Belt Weigher

Get Price Quote

Kwality Convenyors manufactures conveyor belt scales in single, dual and four idler configurations that are easy to use, dependable and provide top performance at a great value. Our scales feature self-storing calibration weights, user friendly weight processors and the longest warranty in the business. Details : Our revolutionary display allows you to increase the efficiency of your operation like never before. The operator can easily interact with multiple scales at the plant and the supervisor can monitor production from the office on a PC or handheld device.

Belt Weigher

Get Price Quote

Interested buyers can place orders with us, timely delivery of the same are our foremost concern. The raw material that is used for manufacturing superior grade products is sourced from the reliable places after complete quality confirmation.

Best Deals from Belt Weigher

Belt Weigher

Get Price Quote

Eastern Weighing Systems is a well-known Manufacturer and Supplier of Belt Weigher. We offer precision-engineered Belt Scales, Hopper Scales and Process Weighing Equipment such as Bin Feeder and Batch Weighing Scale. Belt Weigher is used to measure the exact flow rate as well as quantity of material loaded in a particular period. Incremental optical encoders sense the speed of the Belt Weigher. Moreover, advanced micro-controller panel is fitted to make the Belt Weigher efficient and user-friendly.

Belt Weigher

225,000 Per Set

1 Set(s) (MOQ)

TSAT based belt weigher for accurate and reliable measurement of moving mass on belt conveyor. This technology gives you excellent performance at very negligible maintenance cost as compare to conventional belt weighers.

Belt Weigher

Get Price Quote

A BELT WEIGHER is a piece of industrial equipment used to gauge the mass or flow rate of material travailing over a troughed (cupped) conveyor belt of any length which is able to adequately contain the material being weighed. Commonly incorporated into conveyor belt systems, belt weighers are used in a wide range of industries to report instantaneous flow rate and totalised mass feed rate of powders and bulk solid materials. This data is commonly used for stock control, process control and in bulk material handling processes. A belt weigher replaces a short section of the support mechanism of the belt, which might be one or more sets of idler rollers, or a short section of channel or plate. This weighed support is mounted on load cells, either pivoted, counterbalanced or not, or fully suspended. The mass measured by the load cells is integrated with the belt speed to compute the mass of material moving on the belt, after allowing for the mass of the belt itself.

Belt Weigher

Get Price Quote

We are one of the notable Manufacturers, Exporters and Suppliers of efficient working Belt Weigher. Using only supreme grade components, our team of technical experts produce technologically advanced Belt Weigher in compliance with all set industry standards of quality. Ideal to be used in various industries for packing non-free flowing products effortlessly, Belt Weigher is known for its precise working and long service life. You can purchase best Belt Weigher from us at economic prices. Timely delivery of all orders is our forte. Features : Hassle-free performance High operational fluency Robust construction Longer service life Product Applications : Sugar,Detergent Powder, Poha, Namkeen, Coffee Beans, Sesame, Capsules, Rice, Milk Powder, Nuts, Pet Food, Coconut Powder, Granules, etc.

Belt Weigher

Get Price Quote

INDUS BELT WEIGHERS are reliable, accurate & durable even in the most demanding industrial application. The belt scale is an industrial equipment which measures the rate of flow and total quantity of material being passed over the scale in a time period. The load being transferred to the belt is sensed by 4 high precision loadcells & the speed is sensed by an Incremental optical encoder (Tacho Generator). These two signals are multiplied digitally at the microcontroller based panel. The load per unit length multiplied by speed of the belt gives the rate of flow while the Rate integrated over time gives the totalized value of material passed over the belt.

Belt Feed Weigher

Get Price Quote

We offer belt feed weigher. Type : net weighing and bagging feeder type : belt feeder weighing range : 3 to 25 kgs. Maximum output : 240 bags of 25 kg net hr. system can be used for: citrusfruits, dry fruitsbeans, rice, candies, frozen food, non-food, granules, powder and detergents. pune packaging controls are based on “high-grade” siemens schneider ab component touch screen used for easy operation via “easy going” menu navigation machine is very flexible it can be used for various pack sizes by just selecting one button on hmi. high speeds combined with excellent accuracy system is design with self calibration periodically

Belt Weigher

Get Price Quote

Electric Conveyor Belt Weigher

180,000 Per Units

Belt Weigher

Get Price Quote

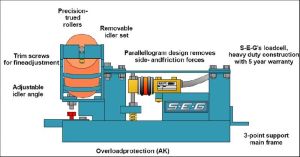

Belt weigher, An experience of over 17000 installations makes SEG Sweden one of the leading belt scale manufacturers in the world. SEG scales in India have proven themselves in most challenging environment like underground mines and trans-shippers. We are sure that once you use SEG, you will not go back to ordinary scales.

Belt Weigher

Get Price Quote

The weigh bridge assembly with precise strain gauge load cellbending beam load. The belt speed sensor assembly, and The electronic cabinet often referred as the totaliser or the integrator.

Belt Weigher

Get Price Quote

A belt weigher is a part of industrial control equipment used to measure the flow rate of material travelling over a troughed conveyor belt of any length. Many such belt scales are active part of the process flow control of conveyor line. A belt weigher replaces a short section of the support mechanism of the long conveyor belts in process industry. Each system consists of microprocessor based control panel, load cell and belt speed measuring device. We provide material totalizer and flow rate analog signal outputs from belt weighers.

Belt Weigher

Get Price Quote

Quality assurance demands accurate and reliable process measurements and controls. To help to meet quality needs of your organization and your customers, you need a quality belt weigher. Belt weigher (also called belt scale) is used to totalize the bulk material carried by belt conveyor and to measure bulk material flow rate TPH. The belt weigher can be installed on new or existing belt conveyor. The system consists of a robust Frame set of weigh Idler, set of Non weighing idlers, a belt speed sensor and an electronic controller. The Frame assembly is suspended on a strong flexure system and transmits the applied material load to a sealed load cell or load cells depending upon the accuracy of measurement desired. Weighing idlers are mounted on weighing frame and leveled in line with Non weighing idlers.

Belt Weigher

Get Price Quote

PEL, Group company of ELECON supplies microprocessor based electronic belt weighers incorporating the latest state-of-the-art technology for continuous weighing applications in cement, steel, chemical, petrochemical industries and coal handling plants. PEL belt weighers consist of three major elements: The weigh bridge assembly with precise strain gauge load cell/bending beam load. The belt speed sensor assembly, and The electronic cabinet often referred as the totaliser or the integrator. Each serves a distinct function in the process of accurately weighing material moving on the belt. Different models of scale carriage are available depending upon the application, scale capacity and belt speed. Capacities from a fraction of tonne to 10,000 TPH. Simple rugged and unitized scale assembly for easy installation. Super precision stainless steel strain gauge load cell applied in tension for highly accurate load measurement. Special trunion bushes to absorb normal shocks and transverse forces. Weigh idler deflection less than 0.025 mm at full load. Brushless digital tacho provides accurate measurement of speed. Fully digital with microprocessor and battery back-up memory. Fully automatic tare and span calibration. Self-checking diagnostics for fault indications. Special electronic calibration facility for frequent calibration checks without handling standard weights.

Belt Weigher

Get Price Quote

PEL, Group company of ELECON supplies microprocessor based electronic belt weighers incorporating the latest state-of-the-art technology for continuous weighing applications in cement, steel, chemical, petrochemical industries and coal handling plants. PEL belt weighers consist of three major elements: The weigh bridge assembly with precise strain gauge load cellbending beam load. The belt speed sensor assembly, and The electronic cabinet often referred as the totaliser or the integrator. Each serves a distinct function in the process of accurately weighing material moving on the belt. Different models of scale carriage are available depending upon the application, scale capacity and belt speed. Capacities from a fraction of tonne to 10,000 TPH. Simple rugged and unitized scale assembly for easy installation. Super precision stainless steel strain gauge load cell applied in tension for highly accurate load measurement. Special trunion bushes to absorb normal shocks and transverse forces. Weigh idler deflection less than 0.025 mm at full load. Brushless digital tacho provides accurate measurement of speed. Fully digital with microprocessor and battery back-up memory. Fully automatic tare and span calibration. Self-checking diagnostics for fault indications. Special electronic calibration facility for frequent calibration checks without handling standard weights.

Belt Weigher

Get Price Quote

Belt weigher r is a compact, rugged belt weigher with stainless steel load cell for use in Raw Material Handling plants. Two idlers weigh beam, with one Load cell and speed sensor assembly.

Continuous belt weigher

Get Price Quote

Technical Details Application range: blending of different fibres - types, colour, fineness or cut lengths Key Features Load cells controlled Production capacity up to 1200 kg/hr The weighing accuracy of ± 1 percent Individual drive Under frame for EBO-K

Belt Weigher

Get Price Quote

Single or multi-idler weighing system for installation on flat or inclined belt conveyor up to 2m wide.Comprises indicator, up to 3 idler frames, speed transmitter, junction boxes and cabling, Weighed transferred via hight-adjustable load button simplifies installation where conveyor, structure are not straight and true, Encoder ensures correct and precise calculations of feed rate.

Belt Weigher

Get Price Quote

Belt Weighers BW90 and BW200 which have been designed especially for dynamically weighing a complete range of solid materials on a belt in severe industrial environments. The special construction, both compact and economical, of Belt Weighers is based on the most recent evolution in the field of load cells. The Belt Weighers are made up of a mechanical mono block structure preassembled and fully prepared for installation without having to carry out changes in the existing structure. The weighing bridge is made up of a single or double idlers that weigh directly on a highly precise and linear load cell.