Oil Seal : -2Circlip : -2Casing Gasket : - 1Mechanical Gasket : -1 set Dismantling :- With the help of our back pull type of design the dismantling of pump (rotating parts). Can be done without dismantling the piping fitted to casing & since belt driven, angle spacer behind the pump to remove, rotating parts without dismantling motor. SPECIAL REMARKS FOR AXIAL FLOW PUMPS Axial flow pumps are having suction from top disharge from side (end) flange or Vice VersaThe direction of rotation of pumps shaft is anti clockwise looking from pulley end for Top suction & clockwise for end suctionTwo holes are provided at the gland plate. One is for inlet of water and another Is for outlet of water. This water is used for cooling seal face as per standard.The water supply should be from clear, cold tap water (pressure not more than 1kg/cmAssembling pulley drive :- for assembling the drive the motor should be moved Towards the pump so that the belts may be placed in their respective grooves by hand Under no circumstances should the belt be forced on to the pulleys with crowbar Wedges, screw or any other type of sharp tools.When V belts have been placed in the pulley grooves the motor then moved away From be then moved away from pump to apply uniform tension to V � belts with the Help of tensioning bolts on base plate, Tensioning Measure the Center distanceAt the center apply force 2 to 3 kg (20 to 30 N). At right angles to belt. The belt should deflect 16 Mm for every meter of center distance. After drive has been running for few days V Belts will Have seated in the groove and drive tension might have reduced. The tension should be corrected again as per above method Applications KEW Pumps has delivered pumping solutions for the most demanding applications in the following industries:- Textile IndustriesChemical IndustriesPharmaceutical Laboratories. Quality We strongly believe in providing total customer satisfaction through excellence in our products and solutions. We listen to our customers and provide them with quality products in a safe and responsible way. Every product is put through a series of quality checks, before the actual delivery. Our vast experience coupled with the strict adherence to stringent quality procedures enables us to produce products of the highest norms complying to International standards. A team of highly proficient professionals carefully plans the entire process and then proceeds accordingly.

Axial Flow Pump

50,000 - 5,000,000 Per Set

Axial Flow Pump

Get Price Quote

Applications: The JEC Axial Flow pump is unmatched in the industry for high volume / Low head pumping requirements, especially when corrosive and/or abrasive solutions are involved. Mainly used in the following application: Evaporator and Crystallizer Circulation Phosphate, Soda Ash, Potash and Sodium Chloride Processing Polypropylene Reactors, Xylene application Black Liquor Evaporator, Chlorine Dioxide Generators Sewage Digesters Raw Water pumping, Flood control, Marine Ballast transfer Design: The Axial Flow pump generates flow by the thrust or lift action of rotating axial vanes of the impeller. The pump has an elbow that directs the flow through the suction and out the discharge end of the pump. It can be used in the top orend suction configuration depending up on the need and Flange dimensions, bolt circle and holes comply with ANSI 816.5, 1508. The back pull out design (up to 14” size) allows for easy maintenance and repair as the rotating element may be removed without disturbing the pipe work. Pump has wear rings as standard and lifting eye on bearing bracket.

Gallop Hi Flow pump

Get Price Quote

Khaitan Gallop Hi Flow is a small and compact shaped pump, which is the best choice for pressurized water supply. The motor body of this pump is made up of extruded aluminium. It provides long life with the huge water storage to meet peak water demand while improving efficiency.

Axial Flow Pump

Get Price Quote

Range of Application: Model KAF & KAFV Series 5",6",8",10",12",14",16",18" ,20" Chemical: Forced evaporator & Crystallizer circulation Paper: Black Liquor concentration , Xylene Crystallizer. Food: Cane , Maize , Sugar evaporator. Municipal: Sewage sludge circulation, sewage disposal. General: Raw water pumping. Range of Temperature: Upto 200 degree C Range of Pressure: Upto 10.5 Kg/(cm)2 Range of Flow: Upto 3500 (m)3/hr Heads: Upto 9 mtrs. Design: Features: Back pull out design coupling with spacer element for rapid dismantling & assembly with propeller & sealing element.. Stuffing box housing designed with jacketing arrangement for cooling or heating. Stuffing box chamber matches the elbow design of casing, so that smooth flow with minimum losses take place, The K factor for calculating losses across the elbow does not exceed 0.1 to 0.3 Available in horizontal single elbow, vertical cantilever & special design as required. Pumps can be furnished with either clockwise or counter clockwise direction of rotation looking from motor end. Direction of flow reversible, The discharge flange can be suction for liquid in which case the impeller is reversed end for end, resulting in suction pressure of rotation looking from motor end.

Horizontal and Vertical Axial Flow Pumps

Get Price Quote

This range of pumps offer widest range of selection depending upon the pumping liquid from clear water to varying degrees of contamination. These pumps are designed to operate at 50Hz or 60 Hz, in single or more than one stage according to head required.

Axial Flow Pump

Get Price Quote

1 Piece(s) (MOQ)