BATCH FRYER MACHINE

350,000 Per Piece

1 Piece (MOQ)

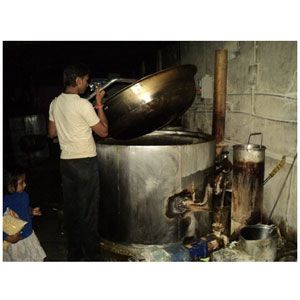

cassava fryer

75,000 - 77,500 Per piece

.“NANS” Gari / Cassava roaster with automatic stirrer. Our “NANS” brand Gari roaster is specially designed for the African’s market. Heating unit is with the help of LPG (liquid petroleum gas), which make the roasting economical & therefore making the roasting profitable. Simple & easy to operate as it has a automatic stirrer. Capacity ranging from : 5 – 100 kgs per hour We are major Manufacturers & Exporters of Agricultural & Food processing machineries specially designed for the African market. The world renowned brnad owners of "NANS" & "REEJA". Country of orgin India. Africa's No:1 Brand "NANS" The only Manufacturers of complete Cassava processing plant in INDIA.

Best Deals from Batch Fryer

2 HP Mild Steel Wood Pellet Bhatti Fryer

190,000 Per Unit

1 Unit (MOQ)

batch fryer

250,000 - 260,000 Per Piece

BATCH FRYER MACHINE

20,000 - 100,000 Per Piece

2 Piece (MOQ)

in our factory is also known as round type frying machine for its round fryer pan. And as the name implies, the fryer uses batches inside to stir the products in the oil so that they can be fried evenly. As a reliable batch type fryer machine manufacturer, we provide quality industrial frying machines with robust built, and they can be customized in sizes and other aspects to meet your needs and requirements. Besides, unlike continuous fryer machine which can work continuously, batch type frying machine can fry products for each batch. As a result, it is suitable for small scale food frying processing line. If you have any question about fryer machines, please feel free to contact us. Features of Batch Type Frying Machine Commercial : Robust design. Built with stainless steel, the batch type fryer machines can work for long time without deformation. Sanitary design. Except for the stainless steel built, our batch type frying machine commercial can be easily cleaned and maintained. For it is designed carefully so that every part of it can be easily accesses, which allows for ease of cleanness and maintenance. Various application. Our industrial batch type fryer machine can be used to fry a great variety of foods, such as potato chips, french fries, onion rings and so on. This great versatility makes it valuable investment, for you can fry many kinds of products with just one machine. Small footprint. The batch type fryer machine is of small scale, which occupies less space. Top final products with less energy use. Due to advanced technology, our batch type frying machine can not only produce optimum end products, but also consume less water and energy during the frying process. Competitive prices. Compared to continuous fryer machines, batch type frying machine is cheaper for it fry products batch after batch. Besides, compared with competitors, our batch type frying machines also enjoy competitive prices, for all of them are designed and manufactured in our own factory.

batch type fryer

85,000 - 150,000 Per Piece

1 Piece (MOQ)

batch fryer

255,000 Per Piece

1 Piece (MOQ)

batch fryer

160,000 Per Piece

BATCH FRYER MACHINE

Get Price Quote

Batch Fryer Machine offered is backed by our extensive experience in this field that assists us in offering exclusive process plant solutions for processing of Besan. These plants are designed for meeting the specific grinding demands and come fitted with meshes available in different sizes that allows out puts in different finish forms including from granular to fine powder. Meeting the specific requirements of customers, these plants can also be made available in different operational specifications and delivers optimum functionality in given processes. Features: • Highly functional range of besan plant impact pulveriser• Specially designed for grinding operations• Comes fitted with meshes in different sizes to allow outputs like granular or fine powder• Suiting specific requirements of customers• Can be made available in different operational specifications• Comes with special tempered high speed beaters for powdering

Rectangular Batch Fryer

350,000 Per Set

We offer Rectangular Batch Fryer. We Introduces a new revolution in frying technology for Chips , Dals, Kurkure, Fryums and other products require high heat requirement, It is a new Rectangular fryer with a combination of Direct & Indirect heating gives you a more than 55% saving in Fuel and double the production capacity

Circular Batch Fryer with Inbuilt Heat Exchanger

Get Price Quote

Heat Exchanger Circular Fryer For Potato/ Banana Wafer & Dal frying. We offering 48" Circular Fryer.The system is consist of : SS-304 Pan Diameter 48" Italian Ecoflam Burner (Diesel/ Gas) Electric panel board with temperature controller Bucket type automatic edible oil filter system Inbuilt Heat Exchanger 3 HP Pump & motors Features : The fryer is best suited for high temperature required product for Frying, such as Potato wafer, Banana wafer, Dal etc.

Circular Batch Fryer

Get Price Quote

The company is counted amidst the distinguished Manufacturers, Exporters and Suppliers of Circular Batch Fryer. The Circular Batch Fryer is best for preparing Bikaneri Bhujiya, Mava, Sev, Soan Papdi, Samosa, Kachori, Gathiya, etc. The special design and tilting mechanism of the Circular Batch Fryer facilitate easy offload of the prepared product. This Circular Batch Fryer is also easy to clean and convenient to maintain. Clients can avail fuel-efficient and durable Circular Batch Fryer from us in the required specifications at very affordable prices.

Direct Diesel Batch Fryer

225,000 Per Set

1 Set(s) (MOQ)

RECTANGLE BATCH FRYER

450,000 Per Set

batch fryer

Get Price Quote

batch fryer

Get Price Quote

Rectangular Circular Batch Fryer

150,000 - 500,000 Per Unit

1 Set (MOQ)

BATCH FRYER MACHINE

190,000 Per Piece

batch fryer

Get Price Quote

Specially designed Stainless steel batch fryers with multiple inlet for oil and filtration system, the shape of the batch fryer can be rectangular or circular. Circular Batch fryers are available in various sizes, Tilting type facility for stainless steel basket for easy removal of the product thereby reducing the oil in the product substantially. Heat Exchangers are inbuilt in the batch fryer there by two way heating of oil is possible. Oil heated which is passing through the stainless steel tubes indirect heat type Oil heated which is kept in the frying pan (kadai by direct heat) INDIRECT HEAT TYPE BATCH FRYER Rectangular or circler indirect heat type batch fryer is fabricated in stainless steel 304 body having pan is mounted on a stainless steel 304 body. The pan is having multiple opening for oil inlet from one side and outlet from the other side, the flow of oil is regulated by an oil circulating pump. The heated oil in the pan is coming from the heat exchanger and going out into the bucket type filter from the side of the pan. The pan is properly insulated from the bottom to avoid heat loss. Continuous bucket type filters for filtering the edible oil continuously. The indirect heat type frying system is connected with digital temperature controller and control panel. The unique feature of this fryer is its tilting system that enables unloading of products in a single stroke after frying for uniform and consistent product quality. ADVANCE ADVANTAGE OF INDIRECT HEAT TYPE BATCH FRYER Latest oil heating technology with inbuilt heat exchanger. The entire system's oil is passed through the bucket type continuous oil filtration system, thus this filtration are the almost total elimination of burnt fines on the finished product reduced carbon build-up. Reduces manpower in frying compare to traditional batch fryer. Complete material of construction is stainless steel 304 grades Oil holding capacity: - 110-140 litters Heat free working environment More than 55% fuel saving as compared traditional system Also available in tilting system thus unloading product in just single stock.

BATCH FRYER MACHINE

350,000 - 550,000 Per Piece